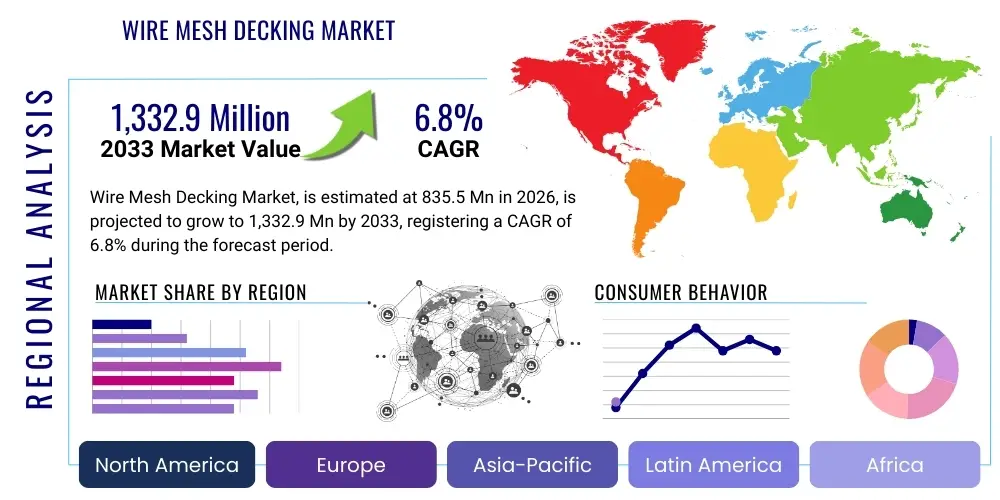

Wire Mesh Decking Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439449 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Wire Mesh Decking Market Size

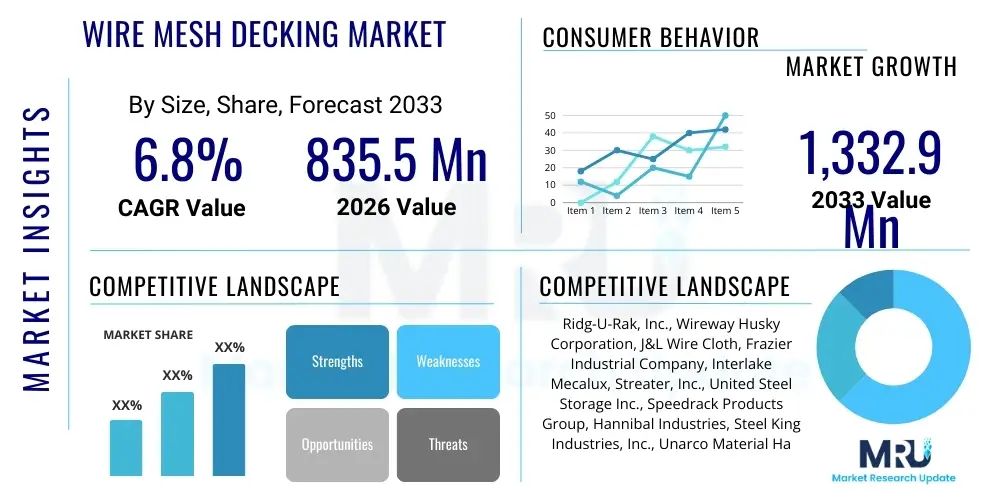

The Wire Mesh Decking Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 835.5 million in 2026 and is projected to reach USD 1,332.9 million by the end of the forecast period in 2033.

Wire Mesh Decking Market introduction

The Wire Mesh Decking Market encompasses the manufacturing, distribution, and installation of steel wire mesh platforms designed to be placed over pallet rack beams. These essential components provide a safe, durable, and versatile surface for storing goods in various industrial and commercial settings. The primary product, wire mesh decking, is engineered from high-strength steel wires, welded together to form a robust grid structure, often featuring channels or flanges to rest securely on rack beams. Its open construction offers significant advantages over solid shelving, including enhanced fire safety due to improved sprinkler penetration, better air circulation, and superior visibility of stored inventory.

Major applications for wire mesh decking span across diverse industries, predominantly in warehousing, logistics, manufacturing, retail, and cold storage facilities. In warehousing, it is critical for optimizing storage density and ensuring the safety of palletized goods. Within manufacturing, it supports organized storage of raw materials, work-in-progress, and finished products. The overarching benefits include increased safety by preventing items from falling through racks, improved inventory management through better visibility, enhanced structural integrity for storage systems, and ease of installation and maintenance. Its adaptability allows it to be used with various pallet sizes and rack configurations, making it a highly flexible storage solution.

Several driving factors are propelling the growth of this market. The continuous expansion of global e-commerce activities necessitates larger and more efficient warehousing and distribution centers, directly increasing the demand for reliable storage infrastructure. Furthermore, advancements in logistics and supply chain management emphasize optimized space utilization and operational safety, making wire mesh decking a preferred choice. The stringent safety regulations in industrial environments, particularly regarding fire safety and workplace accidents, also contribute significantly to its adoption. The construction of new industrial facilities and the modernization of existing ones, especially in emerging economies, are further bolstering market expansion.

Wire Mesh Decking Market Executive Summary

The Wire Mesh Decking Market is experiencing robust growth driven by the escalating demands of global logistics and the persistent expansion of e-commerce. Business trends indicate a strong focus on automation in warehousing, necessitating storage solutions that integrate seamlessly with automated retrieval systems and robotics. This has led to innovations in decking designs, including heavier gauge options and customized configurations that support greater load capacities and specific operational requirements. Sustainability is also emerging as a key business imperative, with manufacturers exploring greener production processes and materials, although the core product remains steel-based. The market is characterized by intense competition among manufacturers, leading to ongoing product development and an emphasis on value-added services such as installation and custom fabrication. Strategic partnerships between decking manufacturers and racking system providers are becoming more common to offer integrated solutions to end-users, enhancing market reach and customer satisfaction.

Regional trends reveal Asia Pacific as a rapidly expanding market, primarily due to accelerated industrialization, the proliferation of e-commerce platforms, and significant investments in logistics infrastructure within countries like China and India. North America and Europe, while mature markets, continue to demonstrate steady demand, driven by the modernization of existing warehouses and the adoption of advanced material handling technologies. These regions often lead in implementing stringent safety standards, which further entrenches the necessity for compliant and robust wire mesh decking solutions. Latin America, the Middle East, and Africa are showing nascent but promising growth, fueled by infrastructure development projects and increasing foreign direct investment in manufacturing and retail sectors. Each region presents unique challenges and opportunities, influenced by local economic conditions, regulatory frameworks, and the pace of digital transformation in supply chains.

Segmentation trends highlight a growing preference for galvanized and powder-coated decking due to their enhanced durability and corrosion resistance, particularly in harsh environments like cold storage or outdoor facilities. The market is also seeing increased demand for custom-sized decking to optimize storage within non-standard rack configurations or for specialized goods. Load capacity requirements are becoming more diverse, ranging from light-duty applications in retail backrooms to heavy-duty installations in large distribution centers, reflecting the varied needs of end-users. While the primary end-users remain warehouse and logistics operators, there is a subtle but noticeable expansion into specialized applications within manufacturing for component staging and assembly line support. The market for used or refurbished decking also exists, catering to budget-conscious small and medium-sized enterprises, although new installations remain the dominant segment. The emphasis across all segments is on solutions that deliver reliability, safety, and efficiency.

AI Impact Analysis on Wire Mesh Decking Market

Users frequently inquire about how Artificial Intelligence (AI) might transform the manufacturing, distribution, and application of wire mesh decking. Key themes revolve around enhanced production efficiency, predictive maintenance for warehouse infrastructure, optimized inventory management, and the integration of smart storage solutions. Concerns often include the initial investment cost, data security, the need for specialized skills, and the potential impact on traditional labor. Expectations are high regarding AI's ability to drive greater operational efficiency, improve safety protocols, and enable more responsive supply chain operations in a dynamic market environment. The core focus is on leveraging AI to move beyond conventional manufacturing and logistics practices towards more intelligent, data-driven approaches.

- AI-driven optimization of manufacturing processes for wire mesh decking, reducing material waste and energy consumption.

- Predictive maintenance analytics for identifying potential wear and tear on decking and racking systems, preventing failures and enhancing safety.

- Integration of AI with warehouse management systems (WMS) to optimize inventory placement on wire mesh decking, improving retrieval efficiency.

- Automated quality control systems using computer vision for inspecting welds and material integrity during decking production.

- AI-powered demand forecasting influencing production schedules for wire mesh decking, aligning supply with market needs more precisely.

- Smart warehouse solutions leveraging AI for robotic picking and autonomous movement across wire mesh-decked racks, enhancing operational speed.

- Data analytics from sensors integrated into decking to monitor load capacities, environmental conditions, and potential structural stresses.

- AI-assisted design tools for customizing wire mesh decking to specific rack dimensions and load requirements with greater precision and speed.

- Enhanced supply chain visibility and optimization for raw material sourcing and distribution of finished wire mesh decking products.

- Improved safety protocols through AI monitoring of human-machine interaction in warehouses utilizing wire mesh decking.

DRO & Impact Forces Of Wire Mesh Decking Market

The Wire Mesh Decking Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the impact forces shaping its trajectory. The primary drivers include the exponential growth of e-commerce and the associated demand for advanced warehousing solutions, leading to increased installation of pallet racking systems that require wire mesh decking for safety and efficiency. Furthermore, stringent safety regulations across industrial sectors, particularly concerning fire safety and employee protection, mandate the use of solutions like wire mesh decking that allow for better sprinkler penetration and prevent product fall-through. The ongoing expansion of global logistics and supply chain networks, coupled with the modernization of existing industrial infrastructure, also significantly contributes to sustained market growth. The intrinsic benefits of wire mesh decking, such as durability, improved ventilation, and versatility across various storage environments, continue to drive its adoption as a preferred shelving alternative.

However, the market also faces notable restraints. The initial capital investment required for establishing or upgrading warehouse racking systems, including wire mesh decking, can be substantial, posing a barrier for smaller enterprises or those with limited budgets. Fluctuations in raw material prices, particularly steel, directly impact the manufacturing cost of wire mesh decking, potentially affecting pricing strategies and profit margins for producers. Economic downturns or geopolitical instabilities can lead to reduced industrial investments, subsequently dampening demand for warehousing equipment. The emergence of alternative storage solutions, such as automated storage and retrieval systems (AS/RS) that may not always integrate traditional decking, also presents a competitive challenge, albeit for highly specialized and capital-intensive operations. The logistical challenges associated with shipping large, bulky decking products over long distances can further add to costs and complexity.

Despite these restraints, significant opportunities exist for market expansion. The increasing adoption of automation and robotics in warehousing presents a chance for manufacturers to develop specialized wire mesh decking solutions that seamlessly integrate with these advanced systems, offering enhanced structural support and operational efficiency. The growing trend towards customized storage solutions, tailored to specific product types or operational workflows, opens avenues for manufacturers to offer bespoke decking products, differentiating themselves in a competitive market. Furthermore, the expansion of industrial infrastructure in emerging economies, driven by rapid urbanization and economic development, provides vast untapped markets for wire mesh decking. Developing innovative coatings and materials to enhance durability and corrosion resistance, particularly for harsh environments like cold storage, also represents a substantial opportunity for product differentiation and market leadership. Lastly, emphasizing the sustainable aspects of steel as a recyclable material can resonate with environmentally conscious clients, creating a niche market advantage.

Segmentation Analysis

The Wire Mesh Decking Market is broadly segmented based on several key parameters including material type, load capacity, application, and end-user industry. This segmentation provides a granular view of market dynamics, revealing specific demand patterns and growth opportunities within distinct niches. Each segment addresses particular operational requirements and budget considerations, influencing product design, manufacturing processes, and distribution strategies. Understanding these segments is crucial for market participants to tailor their offerings effectively and capture specific customer bases, ranging from small retail backrooms to large-scale automated distribution centers.

- By Material Type

- Steel Wire Mesh Decking

- Galvanized Wire Mesh Decking

- Powder Coated Wire Mesh Decking

- Stainless Steel Wire Mesh Decking

- By Load Capacity

- Light Duty (Up to 1,500 lbs)

- Medium Duty (1,501 - 3,000 lbs)

- Heavy Duty (3,001 - 5,000 lbs)

- Extra Heavy Duty (Above 5,000 lbs)

- By Channel Type

- Flared Channel

- Step Channel

- Inverted Channel

- Universal Channel

- By Application

- Pallet Racking Systems

- Shelving Systems

- Mezzanine Floors

- Others (e.g., storage cages, custom applications)

- By End-User Industry

- Warehousing & Logistics

- Manufacturing

- Retail & E-commerce

- Food & Beverage

- Pharmaceutical & Healthcare

- Automotive

- Cold Storage

- Chemicals

- Others (e.g., construction, aerospace)

Value Chain Analysis For Wire Mesh Decking Market

The value chain for the Wire Mesh Decking Market commences with upstream analysis, focusing on the sourcing of primary raw materials. This primarily involves steel, in various forms such as wire rods and sheets, which are procured from steel mills and metal suppliers. The quality and cost of these raw materials significantly impact the final product's performance and market price. Other upstream inputs include various coatings like galvanized zinc or powder coating materials, welding consumables, and specialized machinery for fabrication. Relationships with reliable raw material suppliers are crucial for ensuring consistent quality, managing costs, and maintaining production schedules. Any disruptions in the supply of steel, driven by geopolitical factors, trade policies, or supply-demand imbalances, can reverberate throughout the entire value chain.

Moving downstream, the value chain encompasses the manufacturing processes, distribution channels, and eventually the end-users. Manufacturers transform raw steel into finished wire mesh decking through processes such as cutting, welding, bending, and coating. This stage requires significant capital investment in machinery, skilled labor, and adherence to quality control standards. Post-manufacturing, the products enter the distribution phase, which can involve both direct and indirect channels. Direct distribution often occurs when large manufacturers sell directly to major warehousing and logistics companies, or directly to racking system integrators. This allows for closer customer relationships and potentially more tailored solutions. Indirect distribution involves a network of distributors, wholesalers, and material handling equipment dealers who serve a broader range of smaller and medium-sized customers, providing local stock and faster delivery.

The distribution channel dynamics are critical. Direct sales channels are often employed for large-scale projects or custom orders where direct communication with the manufacturer is beneficial for specification and technical support. These channels build strong, long-term relationships with key clients and offer a higher level of customization. Conversely, indirect channels leverage the established networks of distributors and resellers, allowing manufacturers to reach a wider geographical area and a more diverse customer base without incurring the overhead of a direct sales force in every region. These distributors often provide additional services such as local installation, maintenance, and consultation, adding value to the end-user. The choice between direct and indirect channels, or a hybrid approach, depends on market strategy, target audience, product complexity, and desired market penetration. The efficiency of these channels, including logistics and inventory management, directly impacts the product's availability and cost to the final customer.

Wire Mesh Decking Market Potential Customers

The potential customers for wire mesh decking are primarily end-users who operate and manage storage facilities across a wide spectrum of industries. These buyers are typically organizations that require efficient, safe, and durable solutions for storing palletized or loose goods within racking systems. The decision-makers within these organizations often include warehouse managers, logistics directors, procurement specialists, facility managers, and safety officers, all of whom prioritize different aspects such as cost-efficiency, operational safety, durability, and compliance with industry standards. The diverse needs of these customers drive the demand for various types and specifications of wire mesh decking, from standard sizes to highly customized solutions designed for specific load capacities or environmental conditions. Their purchasing decisions are influenced by factors such as storage density requirements, inventory turnover rates, budget constraints, and the need to integrate with existing material handling equipment.

Major segments of these potential customers include large-scale warehousing and distribution centers, which are the backbone of e-commerce and retail supply chains. These entities require vast quantities of decking to support high-volume operations and often seek robust, heavy-duty options. Manufacturing plants also represent a significant customer base, utilizing wire mesh decking for storing raw materials, components, work-in-progress, and finished goods, often requiring solutions that can withstand specific industrial environments or support specialized production processes. Retailers, from large department stores to small independent shops, use decking in their backroom storage and stockrooms to organize inventory efficiently. The food and beverage industry, particularly cold storage facilities, represents another crucial segment, where galvanized or stainless steel decking is often preferred due to its resistance to corrosion and ability to maintain hygiene standards. Pharmaceutical and healthcare sectors also utilize wire mesh decking for sterile storage environments and precise inventory management.

Beyond these prominent sectors, the automotive industry relies on wire mesh decking for parts storage and assembly line support. Construction companies use it for organizing equipment and materials on job sites or in prefabrication yards. Even government agencies and military logistics operations are potential buyers, requiring durable and compliant storage solutions for supplies and equipment. The expanding role of third-party logistics (3PL) providers further amplifies demand, as these companies manage storage and distribution for multiple clients across various industries, requiring versatile and scalable decking solutions. Ultimately, any business involved in storing physical goods that utilizes pallet racking systems is a potential customer, constantly seeking ways to enhance safety, improve operational efficiency, and optimize their storage footprint through reliable wire mesh decking solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 835.5 Million |

| Market Forecast in 2033 | USD 1,332.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ridg-U-Rak, Inc., Wireway Husky Corporation, J&L Wire Cloth, Frazier Industrial Company, Interlake Mecalux, Streater, Inc., United Steel Storage Inc., Speedrack Products Group, Hannibal Industries, Steel King Industries, Inc., Unarco Material Handling, Schaefer Systems International, Inc., Elite Storage Solutions, Rack Engineering Division, R-Mark Industrial (RMI). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Mesh Decking Market Key Technology Landscape

The technology landscape for the Wire Mesh Decking Market is primarily characterized by advancements in material science, manufacturing automation, and coating technologies, all aimed at enhancing product durability, safety, and cost-effectiveness. The core technology involves precision welding techniques to ensure the structural integrity and load-bearing capacity of the wire mesh. Robotic welding systems are increasingly being adopted to improve consistency, speed up production, and reduce labor costs, thereby optimizing manufacturing efficiency and maintaining high quality standards. These automated systems allow for complex weld patterns and ensure uniform strength across all decking units, which is critical for safety in high-capacity storage applications. Furthermore, computer-aided design (CAD) and computer-aided manufacturing (CAM) software are integral for customizing decking dimensions and channel types to integrate seamlessly with diverse racking systems, offering flexibility to end-users.

Beyond fabrication, coating technologies play a pivotal role in extending the lifespan and enhancing the performance of wire mesh decking. Galvanization, either hot-dip or electro-galvanization, remains a prevalent technology to provide superior corrosion resistance, particularly vital in environments with high humidity, temperature fluctuations, or exposure to certain chemicals, such as in cold storage or outdoor facilities. Powder coating technology offers an alternative, providing an aesthetically pleasing finish in various colors while also adding a layer of protection against minor abrasions and corrosion. These coatings not only protect the steel from environmental degradation but also contribute to the overall hygiene and cleanliness of storage areas, especially in industries like food & beverage and pharmaceuticals where strict sanitation is required. Continuous research and development in coating formulations are yielding more environmentally friendly and more robust protective layers.

Moreover, the integration of smart manufacturing principles, often referred to as Industry 4.0, is gradually influencing the wire mesh decking sector. This includes the use of sensors and data analytics in the production line to monitor machinery performance, predict maintenance needs, and optimize production flows, leading to reduced downtime and improved operational efficiency. The broader application of Internet of Things (IoT) devices in warehousing, though not directly within the decking itself, indirectly impacts its design and integration. As warehouses become smarter, there is a growing need for decking solutions that can support greater automation, accommodate various sensor placements, and withstand increased dynamic loads from automated guided vehicles (AGVs) and robotic systems. Therefore, the technology landscape is evolving to support not just the physical product but also its role within an increasingly interconnected and automated logistics ecosystem.

Regional Highlights

- North America: A mature market characterized by significant investments in large-scale logistics and e-commerce fulfillment centers. The region's strong emphasis on workplace safety standards drives consistent demand for robust and compliant wire mesh decking solutions. Modernization of existing warehouses and the adoption of automation technologies are key growth drivers, with substantial demand originating from the United States and Canada.

- Europe: A stable market witnessing steady demand, primarily from the automotive, retail, and pharmaceutical sectors. Strict European safety regulations and a focus on supply chain efficiency are major contributing factors. Germany, the UK, France, and Benelux countries are key contributors, driven by advanced manufacturing capabilities and a well-established logistics infrastructure.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, burgeoning e-commerce penetration, and massive investments in infrastructure development, particularly in emerging economies like China, India, Japan, and Southeast Asian nations. The region benefits from a large manufacturing base and an expanding consumer market, leading to increased demand for efficient warehousing and storage solutions.

- Latin America: An emerging market experiencing growth due to increasing foreign direct investment, expanding manufacturing capabilities, and the development of new logistics hubs. Countries like Brazil, Mexico, and Argentina are showing promising demand, albeit with varying paces of adoption and infrastructure development.

- Middle East and Africa (MEA): A developing market with significant potential, driven by economic diversification efforts, large-scale infrastructure projects, and the establishment of new trade routes and logistics corridors. The UAE, Saudi Arabia, and South Africa are key markets, benefiting from strategic geographical locations and growing industrial sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Mesh Decking Market.- Ridg-U-Rak, Inc.

- Wireway Husky Corporation

- J&L Wire Cloth

- Frazier Industrial Company

- Interlake Mecalux

- Streater, Inc.

- United Steel Storage Inc.

- Speedrack Products Group

- Hannibal Industries

- Steel King Industries, Inc.

- Unarco Material Handling

- Schaefer Systems International, Inc.

- Elite Storage Solutions

- Rack Engineering Division

- R-Mark Industrial (RMI)

- Warehouse & Rack Professionals

- Husky Rack & Wire

- Nashville Wire Products

- Kingston Shelving

- Penco Products, Inc.

Frequently Asked Questions

Analyze common user questions about the Wire Mesh Decking market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using wire mesh decking over solid shelving?

Wire mesh decking offers superior fire safety due to improved sprinkler penetration, enhanced air circulation for better temperature control, increased visibility of stored inventory, and improved cleanliness by preventing dust and debris accumulation. It also adds a significant layer of safety by preventing items from falling through rack levels and enhancing structural integrity.

How is wire mesh decking installed, and what types are compatible with existing racking systems?

Installation is typically straightforward, with the decking simply dropping into place over the load beams of pallet racking systems. Most wire mesh decking is designed to be compatible with a wide range of common beam sizes and rack manufacturers, often featuring channels (flared, step, inverted, universal) that fit securely. Custom sizes are also available for non-standard configurations.

What factors determine the load capacity of wire mesh decking, and how can it be verified?

The load capacity is primarily determined by the gauge and pattern of the steel wires, the number and design of supporting channels, and the span between the pallet rack beams. Verification often involves manufacturer specifications, testing data, and adherence to industry standards like those from the Rack Manufacturers Institute (RMI), ensuring safe operational limits.

Is wire mesh decking suitable for cold storage or outdoor applications?

Yes, specialized wire mesh decking is highly suitable for these environments. Galvanized wire mesh decking, through hot-dip or electro-galvanization processes, provides excellent corrosion resistance crucial for cold storage facilities where condensation and low temperatures are prevalent, or for outdoor applications exposed to weather elements.

What are the key considerations when choosing between different wire mesh decking finishes, such as galvanized vs. powder-coated?

Choosing between finishes depends on the environment and specific needs. Galvanized decking offers superior corrosion resistance for harsh, damp, or outdoor settings. Powder-coated decking provides a durable, aesthetically pleasing finish, often available in various colors, and offers good protection against wear in standard warehouse environments where extreme corrosion is not a primary concern.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager