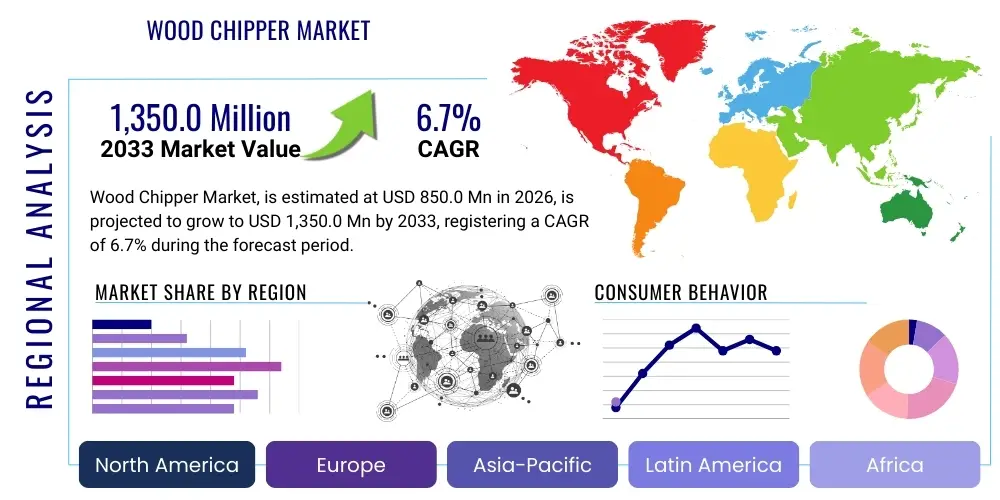

Wood Chipper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438454 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Wood Chipper Market Size

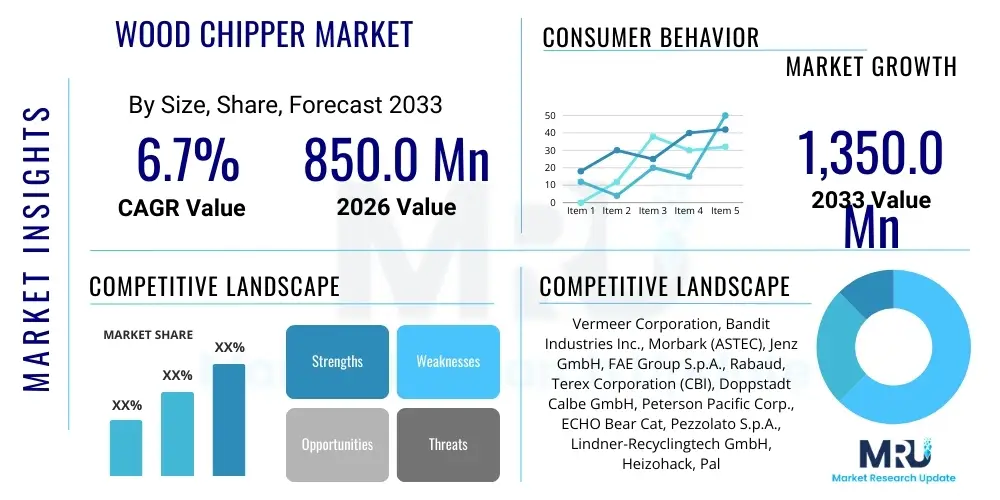

The Wood Chipper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at $850.0 Million USD in 2026 and is projected to reach $1,350.0 Million USD by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by increasing global focus on sustainable forest management practices, coupled with rising demand from the burgeoning landscaping and arboriculture sectors worldwide. Furthermore, rapid urbanization necessitates efficient methods for managing green waste, thereby accelerating the adoption of high-capacity and automated wood chipping equipment.

Wood Chipper Market introduction

The Wood Chipper Market encompasses the manufacturing, distribution, and sale of specialized machinery designed to reduce wood, limbs, brush, and other organic matter into smaller wood chips. These devices are crucial tools utilized across various heavy-duty and light-duty applications, ranging from large-scale forestry operations and biomass production facilities to routine municipal maintenance and residential landscaping projects. The fundamental mechanism involves powerful cutting blades or hammers mounted on a disc or drum, which effectively processes bulk wood material, significantly reducing its volume for easier disposal, mulching, or energy conversion.

Major applications for wood chippers span the entire green industry value chain. In forestry, they are indispensable for clearing logging residue (slash) and preparing land for replanting. For municipalities and utility companies, wood chippers ensure swift clearance of storm debris and regular maintenance of utility lines and rights-of-way. Benefits associated with using modern wood chippers include increased operational efficiency, substantial reduction in material handling costs, and the creation of valuable end-products such as mulch, compost material, or biofuel feedstock. Key driving factors include tightening environmental regulations concerning biomass waste disposal, technological advancements leading to more efficient and safer machinery, and the global push toward utilizing sustainable energy sources derived from wood waste.

Wood Chipper Market Executive Summary

The Wood Chipper Market is currently characterized by strong business trends focusing on digitalization and enhanced safety features. Manufacturers are increasingly integrating telemetry and IoT capabilities into high-capacity commercial models, allowing for predictive maintenance and optimized fleet management. Regional trends indicate robust demand growth in the Asia Pacific (APAC) region, driven by large-scale infrastructure projects and governmental initiatives promoting agricultural residue management. While North America and Europe remain mature markets, they are emphasizing high-performance, emissions-compliant equipment, particularly diesel and PTO-driven models, due to stringent environmental standards. Segment trends highlight the growing preference for engine-driven mobile chippers among professional landscapers due to their versatility, whereas the forestry sector continues to adopt high-throughput, trailer-mounted or self-propelled drum chippers for maximum processing capability.

AI Impact Analysis on Wood Chipper Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Wood Chipper Market primarily center around automation capabilities, predictive maintenance schedules, and the potential for smart material processing. Users are concerned about how AI can optimize feed rates, identify and reject non-wood foreign objects (like rocks or metal) automatically, thereby preventing damage and costly downtime. Expectations revolve around leveraging machine learning to analyze wood density and moisture content in real-time, allowing chippers to dynamically adjust blade speed and torque for optimal chip quality and fuel efficiency, especially in high-volume industrial applications. The integration of AI in diagnostic systems is highly anticipated to transform maintenance practices from reactive to predictive, significantly extending machine lifespan and reducing total cost of ownership for fleet operators.

- Enhanced Predictive Maintenance: AI algorithms analyze operational data (vibration, temperature, fuel consumption) to forecast component failures, scheduling maintenance precisely before breakdowns occur.

- Optimized Feed Control: Machine learning dynamically adjusts the infeed mechanism based on the load and type of wood being processed, maximizing throughput and preventing engine stalling.

- Automated Foreign Object Detection: Vision systems powered by AI identify rocks, metal debris, or other hazardous materials in the infeed stream, initiating automatic halts or rejection mechanisms to protect the cutting rotor.

- Improved Fuel Efficiency: AI-driven engine management systems modulate power delivery based on real-time chipping resistance, leading to significant reductions in operational fuel usage.

- Autonomous Operation Potential: Development of fully autonomous or remote-operated chippers for hazardous environments, reducing manual labor risks.

DRO & Impact Forces Of Wood Chipper Market

The dynamics of the Wood Chipper Market are shaped by a complex interplay of internal and external forces. Key drivers include the escalating need for efficient biomass processing for renewable energy generation, which boosts demand for high-capacity industrial chippers. Additionally, stringent governmental regulations aimed at reducing landfill waste and promoting responsible forestry management necessitate the mechanical reduction of green debris. However, the market faces significant restraints, notably the high initial capital expenditure required for sophisticated, commercial-grade equipment and the shortage of skilled operators capable of maintaining and efficiently running these complex machines. Furthermore, the variability in raw material supply (wood waste) and fluctuating fuel prices pose operational challenges, particularly for smaller contractors.

Opportunities within the market largely revolve around technological innovation. The shift towards electric and hybrid wood chippers addresses concerns related to emissions and noise pollution, appealing to urban and residential contractors. Moreover, market players have a substantial opportunity in developing specialized, compact machinery tailored for niche applications, such as orchard cleanup and vine removal in agriculture, which requires precision and mobility. The primary impact forces influencing market direction are technological advancements (driving efficiency and safety), environmental mandates (pushing sustainable waste management), and economic factors (capital investment costs and operational expenditure), all collectively determining the pace of market penetration and equipment replacement cycles across various end-user industries.

Segmentation Analysis

The Wood Chipper Market is highly segmented based on machinery type, power source, and intended end-use capacity, reflecting the diverse requirements of the global user base. The segmentation facilitates targeted product development, ensuring that forestry professionals, utility companies, and landscaping contractors can access machinery optimized for their specific volume and mobility needs. The market is primarily categorized by the design of the cutting mechanism—disc chippers offer faster processing of smaller materials and higher quality chips, while drum chippers are preferred for handling larger, bulkier logs and varied input material with less demanding chip uniformity standards. Analyzing these segments is critical for understanding market saturation levels and identifying high-growth sub-sectors, particularly in regions where biomass energy production is expanding rapidly.

- By Type:

- Drum Chipper

- Disc Chipper

- Screw/Cone Chipper

- By Power Source:

- PTO (Power Take-Off) Driven

- Engine Driven (Diesel/Gasoline)

- Electric/Hydraulic Driven

- By End-User:

- Forestry and Biomass

- Landscaping and Tree Care (Arboriculture)

- Municipal and Utility

- Agricultural and Horticulture

- By Capacity:

- Low Capacity (Below 6 inches diameter)

- Medium Capacity (6 to 12 inches diameter)

- High Capacity (Above 12 inches diameter)

Value Chain Analysis For Wood Chipper Market

The value chain for the Wood Chipper Market commences with upstream activities involving the sourcing of high-grade raw materials, primarily specialized steel alloys for cutting blades, heavy-duty chassis components, and advanced engine and hydraulic systems. Key upstream suppliers include steel manufacturers, engine producers (e.g., Cummins, John Deere, Perkins), and hydraulic component specialists. The core manufacturing process involves precision machining, assembly, and rigorous quality testing. Downstream activities focus heavily on distribution and post-sale support. Given the complexity and cost of the machinery, direct sales channels are common for large industrial units, often involving specialized manufacturer representatives who offer customized solutions and training.

The distribution channel is generally bifurcated into direct sales for major contracts, often involving highly customized, high-capacity machinery sold directly from the OEM (Original Equipment Manufacturer) to large forestry companies or government entities. Indirect distribution relies on an established global network of authorized dealerships and rental fleet companies. These dealers provide essential services, including local inventory, financing options, technical servicing, and genuine parts supply. This robust indirect network is crucial for reaching smaller end-users such as independent landscaping businesses and residential contractors. The efficiency of the distribution network, particularly the availability of prompt aftermarket service and spare parts, significantly influences brand loyalty and overall customer lifetime value.

Wood Chipper Market Potential Customers

The potential customer base for wood chippers is highly diversified, spanning multiple industries that generate significant quantities of wood and brush debris. The primary end-users are professional entities whose core business involves vegetation management or biomass utilization. Forestry companies are major buyers, seeking heavy-duty, high-throughput chippers to process logging slash efficiently for ecosystem health and commercial biomass fuel. Utility companies and transmission line maintenance crews utilize mobile chippers extensively for vegetation control along power lines and rights-of-way, prioritizing safety and reliability.

A rapidly expanding segment of buyers includes independent landscaping firms and arboriculture specialists. These professionals require highly mobile, engine-driven chippers, often trailer-mounted, capable of operating in diverse urban and suburban environments. Furthermore, municipal departments of public works are consistent purchasers, using chippers for park maintenance, storm cleanup, and street tree removal. Finally, the agricultural sector represents a growing niche, utilizing smaller to medium-capacity PTO-driven chippers for orchard pruning residue and vineyard waste management, transforming agricultural waste into beneficial mulch or soil amendments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850.0 Million USD |

| Market Forecast in 2033 | $1,350.0 Million USD |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vermeer Corporation, Bandit Industries Inc., Morbark (ASTEC), Jenz GmbH, FAE Group S.p.A., Rabaud, Terex Corporation (CBI), Doppstadt Calbe GmbH, Peterson Pacific Corp., ECHO Bear Cat, Pezzolato S.p.A., Lindner-Recyclingtech GmbH, Heizohack, Palax, Först, Rayco Manufacturing Inc., Crary Industries, Timberwolf, Wallenstein Equipment, Farmi Forest. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wood Chipper Market Key Technology Landscape

The Wood Chipper Market is undergoing continuous technological evolution driven by the demands for greater efficiency, reduced environmental impact, and enhanced operator safety. A primary technological focus involves the development of advanced engine systems compliant with stringent emissions standards, such as EPA Tier 4 Final and EU Stage V regulations. This has led to the integration of complex diesel particulate filters (DPF) and selective catalytic reduction (SCR) systems, which, while increasing complexity, ensure environmental adherence necessary for operating in regulated areas. Furthermore, hydraulic systems have seen advancements, allowing for smarter, load-sensing feed control mechanisms that maximize the engine's power output relative to the material being processed, thus optimizing fuel consumption and preventing overloading.

Safety technology represents another critical area of innovation. Modern commercial chippers incorporate sophisticated features such as emergency stop systems integrated into the feed tables, anti-jamming mechanisms, and remote-control capabilities. The integration of telematics and IoT sensors is rapidly becoming standard for fleet management. These systems allow operators and fleet managers to monitor crucial performance metrics in real-time, including operational hours, fuel level, engine diagnostics, and geographical location. This data is essential for optimizing maintenance schedules, managing equipment utilization across different job sites, and improving overall asset performance tracking, transforming how large organizations manage their wood chipping fleets.

Looking ahead, the development of electric and hybrid drive systems is poised to significantly disrupt the market, especially in urban environments where noise and emissions are primary concerns. Hybrid models combine a smaller internal combustion engine with battery packs, offering peak power boosts when needed while maintaining reduced overall running costs and environmental footprint. Concurrently, the mechanical design of the cutting rotors and blades continues to be refined, with manufacturers introducing specialized tungsten carbide-tipped blades that offer superior longevity and chip consistency, reducing the frequency of maintenance and downtime associated with blade replacement and sharpening.

Regional Highlights

Regional dynamics are highly varied, reflecting differences in forestry activity, regulatory environments, and the maturity of landscaping industries. North America, encompassing the United States and Canada, represents a mature market characterized by high demand for heavy-duty, self-propelled, and high-capacity drum and disc chippers. This region is dominated by large-scale forestry operations and highly professionalized tree care services, driving innovation in productivity and compliance with strict safety standards. The strong emphasis on infrastructure maintenance and recovery following severe weather events ensures sustained demand for reliable, powerful equipment.

Europe stands out for its strong regulatory push towards biomass energy utilization and noise reduction in urban settings. This has fostered rapid adoption of electric, hydraulic, and PTO-driven chippers, particularly those manufactured domestically that comply with EU Stage V emission standards. Countries like Germany, Sweden, and Finland are leaders in biomass pellet production, driving the market for industrial, high-volume chipping systems capable of producing highly uniform chips suitable for energy applications. Europe is also a key innovation hub for mobile chipping units designed for utility and municipal work.

The Asia Pacific (APAC) region is projected to exhibit the fastest growth over the forecast period. This rapid expansion is fueled by increasing urbanization, which necessitates extensive infrastructure development and subsequent land clearing. Governmental support for agricultural residue management in nations such as India and China provides a significant boost to demand for medium-capacity chippers. Furthermore, the burgeoning demand for sustainable wood materials and biomass power generation across Southeast Asia is attracting major international manufacturers to establish local distribution and servicing hubs, catering to diverse needs ranging from agricultural waste processing to commercial logging.

- North America: Dominant market share, driven by large commercial forestry operations, advanced arboriculture services, and stringent safety standards promoting high-performance, large-diameter capacity chippers.

- Europe: High adoption rates of environmentally friendly (electric/hybrid) chippers; strong regulatory emphasis on biomass usage and low-emission machinery (EU Stage V compliance).

- Asia Pacific (APAC): Fastest growing market segment, propelled by massive infrastructure development, increasing urbanization, and government initiatives promoting agricultural waste conversion and biomass fuel production.

- Latin America: Growing potential, tied to the expansion of commercial agriculture (e.g., fruit plantations) and sustainable logging practices, primarily adopting PTO-driven and medium-capacity engine-driven units.

- Middle East and Africa (MEA): Emerging market focused on municipal cleanup, landscaping for new urban centers, and managing palm/date tree residue, often relying on imported, durable equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wood Chipper Market.- Vermeer Corporation

- Bandit Industries Inc.

- Morbark (ASTEC Industries)

- Jenz GmbH

- FAE Group S.p.A.

- Rabaud

- Terex Corporation (CBI)

- Doppstadt Calbe GmbH

- Peterson Pacific Corp.

- ECHO Bear Cat

- Pezzolato S.p.A.

- Lindner-Recyclingtech GmbH

- Heizohack

- Palax

- Först (Global Recycling Solutions)

- Rayco Manufacturing Inc.

- Crary Industries

- Timberwolf

- Wallenstein Equipment

- Farmi Forest

Frequently Asked Questions

Analyze common user questions about the Wood Chipper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Drum and Disc wood chippers?

Drum chippers use a rotating drum with blades to aggressively process large, inconsistent materials, typically yielding less uniform chips, favored by forestry. Disc chippers use a flat rotating disc with knives, producing highly uniform chips, preferred for landscaping mulch and pelletizing feedstock.

How do emission standards impact the cost of new commercial wood chippers?

Stringent emission standards (like EPA Tier 4 Final/EU Stage V) require complex engine technologies such as SCR and DPF systems. These additions significantly increase the manufacturing complexity and component cost, directly translating to higher purchase prices for new commercial and industrial-grade chippers.

Which power source segment is experiencing the fastest growth?

The Engine Driven segment (specifically diesel) remains dominant for high-capacity machines, but the Electric/Hydraulic driven segment is experiencing rapid growth, driven by increasing adoption in urban and municipal environments due to lower noise pollution and zero tailpipe emissions.

What are the key safety innovations in modern wood chipping equipment?

Modern wood chippers prioritize operator safety through advanced features including automatic load-sensing feed systems, integrated electronic safety bars (Emergency Stop), and sophisticated anti-kickback mechanisms to ensure material flows safely into the cutting chamber.

What role does telematics play in the Wood Chipper Market?

Telematics enables real-time tracking of chipper performance, usage hours, fuel consumption, and geographical location. This data is critical for optimizing fleet efficiency, scheduling predictive maintenance, and ensuring timely service support, minimizing costly operational downtime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager