Wax Filling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433932 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Wax Filling Machine Market Size

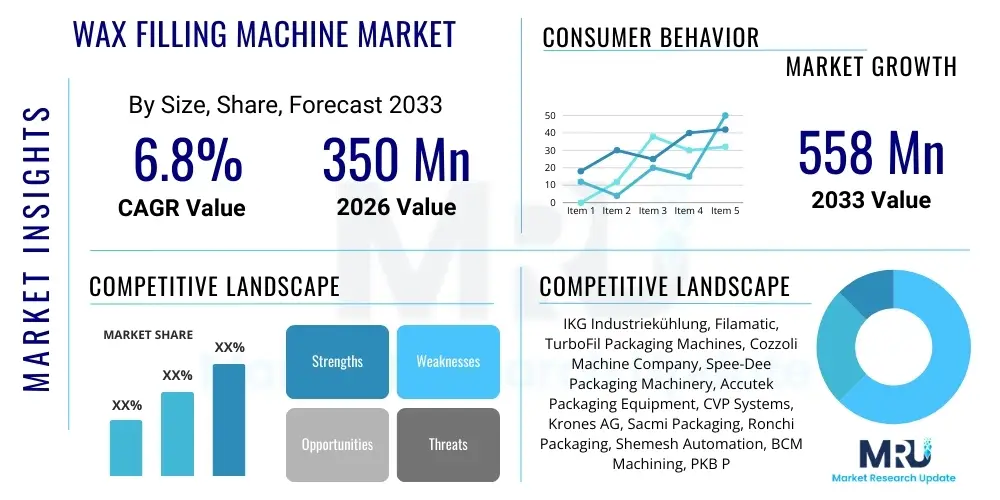

The Wax Filling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 350 Million in 2026 and is projected to reach USD 558 Million by the end of the forecast period in 2033. This consistent expansion is driven primarily by the escalating demand for automated manufacturing processes across high-volume consumer goods industries, particularly cosmetics and home fragrance products like scented candles.

Wax Filling Machine Market introduction

The Wax Filling Machine Market encompasses specialized industrial equipment designed to accurately and efficiently dispense molten or semi-solid wax into containers, molds, or packaging. These sophisticated machines are crucial for maintaining product consistency, maximizing throughput, and ensuring precise weight control in mass production environments. Products manufactured using these systems range widely, including foundational cosmetic items such as lipsticks, balms, and creamy concealers, various types of candles—from traditional pillar and container candles to specialized scented and decorative variants—as well as industrial waxes used for polishing, coating, and protective applications. The operational principle often involves heating the wax material to a controlled liquid state, precise metering via piston or pump mechanisms, and subsequent discharge into the final packaging unit.

Key applications driving market adoption are heavily concentrated in the beauty and home ambiance sectors. The global rise in demand for premium, high-quality scented candles, often involving complex fragrance layers and specific burn characteristics, mandates the use of highly accurate filling machines to prevent product inconsistencies and batch failures. Similarly, the cosmetic industry requires ultra-precise volumetric filling for wax-based components, where minute variations in fill weight can drastically impact product quality and perceived value. Furthermore, the imperative for speed and hygiene in processing consumer goods has made automated and integrated wax filling solutions indispensable components of modern manufacturing lines, displacing older, manual or semi-automatic processes.

The overarching benefits of deploying advanced wax filling technology include significant reduction in product wastage, enhanced production scalability, and compliance with stringent quality assurance standards. Driving factors for market growth include the robust expansion of the candle manufacturing segment globally, technological advancements in machine precision and integration (e.g., servo-driven systems), and the continuous push towards complete factory automation to counteract rising labor costs and improve operational safety. Manufacturers are increasingly focused on developing modular and flexible systems capable of handling a diverse range of wax viscosities and container sizes, thereby improving Return on Investment (ROI) for end-users.

Wax Filling Machine Market Executive Summary

The Wax Filling Machine Market exhibits robust growth propelled by underlying macro-economic business trends, specifically the globalization of premium consumer goods manufacturing and the intense focus on operational efficiency. Current business trends indicate a strong preference among large manufacturers for fully automatic, high-speed rotary machines, particularly those offering advanced features such as automatic wick centering, temperature stabilization across multiple nozzles, and integrated cooling tunnels. This shift is pronounced in established markets like North America and Europe, where regulatory compliance and high labor costs necessitate maximum automation, driving demand for technologically superior equipment that minimizes downtime and human intervention.

Regionally, the Asia Pacific (APAC) market is anticipated to record the highest growth rate, fueled by its status as a primary global manufacturing hub for cosmetics and candles, alongside burgeoning domestic consumption in countries like China and India. While North America and Europe maintain dominance in terms of technology adoption and the size of high-value installations, APAC’s rapid industrialization and capacity expansion efforts are creating significant new opportunities for wax filling machine suppliers. Latin America and the Middle East & Africa (MEA) are emerging as high-potential markets, driven by local manufacturing establishment and increasing disposable incomes leading to higher demand for non-essential consumer wax products.

Segment trends highlight the critical importance of machine capacity and automation level. The Automatic Segment dominates the market share due to scalability benefits, while the High-Speed Rotary category is expected to witness the fastest Compound Annual Growth Rate, reflecting the industry’s need for extremely high throughput rates—especially in lipstick and large-scale candle production. By application, the Candles Segment and the Cosmetics Segment are the undisputed leaders, collectively dictating innovation cycles in terms of heat control accuracy and integration with upstream and downstream packaging operations. The strategic focus for vendors remains centered on enhancing machine flexibility to handle diverse wax formulations, including natural waxes like soy and coconut wax, which require delicate handling and precise temperature management.

AI Impact Analysis on Wax Filling Machine Market

Common user questions regarding AI’s influence on the Wax Filling Machine Market frequently revolve around how artificial intelligence can move beyond simple automation to achieve true predictive operational excellence. Users are keen to understand if AI can significantly reduce material waste (a major concern given fluctuating wax prices), ensure consistent product quality across millions of units, and forecast equipment failures before they occur. Key themes identified include the integration of AI-powered vision systems for instantaneous quality assurance, the feasibility of machine learning algorithms optimizing thermal parameters for different wax types in real-time, and the potential for AI to streamline complex production scheduling and maintenance cycles.

AI is fundamentally transforming wax filling operations by enabling higher levels of control and intelligence that surpass traditional programmed logic controllers (PLCs). Machine learning algorithms, when applied to operational data (temperature, pressure, cycle time, ambient conditions), can dynamically adjust filling parameters to compensate for slight variations in raw material viscosity or ambient temperature changes, ensuring uniform fill volumes and surface quality. This real-time optimization capability is invaluable, particularly in high-precision cosmetics manufacturing where even minor defects in surface finish can lead to product rejection and substantial financial loss. Furthermore, the deployment of deep learning models in quality control ensures that defects such as air bubbles, uneven surfaces, or incorrect wick placement are identified with near-perfect accuracy and immediacy.

The most profound impact of AI is observed in predictive maintenance and operational efficiency improvements. By analyzing sensory data streams from motors, valves, and heating elements, AI models can detect subtle deviations indicating impending mechanical failure long before a catastrophic breakdown occurs, shifting maintenance from reactive to proactive. This dramatically reduces unplanned downtime—a critical factor in high-volume production lines—and extends the operational lifespan of expensive machinery. Integrating AI-driven systems also facilitates better energy management by optimizing heating and cooling cycles based on predictive load requirements, contributing to sustainability goals and lowering operational expenditure.

- AI-Powered Predictive Maintenance: Reduces unplanned downtime by forecasting component failure using anomaly detection in sensor data.

- Real-Time Process Optimization: Machine learning algorithms dynamically adjust wax temperature, pressure, and flow rates based on raw material variability.

- Enhanced Visual Quality Control: AI vision systems instantly identify and reject products with cosmetic defects (e.g., sinkholes, air bubbles, incorrect wicking) with superior accuracy compared to human inspection.

- Throughput Maximization: AI assists in optimizing production scheduling and changeover protocols, minimizing idle time between batches.

- Energy Efficiency: Optimization of heating and cooling cycles reduces power consumption during production runs.

DRO & Impact Forces Of Wax Filling Machine Market

The Wax Filling Machine Market is primarily driven by the unstoppable global trend toward industrial automation, particularly within the high-growth sectors of home fragrance (candles) and personalized cosmetics, while grappling with significant restraints related to capital expenditure and technical complexity. Opportunities arise from customization trends and sustainable manufacturing mandates, which together exert considerable influence on market dynamics. The key driving force remains the increasing volume of production required by global brands, necessitating machines that offer both high throughput and unparalleled accuracy, especially for sensitive products like natural waxes and highly pigmented cosmetic formulations.

The market faces significant resistance from the high initial capital investment required for purchasing and integrating fully automatic, high-precision filling systems. Small and medium-sized enterprises (SMEs) often find this investment prohibitive, relying instead on semi-automatic or refurbished equipment, which slows overall market penetration of cutting-edge technology. Furthermore, the reliance on specialized maintenance skills for these complex electro-mechanical systems and the sensitivity of the equipment to fluctuations in raw material quality (wax viscosity and purity) pose operational challenges. Price volatility in base materials like paraffin, soy, and specialty waxes can also affect manufacturers' profitability and consequently their readiness to invest in new filling machinery.

Despite these challenges, substantial opportunities exist in developing markets and in the niche segment of custom formulations. The growing demand for specialized, limited-edition products and custom cosmetic lines (e.g., indie beauty brands) fuels the need for flexible, easily programmable machines capable of rapid changeovers. Furthermore, sustainability pressures are creating opportunities for machinery compatible with eco-friendly and complex packaging materials, such as bio-plastics or unique glass containers, requiring highly customized nozzle designs and handling mechanisms. The overall impact forces are strongly positive, driven by consumer demand for consistent quality and the manufacturing imperative for efficiency, which collectively outweigh the restraints related to cost.

Segmentation Analysis

The Wax Filling Machine Market is comprehensively segmented based on the degree of automation, the fundamental operational mechanism (type of filler), and the specific end-user application. Understanding these segments is crucial for manufacturers to tailor their product offerings and marketing strategies, as the requirements for a high-volume candle manufacturer differ significantly from those of a pharmaceutical lab producing specialty wax coatings. The segmentation by automation level (Semi-Automatic, Automatic, High-Speed Rotary) dictates production capacity and initial investment, while the segmentation by application (Cosmetics, Candles, Industrial) directly influences the technical specifications regarding temperature control and nozzle design.

The dominance of the Automatic and High-Speed Rotary segments underscores the ongoing trend toward large-scale, efficient manufacturing globally. While Semi-Automatic machines serve niche markets, pilot plants, and smaller operations requiring frequent changeovers, the majority of market revenue is generated by automated systems that can handle hundreds or thousands of units per hour, ensuring continuous production flow and minimizing labor costs. Mechanically, piston fillers remain popular for their high accuracy and reliability, particularly for viscous waxes, whereas pump-based systems offer greater flexibility in handling a wider range of viscosities and are often integrated into modular lines.

- By Type (Automation Level):

- Semi-Automatic Wax Filling Machines

- Automatic Wax Filling Machines

- High-Speed Rotary Wax Filling Machines

- By Application:

- Cosmetics (Lipsticks, Balms, Foundation sticks)

- Candles (Container candles, Votives, Pillars)

- Industrial & Pharmaceutical (Coatings, Polishes, Specialty Waxes)

- By Filler Mechanism:

- Piston Fillers

- Pump Fillers (Gear Pump, Lobe Pump)

- By Control System:

- PLC Control

- Servo-Driven Systems

Value Chain Analysis For Wax Filling Machine Market

The Value Chain for the Wax Filling Machine Market begins with upstream activities focused on the procurement of specialized components and precision engineering materials, moving through design and manufacturing, and culminating in distribution, installation, and after-sales service. Upstream operations are highly dependent on suppliers of high-grade stainless steel (necessary for temperature control and hygiene), sophisticated electronic components (PLCs, servo motors, sensors), and complex pneumatic/hydraulic systems. Specialized engineering expertise is required here to ensure that components can withstand continuous heating cycles and provide the dimensional stability necessary for high filling accuracy.

Midstream activities involve the machine design, assembly, rigorous testing, and quality assurance processes. Manufacturers must focus heavily on R&D to incorporate new technologies, such as advanced human-machine interfaces (HMIs) and modular design elements that allow for quick product changeovers. The transition from manufacturing to distribution often utilizes both direct and indirect channels. Direct sales are preferred for large, complex, and customized high-speed rotary lines, allowing for direct consultation and integration support. Indirect channels, involving regional distributors and agents, are often employed for standard semi-automatic models, leveraging local market knowledge and support capabilities.

Downstream analysis focuses on the end-users and the critical importance of post-sale support. Given the complexity and capital cost of these machines, comprehensive installation, operator training, ongoing maintenance contracts, and rapid supply of spare parts are paramount to customer satisfaction and operational continuity. The relationship between the machine supplier and the end-user (e.g., a major cosmetic manufacturer) is typically long-term, centered around maximizing Overall Equipment Effectiveness (OEE). Effective distribution ensures timely delivery and local technical assistance, which are critical differentiators in competitive regional markets.

Wax Filling Machine Market Potential Customers

The primary customers for wax filling machines are large-scale manufacturers operating within the cosmetic, home fragrance, and specialty chemicals sectors who require high precision and throughput for their wax-based product lines. These customers are segmented based on their production volume and the complexity of their product offerings. Major multinational cosmetic corporations that mass-produce items like lipsticks, foundation sticks, and concealers are crucial buyers, as they demand the highest levels of automation, hygiene standards, and filling accuracy to maintain brand consistency across global markets. Their purchasing decisions are driven by OEE metrics and regulatory compliance.

Another significant segment comprises manufacturers within the rapidly expanding home fragrance industry, primarily candle makers ranging from large industrial producers to specialized artisanal brands that have scaled up their operations. As consumer demand for natural waxes (soy, coconut) and complex, multi-layered scents increases, these buyers seek machines capable of precise temperature maintenance and gentle handling to preserve fragrance integrity and achieve a flawless surface finish. The shift towards automation in this sector is driven by the need to efficiently handle large seasonal production volumes while maintaining high aesthetic quality.

Lastly, specialized industrial and pharmaceutical companies represent a stable customer base. These entities use wax filling machines for precision dosing of medical suppositories, dental waxes, and protective industrial coatings or polishes. Their requirements often focus less on throughput speed and more on validated sterilization processes, extreme dosing accuracy, and adherence to stringent pharmaceutical or industrial safety standards. These buyers often require custom-engineered solutions tailored to highly specific material properties and regulatory frameworks, making them valuable targets for premium, customized equipment suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350 Million |

| Market Forecast in 2033 | USD 558 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IKG Industriekühlung, Filamatic, TurboFil Packaging Machines, Cozzoli Machine Company, Spee-Dee Packaging Machinery, Accutek Packaging Equipment, CVP Systems, Krones AG, Sacmi Packaging, Ronchi Packaging, Shemesh Automation, BCM Machining, PKB Packing, Guangzhou Xili Machinery, Pouchfill Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wax Filling Machine Market Key Technology Landscape

The contemporary technology landscape of the Wax Filling Machine Market is defined by the integration of advanced control systems, precision dosing mechanisms, and highly efficient thermal management solutions. A critical innovation is the shift from mechanical indexing to servo-driven control systems. Servo motors offer superior precision in piston movement and indexing rotation, leading to volumetric filling accuracies within ±0.1% across high-speed operations. This high degree of control is essential for expensive cosmetic ingredients and for ensuring the consistency required for certification in regulated industries. Furthermore, the reliance on Programmable Logic Controllers (PLCs) and sophisticated Human-Machine Interfaces (HMIs) allows operators unprecedented control over complex recipes, enabling rapid changeovers between products with minimal manual adjustments.

Temperature control technology is arguably the most vital technological differentiator in this market. Since wax must be maintained within a very narrow temperature range—molten for filling but cool enough to solidify rapidly without cracking or shrink holes—modern machines incorporate multi-zone heating and cooling systems. These often involve jacketed hoppers, heated pipelines, and precision nozzle temperature control maintained by PID controllers. The use of magnetic stirrers and homogenizers within the holding tanks ensures uniformity of temperature and suspension of pigments or fragrance oils, preventing material separation that could compromise product quality during the filling cycle. Innovations in hygienic design, particularly the use of Clean-In-Place (CIP) systems, are also becoming standard, especially for machines handling pharmaceutical or food-grade waxes.

Future technological advancements are focused on modularity and connectivity, aligning with Industry 4.0 standards. Modular designs enable manufacturers to easily scale production or integrate additional functions, such as automatic wick insertion, cap placement, or integrated cooling tunnels, onto existing lines. The increasing adoption of sensors and IoT connectivity facilitates data collection on every aspect of the filling process—from thermal gradients to machine wear—feeding into AI-driven diagnostic and optimization tools. This connectivity not only enhances remote monitoring and troubleshooting but is crucial for enabling the predictive maintenance models that define the next generation of wax filling equipment.

Regional Highlights

The geographical analysis of the Wax Filling Machine Market reveals distinct patterns of demand, maturity, and growth potential driven by regional manufacturing concentration and consumer affluence. North America and Europe currently represent the most mature markets, characterized by high adoption rates of fully automated, high-precision equipment. These regions have stringent quality standards, high labor costs, and a substantial demand for premium cosmetic and luxury home fragrance products, driving continuous investment in sophisticated, high-OEE machinery. European manufacturers, in particular, lead in developing hygienic and modular systems tailored for complex cosmetic formulations and compliance with EU regulations.

Asia Pacific (APAC) stands out as the fastest-growing region, driven by massive manufacturing scale-up, particularly in China, South Korea, and India. This region is not only a major exporter but is experiencing rapid growth in domestic consumer spending on beauty and wellness products. The demand here is dual-natured: high-volume, cost-effective automation for mass market production, and technologically advanced systems for sophisticated premium cosmetic export manufacturing. The presence of numerous contract manufacturers (CMOs) in APAC further fuels market growth, as they invest heavily in automated machinery to service global brand outsourcing requirements. Investment in local machine fabrication is also rising, challenging traditional Western dominance.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging markets showing promising growth trajectories. LATAM growth is centered around Mexico and Brazil, driven by expanding local cosmetic production and increasing demand for localized manufacturing capacity to reduce reliance on imports. In MEA, the UAE and Saudi Arabia are investing in local industrial capabilities, including specialty chemical and cosmetic production. While the market size in these regions remains smaller compared to APAC or North America, the lack of deeply entrenched legacy systems provides an opportunity for suppliers of modern, flexible automation solutions to penetrate rapidly, often focusing on medium-throughput automatic systems as the initial entry point.

- North America: Market maturity, high expenditure on servo-driven automation, significant focus on cosmetic and high-end candle production, driven by labor efficiency and precision requirements.

- Europe: Strong emphasis on hygienic design, specialized machinery for complex formulations, high regulatory compliance, and leading innovation in modular machine systems.

- Asia Pacific (APAC): Highest projected growth rate, dual market demand (high volume mass market and sophisticated export production), strong growth in China and India’s domestic cosmetic and candle industries.

- Latin America (LATAM): Emerging market, growth driven by localized manufacturing expansion in Brazil and Mexico, focusing on medium-scale automatic equipment.

- Middle East & Africa (MEA): Potential market growth due to industrial diversification and increasing local establishment of consumer goods manufacturing plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wax Filling Machine Market.- IKG Industriekühlung

- Filamatic

- TurboFil Packaging Machines

- Cozzoli Machine Company

- Spee-Dee Packaging Machinery

- Accutek Packaging Equipment

- CVP Systems

- Krones AG

- Sacmi Packaging

- Ronchi Packaging

- Shemesh Automation

- BCM Machining

- PKB Packing

- Guangzhou Xili Machinery

- Pouchfill Systems

- GEA Group

- Bosch Packaging Technology (Syntegon)

- Prodo-Pak Corp.

- Norden Machinery

Frequently Asked Questions

Analyze common user questions about the Wax Filling Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for fully automatic wax filling machines?

The demand is primarily driven by the necessity for high production speed, adherence to stringent quality control standards in cosmetics and candles, and the high cost of manual labor, making automation essential for operational efficiency and scaling production capacity globally.

How does the type of wax affect the required specifications of the filling machine?

Different waxes (e.g., paraffin, soy, coconut) require specific machine adjustments, primarily related to temperature control and viscosity handling. Natural waxes demand gentler handling and precise, stable temperature management to prevent crystallization issues and preserve fragrance integrity, often requiring specialized nozzles and stirring mechanisms.

What role does AI or Industry 4.0 play in modern wax filling operations?

AI integrates machine learning for real-time process optimization, dynamically adjusting temperature and flow based on material input variability. Industry 4.0 enables predictive maintenance, remote diagnostics, and data-driven quality control via integrated sensors and connectivity, significantly enhancing OEE.

Which application segment holds the largest share of the Wax Filling Machine Market?

The Candles and Cosmetics application segments collectively hold the largest market share. The continuous growth in global demand for premium scented candles and mass-produced cosmetic sticks/balms necessitates sustained investment in high-precision filling technology.

What is the typical difference between piston fillers and pump fillers in this market?

Piston fillers are highly valued for volumetric accuracy, especially with thick, viscous waxes and high-precision dosing required in cosmetics. Pump fillers (like gear or lobe pumps) offer greater flexibility across a wider viscosity range and are often preferred for their ease of integration into continuous flow systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager