Wedge Wire Screen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434979 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Wedge Wire Screen Market Size

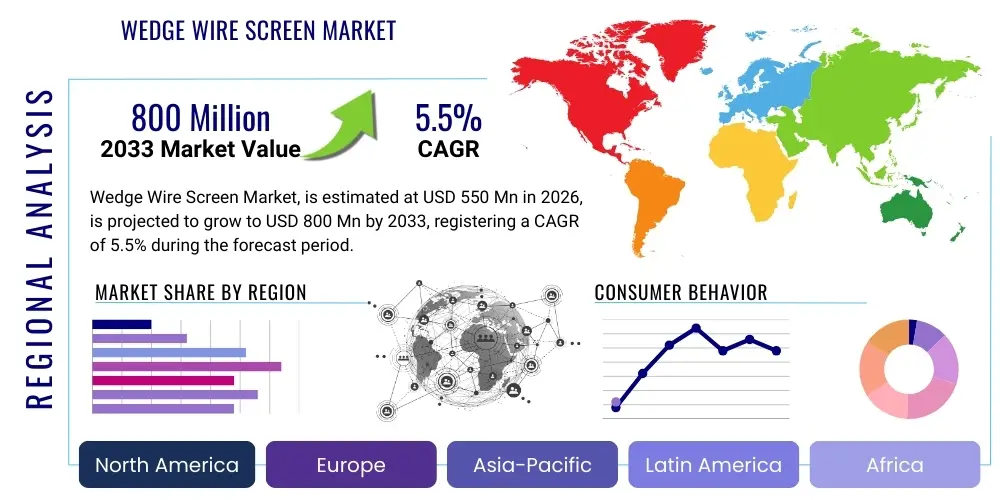

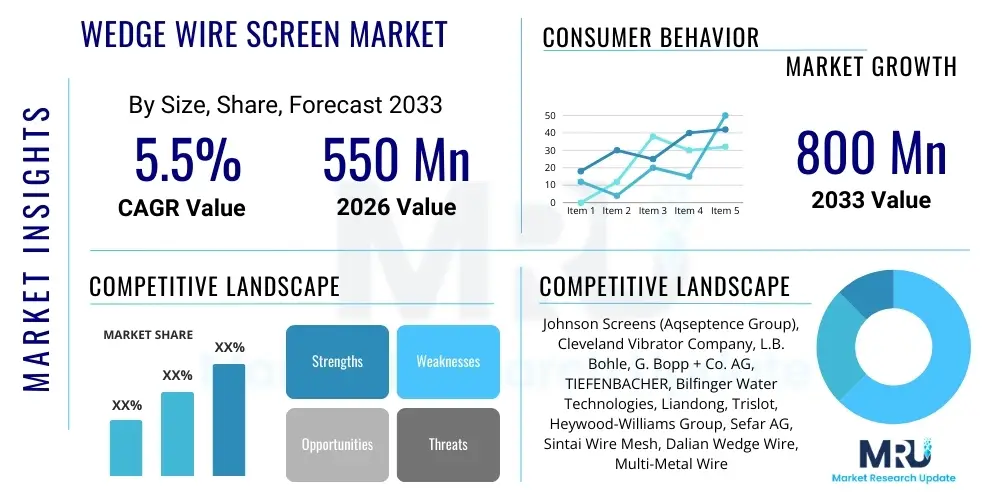

The Wedge Wire Screen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 800 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by increasing global demand for precise separation and filtration solutions across critical industrial sectors, coupled with strict environmental regulations demanding higher purity levels in wastewater treatment and industrial processing. The inherent durability and high efficiency of wedge wire screens, particularly in high-pressure or corrosive environments, position them as essential components over traditional woven mesh alternatives, thereby supporting robust market expansion throughout the projection period.

Wedge Wire Screen Market introduction

The Wedge Wire Screen Market encompasses the production and distribution of specialized screening elements characterized by V-shaped profile wires welded to robust support rods. These screens are engineered to create precise, continuous slot openings that minimize clogging, maximize flow rates, and provide exceptional mechanical strength and longevity. The fundamental design allows for superior filtration efficiency, making them indispensable in applications requiring reliable solid-liquid separation, particle sizing, or media retention. Major applications span vital sectors, including water intake systems, municipal and industrial wastewater treatment, oil and gas drilling (especially downhole filtration), mineral processing and mining, and the food and beverage industry (for brewing and refining). The primary benefits derived from using wedge wire technology include reduced operational downtime due to non-clogging capabilities, improved product yield, superior structural integrity under demanding conditions, and extended service life, which collectively drive their adoption worldwide. Driving factors for this market expansion include rapid industrialization in emerging economies, increasing global population pressure on water resources necessitating advanced filtration, and technological advancements in manufacturing precision that enhance the effectiveness and cost-efficiency of screen production.

Wedge Wire Screen Market Executive Summary

The Wedge Wire Screen Market is poised for significant advancement, dictated by robust business trends emphasizing customized filtration solutions and material innovation, particularly the increased usage of specialized stainless steel and exotic alloys to withstand highly corrosive process media. Industry participants are heavily investing in automated welding techniques and computational fluid dynamics (CFD) modeling to optimize screen design for maximum hydraulic efficiency, targeting sectors like deep-sea oil exploration and high-temperature chemical processing. Regionally, the Asia Pacific (APAC) stands out as the highest growth potential area, driven by massive infrastructure investments in wastewater treatment and burgeoning mining activities, while North America maintains dominance due to mature oil and gas exploration activities and stringent regulatory requirements for industrial discharge. Segment trends clearly show a pronounced shift towards screens used in filtration applications, overshadowing standard dewatering uses, and within materials, the demand for 316L Stainless Steel dominates due to its excellent corrosion resistance. Furthermore, the market is seeing strong adoption of specialized products like sieve bends and nozzle filters, reflecting the growing complexity and precision required in modern industrial separation processes.

AI Impact Analysis on Wedge Wire Screen Market

Common user questions regarding AI’s influence on the Wedge Wire Screen Market frequently center on how these technologies can optimize manufacturing processes, predict equipment failure, and enhance customized product design. Users are particularly concerned with leveraging AI for predictive maintenance to prevent costly downtime associated with screen fouling or wear, thereby extending the operational lifespan of high-value screens used in critical environments such as deep well water systems or refinery separators. Key themes emerging from these inquiries highlight the expectation that AI and Machine Learning (ML) will revolutionize quality control by analyzing real-time sensor data from welding machines to ensure slot uniformity and dimensional accuracy, which is paramount for filtration performance. Furthermore, there is significant interest in using AI algorithms to simulate fluid dynamics within filter assemblies, allowing manufacturers to rapidly design complex screens optimized for specific viscosity, pressure, and particle size distribution requirements, moving the industry toward truly bespoke, performance-guaranteed filtration products rather than standardized off-the-shelf components.

- AI-driven optimization of welding parameters to ensure micron-level slot opening precision.

- Predictive maintenance analytics applied to operational filtration systems to forecast screen clogging or structural degradation, minimizing unplanned shutdowns.

- Enhanced material quality inspection using machine vision systems integrated into the manufacturing line.

- Computational Fluid Dynamics (CFD) simulation accelerated by ML models for rapid, customized screen design specific to end-user process conditions (temperature, viscosity, flow).

- Supply chain optimization for raw materials (specialized alloys) based on predictive demand forecasting and geopolitical risk analysis.

DRO & Impact Forces Of Wedge Wire Screen Market

The dynamics of the Wedge Wire Screen Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that guide strategic decision-making and investment. A significant driver is the critical need for efficient water management and resource recovery across municipal and industrial landscapes globally, where wedge wire screens are essential for pre-treatment and tertiary filtration to meet increasingly stringent regulatory standards for environmental protection. Further driving the market is the sustained exploration and production activities in the oil and gas sector, particularly the necessity for reliable downhole sand control and completion fluids filtration, where the robust, non-clogging nature of V-wire profiles is invaluable. However, the market faces significant restraints, notably the relatively high initial capital investment required for installing high-specification wedge wire filtration systems compared to conventional filtration media, which can deter smaller operations. Furthermore, the volatility in pricing and availability of crucial raw materials, particularly nickel and chromium used in stainless steel and exotic alloys (316L, Duplex), presents a constant challenge to manufacturing cost predictability. The dominant impact force remains regulatory pressure, which continually pushes end-users toward sophisticated, high-performance separation technologies that only wedge wire screens can reliably provide, ensuring steady, technology-led growth despite cost hurdles.

Segmentation Analysis

The Wedge Wire Screen Market is highly diversified, segmented based primarily on Material, Application, and End-User Industry, reflecting the wide range of operational environments and performance requirements these products address. This detailed segmentation allows manufacturers to tailor production strategies and R&D efforts toward high-growth niches. Material segmentation is crucial as it dictates the screen's resistance to corrosion, temperature, and pressure, with Stainless Steel grades dominating due to their balance of cost and durability, although specialized alloys are gaining traction in chemical processing. Application segmentation, ranging from water wells and mining slurries to sugar processing and brewing, determines the required slot opening size and screen configuration (e.g., flat panels, cylinders, baskets). Understanding these segments is key to capturing market share, as each end-user industry has unique compliance standards and operational demands that necessitate specialized design engineering.

- By Material:

- Stainless Steel (304, 316L, 321)

- Exotic Alloys (Duplex, Super Duplex, Hastelloy)

- Carbon Steel

- By Profile Wire Type:

- V-Shape/Wedge Wire

- Triangular Wire

- Other Customized Profiles

- By Application:

- Sizing and Classification

- Filtration and Screening

- Media Retention (Resin Traps)

- Dewatering and Drying

- By End-User Industry:

- Water and Wastewater Treatment

- Oil and Gas (Downhole, Refining)

- Mining and Mineral Processing

- Food and Beverage (Brewing, Sugar Refining)

- Chemical and Petrochemical

- Pulp and Paper

- By Product Type:

- Cylindrical Screens (Strainers, Well Screens)

- Flat Panel Screens (Sieve Bends)

- Header and Lateral Systems

- Nozzle and Distributor Systems

Value Chain Analysis For Wedge Wire Screen Market

The value chain for the Wedge Wire Screen Market begins with upstream activities focused on the procurement and preparation of specialized raw materials, primarily stainless steel wire rod and profile wire, demanding rigorous quality control to ensure metallurgical integrity and consistency. Manufacturers often engage in long-term contracts with key steel suppliers to mitigate price volatility, emphasizing 316L and various exotic alloys due to their high demand in corrosive environments. The core transformation stage involves sophisticated fabrication, where profile wires are meticulously wound and automatically welded onto support rods, a process requiring specialized high-precision machinery and skilled labor. Downstream analysis focuses heavily on distribution and installation, recognizing that these products are often components within larger capital equipment (e.g., reactor vessels, water well assemblies). Distribution channels are typically a mix of direct sales to large OEMs (Original Equipment Manufacturers) in the oil and gas sector and specialized industrial distributors who provide technical support and localized inventory to smaller end-users in municipal water treatment and food processing. The complexity of product specification often necessitates substantial technical consultation, positioning the indirect distribution channel—specialized engineering firms and integration experts—as critical facilitators in the deployment of these custom screening solutions.

Wedge Wire Screen Market Potential Customers

The primary customers for wedge wire screens are large industrial entities and municipal authorities requiring robust, high-precision solid-liquid separation solutions across diverse operational spectra. In the Oil and Gas sector, major international exploration and production companies are key buyers, utilizing these screens extensively as well screens for sand control in boreholes and specialized filter media in refineries and petrochemical plants, where their high mechanical strength and reliable slot geometry are non-negotiable for protecting expensive downstream equipment. Municipal water and wastewater utilities represent another cornerstone customer base, relying on wedge wire intake screens to prevent debris ingress into treatment facilities and various filters and strainers throughout the purification process to meet public health standards. Furthermore, the Mining and Mineral Processing industries are significant purchasers, using flat panel screens and sieve bends for slurry dewatering and mineral classification, valuing the material’s abrasion resistance and high flow capacity. These end-users typically prioritize product longevity, maintenance ease (backwashing capabilities), and compliance with industry-specific pressure and temperature ratings when making procurement decisions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 800 Million |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Johnson Screens (Aqseptence Group), Cleveland Vibrator Company, L.B. Bohle, G. Bopp + Co. AG, TIEFENBACHER, Bilfinger Water Technologies, Liandong, Trislot, Heywood-Williams Group, Sefar AG, Sintai Wire Mesh, Dalian Wedge Wire, Multi-Metal Wire & Parts, ClearEdge Filtration, Global Screen Technology, Bibus AG, C&H Industrial, Jiangsu Kunsheng, Koflo Filtration, Delta Screens. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wedge Wire Screen Market Key Technology Landscape

The technological landscape of the Wedge Wire Screen Market is defined by continuous innovation in manufacturing precision, material science, and computational design tools aimed at maximizing hydraulic efficiency and product longevity. A cornerstone technology is automated resistance welding, specifically TIG (Tungsten Inert Gas) welding, which allows for the creation of extremely precise and structurally sound joints between the profile wire and support rods, ensuring uniform slot openings down to micron tolerances. Advances in automation have drastically improved production speed and consistency, reducing human error and enabling the mass production of highly customized geometries. Crucially, material science plays a vital role; ongoing research focuses on developing high-strength, corrosion-resistant alloys, such as various Duplex and Super Duplex stainless steels, which are essential for applications in high-salinity water intake systems and aggressive chemical environments, extending the operational envelope of wedge wire technology beyond traditional uses. Furthermore, the integration of computational fluid dynamics (CFD) software enables manufacturers to virtually test screen designs for flow dynamics, pressure drop characteristics, and cleaning efficiency (e.g., backwash performance) before physical prototyping, dramatically accelerating the product development cycle and ensuring AEO-optimized designs that reduce energy consumption for end-users.

Modern screen fabrication facilities increasingly utilize robotic welding systems coupled with laser measurement devices that continuously verify slot dimensions during the welding process. This real-time quality assurance is paramount, especially for filtration applications requiring sub-millimeter precision, guaranteeing that the installed screen meets stringent performance criteria. Another key technological trend involves surface treatment technologies, such as specialized coatings or electro-polishing, which are applied to improve flow characteristics and enhance resistance to biofouling or scaling, particularly in municipal water and aquaculture applications. The ability to produce complex forms, including curved screens, cone baskets, and multi-stage filtering elements, is now standard, facilitated by advanced CNC bending and rolling equipment tailored to the unique geometry of wedge wire profiles. These technological advancements collectively reduce manufacturing costs, improve product lifespan, and enhance the overall efficiency of separation processes across all major end-user sectors.

Finally, the growing adoption of Industry 4.0 principles, including sensor integration and the Internet of Things (IoT), is beginning to transform how wedge wire screens are monitored in the field. Intelligent screens embedded with pressure and flow sensors can transmit real-time performance data to maintenance teams, enabling condition-based monitoring and optimizing cleaning schedules. This move towards 'smart filtration components' allows for just-in-time maintenance, maximizing uptime and significantly lowering the total cost of ownership for industrial clients. This technological evolution from a simple static component to an intelligent filter media represents a substantial opportunity for differentiation among market leaders.

Regional Highlights

The global Wedge Wire Screen Market exhibits distinct growth patterns across key geographic regions, dictated by varying levels of industrialization, regulatory frameworks, and resource extraction activities. Asia Pacific (APAC) is projected to be the fastest-growing region, driven by massive urbanization, subsequent demand for clean water infrastructure, and extensive investments in chemical, pharmaceutical, and food processing industries across nations like China, India, and Southeast Asia. The necessity for effective wastewater treatment and environmental compliance in rapidly industrializing zones fuels high demand for durable filtration media.

North America currently holds the largest market share, predominantly due to the substantial presence of the oil and gas industry, particularly in the United States and Canada, where wedge wire screens are indispensable for sand control in hydraulic fracturing and deep-well drilling operations. Furthermore, the region’s mature municipal water and power generation sectors require continuous replacement and upgrade of intake screens and internal vessel components, ensuring a stable demand base. Strict environmental protection agency (EPA) standards governing discharge quality also mandate the use of high-performance screening solutions.

Europe represents a stable and mature market, characterized by high technological standards and a strong focus on sustainable water management and resource efficiency. Demand here is largely driven by stringent EU directives regarding industrial emissions and water quality, promoting the continuous upgrade of existing infrastructure. Countries like Germany and the UK maintain strong domestic manufacturing capabilities, catering to specialized applications in food and beverage (particularly brewing and dairy) and chemical processing, often utilizing high-grade stainless steel and specialized Duplex alloys.

- North America: Dominant market for O&G downhole applications and large-scale water intake systems; high demand for high-pressure customized screens.

- Asia Pacific (APAC): Highest growth region, fueled by infrastructure development, rapid industrial wastewater treatment requirements, and expanding mining operations in Australia and Southeast Asia.

- Europe: Stable market characterized by high regulatory adherence, focused on food safety filtration, petrochemical refining, and sustainable municipal water projects.

- Latin America (LATAM): Significant potential driven by major investments in mining (copper, iron ore) and large-scale agricultural processing, requiring durable screening solutions for mineral slurries and biomass separation.

- Middle East and Africa (MEA): Growing demand related to desalination projects, refinery expansion, and increased oil and gas exploration in arid environments, prioritizing anti-corrosion materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wedge Wire Screen Market.- Johnson Screens (Aqseptence Group)

- Bilfinger Water Technologies

- TIEFENBACHER

- Trislot (Heineken Technical Services)

- Liandong

- Cleveland Vibrator Company

- Delta Screens

- Wire Cloth Manufacturers, Inc.

- G. Bopp + Co. AG

- Sefar AG

- L.B. Bohle

- Multi-Metal Wire & Parts

- ClearEdge Filtration

- Wedge Wire Screen Co.

- Dalian Wedge Wire

- Global Screen Technology

- Sintai Wire Mesh

- Bibus AG

- Koflo Filtration

- C&H Industrial

Frequently Asked Questions

Analyze common user questions about the Wedge Wire Screen market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the demand for wedge wire screens globally?

The primary drivers include increasing global efforts toward stringent environmental compliance, particularly in wastewater treatment and industrial discharge, coupled with the critical need for efficient and reliable filtration and separation solutions in high-growth sectors like oil and gas, mining, and food processing. The non-clogging and high-strength attributes of the screens are crucial for meeting these demands.

What distinguishes wedge wire screens from traditional woven mesh filters?

Wedge wire screens feature continuous slot openings formed by V-shaped profile wires, offering superior non-clogging characteristics, higher flow rates, and exceptional mechanical strength due to the welded construction. Traditional woven mesh is prone to blinding and generally possesses lower mechanical integrity, making wedge wire the preferred choice for demanding industrial applications.

Which end-user industries represent the most significant growth opportunities for the market?

The most significant growth opportunities lie in the municipal and industrial wastewater treatment sectors due to global regulatory pressures, and the specialized filtration needs of the food and beverage industry (especially brewing and sugar refining). Furthermore, the complex filtration requirements of deep-sea oil and gas exploration continue to drive high-value customization opportunities.

How does the choice of material affect the performance and cost of a wedge wire screen?

Material choice directly impacts cost and operational suitability. Stainless steel (304/316L) offers a cost-effective solution for general use, while exotic alloys like Duplex and Hastelloy are significantly more expensive but provide essential resistance to high temperatures, aggressive chemicals, and chloride-induced corrosion, extending screen life in harsh environments.

What key technological advancements are shaping the future of wedge wire screen manufacturing?

Future manufacturing is being shaped by advanced automated welding techniques for achieving micron-level slot precision, the application of Artificial Intelligence (AI) and Computational Fluid Dynamics (CFD) for optimized product design, and the use of specialized surface treatments to enhance anti-fouling and anti-scaling capabilities in operational settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager