Wet Grinders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432599 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Wet Grinders Market Size

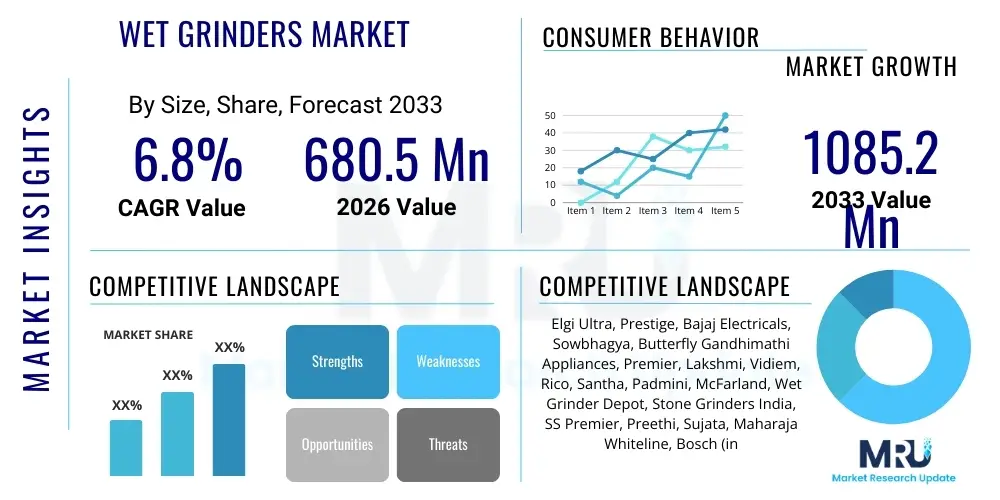

The Wet Grinders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 680.5 Million in 2026 and is projected to reach USD 1085.2 Million by the end of the forecast period in 2033.

Wet Grinders Market introduction

The Wet Grinders Market encompasses a specialized segment within the kitchen appliance industry, focusing on devices designed for pulverizing and blending ingredients, particularly grains and pulses, into fine, smooth pastes or batters essential for South Asian and traditional global cuisines. These appliances utilize heavy grinding stones or rollers operating on a flat surface or a tilting mechanism, facilitating the preparation of staple foods such as idli, dosa, vada, and specific regional sweets and savory dishes. Product descriptions often highlight variations like table-top models, tilting models, and conventional grinders, differentiated by capacity, grinding efficiency, and motor power. Major applications span residential kitchens, commercial establishments including restaurants and catering services, and small-scale food processing units specializing in batter production.

The core benefits driving market adoption include significant time saving compared to manual grinding techniques, consistency and uniformity in batter quality which directly impacts the texture of the final food product, and improved hygiene standards due to streamlined preparation processes. Furthermore, modern wet grinders are engineered for energy efficiency and reduced noise levels, enhancing user convenience in urban settings. Key driving factors for market expansion are the increasing disposable incomes in emerging economies, rapid urbanization leading to smaller kitchen spaces and demand for compact, efficient appliances, and the growing global popularity of ethnic foods, especially Indian and South Asian culinary traditions, which necessitates high-quality batter preparation.

The integration of advanced materials, such as food-grade plastics and durable stainless steel components, along with continuous improvements in motor design to handle heavy loads, ensures longevity and consistent performance, further solidifying the wet grinder’s position as an indispensable kitchen appliance. Manufacturers are actively focused on ergonomic design enhancements, offering features like transparent lids, digital timers, and specialized attachments for kneading and chopping, broadening the appliance's utility beyond traditional grinding tasks and capturing a wider consumer base focused on multifunctional kitchen tools.

Wet Grinders Market Executive Summary

The global Wet Grinders Market is experiencing robust growth fueled by shifting demographic trends and evolving culinary practices. Key business trends include aggressive product diversification by major players into aesthetically appealing and technologically enhanced tilting and table-top models, alongside a focused expansion into untapped international markets driven by diaspora communities and the rising global demand for convenience foods. Manufacturers are increasingly utilizing digital marketing channels and e-commerce platforms to bypass traditional retail bottlenecks and reach a broader consumer base efficiently, particularly targeting younger, tech-savvy urban dwellers seeking high-efficiency appliances.

Regional trends indicate that the Asia Pacific (APAC) region, spearheaded by India and Sri Lanka, remains the largest consumer and production hub due to deep cultural integration of ground batters in daily meals; however, North America and Europe are witnessing accelerated growth. This growth is attributable to immigration patterns creating substantial demand for culturally specific appliances and the adoption of wet grinders in specialized ethnic restaurants and commercial catering operations. Furthermore, growing concerns regarding food processing consistency and hygiene in institutional kitchens are bolstering demand for high-capacity commercial variants across developed economies, pushing manufacturers to comply with stringent international safety and quality standards.

Segment trends highlight the dominance of the table-top grinder segment due to its balance of capacity and space-saving design, making it ideal for modern homes. The tilting wet grinder segment, while smaller, shows higher average transaction values owing to its ease of cleaning and batter collection. In terms of material, the combination of ABS plastic bodies for aesthetics and weight reduction, paired with stainless steel drums for durability and hygiene, constitutes the fastest-growing sub-segment. Innovation is concentrated on reducing grinding time, enhancing power efficiency, and incorporating features that minimize user effort during both operation and post-use cleaning, ensuring high consumer satisfaction across all price points.

AI Impact Analysis on Wet Grinders Market

User queries regarding the impact of AI on the Wet Grinders Market primarily center on three themes: enhanced operational efficiency, predictive maintenance, and the creation of "smart kitchen ecosystems." Users are particularly interested in how AI can automate the grinding process by sensing batter consistency (viscosity and texture) and adjusting motor speed accordingly, thus achieving perfect results without manual intervention. There are also high expectations concerning predictive diagnostics—detecting unusual motor vibrations or excessive heat generation—to prevent mechanical failures, thereby extending product lifespan and reducing service calls. Furthermore, consumers anticipate integration with smart home platforms, allowing remote operation, recipe management linked to grinding parameters, and automated reordering of components or specific ingredients used in the grinding process, positioning the appliance as a networked component of the modern kitchen.

- AI-Enhanced Consistency Control: Implementation of sensors and algorithms to monitor and dynamically adjust grinding time and speed based on real-time batter texture and temperature, ensuring optimal consistency automatically.

- Predictive Maintenance Systems: Utilization of embedded AI modules to analyze motor performance metrics (vibration, heat, load) and predict potential mechanical failures, prompting users for scheduled maintenance before breakdown occurs.

- Smart Recipe Integration: Connecting wet grinders to smart recipe databases that pre-set grinding parameters (e.g., specific coarseness for dosa vs. idli) based on the chosen dish, minimizing user error.

- Voice Command Integration: Enabling hands-free operation and status updates through integration with popular smart home voice assistants (AEO consideration for "how to start wet grinder using voice").

- Energy Optimization: AI managing power consumption by analyzing usage patterns and load requirements, optimizing motor output to reduce electricity expenditure without compromising grinding quality.

- Automated Diagnostics and Troubleshooting: Allowing the appliance to run self-checks and transmit diagnostic data directly to customer service for quicker, more accurate remote troubleshooting.

DRO & Impact Forces Of Wet Grinders Market

The Wet Grinders Market is significantly shaped by a combination of driving factors (D), restraints (R), and opportunities (O), which collectively dictate the impact forces on market trajectory. The primary driver is the accelerating trend of urbanization in developing regions, which correlates directly with an increased demand for convenience and automation in the kitchen. Alongside this, the rising acceptance of standardized, hygienic food preparation methods in commercial settings and the consistent demand from the massive South Asian diaspora worldwide provide a stable foundation for growth. However, market expansion is restrained by the high initial cost of quality wet grinders compared to conventional mixers or blenders, particularly in price-sensitive rural markets. Furthermore, the specialized nature of the appliance means that market adoption is heavily concentrated in specific geographical and cultural niches, limiting broader global penetration.

Opportunities for growth are abundant, primarily centered on technological innovation, such as the development of compact, multifunctional grinders that cater to the space constraints of modern urban apartments and the increasing consumer preference for healthy, home-prepared foods over processed alternatives. The penetration of e-commerce and direct-to-consumer models also presents a massive opportunity to lower distribution costs and increase market reach in second- and third-tier cities. The key impact forces include intense competition driving down prices in the low-end segment, while differentiation is sought through ergonomic design, noise reduction, and smart features in the premium segment. Regulatory impacts related to energy efficiency standards (especially in Western markets) also compel manufacturers to invest continuously in research and development to maintain competitive advantage and compliance.

Segmentation Analysis

The Wet Grinders Market is comprehensively segmented based on product type, capacity, application, and material, allowing for a detailed analysis of specific consumer preferences and commercial requirements. Product types dictate usage ergonomics and kitchen placement, while capacity directly correlates with end-user volume needs, spanning from small residential units to large commercial bulk production systems. The application segmentation differentiates between the primary residential user base and the high-volume commercial sector, each having distinct demands regarding durability, power, and continuous operation capabilities. Material segmentation reflects a balance between cost, aesthetics, and hygiene, with stainless steel and ABS plastic being key defining factors across all market tiers, providing diverse avenues for competitive positioning.

- By Product Type:

- Table Top Wet Grinders

- Tilting Wet Grinders

- Conventional Wet Grinders

- Commercial Wet Grinders

- By Capacity:

- Up to 2 Liters (Small Capacity)

- 2 to 5 Liters (Medium Capacity)

- Above 5 Liters (High Capacity/Commercial)

- By Application:

- Residential

- Commercial (Restaurants, Hotels, Catering, Institutions)

- By Material:

- Stainless Steel Drum and Body

- Stainless Steel Drum with ABS Plastic Body

- Other Combinations

- By Distribution Channel:

- Offline (Retail Stores, Hypermarkets, Specialty Stores)

- Online (E-commerce Platforms, Company Websites)

- By Motor Type:

- Brushed Motors

- Brushless DC (BLDC) Motors

Value Chain Analysis For Wet Grinders Market

The value chain for the Wet Grinders Market begins with upstream activities involving raw material procurement, principally sourcing high-grade stainless steel for drums and rollers, heavy-duty ABS plastic resins for outer bodies, and specialized components like high-torque electric motors, grinding stones (granite or synthetic materials), and electronic controls. Key challenges upstream include managing volatile raw material prices and ensuring the quality and consistency of natural grinding stones. Efficiency gains at this stage often revolve around strategic long-term contracts with specialized motor and plastic suppliers to secure cost advantages and maintain component standardization across diverse product lines, mitigating supply chain disruptions inherent in global sourcing.

Manufacturing and assembly constitute the core of the value chain, where competitive advantage is derived from advanced precision engineering, automation in component assembly, and rigorous quality control checks, particularly for motor winding and stone alignment, which are crucial for performance. Downstream activities involve distribution and sales. The distribution channel is bifurcated into direct sales channels, typically involving large commercial units sold directly to institutional buyers, and indirect channels dominating the residential market. Indirect distribution relies heavily on a network of modern retail outlets, specialized kitchen appliance stores, and, increasingly, large-scale e-commerce platforms which offer superior geographical reach and logistical efficiency, particularly in fragmented markets.

The increasing prominence of online distribution channels has profoundly altered the downstream dynamics, requiring robust logistics management and effective digital marketing to capture consumer attention. Post-sales service and warranty provision form the final, critical link, heavily influencing brand loyalty and repeat purchases. Effective after-sales support requires a wide network of authorized service centers capable of quick repairs and parts replacement. Manufacturers must continuously optimize this entire chain, from raw material conversion to customer feedback integration, ensuring product quality remains high while managing complexity across diverse geographical markets to maximize profitability.

Wet Grinders Market Potential Customers

The Wet Grinders Market serves a highly diverse end-user base, categorized primarily into residential consumers and commercial entities, each demanding unique product specifications. Residential buyers form the largest segment, predominantly comprising households in regions where batter-based foods are dietary staples, such as South Asia, Southeast Asia, and regions with significant South Asian diaspora populations (North America, UK, GCC countries). These customers prioritize compact design, ease of cleaning, aesthetic appeal (especially table-top models), and reliable performance for moderate daily use, typically seeking capacities between 1.5 to 3 liters. Marketing efforts are often tailored towards convenience, time-saving benefits, and the ability to maintain traditional culinary authenticity.

The commercial segment represents a crucial growth area characterized by higher average transaction values and a stringent focus on durability and continuous operational capacity. This segment includes professional kitchens such as large restaurants, hotels, catering services, institutional kitchens (hospitals, university canteens), and specialized small and medium-sized enterprises (SMEs) focused solely on producing and supplying ready-made idli/dosa batter to consumers or retail outlets. Commercial buyers require heavy-duty floor-standing or large tilting models, often with capacities exceeding 10 liters, demanding robust motors capable of sustaining extended operational periods and compliance with commercial food safety standards. Purchasing decisions in this sector are driven by total cost of ownership, energy efficiency, and reliable technical support to minimize downtime.

Emerging potential customers include health-conscious consumers globally who are exploring alternatives to processed flours and seeking kitchen tools for preparing nut butters, specific vegan cheeses, and specialized pastes outside traditional Asian cuisine. This nascent segment is small but highly lucrative, valuing multifunctional capabilities, high-end design, and premium construction materials. Manufacturers are increasingly designing models with variable speed settings and specific attachments to cater to this niche, broadening the definition of wet grinding beyond traditional batter preparation and integrating the appliance into the wider health and wellness food trend.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 680.5 Million |

| Market Forecast in 2033 | USD 1085.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Elgi Ultra, Prestige, Bajaj Electricals, Sowbhagya, Butterfly Gandhimathi Appliances, Premier, Lakshmi, Vidiem, Rico, Santha, Padmini, McFarland, Wet Grinder Depot, Stone Grinders India, SS Premier, Preethi, Sujata, Maharaja Whiteline, Bosch (in specific regional markets), Wonderchef. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wet Grinders Market Key Technology Landscape

The technology landscape of the Wet Grinders Market is primarily focused on enhancing efficiency, durability, and user experience, moving beyond the simple motorized stone concept. A significant technological shift involves the integration of high-efficiency, permanent magnet synchronous motors (PMSM) or Brushless DC (BLDC) motors, replacing older brushed motor designs. BLDC motors offer superior torque, reduced energy consumption, minimal noise pollution, and drastically extended operational life, addressing key consumer pain points related to noise and machine longevity. This transition is crucial for maintaining competitiveness in markets with stringent energy efficiency regulations and meeting the needs of commercial users requiring continuous, quiet operation.

Material science innovation is another critical technological area. Manufacturers are continuously researching lighter, food-grade materials for the outer body, such as advanced ABS polymers, which improve portability and aesthetics without compromising structural integrity or hygiene. Simultaneously, focus is placed on refining the composition and shape of the grinding stones and rollers. Traditional heavy granite stones are being supplemented or replaced by engineered materials designed for faster grinding action and minimal heat generation, which is vital for preserving the nutritional quality and fermentation properties of the batter. Furthermore, the development of patented gear mechanisms and vibration damping technologies is crucial for reducing wear and tear and enhancing the user experience.

The emerging technological frontier involves the integration of smart features and IoT capabilities. This includes adding digital timers with auto shut-off functionalities, sensor-based load detection systems that prevent motor overheating or stalling, and basic microprocessors for operational programming. More sophisticated advancements, aligning with AEO trends, involve Wi-Fi connectivity to enable remote monitoring, firmware updates, and diagnostic functions. These smart enhancements transform the wet grinder from a specialized kitchen tool into a connected appliance, catering to the growing demand for automated and integrated kitchen solutions, particularly in high-income urban residential segments globally.

Regional Highlights

The Asia Pacific (APAC) region dominates the global Wet Grinders Market, driven overwhelmingly by the colossal demand originating from India and Sri Lanka, where wet ground batters form the basis of daily meals. The market saturation is high in major metropolitan areas, leading manufacturers to focus heavily on product upgrades, premiumization, and expanding distribution networks into semi-urban and rural areas. Rapid economic development, rising income levels, and the transition from manual grinding methods to electric appliances are core market drivers. Furthermore, countries like Malaysia, Singapore, and parts of Indonesia also contribute significantly due to shared culinary traditions and high population density, fostering concentrated commercial and residential demand.

North America and Europe represent the fastest-growing regions, albeit from a lower base. This rapid expansion is primarily attributable to large-scale immigration from South Asia, creating a substantial and enduring ethnic market requiring specialized appliances. The commercial application segment, serving the growing popularity of Indian, Sri Lankan, and South Indian specialty restaurants and food processing units, is a key growth propeller in these Western markets. Consumers in North America and Europe often prioritize features such as certifications for safety (e.g., UL, CE), low noise operation, and aesthetic compatibility with modern kitchen designs, pushing manufacturers toward premium, high-efficiency models suitable for smaller, diverse kitchens.

The Middle East and Africa (MEA) region, particularly the Gulf Cooperation Council (GCC) countries, show strong growth potential. This growth is sustained by a significant expatriate population, coupled with increasing local adoption driven by modern retail penetration and improved standards of living. Latin America remains a niche market but shows latent potential for specialized grinding applications, though not primarily driven by South Asian cuisine. Manufacturers must tailor their supply chain and distribution strategies, including establishing robust service infrastructure and localized marketing efforts, to effectively capitalize on the diverse economic and cultural landscapes across these secondary growth regions, ensuring product specifications meet local voltage and safety regulations.

- Asia Pacific (APAC): Market stronghold and largest revenue contributor; driven by residential demand in India, Sri Lanka, and Southeast Asia. Focus on capacity expansion and efficiency improvement for commercial use.

- North America: High-growth market, characterized by diaspora demand and increasing commercial usage in ethnic restaurants; premiumization and noise reduction are key purchase criteria.

- Europe: Steady growth fueled by rising ethnic diversity and professional catering needs; stringent demand for safety certifications and compact, stylish designs.

- Middle East & Africa (MEA): Growth concentrated in GCC nations, supported by high expatriate populations and growing organized retail sector; focus on durability in hot climates.

- Latin America: Emerging niche market; potential for application beyond traditional use (e.g., preparation of specific regional pastes and sauces); limited overall market penetration currently.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wet Grinders Market.- Elgi Ultra Ltd.

- Prestige (TTK Prestige Limited)

- Bajaj Electricals Ltd.

- Butterfly Gandhimathi Appliances Ltd.

- Premier Kitchen Appliances (P.S. Industries)

- Sowbhagya Wet Grinders

- Lakshmi Wet Grinders

- Vidiem (Standard Electricals)

- Rico Appliances

- Santha Products

- Padmini Appliances

- McFarland International

- Wonderchef

- Preethi Kitchen Appliances

- Sujata Appliances

- Usha International

- Maharaja Whiteline

- Bosch Home Appliances (regional focus)

- Panasonic Corporation (select models)

- Sanket Appliances

Frequently Asked Questions

Analyze common user questions about the Wet Grinders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a table-top and a tilting wet grinder, and which is better for home use?

The table-top wet grinder is compact and requires manual lifting of the drum to remove the batter, making it space-efficient. The tilting wet grinder allows the drum to be tilted, facilitating easier pouring and cleaning without lifting heavy components. For home use, the tilting model is often preferred due to its superior ergonomics and ease of maintenance, despite usually having a slightly higher price point.

What capacity wet grinder is recommended for a family of four, and how does capacity affect performance?

For a typical family of four, a wet grinder with a capacity between 1.5 liters and 2.5 liters is generally recommended, balancing volume needs with kitchen space constraints. Capacity directly correlates with the motor's power requirements; larger capacity grinders require significantly more powerful and often heavier-duty motors to ensure consistent and efficient grinding performance without overheating or stalling.

Are wet grinders energy efficient, and what should consumers look for to minimize electricity consumption?

Modern wet grinders, especially those utilizing Brushless DC (BLDC) motor technology, are highly energy efficient compared to older models. Consumers should prioritize models that specify low wattage consumption (typically under 200W for residential use) and look for ISI or equivalent national certification marks indicating adherence to energy performance standards to ensure lower long-term operating costs.

How often should the grinding stones be replaced in a high-quality wet grinder, and what maintenance is required?

In high-quality wet grinders, the grinding stones (typically made of hard granite or engineered stone) are designed for exceptional longevity, often lasting many years, sometimes for the entire product lifespan, under normal residential use. Key maintenance involves thorough cleaning immediately after use, ensuring the drum is dry before storage, and periodically checking the roller alignment and motor couplings, although significant mechanical replacement is rare.

What role does the stainless steel drum play in batter quality, and are plastic drums used in the market?

The stainless steel drum is crucial as it ensures superior hygiene, prevents rusting, and contributes to the consistent cooling of the batter during the grinding process, preventing excessive heat build-up which can prematurely ferment the mixture or degrade its nutritional content. While the outer body is often made of robust ABS plastic, the inner drum, where food contact occurs, is almost universally made of high-grade stainless steel due to food safety regulations and performance requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager