Wire Netting Machinery Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434208 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Wire Netting Machinery Market Size

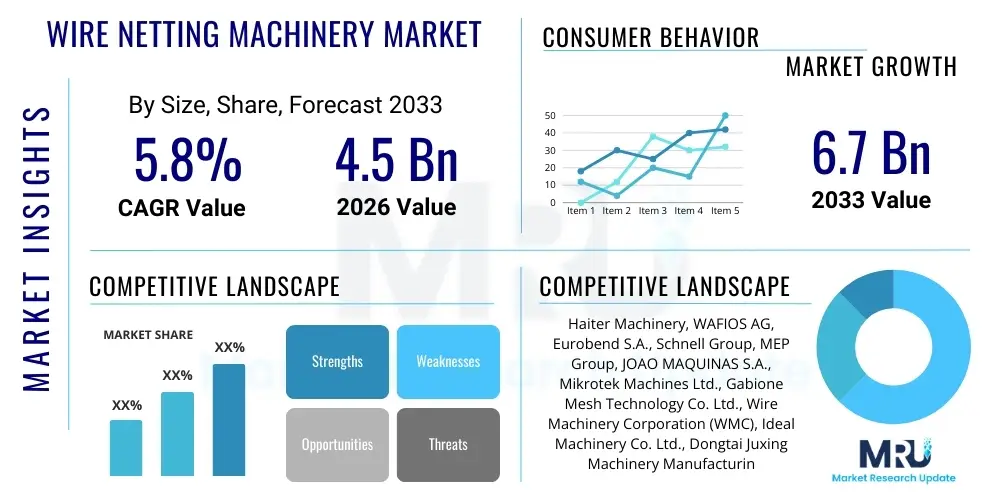

The Wire Netting Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 billion in 2026 and is projected to reach USD 6.7 billion by the end of the forecast period in 2033.

Wire Netting Machinery Market introduction

The Wire Netting Machinery Market encompasses equipment used for manufacturing various types of wire mesh, fences, and netting, crucial for applications spanning agriculture, construction, security, and industrial filtration. These machines include automated systems for weaving, welding, twisting, and coating wire products, ranging from heavy-duty chain-link fences to fine hexagonal poultry netting. The core product description involves highly specialized CNC-controlled devices designed for high-speed, precision production, utilizing materials primarily derived from galvanized steel, stainless steel, and mild steel wires.

Major applications of the resulting wire netting include infrastructural development (highway barriers, gabions), agricultural enclosure systems (livestock fencing, crop protection), and stringent security installations (perimeter security, military bases). The market’s expansion is directly linked to global urbanization trends and increasing investments in robust infrastructure projects, particularly in emerging economies where residential and commercial construction activities are escalating rapidly. Furthermore, stringent safety regulations concerning industrial enclosures and facility security boost the demand for high-quality, durable wire mesh products, thereby driving the adoption of sophisticated machinery.

Key benefits derived from modern wire netting machinery include enhanced production efficiency, reduced labor costs, superior product consistency, and the flexibility to rapidly switch between different mesh sizes and patterns. Driving factors center around technological advancements such as fully automated operation, integration of IoT for remote diagnostics, and the development of energy-efficient systems that minimize operational overhead. The necessity for advanced automation to counter rising labor costs and maintain competitive pricing globally serves as a primary catalyst for market growth across all geographical regions.

Wire Netting Machinery Market Executive Summary

The global Wire Netting Machinery market is currently characterized by a strong shift towards automation and digitalization, fundamentally altering established business trends. Manufacturers are focusing on developing high-speed, precision machinery capable of producing complex mesh structures with minimal waste, addressing the rising global demand for efficient production methods. A crucial business trend involves mergers, acquisitions, and strategic collaborations among established machinery manufacturers and specialized software providers to integrate smart manufacturing capabilities, particularly predictive maintenance and real-time quality control. Furthermore, the push for sustainable manufacturing processes is forcing compliance with stricter environmental regulations, promoting the adoption of energy-efficient electric and hydraulic systems over traditional mechanical counterparts, thus impacting machinery design and capital expenditure.

Regionally, Asia Pacific (APAC) stands out as the dominant growth engine, propelled by massive governmental investments in infrastructure, rapid residential development, and burgeoning agricultural sectors across countries like China, India, and Southeast Asia. North America and Europe, while mature, are characterized by high demand for replacement and upgrade machinery, driven by the need to integrate Industry 4.0 technologies and meet high safety standards. These mature regions prioritize machinery that offers specialized features, such as high anti-corrosion coating application capabilities and integration with enterprise resource planning (ERP) systems, maintaining stable, high-value demand. Latin America and the Middle East and Africa (MEA) present emerging opportunities, primarily supported by increasing mining activities and security infrastructure development projects.

Segment trends reveal a growing preference for fully automated welding and weaving machinery over semi-automatic variants, particularly in high-volume production environments. In terms of wire netting type, demand for welded mesh machinery is outpacing woven mesh machinery, largely due to its superior strength, lower cost per unit, and widespread application in construction and gabion production. Additionally, the machinery dedicated to producing specialized wire products, such as stainless steel mesh for filtration and high-tensile wire for security applications, is experiencing robust growth, signaling a segmentation of the market towards niche, high-value machinery solutions.

AI Impact Analysis on Wire Netting Machinery Market

Common user questions regarding AI’s impact on the Wire Netting Machinery Market frequently revolve around how artificial intelligence can enhance production efficiency, predict equipment failure, and optimize material usage. Users are particularly keen on understanding the feasibility and cost-effectiveness of implementing AI-driven quality inspection systems that can detect micro-defects faster and more accurately than human operators. Concerns often center on data security, the high initial investment required for AI infrastructure, and the need for specialized training to manage complex predictive maintenance algorithms. Overall, the expectation is that AI integration will fundamentally shift the industry toward self-optimizing machinery, minimizing downtime, reducing material scrap rates, and enabling fully customized, on-demand manufacturing capabilities, thereby transforming operational expenditure models.

- AI facilitates predictive maintenance by analyzing sensor data to forecast component wear and scheduling service interventions before catastrophic failures occur, significantly reducing unplanned downtime.

- Machine learning algorithms optimize cutting and welding parameters in real-time based on wire material variations, ensuring consistent product quality and minimizing scrap wire.

- AI-powered vision systems enable high-speed, non-contact quality inspection, automatically identifying defects like mis-welds, incorrect mesh dimensions, or coating irregularities with high precision.

- Generative AI tools assist in simulating new netting designs and production workflows, allowing manufacturers to quickly prototype and scale specialized wire products.

- AI integrates operational data from multiple machines across a factory floor into a unified dashboard, offering prescriptive recommendations for energy efficiency and overall equipment effectiveness (OEE) improvements.

DRO & Impact Forces Of Wire Netting Machinery Market

The Wire Netting Machinery Market is substantially influenced by strong drivers such as the global boom in construction and infrastructure development, particularly in rapidly urbanizing regions, which necessitates vast quantities of fencing, reinforcement mesh, and gabions. Restraints primarily include the high initial capital investment required for purchasing advanced, fully automated CNC machinery, which poses a significant barrier to entry for small and medium-sized enterprises (SMEs). Opportunities are abundant in the field of advanced material processing, specifically the demand for machinery capable of handling specialized alloys like high-tensile steel and stainless steel for filtration and security applications, alongside integrating sustainable manufacturing practices.

Driving forces also include the persistent global trend towards increasing automation driven by rising labor costs and the need for precision manufacturing that manual operations cannot consistently achieve. Furthermore, the stringent regulatory environment in developed nations regarding construction safety and perimeter security mandates the use of certified, high-quality wire netting, thereby pushing machinery manufacturers to adhere to higher production standards. These market dynamics create a continuous need for investment in R&D to maintain competitive advantage.

The primary impact forces acting on this market involve technological obsolescence, where rapid advancements in machinery efficiency and digitalization pressure existing producers to upgrade their equipment sooner than typical lifecycle schedules. Economic volatility, particularly fluctuating steel wire prices and global trade disputes, can significantly impact input costs and profitability across the value chain, forcing machinery suppliers to offer flexible financing and leasing options to mitigate buyer risk. The combined influence of these drivers, restraints, and opportunities dictates the pace and direction of technological adoption and market penetration globally.

Segmentation Analysis

The Wire Netting Machinery Market is fundamentally segmented based on factors such as the type of machinery (which dictates the final product structure), the degree of operation automation, and the material application suitability. Understanding these segments is crucial for manufacturers to target specific industrial needs, ranging from basic agricultural fencing to high-precision industrial filters. The automation level—spanning from semi-automatic to fully CNC-controlled systems—is a key differentiating factor influencing both machine price and output capacity, directly serving different tiers of industrial consumers globally. Furthermore, the machinery is segmented based on the end-user application, highlighting the distinct requirements of the construction, agriculture, and security sectors, each demanding specialized operational capabilities and material throughput.

- By Machinery Type:

- Welded Wire Mesh Machinery (e.g., Automatic Mesh Welding Machines)

- Woven Wire Mesh Machinery (e.g., Hexagonal Netting Machines, Chain Link Fencing Machines, Crimped Mesh Machines)

- Twisting and Knotting Machinery (e.g., Gabion Mesh Machines, Field Fence Machines)

- Auxiliary Machinery (e.g., Wire Straightening and Cutting Machines, Wire Drawing Machines, Coating Equipment)

- By Operation Automation:

- Semi-Automatic Machinery

- Fully Automatic Machinery (CNC Controlled)

- By Application:

- Construction and Infrastructure (Reinforcement Mesh, Gabions)

- Agriculture and Forestry (Farm Fencing, Poultry Netting)

- Industrial and Filtration (Fine Mesh Screens, Sieves)

- Security and Perimeter Fencing (High-security Fence Panels)

- By Wire Material Suitability:

- Galvanized Steel Wire

- Stainless Steel Wire

- Low Carbon Steel Wire

Value Chain Analysis For Wire Netting Machinery Market

The value chain for the Wire Netting Machinery Market begins with the upstream procurement of essential components, including high-precision mechanical parts, electronic control systems (PLCs, servo motors), and specialized tooling, often sourced from global suppliers specializing in industrial automation. Raw materials such as structural steel for the machine chassis and specialized alloys for cutting and welding components form the foundational input. Efficiency in the upstream segment relies heavily on managing supplier relationships to ensure timely delivery of high-quality, standardized components, crucial for maintaining the precision required in modern wire processing equipment. Manufacturers engaging in machinery production must maintain high internal quality control standards throughout the assembly process to ensure machine longevity and operational reliability, which translates directly into customer satisfaction and market reputation.

The core manufacturing stage involves design, assembly, testing, and system integration. Modern machinery manufacturers often incorporate proprietary software for machine control, leading to high intellectual property value. The distribution channel is pivotal; due to the high value and complexity of the machinery, sales are often conducted directly by the manufacturer or through specialized, highly technical distributors or agents. Direct sales ensure deep customer engagement, facilitating customization and post-sale technical support, which is critical for complex industrial equipment. Indirect channels, primarily used for market penetration in geographically distant or emerging markets, rely on distributors providing localized installation, maintenance, and spare parts inventory, thereby bridging the geographical gap.

Downstream analysis focuses on the end-users—the wire netting producers—who utilize the machinery to manufacture finished products for sectors like construction, agriculture, and security. The effectiveness of the machinery directly impacts the profitability of these end-users through increased output speed, reduced material waste, and lower energy consumption. After-sales service, including maintenance contracts, provision of spare parts, and operator training, constitutes a significant portion of the downstream value. Given the specialized nature of the equipment, robust and responsive technical support is a major competitive differentiator, ensuring sustained machine performance and a long operational lifespan for the buyers.

Wire Netting Machinery Market Potential Customers

The primary potential customers and end-users of Wire Netting Machinery are large-scale industrial wire producers, specialized fabrication companies, and conglomerates focused on construction materials and infrastructure components. These customers typically operate high-volume facilities requiring fully automated, continuous operation machinery to meet the consistent demand for standardized products like concrete reinforcement mesh or large quantities of agricultural fencing. Their purchasing decisions are heavily influenced by the machine’s production capacity, overall equipment effectiveness (OEE), maintenance costs, and the capability to integrate seamlessly with existing factory automation systems, demanding high levels of reliability and technical sophistication.

A secondary but rapidly growing segment comprises small-to-medium enterprises (SMEs) and regional workshops specializing in custom wire products, such as decorative meshes, industrial filtration screens, or bespoke security fences. These buyers often seek semi-automatic or modular machinery that offers flexibility, quick changeover times for different product specifications, and a lower initial capital investment compared to the large-scale industrial systems. Their focus is less on sheer volume and more on versatility and the ability to handle a diverse range of materials, driving demand for specialized, smaller footprint machines capable of high precision and unique wire manipulation techniques.

Furthermore, governmental bodies and large infrastructure development contractors also act as indirect customers, driving demand through large tenders that mandate specific wire netting requirements (e.g., high-tensile mesh for landslide mitigation or certified gabions for river bank stabilization). These requirements create a stable, high-quality demand environment for the wire netting manufacturers, who, in turn, drive the sustained procurement of advanced machinery. Geographically, construction material suppliers in fast-developing regions in APAC and the Middle East represent high-potential customer bases due to the rapid urbanization and associated infrastructure build-out.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 billion |

| Market Forecast in 2033 | USD 6.7 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Haiter Machinery, WAFIOS AG, Eurobend S.A., Schnell Group, MEP Group, JOAO MAQUINAS S.A., Mikrotek Machines Ltd., Gabione Mesh Technology Co. Ltd., Wire Machinery Corporation (WMC), Ideal Machinery Co. Ltd., Dongtai Juxing Machinery Manufacturing Co. Ltd., Breda Elettromeccanica S.p.A., HJM Asia Engineering, M.H. Maschinen- & Anlagenbau GmbH, Promostar S.r.l., SAMRAT, EVG Entwicklungs- und Verwertungs-Gesellschaft m.b.H., Zwick GmbH & Co. KG, China Fencing Wire Mesh Machine Co. Ltd., AFT-Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Netting Machinery Market Key Technology Landscape

The technological landscape of the Wire Netting Machinery Market is dominated by the integration of advanced computer numerical control (CNC) systems, allowing for precise control over complex weaving and welding patterns, significantly enhancing output accuracy and minimizing setup times. Modern machinery relies heavily on high-speed servo-driven mechanisms for wire feeding and cutting, replacing older mechanical linkages, which translates into higher operational speeds, reduced energy consumption, and superior reliability. Furthermore, there is a strong emphasis on modular design, enabling manufacturers to quickly configure machines to produce various wire products, such as switching from square welded mesh to hexagonal netting with minimal tooling changeover, thereby boosting overall production flexibility for end-users.

A key area of innovation is the development of sophisticated welding technology, particularly for welded mesh production. Resistance welding systems are becoming smarter, utilizing real-time monitoring and adaptive controls to adjust current and pressure based on fluctuations in material thickness or composition, ensuring consistent weld quality across the entire mesh panel, which is crucial for structural applications. Alongside welding, advanced coating technologies are being integrated directly into the production line. Hot-dip galvanizing simulation and electro-galvanizing systems attached to the netting machine enhance the corrosion resistance of the final product, serving high-demand markets like marine construction and exterior infrastructure projects, thereby increasing the value proposition of the finished wire.

The rise of Industry 4.0 principles is evident through the adoption of Internet of Things (IoT) sensors and connectivity across the machinery fleet. These integrated sensors monitor variables such as vibration, temperature, and current draw, transmitting data to cloud-based analytical platforms. This facilitates comprehensive remote diagnostics and predictive maintenance scheduling, reducing the reliance on manual inspections and optimizing equipment uptime. Machine manufacturers are also incorporating specialized software interfaces that offer operators intuitive graphical controls, detailed production reports, and integration capabilities with manufacturing execution systems (MES), ensuring seamless data flow and operational efficiency across the entire manufacturing facility.

Regional Highlights

- Asia Pacific (APAC): This region is the largest and fastest-growing market, primarily fueled by massive infrastructure investments in China, India, and Southeast Asian nations. Rapid urbanization and subsequent demand for residential and commercial construction, coupled with significant agricultural activities, drive high volume demand for both basic and advanced wire netting machinery.

- North America: Characterized by a highly competitive and technologically mature market. Demand is largely driven by the replacement of aging equipment with highly automated, CNC-controlled machinery that emphasizes precision, energy efficiency, and compliance with stringent occupational safety standards. Security fencing remains a high-value application segment.

- Europe: Europe is focused on quality, sustainability, and technological innovation. The market exhibits steady demand for machinery specializing in high-grade materials (like stainless steel mesh for industrial filtration) and highly automated systems that meet strict environmental regulations and high labor cost structures. Germany, Italy, and Spain are key manufacturing hubs.

- Latin America (LATAM): Growth is tied to commodity sectors, particularly mining and oil & gas, which require durable fencing and security mesh. Brazil and Mexico are leading markets, showing increased adoption of imported automated machinery to improve competitiveness against global suppliers.

- Middle East and Africa (MEA): This region is experiencing significant market development driven by large-scale government-backed construction projects (e.g., megacities and transportation networks) and increasing focus on national security infrastructure, creating emerging demand for specialized security and gabion mesh machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Netting Machinery Market.- Haiter Machinery

- WAFIOS AG

- Eurobend S.A.

- Schnell Group

- MEP Group

- JOAO MAQUINAS S.A.

- Mikrotek Machines Ltd.

- Gabione Mesh Technology Co. Ltd.

- Wire Machinery Corporation (WMC)

- Ideal Machinery Co. Ltd.

- Dongtai Juxing Machinery Manufacturing Co. Ltd.

- Breda Elettromeccanica S.p.A.

- HJM Asia Engineering

- M.H. Maschinen- & Anlagenbau GmbH

- Promostar S.r.l.

- SAMRAT

- EVG Entwicklungs- und Verwertungs-Gesellschaft m.b.H.

- Zwick GmbH & Co. KG

- China Fencing Wire Mesh Machine Co. Ltd.

- AFT-Group

Frequently Asked Questions

Analyze common user questions about the Wire Netting Machinery market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automated wire netting machinery?

The primary driver is the necessity for high production output and enhanced efficiency coupled with rising global industrial labor costs. Fully automated, CNC-controlled machines offer superior precision, higher operational speeds, and consistent product quality that semi-automatic systems cannot match, reducing dependency on manual labor and optimizing overall equipment effectiveness (OEE).

Which geographical region holds the largest market share for wire netting machinery?

The Asia Pacific (APAC) region currently dominates the market share due to unprecedented growth in infrastructure development, massive governmental investments in construction, and rapid urbanization across major economies like China, India, and Southeast Asia, creating immense demand for reinforcement mesh and fencing products.

What are the key technological advancements influencing modern wire mesh machinery?

Key technological advancements include the integration of Industry 4.0 elements such as IoT sensors for predictive maintenance, advanced servo motor control systems for high-speed precision movement, smart resistance welding technology for superior joint strength, and CNC integration for rapid, flexible pattern changeovers.

How does raw material price volatility affect the Wire Netting Machinery Market?

Volatility in the cost of steel wire and related alloys significantly impacts the production cost for end-users (wire netting manufacturers). This volatility can lead to deferred machinery purchasing decisions, as manufacturers become cautious about high capital expenditure when profitability margins are uncertain, thereby slowing down market growth in the short term.

What types of wire netting machinery are experiencing the fastest growth in demand?

Welded wire mesh machinery, particularly those used for concrete reinforcement and gabion production, is experiencing the fastest growth. This is attributed to its high structural strength, cost-effectiveness in construction applications, and the efficiency afforded by modern automated welding lines compared to traditional woven processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager