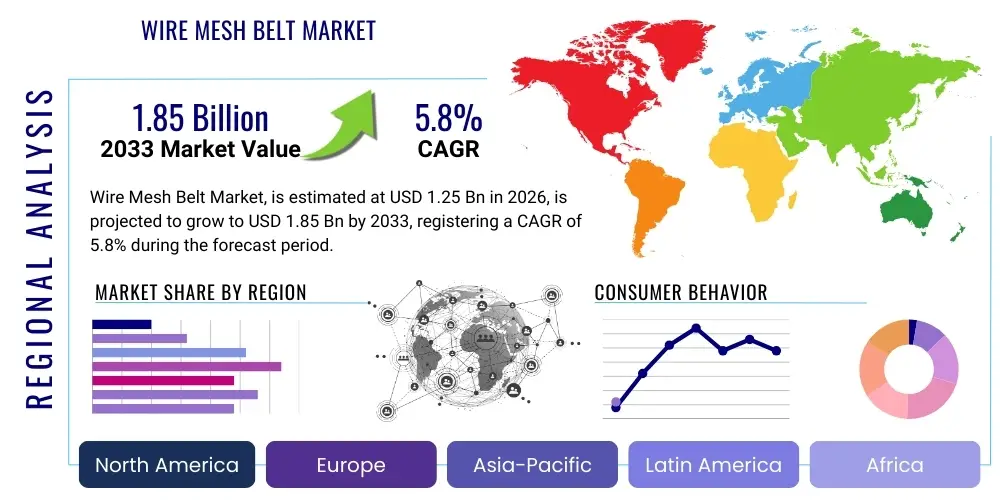

Wire Mesh Belt Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435378 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Wire Mesh Belt Market Size

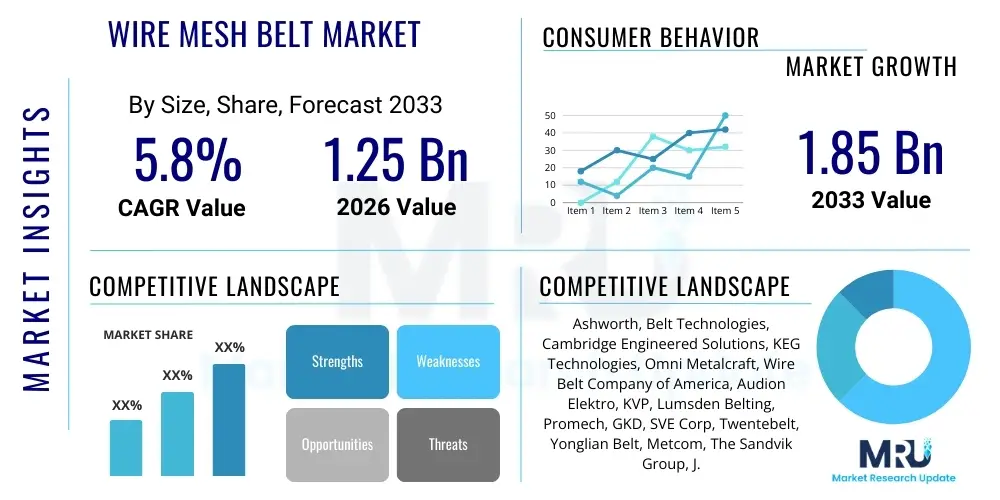

The Wire Mesh Belt Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.85 Billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by expanding industrial automation across various manufacturing sectors, particularly in regions experiencing rapid infrastructure development and increased consumer demand for processed goods.

The market valuation reflects the essential role wire mesh belts play in high-temperature environments and critical industrial processes where conventional conveyor materials fail. Industries such as food processing, metallurgy, and glass manufacturing rely heavily on these belts due to their durability, permeability, and resistance to extreme conditions, ensuring efficient material movement and processing integrity. The increasing complexity of modern manufacturing processes necessitates high-performance conveying solutions, further cementing the market's upward trend.

Wire Mesh Belt Market introduction

The Wire Mesh Belt Market encompasses the manufacturing, distribution, and utilization of conveyor belts constructed from interconnected wires, typically made of stainless steel or specialized alloys. These products are engineered for conveying materials through industrial processes requiring specific environmental controls, such as high heat (furnaces), cryogenic temperatures (freezing tunnels), washing, or drying. Their open structure facilitates drainage, circulation of air or liquids, and minimized heat retention, making them indispensable in specialized manufacturing environments.

Major applications of wire mesh belts span across the food and beverage industry, particularly in baking, freezing, and pasteurization; heat treatment processes in metallurgy, including sintering and annealing; and general material handling where cleanliness and strength are paramount. The inherent benefits of these belts, such as exceptional wear resistance, minimal maintenance requirements, and chemical inertness, drive their widespread adoption. Furthermore, technological advancements leading to stronger, lighter, and more temperature-resistant alloys contribute significantly to market expansion.

Driving factors for the market include the global push toward greater industrial automation to enhance productivity and reduce operational costs. The stringent hygiene standards in the food and pharmaceutical sectors necessitate the use of easily cleanable and non-corrosive conveying surfaces, favoring stainless steel wire mesh belts. Additionally, the growing demand for durable furnace belts in the steel and glass manufacturing industries, especially in emerging economies, fuels continuous market demand and technological innovation.

Wire Mesh Belt Market Executive Summary

The Wire Mesh Belt Market is characterized by robust demand across core industrial verticals, driven fundamentally by the need for reliable, temperature-resistant, and hygienic conveying solutions. Current business trends indicate a strong focus on customization, where manufacturers are developing application-specific belts utilizing advanced materials like high-nickel alloys to withstand corrosive or extremely hot environments, moving away from standardized products. Key industry players are also investing in smart manufacturing integration, incorporating sensors and IoT capabilities into conveyor systems to enable predictive maintenance and optimize belt lifespan, thus addressing end-user demands for enhanced operational uptime.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive investments in infrastructure, rapidly expanding automotive manufacturing bases, and significant growth in the processed food sector, particularly in China and India. North America and Europe, while mature markets, continue to drive innovation, emphasizing energy-efficient belt designs and compliance with stringent food safety regulations. Meanwhile, Latin America and MEA show nascent potential, largely linked to the development of mining operations and localized food production facilities, offering new avenues for market penetration for global manufacturers.

Segment trends highlight the dominance of stainless steel materials due to their corrosion resistance and suitability for food contact applications. The Chain Driven segment is experiencing accelerated growth, particularly in heavy-duty material handling and high-load furnace applications, owing to its superior tracking capabilities and positive drive mechanism. Furthermore, the Food Processing application segment maintains the largest market share, consistently demanding higher quality, easier-to-clean belts to meet increasingly rigorous global hygiene standards and production quotas.

AI Impact Analysis on Wire Mesh Belt Market

Common user questions regarding AI's impact on the Wire Mesh Belt Market revolve around predictive failure, optimization of material flow, and automated quality control during belt manufacturing. Users are primarily concerned with how AI can extend the operational lifespan of expensive belts operating under extreme stress (e.g., high temperatures or heavy loads) and how it can enable just-in-time maintenance scheduling. There is significant interest in utilizing machine learning algorithms to analyze vibration data, temperature variances, and load distribution collected via embedded sensors (IoT), thereby identifying precursors to belt failure. The overarching expectation is that AI integration will shift maintenance practices from reactive to predictive, drastically reducing unplanned downtime and improving overall equipment effectiveness (OEE) in high-throughput industrial settings.

The implementation of Artificial Intelligence and advanced analytics is set to revolutionize the operational management of wire mesh belt conveyor systems. By processing vast datasets generated by IoT sensors integrated into conveyor systems, AI algorithms can accurately model complex wear patterns, temperature cycles, and stress points. This capability allows operators to fine-tune production parameters in real-time to minimize stress on the belts, leading to longer service intervals and reduced consumption of spare parts. Furthermore, AI-driven visual inspection systems utilizing computer vision are beginning to replace manual inspection for detecting minor defects, such as loose wires or weld cracks, during both the manufacturing process and operational deployment.

Beyond maintenance, AI is also impacting the belt design and fabrication process. Generative design tools, powered by AI, can rapidly iterate through thousands of material compositions and weave patterns to optimize belts for specific functions—for example, maximizing airflow while maintaining tensile strength, or minimizing thermal mass for energy efficiency in heating and cooling processes. This integration of sophisticated data analysis into design cycles ensures that new products are inherently more efficient and durable, catering precisely to the demanding specifications of industries like glass tempering and continuous sterilization.

- AI enhances predictive maintenance by analyzing sensor data (vibration, temperature, tension) to forecast imminent belt failure.

- Machine learning optimizes production scheduling and material flow rates based on real-time belt performance and load capacity.

- Computer vision systems enable automated, high-speed defect detection during the wire mesh belt manufacturing process, improving quality assurance.

- Generative AI tools assist engineers in designing optimal belt geometries and material compositions for specialized applications (e.g., high-temperature resistance).

- AI-driven energy management systems adjust belt speed and furnace settings to minimize energy consumption while preserving belt integrity.

DRO & Impact Forces Of Wire Mesh Belt Market

The Wire Mesh Belt Market is profoundly influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and market trajectory. Key drivers include the accelerated adoption of automation in industries requiring continuous, high-temperature processing, such as commercial baking and metal sintering. This demand is counterbalanced by significant restraints, primarily the high initial investment cost associated with specialized alloy belts and the complexities related to proper installation, tracking, and maintenance of wide, heavy-duty conveyor systems. Opportunities arise from the ongoing development of advanced materials, offering greater efficiency and longevity, and the expansion into emerging applications like solar panel manufacturing and advanced battery production, which require highly precise thermal processing capabilities.

The primary impact forces driving the market expansion relate to technological innovation and regulatory pressures. The constant pressure from end-users to increase throughput and reduce energy consumption forces manufacturers to innovate, leading to the development of lighter, open-weave belts that facilitate rapid heating and cooling. Furthermore, increasingly stringent global food safety and hygiene regulations (such as HACCP and FDA guidelines) strongly mandate the use of non-porous, easily cleanable stainless steel conveying surfaces, thereby reinforcing the demand for specific types of wire mesh belts over alternatives. These forces ensure that material performance and sanitary design remain core competitive advantages.

Conversely, economic fluctuations and raw material price volatility act as restraining forces. Since wire mesh belts are heavily dependent on metals like nickel, chromium, and specialized steel, unpredictable commodity pricing can significantly impact manufacturing costs and final product pricing, sometimes deterring smaller businesses from upgrading their conveyor infrastructure. Additionally, the availability of highly specialized technical personnel required for advanced belt welding, maintenance, and troubleshooting remains a challenge in several key industrial regions, contributing to operational restraints for end-users seeking maximal uptime.

Segmentation Analysis

The Wire Mesh Belt Market is comprehensively segmented based on material type, belt type, and primary application, allowing for a detailed understanding of diverse industrial demands. Segmentation highlights the pivotal role of material science, with stainless steel dominating due to its hygiene properties, while specialized high-nickel alloys capture the high-value, high-temperature segments. The structural type segmentation differentiates between various weaving and reinforcement methods, catering to needs ranging from lightweight food applications to extremely heavy-duty metallurgical handling. Application segmentation clearly delineates the market’s reliance on capital-intensive industries such as food processing and heat treatment, providing targeted strategies for market penetration and product development.

- By Material:

- Stainless Steel (304, 316, 310)

- Carbon Steel

- High-Nickel Alloys (Inconel, Hastelloy)

- Other Specialized Materials

- By Type:

- Balanced Weave Belts

- Compound Balanced Weave Belts

- Rod Reinforced Belts

- Chain Driven Belts

- Flat Wire Belts

- Spiral Woven Belts

- By Application:

- Food Processing (Baking, Cooling, Freezing, Washing)

- Heat Treatment and Metallurgy (Sintering, Annealing, Brazing)

- Glass and Ceramics Manufacturing

- Chemical Processing and Petrochemicals

- Material Handling and General Industrial

- Electronics and Solar Panel Manufacturing

Value Chain Analysis For Wire Mesh Belt Market

The value chain for the Wire Mesh Belt Market begins with the upstream sourcing of high-grade raw materials, primarily specialized stainless steel wire rods and alloy elements (like nickel and chromium). The efficiency and stability of this upstream segment are critical, as material quality directly impacts the final belt's performance in extreme environments. Manufacturers engage in complex processes including wire drawing, weaving, welding, and assembly, requiring high precision machinery and skilled labor. Differentiation at this stage often comes from proprietary weaving techniques and advanced heat-treating procedures designed to maximize tensile strength and minimize stretching.

The downstream analysis focuses on the distribution channels and end-user integration. Products typically move through direct sales teams for large industrial OEMs and complex custom installations, and through specialized industrial distributors or engineering firms for maintenance, repair, and operations (MRO) replacement parts. Direct sales ensure tight technical consultation necessary for complex furnace or tunnel freezer applications, while indirect channels provide widespread regional accessibility for standard or semi-standard belt types. Effective inventory management by distributors is essential to minimize downtime for end-users relying on prompt belt replacement.

The potential for value addition lies significantly in post-sale services, including installation guidance, routine inspection, and troubleshooting for tracking issues or premature wear. Companies that offer comprehensive lifecycle management, incorporating digital monitoring and predictive maintenance services, capture higher profit margins and establish stronger customer loyalty. The entire chain is highly sensitive to quality control, as a single faulty weld can lead to catastrophic system failure, making rigorous testing throughout the manufacturing and installation phases paramount for sustaining market reputation.

Wire Mesh Belt Market Potential Customers

Potential customers for wire mesh belts are diverse, encompassing any industry that requires continuous movement of products through controlled process environments, particularly those involving high temperatures, cooling, washing, or strict hygiene standards. The primary end-users are large-scale industrial operators who integrate these belts into automated production lines and capital equipment, such as continuous furnaces, sterilization tunnels, and industrial freezers. Their purchasing decisions are driven by factors like operational lifespan, resistance to chemical corrosion or thermal shock, and the belt's compliance with industry-specific quality certifications.

The most significant consumer segment remains the food and beverage industry, including commercial bakeries, poultry processing plants, and confectionery manufacturers, who require belts for continuous baking, cooling, drying, and washing cycles. These customers prioritize food-grade stainless steel (e.g., 316) and designs that minimize bacterial traps. The second major customer base includes manufacturers in the heavy industry sector, such as automotive parts producers performing metal brazing and annealing, and glass manufacturers using high-temperature lehrs, who demand specialized alloys capable of withstanding extreme thermal loads and heavy stress.

A growing customer base includes companies in the emerging technology sectors, particularly those manufacturing lithium-ion batteries, solar panels, and specialized electronics. These processes require extremely uniform temperature profiles and precise conveying through delicate assembly stages, driving demand for belts with very tight tolerances and smooth surfaces. Identifying and partnering with original equipment manufacturers (OEMs) of industrial processing machinery (e.g., furnace builders) is a crucial strategy for wire mesh belt suppliers, as OEMs often dictate the specifications for belts installed in new production lines.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ashworth, Belt Technologies, Cambridge Engineered Solutions, KEG Technologies, Omni Metalcraft, Wire Belt Company of America, Audion Elektro, KVP, Lumsden Belting, Promech, GKD, SVE Corp, Twentebelt, Yonglian Belt, Metcom, The Sandvik Group, J. W. Winco, Wirtz Wire Mesh, SideDrive Conveyor Solutions, Quality Metal Mesh. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Mesh Belt Market Key Technology Landscape

The technological landscape in the Wire Mesh Belt Market is moving towards advanced material science and smart integration to enhance durability and predictive maintenance capabilities. A critical technological trend involves the development of proprietary high-nickel alloys (such as specialized grades of Inconel and Hastelloy) optimized for specific furnace applications, offering superior creep resistance and oxidation resistance at temperatures exceeding 1100°C. These advancements address the industry's need for longer-lasting belts in demanding environments like continuous brazing and annealing furnaces, reducing replacement frequency and associated operational interruptions. Furthermore, precision welding and assembly techniques, including laser welding, are increasingly being employed to achieve stronger, more uniform joints, which are less prone to stress cracking and deformation.

Another significant technological shift is the incorporation of digitization and sensor technology. Smart belts are being equipped with miniature, high-temperature resistant IoT sensors and data loggers capable of monitoring parameters such as belt tension, operating temperature profile, and lateral alignment in real-time. This technology enables sophisticated predictive maintenance programs, allowing operators to preemptively correct tracking issues or schedule maintenance based on actual wear data rather than fixed schedules. The utilization of specialized software for simulating thermal and mechanical stresses prior to manufacturing also contributes to designing belts with optimized performance characteristics and reduced material usage.

In the food processing sector, the focus is on hygienic design and novel coatings. Manufacturers are developing belt surfaces and weaving patterns that minimize crevices where bacteria can accumulate, facilitating quicker and more effective Clean-In-Place (CIP) procedures. Technologies such as edge capping and proprietary wire flattening techniques are utilized to create smooth, easy-to-sanitize surfaces. These innovations are crucial for maintaining compliance with strict global food safety regulations and reducing the risk of cross-contamination during large-scale processing operations, ensuring technology remains aligned with regulatory mandates.

Regional Highlights

Regional dynamics play a crucial role in the overall growth and segmentation of the Wire Mesh Belt Market, reflecting varying levels of industrial maturity, regulatory standards, and investment in manufacturing automation. The market can be broadly analyzed across five major geographic regions, each presenting distinct demand drivers and competitive characteristics.

- Asia Pacific (APAC): APAC represents the fastest-growing region, driven by massive foreign direct investment in manufacturing and infrastructure, particularly in China, India, and Southeast Asian nations. The region’s rapid expansion of the processed food industry, coupled with significant growth in metallurgy (steel and aluminum production) and automotive manufacturing, creates a massive demand for both standard and high-performance wire mesh belts. Low manufacturing costs and increasing adoption of automation technologies further solidify APAC’s dominance in market volume.

- North America: Characterized by high technological adoption and stringent regulatory requirements, North America is a mature market focused on innovation and high-value applications. Demand is primarily driven by the replacement cycle, modernization of existing industrial infrastructure, and the necessity for superior hygienic belts in the food and pharmaceutical industries. Emphasis is placed on energy efficiency, longevity, and integrating smart technologies for predictive maintenance.

- Europe: Europe exhibits strong demand fueled by strict adherence to industrial quality standards (such as CE marking) and environmental regulations. The market here is sustained by the sophisticated automotive, aerospace, and advanced manufacturing sectors (including glass and ceramics). Germany, Italy, and France are key contributors, focusing on custom-engineered, specialized belts for precision heat treatment and complex handling systems, prioritizing durability and specialized material alloys.

- Latin America (LATAM): LATAM is an emerging market with moderate growth potential, tied closely to the expansion of regional food processing capabilities and localized heavy industry, particularly mining and construction materials. While often price-sensitive, increased investment in automation in countries like Brazil and Mexico is gradually boosting the requirement for reliable, standard-specification wire mesh belts.

- Middle East and Africa (MEA): This region shows specialized growth, largely concentrated in energy-intensive industries such as petrochemicals and localized food production facilities. Market expansion is sporadic but significant, driven by large-scale capital projects, including refinery expansions and the development of centralized commercial bakeries and packaging operations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Mesh Belt Market.- Ashworth

- Belt Technologies

- Cambridge Engineered Solutions

- KEG Technologies

- Omni Metalcraft

- Wire Belt Company of America

- Audion Elektro

- KVP (A Habasit Company)

- Lumsden Belting

- Promech

- GKD – GEBR. KUFFERATH AG

- SVE Corp

- Twentebelt

- Yonglian Belt

- Metcom

- The Sandvik Group

- J. W. Winco

- Wirtz Wire Mesh

- SideDrive Conveyor Solutions

- Quality Metal Mesh

Frequently Asked Questions

Analyze common user questions about the Wire Mesh Belt market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using wire mesh belts over solid or plastic conveyor belts?

Wire mesh belts offer superior material permeability, allowing for efficient circulation of air, liquids, or heat (crucial for drying, cooling, and baking). They also provide excellent resistance to extreme temperatures, chemical corrosion, and heavy loads, making them indispensable in high-temperature or washdown environments where traditional materials fail. Their open structure also ensures better hygiene and drainage.

Which material type dominates the wire mesh belt market and why?

Stainless Steel, particularly grades 304 and 316, dominates the market due to its exceptional resistance to corrosion, high strength-to-weight ratio, and compliance with stringent food safety and hygiene regulations (FDA/HACCP). Its durability and ease of cleaning make it the preferred choice for the expansive food processing application segment.

How is industrial automation impacting the demand for wire mesh belts?

Industrial automation is significantly increasing demand by driving the necessity for continuous, reliable, and high-speed processing lines. Automated systems require belts capable of operating for extended periods under stress (high temperatures or heavy loads) with minimal human intervention, accelerating the adoption of high-performance, specialized wire mesh belts, especially chain-driven types for positive tracking.

What is the significance of the Chain Driven Wire Mesh Belt segment?

The Chain Driven segment is crucial for heavy-duty and furnace applications. Its design, which uses precision roller chains attached to the belt edges, ensures positive tracking, eliminates belt wandering, and handles extremely high tensile loads and wide widths efficiently. This configuration is essential for processes requiring absolute alignment consistency under high thermal stress, such as metal sintering.

What are the key technological advancements shaping the future of this market?

Future growth is being shaped by the integration of IoT sensors for real-time monitoring and predictive maintenance (Smart Belts), the development of proprietary high-nickel alloys for ultra-high temperature resistance (above 1100°C), and the implementation of hygienic design principles to meet evolving food safety standards globally. These innovations focus on maximizing operational uptime and belt lifespan.

Which region offers the most significant growth opportunities for new manufacturers?

The Asia Pacific (APAC) region offers the most significant growth opportunities, driven by rapid industrialization, massive investments in the food processing sector, and the expansion of heavy industries like metallurgy and automotive manufacturing in economies such as China, India, and Vietnam. The sheer volume of new capital projects ensures sustained demand for conveyor systems.

What major restraints impede the growth of the Wire Mesh Belt Market?

The primary restraints include the high initial capital investment required for specialized, custom-engineered belts, particularly those made from expensive high-nickel alloys. Additionally, market growth is often hampered by the complex installation and maintenance procedures necessary to ensure optimal belt tracking and prevent premature failure, demanding specialized technical expertise.

How do wire mesh belts contribute to energy efficiency in industrial heating processes?

Wire mesh belts, especially those with an open spiral weave, possess a low thermal mass compared to solid belts. This allows them to heat up and cool down rapidly, minimizing the energy required to bring the belt material itself up to the required processing temperature. This property translates directly into reduced energy consumption for continuous furnaces and kilns.

What are the critical considerations when selecting a wire mesh belt for a specific application?

Critical considerations include the maximum operating temperature, the required tensile strength (load capacity), the ambient atmosphere (e.g., presence of corrosive chemicals or moisture), the need for positive tracking (Chain Driven vs. Friction Driven), and the required porosity (open area) for drainage or heat circulation. Material selection must align strictly with the environmental constraints of the process.

What role does the metallurgy industry play in driving demand for specialized belts?

The metallurgy industry, encompassing processes like continuous sintering, annealing, and brazing of metal powders and components, requires belts capable of operating continuously in extreme heat, often exceeding 1000°C, under heavy loads. This necessitates specialized, customized belts made from high-nickel and refractory alloys, making metallurgy a high-value, high-specification segment for wire mesh belt manufacturers.

How has the rise of electric vehicle (EV) battery production influenced the market?

EV battery production has created a niche, high-growth segment. Manufacturing processes, such as cathode and anode drying, require specialized, ultra-clean, and precise wire mesh belts that ensure uniform temperature distribution and particulate control, driving demand for high-quality stainless steel belts with exceptionally tight flatness and weave tolerances.

Explain the concept of 'Balanced Weave' in wire mesh belts.

The Balanced Weave is the most popular and versatile construction type, characterized by alternating left- and right-hand spirals joined by straight rods. This design inherently self-tracks and provides excellent dimensional stability, ensuring the belt runs straight and true. It is widely used across medium-load applications requiring good flexibility and moderate temperature resistance.

What is the primary function of a Flat Wire Belt in material handling?

Flat Wire Belts, constructed using flat strips connected by rods, are primarily used in high-load, open applications such as washing, sorting, and drying of bulk products. Their large, flat surface area provides maximum product support while the large openings allow for efficient drainage and air flow, commonly seen in freezing tunnels and food preparation areas.

How do manufacturers ensure the longevity of belts operating in extreme heat?

Manufacturers ensure longevity in extreme heat by selecting specialized high-nickel alloy materials (like Inconel or specific high-chromium steels) that resist thermal creep and oxidation. They also utilize compound weaves and rod reinforcement structures to distribute stress more evenly, and often incorporate precise heat treatments during fabrication to maximize the alloy's crystalline strength and durability.

What impact do strict environmental regulations have on belt manufacturing processes?

Strict environmental regulations, particularly in Europe and North America, mandate cleaner manufacturing processes, including optimized metal treatment and waste reduction. This encourages manufacturers to adopt highly efficient, closed-loop welding and cleaning systems and to focus on developing durable belts with longer lifecycles, thereby reducing the frequency of disposal and material consumption.

How are advancements in digital twin technology affecting wire mesh belt usage?

Digital twin technology allows industrial operators to create virtual replicas of their conveyor systems. By simulating various operating conditions (load, speed, temperature), engineers can predict how a specific wire mesh belt will perform, identify potential failure points before physical deployment, and optimize maintenance schedules, leading to significant cost savings and improved reliability.

Which segment—OEM or MRO—drives the majority of the market revenue?

The Maintenance, Repair, and Operations (MRO) segment typically accounts for the majority of market revenue. While Original Equipment Manufacturers (OEMs) provide the initial installation volume, the continuous need for replacement belts—due to wear and tear in harsh industrial environments—creates a steady, high-volume revenue stream in the MRO segment.

Why is wire tracking a critical concern for wide wire mesh belts?

Tracking, or the tendency of the belt to move side-to-side, is critical for wide belts, especially in high-temperature furnaces. Poor tracking can cause the belt edges to rub against the furnace walls or guides, leading to premature wear, breakage, and catastrophic system failure. This necessity drives demand for stable weaves and positive drive methods like chain-driven systems.

How does the electronics industry utilize specialized wire mesh belts?

The electronics industry uses specialized fine-mesh belts for processes like component soldering, drying, and surface treatment. These belts require extremely fine pitch and flat surfaces to handle small, delicate electronic components, often demanding non-magnetic or highly clean materials to prevent contamination during manufacturing.

What role does customization play in the competitive landscape?

Customization is a core competitive differentiator. Since industrial applications often involve unique temperatures, loads, and chemicals, manufacturers that can rapidly design and produce application-specific belts (adjusting weave, material alloy, and edge finishes) are highly favored. This capability allows them to capture high-value contracts and secure long-term partnerships with major industrial clients.

What is the expected growth trajectory for the food processing application segment?

The food processing segment is expected to maintain robust and stable growth, driven by increasing global population, rising demand for packaged and frozen foods, and continuous pressure to adhere to stricter international hygiene standards. This necessitates ongoing upgrades and replacements of conveyor systems with durable, sanitary stainless steel mesh belts.

How does volatility in nickel prices affect market dynamics?

Volatility in nickel prices significantly impacts the overall market cost structure. Since stainless steel and high-nickel alloys are essential for high-performance belts, sharp price increases for nickel can lead to higher manufacturing costs, increased end-user product prices, and potential delays in capital expenditure for belt replacement or new system installation by price-sensitive customers.

What are Rod Reinforced Wire Mesh Belts used for?

Rod Reinforced belts are utilized for extremely heavy loads, often in conjunction with high temperatures, such as in metallurgical furnaces or heavy-duty washing equipment. They feature heavy-duty rods that run across the width of the belt, significantly enhancing lateral rigidity, minimizing stretch, and providing maximum tensile strength under strenuous operational conditions.

Define Generative Engine Optimization (GEO) in the context of this market report.

Generative Engine Optimization (GEO) involves structuring and presenting market data and insights (such as key trends, segment analyses, and Q&A) in a clear, comprehensive, and highly contextual manner that is easily digestible and retrievable by advanced generative AI systems and large language models, ensuring high visibility in future AI-driven research queries.

What differentiates high-nickel alloy belts (e.g., Inconel) from standard stainless steel (304)?

High-nickel alloy belts are specifically engineered to maintain their mechanical integrity and resistance to deformation (creep) at temperatures exceeding the limits of standard stainless steel (typically above 800°C). They offer vastly superior oxidation and corrosion resistance in highly aggressive atmospheres, making them mandatory for critical, extreme-temperature furnace applications in aerospace and high-end metallurgy.

How do manufacturers address the challenge of belt edge damage?

Manufacturers address edge damage, a common failure point, through various techniques, including specialized edge finishing (like welded button or folded edges), the integration of heavier gauge wires at the perimeter, and the use of edge retainers or guide plates in the conveyor design. For positive drive systems, robust chain attachment techniques are essential to mitigate stress concentration at the edges.

What is the primary concern for end-users when purchasing high-value wire mesh belts?

The primary concern for end-users is the total cost of ownership (TCO) and operational lifespan. Given the high initial investment, buyers prioritize durability, minimal maintenance requirements, and reliable performance over several years. Manufacturers must demonstrate extended Mean Time Between Failures (MTBF) and provide robust warranties and support services to satisfy this concern.

In which application segment is the 'Spiral Woven' belt type most prevalent?

The Spiral Woven belt type is most prevalent in general food processing applications, particularly for light to moderate loads in baking, washing, and cooling operations. Its structure allows for various degrees of open area, offering flexibility and cost-effectiveness for standard industrial conveying needs.

How does the demand from the solar panel manufacturing industry contribute to market growth?

Solar panel manufacturing, specifically in the production of photovoltaic cells and components, requires extremely precise thermal processing (e.g., firing). This drives specialized demand for wire mesh belts with extremely tight tolerances, high cleanliness, and excellent thermal stability to ensure uniform temperature gradients and prevent contamination of sensitive silicon materials.

What role do distributors play in the Wire Mesh Belt market value chain?

Distributors play a vital role in providing local stock and rapid supply of standard replacement belts (MRO). They also offer regional technical support, facilitating the selection and installation of appropriate belts for smaller and medium-sized enterprises, bridging the gap between highly technical manufacturers and diverse end-users.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Wire Mesh Belt Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Wire Mesh Belt Market Statistics 2025 Analysis By Application (Construction, Agricultural, Food, Mine), By Type (Stainless Steel Wire Mesh belt, Metal Wire Mesh belt), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Wire Mesh Belt Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Metal Wire Mesh belt, Stainless Steel Wire Mesh belt), By Application (Mine Industry, Food Industry, Agricultural Industry, Construction Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager