Wire Mesh Grips Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435231 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Wire Mesh Grips Market Size

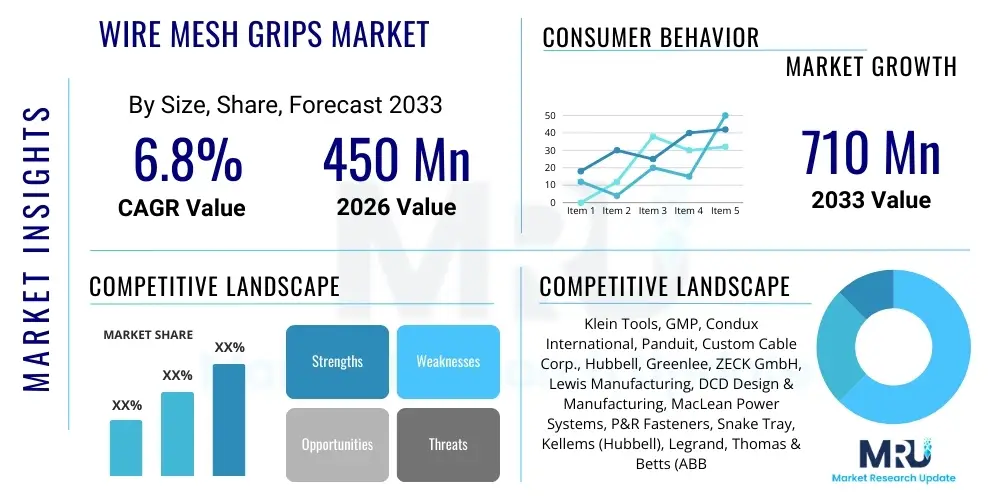

The Wire Mesh Grips Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Wire Mesh Grips Market introduction

The Wire Mesh Grips Market encompasses a range of specialized tools and components designed primarily for pulling, supporting, and managing electrical cables, fiber optic cables, and conduits across various industrial and infrastructure settings. These grips, often constructed from high-strength galvanized steel or stainless steel wire mesh, function by providing a uniform, self-tightening grip around the cable jacket. This mechanism ensures that the pulling force is distributed evenly, minimizing strain and damage to the conductors or insulation during installation or maintenance operations. Key applications span utility infrastructure, telecommunications, mining, marine, and heavy construction, making them indispensable components in modern cabling projects.

Wire mesh grips, sometimes referred to as cable socks or cable grips, are categorized based on their application type, such as single eye, double eye, closed mesh, or variable mesh styles, catering to different load requirements and installation environments. The rising global investment in power grid modernization, renewable energy projects, and the rollout of 5G networks are significantly driving the demand for reliable and efficient cable management solutions. Furthermore, stringent safety regulations governing electrical installations necessitate the use of tested and certified gripping tools, reinforcing market growth. The intrinsic benefits of using wire mesh grips, including enhanced operational safety, reduced installation time, and protection against cable abrasion, solidify their critical role in civil engineering and utility sectors.

Major driving factors include the continuous expansion of data centers globally, the increasing adoption of smart infrastructure initiatives, and governmental pushes for upgrading aging utility infrastructure in developed economies. The versatility of these grips, capable of handling complex pulling scenarios, temporary cable supports, and permanent strain relief applications, ensures sustained market relevance. Their fundamental function is enabling efficient cable installation over long distances and through challenging pathways, which is critical in maintaining the pace of global connectivity and electrification efforts.

Wire Mesh Grips Market Executive Summary

The Wire Mesh Grips Market is characterized by steady growth driven predominantly by global infrastructure development and technological advancements in connectivity, particularly the widespread deployment of 5G and fiber optics. Business trends indicate a strong move toward customization and specialization, with manufacturers offering grips tailored for specific cable diameters, jacket materials, and environmental resistance (e.g., corrosion resistance for marine or underground use). The competitive landscape is moderately fragmented, with key players focusing on expanding their distribution networks and innovating materials science to enhance product longevity and load bearing capacity. Sustainability considerations are also becoming pertinent, encouraging the use of recyclable materials and manufacturing processes that minimize environmental impact, especially in European markets.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, propelled by massive urbanization, infrastructure investment in countries like China and India, and the rapid build-out of new manufacturing facilities requiring complex power and data cabling systems. North America and Europe, while mature, maintain strong market shares driven by mandated infrastructure upgrades, grid resilience projects, and high safety standards requiring certified cable management tools. Trends in these regions favor high-load, multi-weave grips for heavy industrial applications and specialized grips for demanding environments like offshore wind farms.

Segment trends highlight the dominance of the Single Eye/Closed Mesh grips due to their versatility and suitability for standard pulling applications. However, the Double Eye/Split Mesh segment is projected to exhibit faster growth, catering to applications where the cable is already terminated or requires mid-span access. By material, galvanized steel grips remain the standard for cost-effectiveness, but stainless steel grips are gaining traction in corrosion-prone environments, such reflecting a shift towards durability and total cost of ownership rather than initial purchase price. The utilities and telecom sectors consistently represent the largest end-user segments, underscoring the market's reliance on large-scale public and private infrastructure projects.

AI Impact Analysis on Wire Mesh Grips Market

User queries regarding the impact of Artificial Intelligence (AI) on the Wire Mesh Grips market primarily revolve around operational efficiency, predictive maintenance, and manufacturing optimization. Key themes center on whether AI can enhance the design process of grips for maximum load distribution, how smart sensors integrated into cabling systems (managed by AI) might affect the demand for traditional grips, and the potential for automated inventory management and quality control during the manufacturing of the mesh itself. Users are concerned about the future role of manual gripping tools in highly automated installation processes and expect AI to streamline logistics and supply chain predictability for raw materials like high-tensile wire. The consensus indicates that while AI will not replace the fundamental product, it will significantly optimize the lifecycle—from production to installation planning.

- AI-driven optimization of mesh weave patterns to maximize tensile strength and minimize material usage.

- Predictive maintenance analytics integrated into cable installation planning, reducing instances of cable damage requiring emergency gripping solutions.

- Enhanced quality control using machine vision systems to detect microscopic defects in wire strands and mesh structure during manufacturing.

- Optimization of logistics and supply chain management for high-demand grips, improving lead times and inventory accuracy.

- Development of smart installation tools incorporating AI algorithms for calculating optimal pulling tension, indirectly supporting the effective deployment of wire mesh grips.

DRO & Impact Forces Of Wire Mesh Grips Market

The Wire Mesh Grips Market is profoundly influenced by various macro- and micro-economic factors that shape its trajectory. The primary drivers revolve around global infrastructural needs, particularly the continuous modernization of power grids and the expansive rollout of high-speed telecommunication networks. Restraints largely stem from fluctuating raw material costs, specifically steel and specialized alloys, and the challenge of low-cost imitation products potentially compromising safety standards. Opportunities exist in emerging specialized applications such as offshore renewable energy (wind and solar) and deep-sea cable laying, requiring custom, high-performance, and corrosion-resistant grips. These forces interact to define the competitive dynamics and growth potential, making market forecasting reliant on global capital expenditure trends in utilities and construction.

Drivers include government initiatives pushing for smart cities and robust national broadband coverage, which necessitate significant trenching, ducting, and aerial cabling, all dependent on effective cable pulling mechanisms. Furthermore, the increasing complexity and weight of modern cables (especially high-voltage power cables) demand higher safety factor grips, driving demand for premium products. However, the market faces restraints such as the lengthy regulatory approval processes for infrastructure projects, which can slow down deployment cycles, and the potential for substitution by specialized robotic cable handling systems in niche, highly automated environments. The dependence on large infrastructure budgets makes the market vulnerable to economic slowdowns or shifts in governmental spending priorities.

Impact forces such as rapid urbanization in developing regions act as a strong positive catalyst, whereas ongoing trade disputes affecting steel prices introduce volatility and uncertainty into manufacturing costs. The switch from copper to lighter, more complex fiber optic cables presents both a challenge (reduced overall pulling tension required) and an opportunity (demand for specific, gentler grips for delicate fibers). Overall, the long-term need for reliable energy transmission and data connectivity globally ensures that the underlying demand for cable management tools, including wire mesh grips, remains fundamentally strong, prioritizing reliability and safety over minor cost reductions.

Segmentation Analysis

The Wire Mesh Grips Market is comprehensively segmented based on material, type, application, and end-use industry, reflecting the specialized requirements across various sectors. This detailed segmentation allows manufacturers to tailor products precisely to the tensile strength, environmental resistance, and application complexity demanded by end-users. The analysis confirms that product differentiation—whether through specialized stainless steel weaves for marine applications or single-eye grips for standard pulling—is crucial for competitive advantage. Understanding these segments is vital for stakeholders to identify high-growth niches, particularly those associated with emerging renewable energy infrastructure and complex industrial installations.

- By Material:

- Galvanized Steel

- Stainless Steel (304, 316)

- Non-metallic (e.g., Aramid Fiber)

- By Type:

- Single Eye Grips (Closed Mesh)

- Double Eye Grips (Split Mesh/Lace-up)

- Offset Eye Grips

- Support Grips (Strain Relief Grips)

- Pulling Grips (Medium, Heavy Duty)

- By Application:

- Cable Pulling

- Cable Support/Strain Relief

- Cable Taping/Splicing

- By End-Use Industry:

- Utilities & Power Transmission

- Telecommunications & Data Centers

- Construction & Industrial

- Mining & Marine

- Oil & Gas

Value Chain Analysis For Wire Mesh Grips Market

The value chain for the Wire Mesh Grips market begins with the procurement of specialized raw materials, primarily high-tensile wire (galvanized or stainless steel), followed by sophisticated manufacturing and weaving processes. Upstream activities involve sourcing high-quality, certified steel alloys that meet stringent load-bearing and corrosion resistance specifications. Efficient procurement and material processing are critical, as the quality of the base wire directly dictates the final product's safety rating and performance. Manufacturers engage in complex, precision weaving or braiding techniques to create the mesh grips, adhering to recognized standards (e.g., ASTM, UL) to ensure reliable load distribution and prevent cable damage during high-tension pulling operations.

Downstream analysis focuses on the distribution channels and end-user engagement. Due to the technical nature and safety implications of the product, distribution relies heavily on specialized industrial distributors, electrical wholesale networks, and infrastructure project supply chains. Direct sales channels are often employed for large, custom orders placed by major utility companies or EPC (Engineering, Procurement, and Construction) firms managing national-level projects. Indirect channels, involving wholesalers and retailers, serve smaller contractors and maintenance markets. The effectiveness of the value chain is determined by the seamless collaboration between manufacturers and distributors to provide technical support, rapid delivery for time-sensitive infrastructure projects, and consistent stock availability across various sizes and specifications.

The distribution ecosystem is bifurcated: high-volume, standard products move through indirect, broad distribution networks, while highly specialized, heavy-duty, or custom-designed grips (e.g., for offshore drilling or underground mining) often necessitate direct engagement with the end-user or specialized agents. Successful firms within the wire mesh grips market excel by optimizing their inventory management to handle thousands of product SKUs (based on cable diameter, grip length, and material) and by ensuring that their distribution partners possess the necessary technical expertise to advise customers on correct grip selection for safety and performance.

Wire Mesh Grips Market Potential Customers

Potential customers for wire mesh grips span the entirety of the global infrastructure and construction sectors, focusing primarily on entities involved in the installation and maintenance of high-capacity cabling systems. The primary buyers are large utility providers (power and water), telecommunication companies rolling out extensive fiber optic and 5G networks, and major civil engineering contractors responsible for large-scale infrastructure builds such as tunnels, bridges, and industrial complexes. These customers demand grips that offer certified pulling strength, durability, and compliance with stringent safety regulations, often purchasing in bulk for project deployment.

Secondary buyers include industrial maintenance organizations, electrical wholesale distributors who service smaller contractors, and specialized sectors such as the mining, oil & gas, and marine industries. In the mining and oil & gas sectors, grips must withstand harsh, corrosive environments and extreme temperature variations, leading to a preference for stainless steel and specialized alloy grips. Marine customers, including shipbuilders and offshore platform operators, require highly durable, non-corrosive grips for crucial cable support and watertight applications. Procurement decisions are typically driven by engineering specifications, safety certifications, and total life cycle cost, rather than simply the unit purchase price, emphasizing quality assurance.

The rapid proliferation of data centers globally represents a high-growth segment of potential customers. Data center operators and their specialized installation contractors require high volumes of support grips (strain relief) to manage the massive density of internal cabling, ensuring longevity and preventing signal loss. Furthermore, the burgeoning renewable energy sector, including utility-scale solar farms and onshore/offshore wind farms, requires specialized heavy-duty pulling grips for the installation of large, high-voltage inter-array cables, establishing them as a significant and expanding customer base demanding custom-engineered solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Klein Tools, GMP, Condux International, Panduit, Custom Cable Corp., Hubbell, Greenlee, ZECK GmbH, Lewis Manufacturing, DCD Design & Manufacturing, MacLean Power Systems, P&R Fasteners, Snake Tray, Kellems (Hubbell), Legrand, Thomas & Betts (ABB), Cembre, Tappan Wire & Cable, Sumner Manufacturing, Utilux |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Mesh Grips Market Key Technology Landscape

The technological landscape of the Wire Mesh Grips market centers less on radical digital transformation and more on advanced material science, precision engineering, and adherence to evolving safety standards. The core technology involves highly specialized wire weaving machinery (braiding equipment) that ensures consistent, high-density mesh formation, critical for equalizing strain across the cable jacket. Key technological developments focus on enhancing the anti-rotation characteristics of the grips, particularly for heavy-duty pulling, and improving the interface where the grip attaches to the pulling swivel or hoisting equipment to prevent catastrophic failure under load. Manufacturers are continually investing in Finite Element Analysis (FEA) software to model and predict grip performance under various load and friction conditions, optimizing material use and design geometry.

A significant area of technological focus is the development of grips made from specialty materials, such as high-tensile stainless steel alloys (316, duplex) that offer superior corrosion and fatigue resistance required in offshore or subterranean environments, where standard galvanized steel fails prematurely. Furthermore, the introduction of non-metallic, Aramid fiber-based grips represents an emerging technology, offering high strength-to-weight ratios and non-conductive properties, which are essential for specific telecommunications and sensitive electrical applications. These advanced materials require new manufacturing techniques and quality control measures, driving up the precision requirements in production.

Technology also impacts the regulatory side, with specialized testing apparatus required to certify grip strength and cycle life according to international standards (e.g., IEC, NEMA). Integration technologies, though indirect, include smart pulling systems that monitor tension and distance in real-time, feeding data back to operators to ensure that the grips are not subjected to forces exceeding their safe working load limit. This holistic approach, combining material innovation with smart monitoring tools, defines the current technological trajectory, ensuring safer and more reliable cable installations.

Regional Highlights

- North America: This region maintains a significant market share, driven by massive federal investment in grid modernization, renewable energy integration (especially utility-scale solar and wind), and the mandated replacement of aging infrastructure. The market is mature but characterized by high safety standards and a preference for branded, certified heavy-duty grips. The rapid expansion of data center infrastructure, particularly in the US, fuels continuous demand for specialized strain relief and support grips.

- Europe: Europe is a key market propelled by strict regulatory frameworks governing safety and quality in electrical installations (e.g., IEC standards). Growth is particularly strong in offshore renewable energy installations (North Sea wind farms), requiring specialized stainless steel grips designed for extreme marine environments. Countries like Germany and the UK are leading contributors due to continuous infrastructure investment and telecommunication network upgrades.

- Asia Pacific (APAC): APAC is the fastest-growing region globally, attributed to rapid urbanization, massive infrastructure projects (roads, rail, ports), and extensive deployment of 5G and fiber optic networks across densely populated areas. Economic powerhouses like China and India are major consumers, focusing on both high-volume standard grips for general construction and specialized grips for large-scale energy transmission projects. Market entry is competitive, with a mix of international and local manufacturers.

- Latin America (LATAM): Growth in LATAM is tied to investment in modernizing outdated power distribution networks and improving internet connectivity in rapidly developing urban areas. Political and economic stability fluctuations can impact project timelines, but long-term potential remains strong, particularly in countries focusing on utility expansion and mining operations (requiring robust grips).

- Middle East and Africa (MEA): This region exhibits robust demand driven by large-scale oil & gas infrastructure projects, rapid expansion of smart cities (e.g., Saudi Arabia, UAE), and the development of major utility infrastructure to support population growth. The harsh desert environments necessitate grips with excellent thermal and corrosion resistance, driving demand for premium stainless steel products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Mesh Grips Market.- Klein Tools

- GMP (General Machine Products)

- Condux International

- Panduit Corp.

- Custom Cable Corp.

- Hubbell Incorporated (Kellems)

- Greenlee (Emerson)

- ZECK GmbH

- Lewis Manufacturing Company

- DCD Design & Manufacturing

- MacLean Power Systems

- P&R Fasteners

- Snake Tray

- Legrand

- Thomas & Betts (ABB)

- Cembre S.p.A.

- Tappan Wire & Cable

- Sumner Manufacturing

- Utilux

- Techflex, Inc.

Frequently Asked Questions

Analyze common user questions about the Wire Mesh Grips market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the growth of the Wire Mesh Grips market?

The primary growth drivers are large-scale global infrastructure investments, particularly in the modernization of electrical power grids, the rapid global rollout of 5G telecommunication networks, and the expansion of specialized energy sectors such as offshore wind farming and centralized data centers.

How does stainless steel differ from galvanized steel grips in application?

Stainless steel grips (typically 304 or 316 grade) offer superior resistance to corrosion, moisture, and extreme temperatures, making them essential for harsh environments like marine, underground, and chemical processing facilities. Galvanized steel grips are standard and more cost-effective for general construction and indoor applications where corrosion risk is minimal.

What are the main segments of the Wire Mesh Grips market based on type?

The market is segmented mainly into Single Eye Grips (closed mesh, used for standard pulling), Double Eye Grips (split or lace-up mesh, used when cable ends are terminated), Offset Eye Grips, and Support/Strain Relief Grips (used for permanent cable suspension and vibration dampening).

Which region currently leads the Wire Mesh Grips market in terms of growth potential?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth, fueled by intense urbanization, governmental focus on expanding national digital infrastructure, and massive capital expenditure on power transmission projects across countries like China, India, and Southeast Asian nations.

What role does safety certification play in the procurement of wire mesh grips?

Safety certification (e.g., UL, IEC, ASTM) is crucial as it verifies the safe working load limits and ensures the grip will distribute pulling tension evenly without damaging expensive cables. Procurement in utility and heavy industrial sectors strictly mandates certified grips to comply with project safety regulations and minimize liability risks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager