Wire Speculum Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435439 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Wire Speculum Market Size

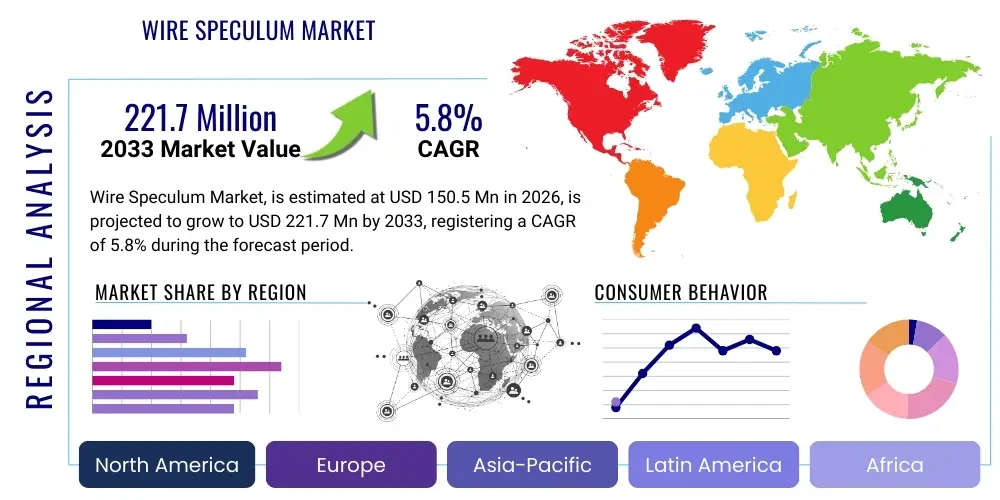

The Wire Speculum Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 150.5 Million in 2026 and is projected to reach USD 221.7 Million by the end of the forecast period in 2033.

Wire Speculum Market introduction

The Wire Speculum Market encompasses specialized medical devices primarily utilized in ophthalmic surgery to retract and hold the eyelids away from the globe, ensuring optimal surgical visibility and preventing contamination of the surgical field. These instruments, typically constructed from high-grade stainless steel or titanium alloys, are essential for procedures ranging from cataract extraction and corneal transplantation to vitreoretinal surgeries. The design emphasizes minimal trauma to delicate periocular tissues while maintaining a stable and consistent retraction force throughout the duration of the operation. Standardization in sizing and sterilization protocols is crucial for market acceptance, making material science and ergonomic design key differentiators among manufacturers.

Wire specula are critical components in the armamentarium of ophthalmic surgeons worldwide. They are categorized based on their mechanism, such as those employing a spring mechanism for automatic opening (e.g., Barraquer or McPherson specula) and those with adjustable locking mechanisms. Major applications include high-volume procedures like phacoemulsification (cataract surgery), which drives consistent demand, as well as complex reconstructive procedures. The fundamental benefit of these devices lies in their capacity to stabilize the operative area, significantly reducing the risk of complications associated with inadvertent eyelid movement or eyelashes interfering with the microscopic view. They are manufactured under stringent quality controls, often involving micro-machining and electropolishing techniques to ensure smooth, non-reflective surfaces.

Driving factors in this market include the global increase in the prevalence of age-related ophthalmic conditions, particularly cataracts and diabetic retinopathy, necessitating frequent surgical interventions. Furthermore, the rising adoption of disposable specula in Ambulatory Surgical Centers (ASCs) to mitigate cross-contamination risks, coupled with advancements in surgical techniques demanding higher precision instruments, fuels market expansion. The sustained investment in healthcare infrastructure across emerging economies and the increasing accessibility of elective ophthalmic procedures also contribute significantly to the projected CAGR over the forecast period, emphasizing the device’s indispensable role in modern surgical practice.

Wire Speculum Market Executive Summary

The Wire Speculum Market is experiencing robust growth driven by high procedural volumes and a global shift toward standardized, high-quality ophthalmic care. Key business trends include the consolidation of specialized surgical instrument manufacturers and a heightened focus on producing single-use, sterile specula to meet rigorous infection control guidelines, particularly in high-throughput surgical environments. Companies are strategically investing in specialized coating technologies, such as anti-reflective finishes, to improve visual clarity for surgeons utilizing high-magnification microscopes. The competitive landscape is characterized by innovation in ergonomic design aimed at minimizing surgeon fatigue and improving patient comfort during lengthy procedures, alongside aggressive pricing strategies in the reusable segment targeting established hospital systems.

Regionally, North America and Europe maintain leading positions due to established reimbursement frameworks and advanced healthcare infrastructure, facilitating the rapid adoption of premium and specialized speculum designs. However, the Asia Pacific region (APAC) is projected to exhibit the fastest growth, propelled by massive population bases, increasing rates of diabetic retinopathy, and government initiatives aimed at reducing preventable blindness through increased cataract surgery provision. Regional trends also show a localized preference for specific materials, with titanium specula gaining traction in markets where weight reduction and high tensile strength are prioritized, especially in complex vitreoretinal centers.

Segment trends highlight the dominance of the self-retaining specula sub-segment due to operational efficiency and ease of use compared to manual variants. The end-user segment is increasingly favoring Ambulatory Surgical Centers (ASCs) over traditional hospitals, driven by cost-efficiency and specialized focus, leading to strong demand for high-volume supply contracts. Furthermore, while stainless steel remains the material of choice for its cost-effectiveness and durability, specialized alloys are seeing increased adoption in pediatric and reconstructive ophthalmology where tissue handling requires ultra-delicate instrumentation. Sustainability concerns are also beginning to influence the market, prompting some manufacturers to explore bio-compatible materials or enhanced recycling programs for instruments.

AI Impact Analysis on Wire Speculum Market

User inquiries regarding AI's influence on the Wire Speculum market often center on whether automation might replace traditional instruments, how AI diagnoses impact surgical volume, and if AI can assist in the manufacturing quality control of these precise tools. The central theme emerging from these inquiries is the expectation that while AI will not directly replace the mechanical function of a wire speculum, it will profoundly affect the procedural workflow and subsequent market demand. Specifically, users are keen to understand how AI-driven retinal scanning and diagnostic algorithms lead to earlier detection of conditions like cataracts or macular degeneration, thus scheduling more surgical interventions and creating a consistent, elevated demand for specula. Furthermore, there is significant interest in AI's role in optimizing the supply chain and ensuring the microscopic precision required for modern ophthalmic instruments.

Although the wire speculum itself is a mechanical, non-digital device, its market fate is intrinsically linked to the volume of ophthalmic surgeries, which AI is demonstrably increasing. AI systems enhance diagnostic accuracy and efficiency, allowing ophthalmologists to triage patients more effectively and maximize operating theater utilization. For instance, in high-volume settings, automated image analysis can quickly identify surgical candidates, shortening the diagnostic cycle and increasing the number of procedures performed annually. This increase in procedural throughput ensures sustained demand for both single-use and reusable specula, acting as a crucial demand accelerator rather than a direct technological disruptor.

Beyond demand generation, AI is beginning to play a role in the manufacturing segment. Quality control systems utilizing machine vision and deep learning algorithms can inspect the intricate curvatures and minute surface details of wire specula, ensuring compliance with extremely tight tolerances necessary for micro-surgery. This AI-enhanced quality assurance minimizes manufacturing defects, guaranteeing that the instruments maintain the precise retraction force and ergonomic profile required for patient safety and surgical efficacy. This application of AI elevates product reliability across the market, indirectly favoring manufacturers who invest in these advanced QC processes, thereby setting a new standard for product quality.

- AI-driven diagnostics accelerate patient identification for ophthalmic surgery, significantly increasing procedural volume.

- Optimized surgical scheduling and resource allocation using AI directly translate to higher utilization rates for specula.

- AI machine vision systems are employed in manufacturing for ultra-precise quality control of curvature and surface finish.

- Predictive maintenance analytics for surgical equipment fleets, including sterilization cycles, indirectly impacts the lifespan and procurement cycles of reusable specula.

- AI assists in analyzing post-operative outcomes, refining surgical protocols that may influence preferred speculum designs (e.g., lower profile or specialized fixation).

DRO & Impact Forces Of Wire Speculum Market

The market dynamics for wire specula are shaped by a complex interplay of clinical needs, economic pressures, and stringent regulatory oversight. Key drivers include the demographic shift toward an aging global population, which correlates directly with an increasing incidence of cataracts and other ocular degenerative diseases requiring surgical intervention. This driver is powerfully amplified by technological advancements in micro-surgical techniques, such as Femtosecond Laser-Assisted Cataract Surgery (FLACS), which necessitate highly precise and stable retraction devices to ensure surgical success. The opportunity landscape is expanding due to improved healthcare access in developing regions, creating massive untapped markets for both basic and advanced surgical toolkits, alongside the growing trend of disposable instruments offering simplified infection control protocols.

However, the market faces significant restraints. The most prominent restraint is the increasing cost and complexity associated with sterilization and reprocessing of reusable instruments, especially in smaller clinics lacking advanced central sterile supply departments (CSSDs). Furthermore, the high initial investment required for specialized specula made from premium materials like titanium, coupled with intense regulatory scrutiny from bodies such as the FDA and EU MDR regarding biocompatibility and manufacturing traceability, poses a barrier to entry for smaller players. Pricing pressure from Group Purchasing Organizations (GPOs) and public health systems also restricts profit margins, forcing manufacturers to optimize production efficiency without compromising the critical quality of the device.

The impact forces driving the market trajectory are predominantly centered around safety and efficiency. The imperative for patient safety mandates strict adherence to sterilization guidelines, which favors the single-use segment. Conversely, efficiency demands in high-volume ASCs push for durable, lightweight, and easily manipulated instruments that minimize turnover time between cases. The regulatory environment acts as a persistent force, requiring continuous compliance updates and validation studies, thereby raising operational costs but simultaneously guaranteeing high quality standards for the end-users. Opportunities arise from developing modular or customizable speculum systems that can adapt to different patient anatomies (e.g., pediatric vs. adult) and diverse surgical approaches, offering a tailored solution to surgeons.

- Drivers: Rising global prevalence of ocular diseases; Increasing adoption of advanced ophthalmic micro-surgical techniques; Expansion of Ambulatory Surgical Centers (ASCs).

- Restraints: Stringent regulatory landscape and high compliance costs; Challenges and costs associated with reprocessing and sterilization of reusable instruments; Price sensitivity and pressure from large procurement groups.

- Opportunities: Untapped potential in emerging economies due to improving healthcare infrastructure; Development of specialized, ergonomic, and minimally invasive speculum designs; Growth in the single-use disposable segment for enhanced infection control.

- Impact Forces: Technological advancements in material science improving tensile strength and biocompatibility; Heightened global emphasis on cross-contamination prevention (favoring disposables); Economic pressures driving demand for cost-effective, high-quality instrumentation.

Segmentation Analysis

The Wire Speculum Market is fundamentally segmented based on factors such as product type, material, application, and end-user, reflecting the diverse clinical requirements across the field of ophthalmology. Analyzing these segments provides crucial insights into procurement patterns and areas of fastest growth. The segmentation by material, specifically between stainless steel and specialized alloys like titanium, is critical as it relates directly to cost, weight, durability, and usage context (e.g., MRI compatibility). The product type segmentation distinguishes between self-retaining models (which dominate the market due to their superior stability) and manually adjustable variants.

Segmentation by application is predominantly focused on high-volume procedures like cataract surgery, which constitutes the largest segment, followed by corneal and vitreoretinal surgery, requiring highly specialized specula tailored for deep-set eyes or specific incision angles. The end-user analysis reveals a clear shift in purchasing power towards specialized ophthalmic clinics and Ambulatory Surgical Centers (ASCs). These facilities often prioritize disposable options for speed and infection control, whereas large, academic hospitals typically maintain extensive inventories of reusable, high-end instruments that support a wider range of complex surgical specialties.

Understanding these segments allows market participants to tailor their product offerings, marketing strategies, and distribution channels effectively. For instance, manufacturers targeting ASCs focus on volume, sterile packaging, and cost-per-procedure metrics, while those focusing on specialized surgical centers emphasize instrument precision, advanced material composition, and ergonomic validation by leading surgeons. This granular segmentation reflects the high degree of specialization within modern ophthalmic practice, ensuring that every type of procedure, from routine exams to complex reconstruction, has an optimized instrument available.

- By Product Type:

- Self-retaining Wire Speculum (Barraquer, McPherson)

- Non-self-retaining/Manual Wire Speculum

- By Material:

- Stainless Steel Wire Speculum

- Titanium Alloy Wire Speculum

- Other Specialized Alloys (e.g., Nickel-Titanium)

- By Application:

- Cataract Surgery

- Glaucoma Surgery

- Corneal Surgery (e.g., PKP, DSAEK)

- Vitreoretinal Surgery

- Oculoplastic and Reconstructive Surgery

- By End-User:

- Hospitals and Clinics

- Ambulatory Surgical Centers (ASCs)

- Specialty Ophthalmology Centers

Value Chain Analysis For Wire Speculum Market

The value chain for the Wire Speculum market begins with upstream activities focused heavily on sourcing specialized, medical-grade raw materials. Given that specula require extremely high tensile strength, anti-corrosive properties, and biocompatibility, suppliers must provide certified stainless steel (typically 300 series) or surgical-grade titanium alloys. Upstream material procurement is critical, demanding strict quality checks to ensure material purity and consistency, which directly impact the final instrument's performance and regulatory compliance. Manufacturers often rely on a select group of specialized metal processors who can provide the wire stock with the precise dimensions and mechanical properties necessary for micro-instrument fabrication, ensuring non-magnetic properties where required for advanced imaging compatibility.

The core manufacturing and midstream processes involve sophisticated precision engineering, including specialized bending, cutting, micro-welding, and surface treatment (polishing, passivation, and electropolishing) to remove microscopic burrs and achieve a non-glare finish. Many high-end specula require cleanroom assembly and validation. Downstream logistics involve rigorous sterilization, packaging, and subsequent distribution. Due to the small size and high unit value, secure inventory management and compliant sterile barrier systems (SBS) are essential. Direct distribution channels are often employed when dealing with large hospital networks or specialized teaching institutions, allowing for direct technical support and customized inventory solutions.

Indirect distribution, involving regional or national distributors, is more common for reaching smaller clinics and ASCs, particularly in geographically fragmented markets. These distributors leverage established supply networks and local regulatory expertise. The preference for single-use specula heavily influences the distribution flow, requiring efficient, high-volume logistical support to ensure continuous supply to high-throughput surgical centers. Regardless of the channel, stringent quality assurance is required at every touchpoint until the instrument reaches the operating room, emphasizing the high-stakes nature of medical device logistics and inventory handling.

Wire Speculum Market Potential Customers

The primary potential customers and end-users of wire specula are institutions specializing in ophthalmic care. Hospitals, particularly those with dedicated ophthalmology departments or surgical units, represent a foundational customer segment. These facilities typically handle the broadest range of cases, including complex, emergency, and pediatric ophthalmic surgeries, requiring a diverse inventory of specialized, high-durability reusable specula. Procurement within large hospital systems is often centralized through Group Purchasing Organizations (GPOs), making contract negotiation and long-term service agreements crucial for market penetration.

Ambulatory Surgical Centers (ASCs) focused purely on high-volume elective procedures, predominantly cataract surgery, constitute the fastest-growing customer base. ASCs prioritize efficiency, cost-effectiveness, and turnaround time. Consequently, they are significant buyers of sterile, single-use wire specula, simplifying inventory management and eliminating the overhead associated with reprocessing. Targeting ASCs requires manufacturers to offer competitive bulk pricing and reliable, just-in-time delivery systems, aligning product features with the fast-paced, outpatient surgical environment they operate within.

Specialty Ophthalmology Clinics and private practices, especially those performing in-office minor procedures (e.g., punctual plug insertion or minor lid procedures), form another important segment. While their volume demand per entity may be lower than hospitals or ASCs, their cumulative purchasing power is substantial. These customers often value instruments that are ergonomic, easy to sterilize in smaller autoclave units, or readily available in sterile, disposable packs. Furthermore, teaching institutions and research labs represent niche but critical customers, requiring state-of-the-art instruments for surgical training and development of new operative techniques, often influencing future market preferences and adoption cycles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150.5 Million |

| Market Forecast in 2033 | USD 221.7 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bausch + Lomb, Alcon, Johnson & Johnson Vision, Katena Products, Inc., Rumex International, Beaver-Visitec International (BVI), Sklar Instruments, Millennium Surgical, Teleflex Incorporated, ASICO, Optos Plc, Carl Zeiss Meditec, Heine Optotechnik, Keeler Ltd., Surgistar, Accutome Inc., Geuder AG, Duckworth & Kent Ltd., Integra Lifesciences, Ocular Instruments. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wire Speculum Market Key Technology Landscape

The technology landscape for the Wire Speculum Market is defined less by digital innovation and more by precision manufacturing, advanced material science, and ergonomic engineering. Crucially, the fabrication of wire specula relies on Computer Numerical Control (CNC) wire forming and micro-machining processes that ensure the precise symmetry, consistent opening force, and smooth curvature required to minimize tissue damage. This high level of manufacturing precision is essential, especially for instruments used in conjunction with advanced surgical microscopes, where any manufacturing imperfection is highly magnified. Furthermore, technologies focusing on passivation and electropolishing are standard practice to maximize corrosion resistance and create a non-reflective surface, which is vital for reducing glare under intense operating room lighting.

Material technology is a central differentiator. While standard surgical stainless steel remains dominant due to its durability and cost-effectiveness, the increasing demand for specialized procedures is driving the adoption of premium alloys. Nickel-titanium (Nitinol) alloys, known for their superelasticity and shape memory characteristics, are occasionally explored for their potential to create ultra-gentle, self-adjusting retraction mechanisms, offering enhanced conformability to the orbit. Additionally, the development of sterile packaging technology—including specialized barrier films and validated ethylene oxide (EO) or gamma sterilization processes—is critical for the single-use segment, ensuring product integrity and compliance until the point of use.

Current technological advancements are also focused on improving the ergonomic interface for the surgeon and the comfort profile for the patient. Research and development efforts are aimed at reducing the overall profile and weight of the instruments without sacrificing retraction stability, particularly relevant in complex vitreoretinal surgeries where space is constrained. Furthermore, the development of integrated specula systems that may incorporate suction or illumination features, though currently niche, represents a future technological direction where multi-functional instruments enhance procedural efficiency. The integration of robust traceability technologies, such as micro-laser etching for Unique Device Identification (UDI), is also becoming standard practice to comply with global regulatory requirements, improving patient safety records and supply chain visibility.

Regional Highlights

Regional dynamics play a crucial role in shaping the Wire Speculum Market, influenced primarily by healthcare spending, disease prevalence, and regulatory frameworks.

- North America: This region holds a leading market share due to its sophisticated healthcare infrastructure, high reimbursement rates for ophthalmic procedures, and the presence of major market players and early technology adopters. The U.S. demand is consistently high, driven by the aging population and the widespread preference for single-use instruments in Ambulatory Surgical Centers (ASCs) to maintain stringent infection control standards.

- Europe: The European market demonstrates steady growth, supported by universal healthcare coverage and high patient acceptance of cataract surgery. Stringent regulatory adherence, particularly concerning the EU Medical Device Regulation (MDR), influences product design and manufacturing standards, favoring high-quality, traceable reusable instruments in large public hospital systems, though disposable use is increasing.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by massive, rapidly aging populations in China and India, increasing healthcare expenditure, and concerted efforts by governments and NGOs to address the backlog of treatable blindness. This region offers significant growth potential for cost-effective, high-volume instrumentation, with demand split between high-end specula in major metropolitan centers and economical reusable devices in rural settings.

- Latin America (LATAM): Growth in LATAM is characterized by improving economic conditions in key markets like Brazil and Mexico, leading to greater investment in specialized medical infrastructure. The market is highly price-sensitive, balancing demand for affordable reusable instruments with gradual adoption of disposable options in private clinics.

- Middle East and Africa (MEA): This region presents a fragmented market. Growth in the GCC countries is strong, mirroring European standards due to high per-capita healthcare spending. However, in many African nations, the market is primarily driven by charitable organizations and international aid programs, focusing on essential, durable, and highly sterilizable instruments for mass outreach campaigns.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wire Speculum Market.- Bausch + Lomb (a Bausch Health Company)

- Alcon

- Johnson & Johnson Vision

- Katena Products, Inc.

- Rumex International

- Beaver-Visitec International (BVI)

- Sklar Instruments

- Millennium Surgical

- Teleflex Incorporated

- ASICO

- Optos Plc

- Carl Zeiss Meditec

- Heine Optotechnik

- Keeler Ltd.

- Surgistar

- Accutome Inc.

- Geuder AG

- Duckworth & Kent Ltd.

- Integra Lifesciences

- Ocular Instruments

Frequently Asked Questions

Analyze common user questions about the Wire Speculum market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the increased demand for disposable wire specula?

The primary driver is the necessity for stringent infection control and minimizing the risk of cross-contamination, particularly in high-volume Ambulatory Surgical Centers (ASCs). Disposable options eliminate the high cost, time, and complexity associated with cleaning and reprocessing reusable instruments, contributing to overall operational efficiency and patient safety compliance.

How does material choice (Stainless Steel vs. Titanium) influence the Wire Speculum Market?

Stainless steel dominates due to its cost-effectiveness, durability, and robust sterilization capabilities, catering to the broad market. Titanium alloys, while more expensive, are favored for specialized, low-profile, and lightweight instruments used in complex vitreoretinal surgery or pediatric cases, offering superior strength-to-weight ratio and greater tissue gentleness.

Which application segment accounts for the highest utilization of wire specula?

Cataract surgery (phacoemulsification) holds the largest market share in terms of utilization. Due to the high global prevalence of cataracts and the standardized nature of the procedure, cataract extraction drives the vast majority of demand for both reusable and disposable wire specula worldwide.

How do global regulatory changes, such as the EU MDR, impact speculum manufacturers?

Regulatory changes, particularly the EU MDR, impose stricter requirements on traceability, clinical evidence, and quality management systems for all medical devices, including wire specula. This increases compliance costs and the complexity of market entry but ensures higher product quality and greater transparency across the supply chain, favoring established, high-compliance manufacturers.

What is the role of ergonomic design in the modern Wire Speculum Market?

Ergonomic design is increasingly crucial, focusing on minimizing stress on the periocular tissues while providing surgeons with optimal visibility and control. Manufacturers are developing low-profile, balanced, and non-slip designs to reduce surgeon fatigue during long procedures and enhance overall precision and patient comfort, aligning with the trend towards minimally invasive surgery.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager