Wood Carving Tools Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432569 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Wood Carving Tools Market Size

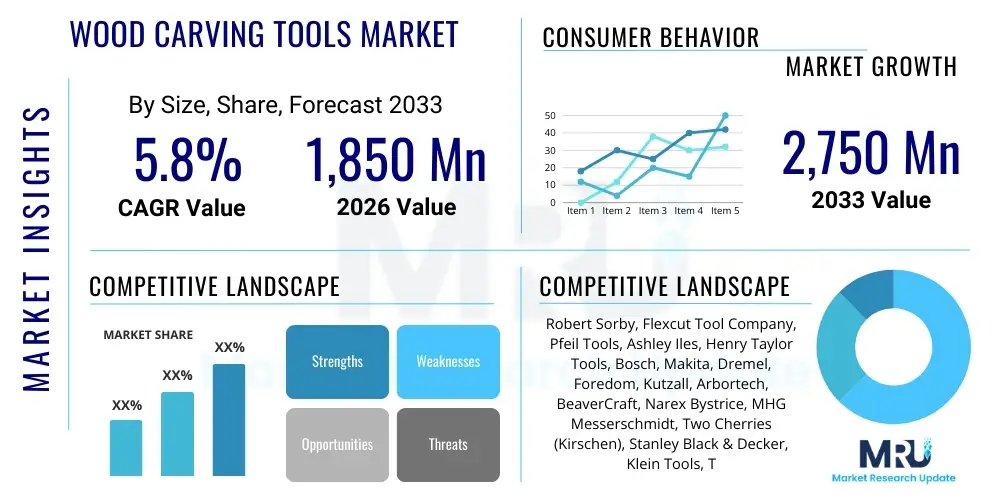

The Wood Carving Tools Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1,850 Million in 2026 and is projected to reach USD 2,750 Million by the end of the forecast period in 2033. This substantial growth is fundamentally driven by the resurgence in traditional craftsmanship, coupled with significant technological advancements enabling greater precision and efficiency in carving processes. The global appetite for bespoke furniture, artisanal decorative items, and architectural detailing continues to fuel demand for both specialized hand tools and advanced power carving equipment.

Market expansion is particularly noticeable across developing economies where disposable incomes are rising, leading to increased investment in home décor and luxury goods that often feature intricately carved wood elements. Furthermore, the proliferation of online platforms dedicated to showcasing and selling handcrafted goods has significantly broadened the addressable market for wood carving professionals and hobbyists alike. The integration of ergonomic designs and durable materials, such as high-carbon steel and specialized alloys, enhances the longevity and user experience of these tools, justifying premium pricing and driving value growth.

While the market is mature in certain segments, innovation remains a key factor. Manufacturers are focusing heavily on developing specialized micro-tools for detailed work and robust power tools that minimize vibration and fatigue, appealing to a wide demographic, from industrial users in furniture manufacturing to individual hobbyists seeking high-quality, reliable instruments. This balanced demand across professional and DIY segments ensures stable and predictable market expansion throughout the forecast period, positioning the Wood Carving Tools Market as resilient against minor economic fluctuations.

Wood Carving Tools Market introduction

The Wood Carving Tools Market encompasses a diverse range of instruments designed for shaping, texturing, and finishing wood surfaces, ranging from traditional hand-powered chisels, gouges, and knives to modern electric rotary tools, flex-shaft machines, and specialized CNC bits. These tools are indispensable for creating sculptures, relief carvings, detailed architectural elements, decorative furniture components, and fine art pieces. Major applications span woodworking studios, furniture manufacturing, restoration and preservation projects, educational institutions, and the rapidly growing artisanal hobbyist sector. The primary benefits of these specialized tools include precision control, material removal efficiency, aesthetic versatility, and the ability to execute complex designs that machinery alone cannot replicate. The market is fundamentally driven by the rising global interest in artisanal crafts, the increasing demand for customizable and unique wood products, and continuous innovation in tool ergonomics and material science, making the demanding craft more accessible and efficient for a broader audience.

Wood Carving Tools Market Executive Summary

The Wood Carving Tools Market is characterized by a favorable blend of enduring traditional demand and rapid technological integration. Business trends indicate a strong move toward e-commerce platforms and direct-to-consumer models, allowing niche manufacturers to reach specialized global audiences effectively. There is an increasing focus on sustainability, with consumers preferring tools made from ethically sourced materials and processes. Regionally, Asia Pacific (APAC) is emerging as the fastest-growing market due to robust infrastructure development, booming furniture manufacturing industries, and a rich historical tradition of wood craftsmanship, particularly in countries like China and India. North America and Europe, however, maintain market dominance in terms of value, driven by a high concentration of high-end custom woodworkers and established brand loyalty toward premium tool manufacturers. Segment trends highlight that while the Hand Tools segment holds a significant share due to its foundational role in fine art carving, the Power Tools segment is experiencing higher growth, propelled by the demand for rapid material removal and efficiency in large-scale commercial applications. Material-wise, high-carbon steel tools remain the standard, but ceramics and specialized tungsten carbide tips are gaining traction for durability and edge retention in intricate, high-wear applications, signaling a market trajectory focused on performance and longevity.

AI Impact Analysis on Wood Carving Tools Market

User queries regarding the impact of Artificial Intelligence on the Wood Carving Tools Market primarily revolve around automation fears, the potential for AI-driven design optimization, and the integration of smart technologies into power carving machinery. Key themes analyzed suggest users are concerned about whether AI-driven CNC machining will completely displace traditional hand carving skills, and conversely, they are curious about how AI can assist artisans—perhaps through predictive maintenance for tools, optimizing toolpath generation for hybrid carving (hand finishing of machine-carved blanks), or through generative design tools that provide complex, carve-ready patterns. The summary consensus indicates that while AI heavily influences the high-volume, precision manufacturing of wood products via robotics and sophisticated CNC routers, its direct impact on specialized hand tools is limited to quality control during manufacturing and supply chain management. For the artisan, AI acts less as a replacement and more as a sophisticated assistant, enhancing efficiency without diminishing the value of human skill in the final creative process.

- AI-enabled CNC machining increases demand for specialized, high-tolerance CNC carving bits and accessories, potentially diminishing demand for entry-level hand tools in commercial settings.

- Predictive analytics driven by AI optimizes the maintenance schedules for high-value power carving equipment, maximizing uptime in professional workshops.

- AI algorithms assist in optimizing tool geometry and material composition during the manufacturing phase, leading to better performing and more ergonomic hand tools.

- Generative AI tools provide complex 3D wood carving patterns, acting as design prompts that expand the creative output and complexity available to traditional carvers.

- AI improves supply chain efficiency by forecasting demand for specific niche carving tools, ensuring better inventory management and minimizing stockouts for specialty manufacturers.

DRO & Impact Forces Of Wood Carving Tools Market

The Wood Carving Tools Market dynamics are governed by a robust set of driving factors (D), inherent restraining challenges (R), and compelling opportunities (O), which collectively define the impact forces shaping market trajectory. The primary drivers include the global consumer shift towards premium, customized wooden decor and furniture, the growing popularity of woodworking as a vocational skill and hobby, and continuous technological refinements in power tool performance and precision. Conversely, restraints involve the high initial investment required for professional-grade specialized tools, the relatively steep learning curve associated with advanced carving techniques, and fluctuating raw material costs, particularly high-grade steel and exotic woods. Significant opportunities arise from the integration of hybrid tools (combining power and precision hand finishing), the expansion into specialized educational workshops globally, and leveraging e-commerce and social media platforms for targeted marketing to hobbyists. These elements create strong, push-pull impact forces, where the demand for personalized artistry significantly outweighs the challenges posed by skill acquisition difficulty, leading to moderate to high positive momentum across the forecast period.

Segmentation Analysis

The Wood Carving Tools Market is segmented based on critical attributes including Tool Type, Application, Material, Distribution Channel, and End-User, providing a granular view of market dynamics and revenue streams. Analyzing these segments helps stakeholders identify high-growth areas and tailor product development and marketing strategies accordingly. The diversity of tooling required for various carving techniques, such as relief carving versus sculptural work, necessitates a broad product portfolio from market leaders. Furthermore, the segmentation by End-User (Professional vs. Hobbyist) is crucial, as professionals prioritize durability, precision, and efficiency (often opting for high-end power tools and specialized hand sets), while hobbyists typically seek versatile, easy-to-use, and affordably priced entry-level kits, impacting both pricing strategies and channel focus.

- By Tool Type:

- Hand Tools (Chisels, Gouges, V-tools, Skews, Knives, Mallets)

- Power Tools (Rotary Tools, Angle Grinders, Chainsaw Carvers, Flex Shaft Tools)

- CNC Carving Bits and Accessories

- By Application:

- Sculpture and Figurative Carving

- Furniture and Architectural Detail

- Relief Carving

- Lettering and Detailing

- Wood Turning

- By Material:

- High-Carbon Steel

- Stainless Steel

- Tungsten Carbide

- Ceramic/Zirconia

- By End-User:

- Professional Woodworkers and Artisans

- Hobbyists and DIY Enthusiasts

- Educational Institutions and Workshops

- By Distribution Channel:

- Offline (Specialty Stores, Hardware Stores, Retail Chains)

- Online (E-commerce Platforms, Brand Websites)

Value Chain Analysis For Wood Carving Tools Market

The value chain for the Wood Carving Tools Market begins with the Upstream activities centered on sourcing high-quality raw materials, primarily specialized steel alloys (such as high-carbon steel or chrome vanadium), exotic hardwoods for handles, and precision-engineered plastics for power tool casings. Critical elements at this stage involve smelting, forging, and heat treatment processes crucial for achieving the required hardness and edge retention in cutting tools. Manufacturers must establish reliable supply agreements to mitigate price volatility and ensure material traceability, especially for specialized materials like Japanese laminated steel or tungsten carbide inserts used in high-end industrial tooling. The quality of these inputs directly dictates the performance and market acceptance of the final product, making material procurement a critical competitive factor.

Midstream activities encompass the core manufacturing and assembly processes, including stamping, grinding, precision honing, handle fitting, and complex electronic assembly for power tools. This stage involves significant investment in advanced machinery like CNC grinding centers and automated heat treatment furnaces to achieve high tolerances and consistency. Key manufacturing differentiators include ergonomic design integration to minimize user fatigue, and specialized coating processes (e.g., titanium nitride) to enhance tool longevity. Quality control and rigorous testing, especially for edge sharpness and balance, are paramount before moving to distribution. Companies frequently outsource handle production or non-critical components to optimize cost structures while maintaining proprietary control over blade manufacturing.

Downstream analysis focuses on distribution channels and end-user engagement. The distribution channel is bifurcated into direct and indirect methods. Direct sales increasingly leverage proprietary brand websites and specialized e-commerce platforms, offering better profit margins and direct customer feedback. Indirect sales utilize established networks of specialty woodworking stores, large retail hardware chains (like Home Depot or Lowe’s), and authorized international distributors. Specialty stores are crucial for high-end, niche tools, providing expert consultation, while large retailers cater efficiently to the DIY and hobbyist segments. Effective logistics and inventory management across these channels are essential to meet seasonal demand fluctuations, particularly during holiday periods associated with gift-buying for hobbyists.

Wood Carving Tools Market Potential Customers

The potential customer base for the Wood Carving Tools Market is highly segmented, primarily comprising Professional Woodworkers and Artisans, along with a vast and rapidly expanding segment of Hobbyists and DIY Enthusiasts. Professional carvers, who are the primary buyers of high-precision, premium hand tools and industrial-grade power carving systems, require tools that offer unmatched durability, ergonomic comfort for long working hours, and certified performance specifications. Their purchasing decisions are heavily influenced by brand reputation, material quality (e.g., tool steel grade), and specialized design features tailored for specific artistic or architectural demands, often resulting in recurring purchases to maintain their essential tool kits.

The Hobbyist and DIY segment represents the largest volume market, driven by individuals engaging in carving for relaxation, creative expression, or small-scale entrepreneurial projects. This group typically seeks versatile carving sets, introductory kits, and budget-friendly power tools that offer ease of use and safety features. This segment is highly responsive to online educational content, tutorials, and social media endorsements, leading manufacturers to focus marketing efforts on accessibility and integrated kits. Growth in this area is correlated with increased leisure time and the rising popularity of home improvement and artisanal crafts globally.

Additionally, educational institutions, including vocational schools, art colleges, and specialized woodworking workshops, constitute a crucial institutional buyer segment. These organizations purchase durable, reliable tools in bulk for student use. Their purchasing criteria often prioritize longevity, standardized quality, and safety certification. Finally, restoration and preservation specialists form a niche, high-value customer group that demands specialized historical reproduction tools and precise micro-carving instruments for sensitive conservation work on antiques and cultural heritage pieces, underscoring the market's requirement for both mass-produced efficiency and highly specialized precision tooling.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,850 Million |

| Market Forecast in 2033 | USD 2,750 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Robert Sorby, Flexcut Tool Company, Pfeil Tools, Ashley Iles, Henry Taylor Tools, Bosch, Makita, Dremel, Foredom, Kutzall, Arbortech, BeaverCraft, Narex Bystrice, MHG Messerschmidt, Two Cherries (Kirschen), Stanley Black & Decker, Klein Tools, Tormek, Woodpeckers, R. B. Woodcraft. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wood Carving Tools Market Key Technology Landscape

The Wood Carving Tools Market, while rooted in traditional crafts, is increasingly influenced by advancements in material science and manufacturing precision. A key technological trend is the adoption of Computer Numerical Control (CNC) technology, not only in automated carving machines but also in the production of the carving tools themselves. CNC grinding and sharpening processes ensure unparalleled consistency in blade geometry, edge angles, and curvature, critical for high-performance gouges and chisels. Furthermore, manufacturers are heavily investing in specialized heat treatment technologies, such as cryogenic processing, to enhance the hardness, toughness, and longevity of high-carbon and specialized tool steels, reducing the frequency of maintenance required by the end-user.

Another significant area of technological evolution is the integration of advanced materials, particularly in the Power Tools segment. The use of high-density tungsten carbide and specialized ceramic compounds for rotary burrs and abrasive cutters allows for faster material removal on tough woods while maintaining structural integrity and heat resistance, leading to cleaner cuts and extended tool life. In hand tools, the focus is shifting towards ergonomic design facilitated by advanced computational fluid dynamics and materials like engineered composites and high-damping elastomers for handles, which significantly reduce vibrational stress and user fatigue, thereby increasing the practical usability of the tools for professionals engaged in lengthy carving sessions.

Finally, the growing sophistication of powered carving systems, such as flexible shaft tools and specialized power chisels, incorporates brush-less DC motors (BLDC). BLDC technology provides superior efficiency, higher torque at lower speeds, and reduced noise and vibration compared to traditional brushed motors. This technological upgrade directly caters to professional carvers who demand precise speed control and consistent power output for intricate detailing work. The convergence of superior metallurgy, precise manufacturing via CNC, and the adoption of high-efficiency motor technology are the primary drivers enhancing product performance and setting new standards within the competitive landscape.

Regional Highlights

- North America: This region holds a significant market share, driven by a strong DIY culture, high disposable incomes, and an established market for custom high-end furniture and artisanal goods. The US is the largest consumer, showing high demand for both premium European hand tools and specialized power carving systems (Dremel, Foredom). Canada also contributes substantially, particularly in specialized areas like wildlife carving and totem pole restoration.

- Europe: Characterized by a deep-rooted tradition of fine woodworking and carving, Europe remains a critical market. Countries like Germany, the UK, and France are major consumers and producers, renowned for high-quality, precision hand tools (e.g., Pfeil, Narex). The emphasis here is on quality and longevity, favoring specialized artisan tools over mass-market products. The restoration and heritage conservation sectors are significant demand drivers.

- Asia Pacific (APAC): Expected to register the highest CAGR during the forecast period. This growth is fueled by massive infrastructure and construction projects, a thriving furniture export industry (especially in China, Vietnam, and Indonesia), and a burgeoning middle class increasing expenditure on home decor. Traditional woodworking techniques remain highly valued, leading to strong demand for both domestically produced and imported high-performance tools.

- Latin America (LATAM): The market is characterized by moderate growth, primarily driven by domestic furniture manufacturing and local crafts sectors. Brazil and Mexico are key markets, where economic stabilization and increasing urbanization are boosting demand for affordable yet reliable tools for both professional and amateur use. Distribution often relies on local hardware retailers and regional importers.

- Middle East and Africa (MEA): This region presents nascent but accelerating market potential. Demand is largely concentrated in the GCC states due to high-value architectural projects requiring detailed interior woodwork and luxury décor. South Africa and the UAE are the leading consumers, importing high-end tools to cater to specialized construction and restoration niche markets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wood Carving Tools Market.- Robert Sorby

- Flexcut Tool Company

- Pfeil Tools

- Ashley Iles

- Henry Taylor Tools

- Bosch

- Makita

- Dremel

- Foredom

- Kutzall

- Arbortech

- BeaverCraft

- Narex Bystrice

- MHG Messerschmidt

- Two Cherries (Kirschen)

- Stanley Black & Decker

- Klein Tools

- Tormek

- Woodpeckers

- R. B. Woodcraft

Frequently Asked Questions

Analyze common user questions about the Wood Carving Tools market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the professional Wood Carving Tools Market?

The primary factor driving professional market growth is the increasing global demand for bespoke, high-quality, and intricately detailed wooden products, including custom furniture, architectural elements, and fine art pieces, which necessitates investment in high-precision, durable, and ergonomic specialized tooling.

How do Hand Tools compare to Power Tools in terms of market share and future growth projections?

Hand tools currently hold a substantial market share due to their necessity in fine finishing and traditional artistry. However, power tools (such as rotary tools and specialized power chisels) are projected to exhibit a higher CAGR, driven by their efficiency, speed of material removal, and rising adoption among both commercial workshops and time-conscious hobbyists.

Which geographical region is expected to show the fastest growth rate for wood carving tool adoption?

Asia Pacific (APAC) is anticipated to register the fastest growth rate. This acceleration is attributed to rapid urbanization, significant expansion in the furniture manufacturing industry, and the increasing consumer disposable income dedicated to artisanal home furnishings in key countries like China, India, and Vietnam.

What technological advancements are most significantly impacting the quality and longevity of modern carving tools?

Key technological advancements include the use of sophisticated CNC grinding for consistent blade geometry, specialized cryogenic heat treatment processes to enhance steel toughness and edge retention, and the integration of highly efficient Brushless DC motors (BLDC) in modern power carving systems, improving precision and tool life.

What role does the e-commerce distribution channel play in the overall Wood Carving Tools Market?

E-commerce plays a critical and expanding role, especially for niche and specialty tools. It facilitates direct-to-consumer sales, allowing boutique manufacturers to reach global professional and hobbyist markets, and serves as the primary platform for beginners seeking introductory carving kits and detailed product tutorials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager