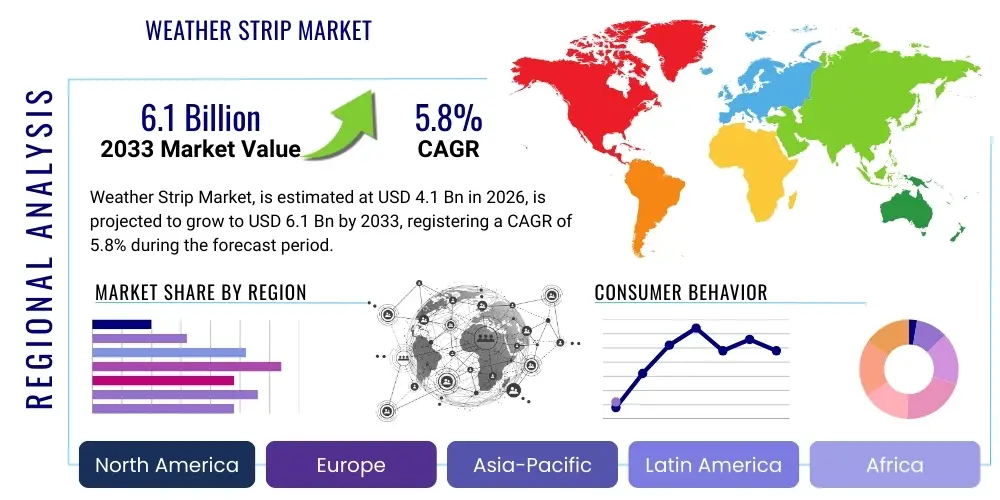

Weather Strip Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434929 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Weather Strip Market Size

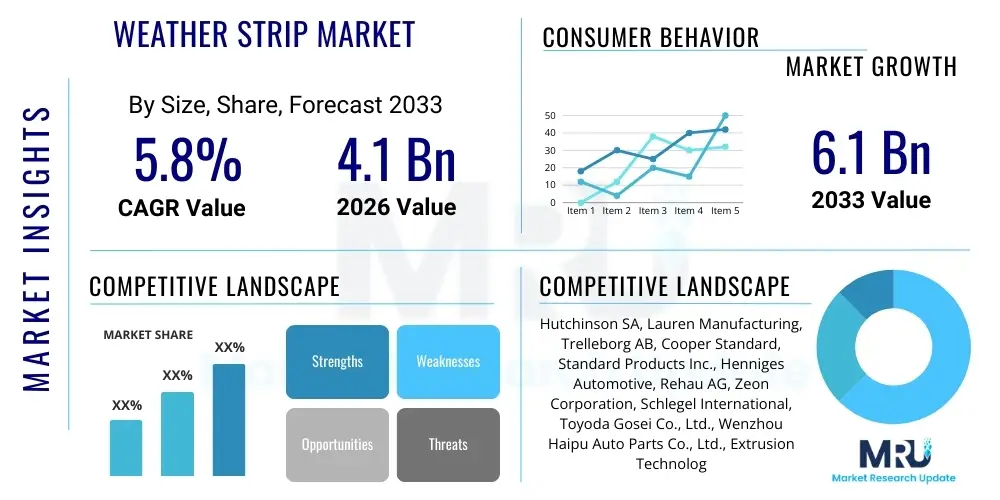

The Weather Strip Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Weather Strip Market introduction

The Weather Strip Market encompasses the production and distribution of sealing materials used primarily to prevent the ingress of weather elements such as air, water, dust, and sound through gaps around moving components, predominantly in doors, windows, and automotive applications. These essential components, often manufactured from materials like EPDM, silicone, PVC, and TPE, are crucial for maintaining thermal performance and energy efficiency within residential, commercial, and transportation structures. The product's fundamental function is to create a reliable barrier, contributing significantly to improved indoor air quality and reduced heating, ventilation, and air conditioning (HVAC) costs, thereby aligning directly with global sustainability objectives and stricter building codes.

Major applications of weather strips span across the building and construction industry, where they are vital for minimizing energy loss in new construction and large-scale renovation projects, and the automotive sector, where they enhance ride comfort, acoustic insulation, and protect vehicle interiors from external conditions. Furthermore, weather strips are increasingly utilized in specialized industrial equipment and cold storage facilities where stringent temperature control and sealing capabilities are required. The inherent simplicity and high cost-effectiveness of these solutions, combined with their critical role in optimizing building performance, underscore their continuous demand trajectory across diverse end-use verticals globally.

The primary benefit derived from weather stripping is energy conservation, achieved by eliminating drafts and preventing air exchange between interior and exterior environments. This performance enhancement is the key driving factor for market growth, particularly in regions facing escalating energy prices and government mandates promoting green building standards. Other significant driving factors include the rapid pace of urbanization in developing economies, necessitating increased residential and commercial construction, and the ongoing trend in the automotive industry toward lighter, more fuel-efficient vehicles that require superior sealing mechanisms to maintain structural integrity and minimize noise pollution. Consequently, product innovation centered on durability, material sustainability, and enhanced sealing efficiency remains a core strategic focus for market participants.

Weather Strip Market Executive Summary

The global Weather Strip Market is experiencing steady expansion, predominantly fueled by robust growth in the residential and commercial construction sectors across Asia Pacific, coupled with stringent regulatory standards related to energy efficiency in North America and Europe. Key business trends indicate a heightened focus on mergers, acquisitions, and strategic collaborations aimed at integrating advanced manufacturing techniques, such as continuous vulcanization and specialized extrusion processes, to improve product quality and output volume. Furthermore, the shift toward high-performance materials like thermoplastic elastomers (TPE) and silicone is creating new opportunities for premium pricing, challenging traditional materials like EPDM and PVC in specialized, high-specification applications, particularly within the luxury automotive segment and passive house construction projects.

Regional trends clearly highlight the Asia Pacific region as the dominant and fastest-growing market, driven by massive infrastructure spending, rapid industrialization, and favorable demographics, which are consistently elevating the demand for basic and advanced sealing solutions. Conversely, mature markets like Europe and North America demonstrate growth primarily through replacement, refurbishment, and adherence to evolving building codes that prioritize thermal envelope tightness, requiring weather strip products with superior U-factors and air leakage prevention capabilities. This divergence in regional growth dynamics necessitates tailored market entry strategies focusing either on high-volume, cost-competitive products in emerging economies or high-specification, sustainable solutions in developed regions.

Segmentation trends reveal that the Material segment is undergoing significant transformation, with TPE exhibiting the highest anticipated CAGR due to its superior flexibility, recyclability, and resistance to UV exposure, making it a compelling alternative to conventional rubber materials. In terms of Application, the doors and windows segment retains the largest market share, directly correlated with the cyclical nature of the construction industry, while the automotive segment demonstrates reliable, application-specific growth driven by the increasing complexity of vehicle design and the electrification trend, which demands exceptional noise, vibration, and harshness (NVH) control. Market participants are increasingly investing in proprietary material formulations and customized design services to cater effectively to the highly diversified needs of large-scale OEMs and regional construction firms.

AI Impact Analysis on Weather Strip Market

User inquiries regarding the influence of Artificial Intelligence (AI) in the Weather Strip Market predominantly focus on optimizing production lines, enhancing material science R&D, and improving demand forecasting precision in a supply chain frequently affected by raw material price volatility. Users are seeking to understand how AI-driven analytics can minimize waste during the extrusion and molding processes, predict equipment failure in vulcanization plants (preventing costly downtime), and, crucially, how machine learning algorithms can accelerate the discovery and testing of novel sustainable polymers, such as bio-based or high-durability TPEs, thereby reducing the time-to-market for next-generation weather sealing solutions. The primary concerns revolve around the initial capital investment required for AI integration and the need for specialized data scientists to manage complex predictive models tailored for specific rubber and plastic processing environments.

- AI-powered predictive maintenance reduces equipment failure rates, especially in continuous vulcanization lines.

- Machine learning algorithms optimize raw material blending and curing schedules, minimizing scrap rates and ensuring dimensional consistency.

- Advanced analytics improve supply chain resilience by accurately predicting future demand based on construction permits and automotive production schedules.

- AI-assisted material science accelerates the development of sustainable, high-performance polymer formulations for enhanced durability.

- Automated visual inspection systems using computer vision ensure zero-defect output by identifying subtle flaws in extruded profiles during production.

DRO & Impact Forces Of Weather Strip Market

The dynamics of the Weather Strip Market are highly influenced by a balance of persistent drivers and structural restraints, punctuated by emerging opportunities rooted in sustainability and smart technology integration. Key drivers include stringent governmental regulations mandating energy efficiency in new and existing buildings, compelling builders and homeowners to adopt high-quality sealing solutions to meet energy performance targets. Furthermore, the global proliferation of automotive manufacturing, particularly in emerging Asian economies, provides a stable, high-volume demand base. Restraints primarily involve the significant volatility of petrochemical-derived raw material prices, such as polymers and additives, which directly impact manufacturing costs and necessitate flexible pricing strategies. Additionally, the fragmented nature of the market, particularly the lower-end commodity segment, exerts downward pressure on profitability for smaller participants.

Opportunities for market expansion are strongly linked to the increasing global focus on green building initiatives and the push toward net-zero energy structures, driving demand for premium, technologically advanced weather strips like intumescent seals and those incorporating phase change materials. The growing market for smart homes and automated building systems also presents opportunities, necessitating durable seals for automated windows and doors that can withstand frequent movement. The impact forces analysis, utilizing Porter’s framework, indicates a moderate to high bargaining power of buyers, especially large automotive OEMs and major construction contractors who procure materials in bulk and demand specialized products under strict quality specifications. Supplier power is also high due due to the reliance on key petrochemical feedstock suppliers.

The threat of new entrants remains relatively moderate; while the manufacturing process for basic PVC or EPDM strips is established, achieving the consistency and quality required for high-performance applications (e.g., medical, aerospace, or high-end architectural systems) requires significant capital investment in specialized extrusion and formulation technology, posing a barrier. The threat of substitutes is low, as weather strips provide an indispensable function that cannot be easily replaced by alternative building components, though material substitution (e.g., switching from rubber to TPE) within the weather strip category is a constant market feature. Overall, market stability is maintained by the essential, non-discretionary nature of the product across core end-use industries, ensuring sustained demand despite economic fluctuations.

Segmentation Analysis

The Weather Strip Market segmentation provides a granular view of market structure based on the type of material utilized, the specific application area, and the end-user industry procuring the product. Analyzing these segments is critical for manufacturers to tailor product development and marketing efforts, focusing on niche requirements such as UV resistance for exterior applications (material segmentation) or acoustic performance for passenger vehicles (application segmentation). The market’s complexity is driven by the performance trade-offs inherent in different materials—for example, silicone offering superior temperature resistance but higher cost, versus EPDM providing a cost-effective balance of durability and flexibility. Strategic positioning requires a deep understanding of which material best serves the long-term needs of specific end-user segments, such as large-scale residential construction or specialized aerospace components.

- By Material:

- EPDM (Ethylene Propylene Diene Monomer)

- PVC (Polyvinyl Chloride)

- Silicone

- TPE (Thermoplastic Elastomer)

- Others (Foam, Felt, Metal, etc.)

- By Application:

- Doors

- Windows

- Automotive

- Industrial & Others (e.g., Appliance, Marine)

- By End-User:

- Residential Construction

- Commercial Construction

- Industrial Construction

- Automotive OEM

- Aftermarket & Renovation (DIY)

Value Chain Analysis For Weather Strip Market

The value chain for the Weather Strip Market begins with upstream activities centered on the procurement and refinement of essential raw materials, primarily synthetic rubbers (such as EPDM and silicone polymers) and thermoplastics (like PVC and TPE). This stage is characterized by high capital intensity and reliance on the petrochemical industry, making pricing highly susceptible to global oil market fluctuations. Key value addition at this stage involves sophisticated compounding—mixing polymers with various additives, fillers, and vulcanizing agents to achieve precise performance characteristics such as UV stability, flame retardancy, or specific compression set values required by the final application. Establishing secure, long-term supply contracts with major chemical manufacturers is a critical success factor for downstream producers.

The midstream phase involves the manufacturing process, which is dominated by high-precision extrusion, molding (injection or compression), and continuous vulcanization techniques. Manufacturers leverage specialized tooling and highly automated production lines to produce consistent profiles in high volumes. This stage requires significant investment in quality control measures, including dimensional verification and performance testing (e.g., accelerated weathering tests). Forward integration strategies, where compounders also perform extrusion, allow for greater control over material properties and lower production costs. Customized component design and tooling fabrication represent substantial intellectual property and value at this stage, particularly for components destined for sophisticated automotive sealing systems.

Downstream analysis focuses on distribution channels and end-user engagement. Distribution is multifaceted, involving both direct sales to large Original Equipment Manufacturers (OEMs), such as automotive companies and major window/door fabricators, and indirect channels for the renovation and aftermarket sectors. Indirect distribution relies heavily on professional distributors, large retail hardware chains (for DIY customers), and specialized industrial suppliers. Direct sales necessitate robust technical support and collaborative R&D capabilities, while indirect channels demand high logistical efficiency and strong brand recognition. The proliferation of e-commerce is also impacting downstream activities, allowing smaller manufacturers to reach localized DIY markets directly, although large-volume industrial sales remain relationship-based and require specialized sales engineering support.

Weather Strip Market Potential Customers

The primary consumers for weather strip products are segmented across highly diversified industrial and construction end-users, each demanding specific material attributes and profile geometries. The largest volume segment comprises residential and commercial construction firms and component manufacturers (such as window and door fabricators). These buyers require seals that ensure compliance with stringent local building codes focused on energy efficiency (e.g., R-value improvement and air infiltration reduction). Their purchasing decisions are primarily influenced by product lifespan, ease of installation, and volume-based pricing, making long-term supply agreements and consistent quality delivery paramount for suppliers.

The automotive industry constitutes another critical customer base, particularly Original Equipment Manufacturers (OEMs). These customers require highly engineered, custom-designed sealing systems (e.g., glass runs, primary door seals) that must meet exacting specifications for noise, vibration, and harshness (NVH) mitigation, aesthetics, and resistance to environmental stress (ozone, temperature extremes). Procurement in the automotive sector is characterized by intense qualification processes, long contract cycles, and mandatory adherence to IATF 16949 quality standards, demanding suppliers with advanced R&D capabilities and zero-defect manufacturing protocols. The transition to electric vehicles (EVs) is further elevating demand for enhanced acoustic insulation seals.

A third significant customer group is the aftermarket and renovation segment, including professional contractors and DIY homeowners. These buyers typically access products through retail channels or specialty distributors. Their focus is on readily available, easy-to-install products (like adhesive-backed foam or pre-cut strips) that provide immediate improvement in energy performance. While unit volumes per transaction are smaller, the overall aggregate demand from this highly dispersed segment is substantial, particularly during economic downturns when consumers prioritize repair and energy-saving renovations over full structural replacements. Industrial customers, including manufacturers of appliances, HVAC systems, and cold storage units, represent a niche segment requiring highly specialized, often fire-resistant or chemical-resistant seals, valuing technical specifications over bulk cost savings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hutchinson SA, Lauren Manufacturing, Trelleborg AB, Cooper Standard, Standard Products Inc., Henniges Automotive, Rehau AG, Zeon Corporation, Schlegel International, Toyoda Gosei Co., Ltd., Wenzhou Haipu Auto Parts Co., Ltd., Extrusion Technology, Quanex Building Products, 3M Company, Ultrafab Inc., Semperit AG Holding, LMI Custom Cosmetics, Sika AG, Dorman Products, Chuangli Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Weather Strip Market Key Technology Landscape

The technological evolution within the Weather Strip Market is driven primarily by demands for enhanced durability, superior thermal performance, and compliance with increasingly rigorous environmental standards. The core manufacturing technology remains advanced extrusion and co-extrusion processes, which allow for the creation of complex, multi-component profiles combining materials with different hardnesses (e.g., rigid base for mounting combined with a soft sealing lip). Recent technological advancements focus on continuous vulcanization processes utilizing microwaves or hot air tunnels, enabling faster production speeds and ensuring highly uniform curing of rubber-based materials, which is crucial for achieving consistent compression set and long-term sealing integrity. Furthermore, specialized surface treatments, such as flocking or PTFE coatings, are essential for automotive seals to reduce friction and improve the smooth operation of power windows, representing a significant area of technological sophistication.

Material science innovation is equally pivotal. The shift towards Thermoplastic Elastomers (TPEs), particularly TPV (Thermoplastic Vulcanizates), represents a major technological leap. TPEs offer the durability and flexibility of traditional rubber but are fully recyclable, aligning with circular economy objectives and reducing overall life cycle costs. Manufacturers are investing heavily in customized TPE formulations that can match or exceed EPDM performance in key areas like weather resistance and heat aging, while maintaining better processing efficiency. In the high-end architectural sector, the integration of smart materials, such as phase change materials (PCMs) within weather strip cores, is being explored to offer dynamic thermal regulation capabilities, further enhancing building energy performance beyond simple air sealing.

Furthermore, digital manufacturing technologies, including 3D printing, are emerging in the prototyping and custom tooling phases, significantly reducing lead times for complex, low-volume designs required by specialized industrial customers. Quality control is increasingly reliant on non-contact measurement systems, such as laser and optical scanners, integrated directly into the production line. These systems provide real-time, high-precision dimensional analysis, ensuring that extruded profiles meet the tight tolerances demanded by automotive and aerospace clients. Overall, the technology landscape emphasizes precision engineering, material sustainability, and process automation to maintain competitiveness and comply with high-performance mandates across all key end-user markets.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, product mix, and competitive landscape of the global Weather Strip Market, reflecting variations in climate, building codes, and industrial maturity.

- Asia Pacific (APAC) Market Dominance: The APAC region is projected to maintain the largest market share and exhibit the highest growth rate during the forecast period. This robust performance is primarily driven by massive government investments in infrastructure, rapid urbanization, and a continuous boom in both residential and commercial construction across major economies like China, India, and Southeast Asian nations. The region’s burgeoning automotive manufacturing sector, fueled by both domestic demand and status as a global production hub, ensures substantial, consistent uptake of weather strips for vehicle sealing applications. While cost-competitiveness often dictates procurement in the mass market, increasing consumer awareness regarding energy efficiency, particularly in sophisticated markets like Japan and South Korea, is gradually driving demand for premium sealing materials.

- North America Market Maturity and Regulatory Focus: North America represents a mature yet high-value market, characterized by strict energy efficiency standards such as those enforced by the International Energy Conservation Code (IECC) and local building departments. Growth here is primarily driven by renovation projects, replacements, and the adoption of high-performance seals, especially silicone and TPE, in high-end window and door systems designed for severe climate conditions. The substantial presence of major automotive OEMs necessitates continuous innovation in NVH reduction seals. Market players often focus on specialized, niche products offering superior thermal performance and extended warranties to capture the refurbishment segment effectively.

- Europe Market Emphasis on Sustainability and Passive House Standards: The European market is highly regulated and strongly focused on environmental sustainability and achieving net-zero energy building targets. Initiatives like the Passive House standard necessitate sealing components with exceptional airtightness and thermal break properties, significantly boosting demand for advanced TPE and multilayered EPDM systems. While overall construction volume growth may be slower than in APAC, the value generated per unit is high due to the mandatory requirement for certified, sustainable materials and complex profile geometries. Eastern European countries are showing steady growth, transitioning from traditional materials to modern, energy-efficient sealing solutions.

- Latin America, Middle East, and Africa (LAMEA) Emerging Growth: LAMEA represents diverse opportunities. The Middle East, particularly the Gulf Cooperation Council (GCC) states, sees demand driven by massive, climate-controlled commercial projects and luxury residential construction, requiring weather strips that can withstand extreme heat and sand ingress. Africa, while highly fragmented, offers long-term potential fueled by expanding residential infrastructure projects. Latin America's market growth is cyclical, highly dependent on local economic stability and government investment in public housing, with Brazil and Mexico leading regional consumption, particularly in the automotive manufacturing hubs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Weather Strip Market.- Hutchinson SA

- Lauren Manufacturing

- Trelleborg AB

- Cooper Standard

- Standard Products Inc.

- Henniges Automotive

- Rehau AG

- Zeon Corporation

- Schlegel International

- Toyoda Gosei Co., Ltd.

- Wenzhou Haipu Auto Parts Co., Ltd.

- Extrusion Technology

- Quanex Building Products

- 3M Company

- Ultrafab Inc.

- Semperit AG Holding

- LMI Custom Cosmetics

- Sika AG

- Dorman Products

- Chuangli Group

Frequently Asked Questions

Analyze common user questions about the Weather Strip market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Weather Strip Market?

The primary driver is the global increase in stringent energy efficiency mandates and building codes, compelling both new construction and renovation projects to use high-quality weather stripping to reduce air leakage and lower HVAC operational costs, directly supporting environmental sustainability goals.

Which material segment holds the most promising growth outlook in the forecast period?

The Thermoplastic Elastomer (TPE) segment, specifically TPV, is projected to exhibit the highest growth rate. TPE offers superior flexibility, recyclability, and excellent resistance to weathering compared to traditional materials, making it preferred for high-performance architectural and automotive sealing applications.

How does the volatile price of raw materials impact weather strip manufacturers?

Volatility in the price of petrochemical derivatives, which are essential raw materials for EPDM and PVC, significantly increases manufacturing costs. This often leads to reduced profit margins unless suppliers can secure long-term, fixed-price contracts or successfully implement price escalators in agreements with major buyers.

Which regional market is the largest consumer of weather strips globally?

Asia Pacific (APAC) currently dominates the market share due to unparalleled growth in construction activities, urbanization, and a vast automotive manufacturing base in countries like China and India, driving consistent and large-volume demand across all application segments.

What role does advanced technology play in modern weather strip production?

Advanced technology focuses on highly automated co-extrusion and continuous vulcanization processes for greater precision and speed. Furthermore, AI-driven quality control (using optical scanners) and the development of sustainable, high-performance materials like bio-based TPEs are crucial for meeting complex OEM specifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automobile Weather Strip Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Automobile Weather Strip Market Size Report By Type (EPDM Strip, TPE/TPO/TPV Strip, Other Strip), By Application (Passenger Vehicle, Commercial Vehicle), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Automobile Weather Strip Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (TPE/TPO/TPV, EPDM, Other Materials), By Application (Doorframe, Engine Hood, Other Materials), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager