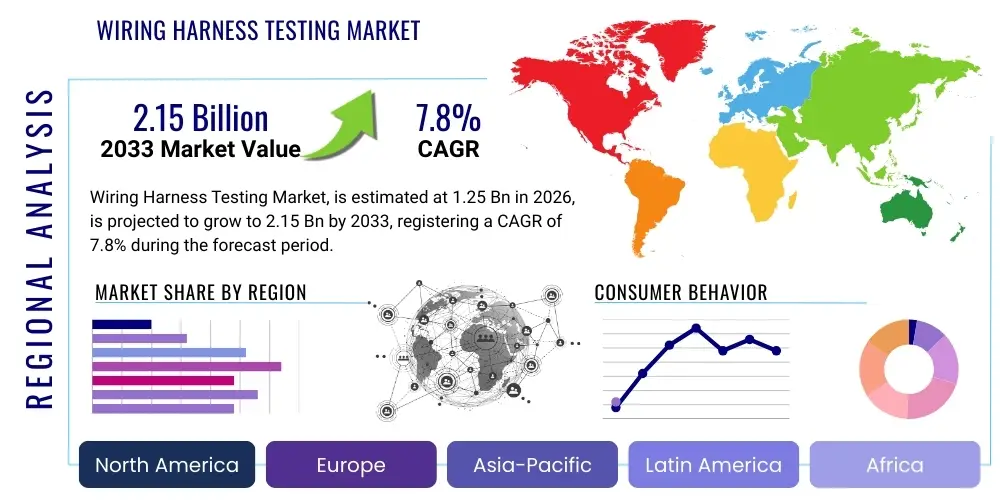

Wiring Harness Testing Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440543 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Wiring Harness Testing Market Size

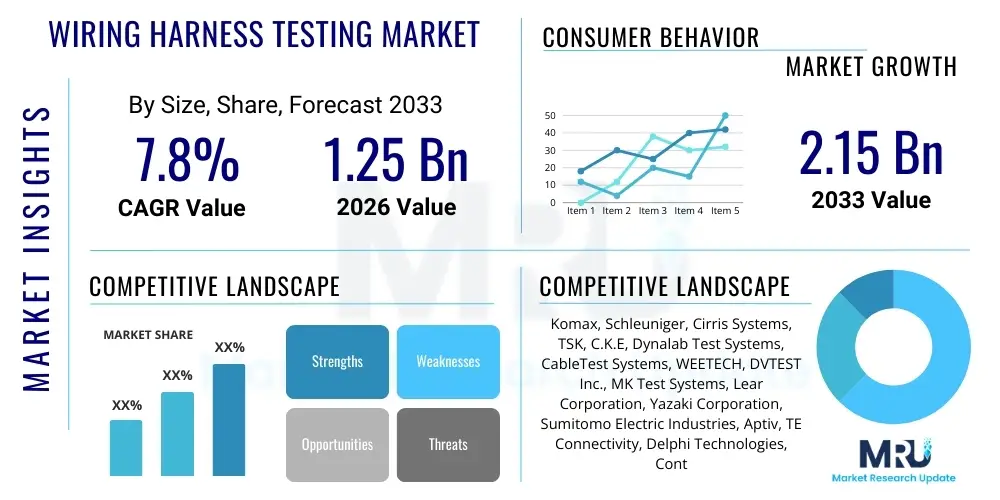

The Wiring Harness Testing Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 2.15 billion by the end of the forecast period in 2033. This robust growth is primarily driven by the escalating complexity of electrical systems across various industries, coupled with stringent regulatory standards for safety and performance.

Wiring Harness Testing Market introduction

The Wiring Harness Testing Market encompasses the global industry dedicated to the inspection, verification, and validation of electrical wiring harnesses. These harnesses, critical components in virtually all electronic and electrical systems, require rigorous testing to ensure their functionality, reliability, and safety. The market includes a wide array of testing equipment, software, and services designed to detect faults such as open circuits, short circuits, miswires, continuity issues, and insulation resistance problems, among others.

Major applications for wiring harness testing span diverse sectors, prominently including automotive, aerospace & defense, consumer electronics, industrial machinery, and medical devices. In the automotive industry, for instance, complex harnesses in modern vehicles, especially electric vehicles (EVs) and autonomous systems, necessitate exhaustive testing to prevent critical failures. Similarly, in aerospace, the integrity of wiring harnesses is paramount for aircraft safety and operational efficiency.

The primary benefits of effective wiring harness testing include enhanced product quality, reduced manufacturing defects, improved operational safety, and prolonged product lifespans. By identifying potential flaws early in the production cycle, manufacturers can significantly mitigate warranty claims, product recalls, and reputational damage. Key driving factors for market growth involve the increasing demand for advanced electronic systems, miniaturization trends, the rise of Industry 4.0, and a global emphasis on product reliability and regulatory compliance.

Wiring Harness Testing Market Executive Summary

The Wiring Harness Testing Market is experiencing significant momentum, propelled by rapid advancements in vehicle electrification and automation, alongside the expanding scope of IoT and smart manufacturing. Business trends indicate a shift towards more sophisticated, automated, and integrated testing solutions capable of handling higher harness complexity and varying production volumes. Companies are investing in R&D to develop intelligent testing platforms that incorporate features like predictive analytics and machine learning, aiming to reduce testing time and enhance accuracy while minimizing human intervention and associated errors. This strategic evolution is critical for manufacturers striving for higher quality outputs and operational efficiencies in competitive global markets.

Regional trends highlight North America and Europe as mature markets driven by stringent regulatory frameworks and the presence of major automotive and aerospace OEMs, fostering demand for advanced and highly reliable testing equipment. The Asia Pacific region, however, is emerging as the fastest-growing market, fueled by robust manufacturing expansion, increasing foreign investments, and a burgeoning consumer electronics sector, particularly in countries like China, India, and Japan. Latin America, the Middle East, and Africa are also showing steady growth, attributed to industrialization and infrastructure development initiatives.

Segment trends reveal a strong inclination towards automated and semi-automated testing solutions over traditional manual methods, driven by the need for speed, precision, and consistency in high-volume production environments. Moreover, the demand for high-voltage and insulation resistance testers is surging, largely due to the proliferation of electric and hybrid vehicles which utilize higher operating voltages. Applications in automotive and aerospace continue to dominate, but other sectors like industrial automation and telecommunications are also contributing substantially to market expansion, requiring specialized testing for their unique harness configurations and operational demands.

AI Impact Analysis on Wiring Harness Testing Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) are transforming the traditional landscape of wiring harness testing. Common questions revolve around AI's ability to enhance fault detection accuracy, reduce testing cycle times, minimize human error, and enable predictive maintenance. There's significant interest in AI's role in automating complex decision-making processes, integrating with existing testing infrastructure, and addressing the challenges posed by increasingly intricate harness designs. The overarching expectation is that AI will introduce a paradigm shift towards smarter, more efficient, and proactive testing methodologies, moving beyond conventional diagnostic approaches to preventative and prescriptive insights.

- AI-driven anomaly detection improves fault identification speed and accuracy, even for subtle defects.

- Machine learning algorithms optimize test sequences and parameters, reducing overall testing time.

- Predictive maintenance capabilities allow for proactive identification of potential equipment failures in testing apparatus.

- AI enhances data analysis from test results, providing deeper insights into manufacturing process improvements.

- Automated visual inspection using AI reduces human error in detecting cosmetic or structural defects.

- Integration of AI in robotic testing systems enables precise and repeatable manipulation of harnesses.

DRO & Impact Forces Of Wiring Harness Testing Market

The Wiring Harness Testing Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all contributing to its evolving impact forces. Key drivers include the relentless increase in the complexity and sophistication of electrical systems across industries, particularly within automotive (driven by EVs and autonomous vehicles) and aerospace sectors. Stricter regulatory standards globally, mandating higher levels of safety and reliability for electronic components, further compel manufacturers to invest in advanced testing solutions. The growing demand for robust, high-performance electronics in consumer devices and industrial machinery also fuels market expansion, emphasizing the necessity for flawless wiring harness integrity.

Conversely, the market faces several restraints that could impede its growth trajectory. The high initial capital investment required for acquiring and implementing advanced automated testing equipment poses a significant barrier, especially for smaller and medium-sized enterprises. Furthermore, the rapid pace of technological change often leads to equipment obsolescence, necessitating frequent upgrades and re-investments. The shortage of skilled personnel capable of operating, maintaining, and interpreting results from complex testing systems also represents a notable challenge, creating a demand-supply gap in specialized expertise.

Despite these restraints, substantial opportunities are emerging that are poised to accelerate market growth. The increasing adoption of AI and machine learning in testing processes offers pathways for enhanced efficiency, predictive maintenance, and optimized fault detection. The ongoing global shift towards electric and hybrid vehicles presents a massive growth opportunity, as these vehicles incorporate significantly more complex and high-voltage wiring harnesses requiring specialized testing. Furthermore, the expansion into new application areas such as smart infrastructure, renewable energy systems, and advanced medical devices creates diversified revenue streams and broadens the market's addressable scope, pushing innovation in testing methodologies and equipment design.

Segmentation Analysis

The Wiring Harness Testing Market is intricately segmented across various dimensions to cater to the diverse needs of different industries and applications. These segments provide a granular view of market dynamics, allowing for a detailed understanding of demand patterns, technological preferences, and growth opportunities within specific categories. Understanding these segmentations is crucial for manufacturers, service providers, and investors to strategically position themselves and develop targeted solutions that meet evolving market requirements and address specific pain points across the value chain.

- By Product Type:

- Continuity Testers

- Hi-Pot (High Potential) Testers

- Insulation Resistance Testers

- Resistance Measurement Testers

- Inductance & Capacitance Testers

- Functional Testers

- By Test Method:

- Manual Testing

- Semi-Automated Testing

- Automated Testing

- By Application:

- Automotive

- Aerospace & Defense

- Consumer Electronics

- Industrial

- Medical Devices

- Telecommunications

- Others (e.g., Energy, Rail)

- By End-User:

- Original Equipment Manufacturers (OEMs)

- Tier-1 Suppliers

- Contract Manufacturers

- Maintenance, Repair, and Overhaul (MRO)

- By Voltage Type:

- Low Voltage Wiring Harnesses

- High Voltage Wiring Harnesses

Value Chain Analysis For Wiring Harness Testing Market

The value chain for the Wiring Harness Testing Market begins with the upstream analysis, which primarily involves raw material suppliers and component manufacturers. This includes producers of wires, connectors, terminals, insulation materials, and specialized electronic components that form the wiring harness. Quality and consistency at this foundational stage are paramount, as defects in raw materials can propagate throughout the entire manufacturing and testing process, impacting the final product's reliability. Research and development activities also play a crucial upstream role, focusing on new materials, miniaturization, and improved electrical properties to support advanced harness designs.

Moving downstream, the value chain progresses through wiring harness manufacturers who assemble these components, followed by the actual testing equipment providers and testing service providers. Testing equipment manufacturers develop the sophisticated hardware and software required for various tests, ranging from continuity and insulation resistance to high-potential and functional checks. Testing service providers, often third-party laboratories or specialized divisions within large enterprises, offer expert testing services, particularly for complex, specialized, or high-volume testing requirements. This phase ensures that the assembled harnesses meet stringent performance and safety standards before integration into final products.

The distribution channel for wiring harness testing products and services involves both direct and indirect approaches. Direct distribution is common for large-scale equipment sales and customized solutions, where equipment manufacturers engage directly with major OEMs and Tier-1 suppliers to provide tailored systems, training, and support. Indirect channels include distributors, resellers, and system integrators who facilitate broader market reach, particularly for standardized equipment and consumable components, offering localized sales, installation, and after-sales support. This multi-faceted approach ensures efficient delivery of testing solutions to a diverse customer base across various industries globally.

Wiring Harness Testing Market Potential Customers

Potential customers for the Wiring Harness Testing Market are diverse and span across numerous industrial sectors, primarily defined by their reliance on complex electrical and electronic systems. The automotive industry represents a significant segment, encompassing global automotive OEMs and their extensive network of Tier-1 and Tier-2 suppliers involved in manufacturing vehicles, sub-assemblies, and specialized components like infotainment systems, engine control units, and advanced driver-assistance systems (ADAS). As vehicles become increasingly electrified and autonomous, the demand for rigorous testing of high-voltage and data-intensive wiring harnesses continues to surge among these players.

Beyond automotive, the aerospace and defense sector constitutes another critical customer base. Manufacturers of commercial aircraft, military jets, helicopters, satellites, and various defense systems require extremely high reliability and precision in their wiring harnesses due to critical safety and operational demands. Companies involved in MRO (Maintenance, Repair, and Overhaul) for aircraft also frequently utilize wiring harness testing solutions to ensure continued airworthiness and operational safety throughout an aircraft's lifecycle. These customers often demand highly specialized and certified testing equipment that can withstand rigorous environmental and performance validations.

Furthermore, the consumer electronics industry, with its rapid product cycles and drive for miniaturization, represents a growing segment of potential customers. Manufacturers of smartphones, laptops, home appliances, and wearable devices require efficient and accurate testing solutions for their intricate internal wiring. The industrial sector, including producers of heavy machinery, robotics, factory automation equipment, and power generation systems, also forms a substantial customer base. Finally, the medical device industry, telecommunications equipment manufacturers, and railway system integrators also rely heavily on robust wiring harness testing to ensure the safety, functionality, and longevity of their sophisticated electronic products, making them key targets for market players.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.15 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Komax, Schleuniger, Cirris Systems, TSK, C.K.E, Dynalab Test Systems, CableTest Systems, WEETECH, DVTEST Inc., MK Test Systems, Lear Corporation, Yazaki Corporation, Sumitomo Electric Industries, Aptiv, TE Connectivity, Delphi Technologies, Continental AG, Bosch, Eaton, Molex |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wiring Harness Testing Market Key Technology Landscape

The key technology landscape of the Wiring Harness Testing Market is characterized by a continuous drive towards automation, higher precision, and integration with advanced digital capabilities. Modern testing systems increasingly leverage sophisticated software for test sequence generation, data acquisition, and fault diagnosis, moving beyond rudimentary continuity checks to comprehensive functional validations. This includes the adoption of modular test architectures that allow for flexible configuration and scalability, accommodating a wide range of harness types and complexities, from simple automotive harnesses to intricate aerospace assemblies.

Another prominent technological trend is the integration of high-voltage testing capabilities, crucial for the burgeoning electric vehicle (EV) market and other high-power applications. This involves specialized equipment designed to safely and accurately perform insulation resistance and dielectric withstand (Hi-Pot) tests at elevated voltages, ensuring the integrity and safety of high-voltage wiring systems. Furthermore, advanced vision systems and robotic automation are becoming integral, enabling automated visual inspection for physical defects, connector verification, and precise handling of harnesses during the testing process, thereby minimizing human error and increasing throughput.

The market is also witnessing a significant push towards incorporating Industry 4.0 principles, including the Internet of Things (IoT) and Artificial Intelligence (AI). IoT sensors embedded in testing equipment facilitate real-time data collection and remote monitoring, while AI and machine learning algorithms are being utilized for predictive maintenance of testing machines, anomaly detection in test results, and optimization of test protocols. This technological evolution aims to create smarter, more efficient, and interconnected testing environments that can adapt to rapid changes in product design and manufacturing processes, enhancing overall quality control and reducing time-to-market.

Regional Highlights

- North America: A mature market driven by significant presence of automotive and aerospace OEMs; strong emphasis on safety regulations and advanced testing solutions. High adoption of automated testing due to high labor costs and demand for precision.

- Europe: Dominated by stringent EU regulations and a robust automotive industry (Germany, France, UK). Focus on high-quality, reliable testing for complex systems, particularly in premium vehicles and industrial automation.

- Asia Pacific (APAC): Fastest-growing region due to rapid industrialization, expanding manufacturing bases (China, India), and increasing demand for consumer electronics. Significant investments in automotive and electronics production driving demand for cost-effective and efficient testing solutions.

- Latin America: Emerging market with steady growth driven by expanding automotive manufacturing and infrastructure development. Increasing adoption of semi-automated and automated testing solutions as industries modernize.

- Middle East and Africa (MEA): Growth attributed to diversified economic development, investments in industrial and automotive sectors, and infrastructure projects. Demand for robust testing equipment for harsh operating environments and growing local manufacturing capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wiring Harness Testing Market.- Komax

- Schleuniger

- Cirris Systems

- TSK

- C.K.E Co., Ltd.

- Dynalab Test Systems

- CableTest Systems

- WEETECH GmbH

- DVTEST Inc.

- MK Test Systems Ltd.

- Lear Corporation

- Yazaki Corporation

- Sumitomo Electric Industries

- Aptiv PLC

- TE Connectivity

- Delphi Technologies (BorgWarner Inc.)

- Continental AG

- Robert Bosch GmbH

- Eaton Corporation

- Molex LLC

Frequently Asked Questions

What is a wiring harness testing market?

The wiring harness testing market comprises the global industry focused on equipment, software, and services for inspecting, verifying, and validating electrical wiring harnesses. This ensures their functionality, reliability, and safety across various applications like automotive, aerospace, and consumer electronics, detecting faults such as open circuits, short circuits, and miswires.

What are the primary drivers for the growth of this market?

Key drivers include the escalating complexity of electrical systems in modern vehicles and electronic devices, stringent global safety and quality regulations, and the rapid expansion of electric vehicles (EVs) and autonomous driving technologies, all demanding rigorous testing to prevent failures and ensure product integrity.

How does AI impact wiring harness testing?

AI significantly enhances wiring harness testing by improving fault detection accuracy through anomaly detection, optimizing test sequences with machine learning, enabling predictive maintenance of testing equipment, and refining data analysis for manufacturing process improvements, leading to more efficient and reliable testing outcomes.

Which regions are leading in wiring harness testing market growth?

While North America and Europe remain mature markets with strong regulatory frameworks, the Asia Pacific region is experiencing the fastest growth. This surge is fueled by robust manufacturing expansion, increasing foreign investments, and a burgeoning consumer electronics and automotive sector in countries like China and India.

What are the key types of wiring harness testing equipment?

Key types of testing equipment include continuity testers for basic circuit verification, Hi-Pot (High Potential) testers for insulation integrity, insulation resistance testers, resistance measurement testers, and functional testers which simulate operational environments to validate overall performance of the harness assembly.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager