Wood-Fiber Gypsum Board Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432812 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Wood-Fiber Gypsum Board Market Size

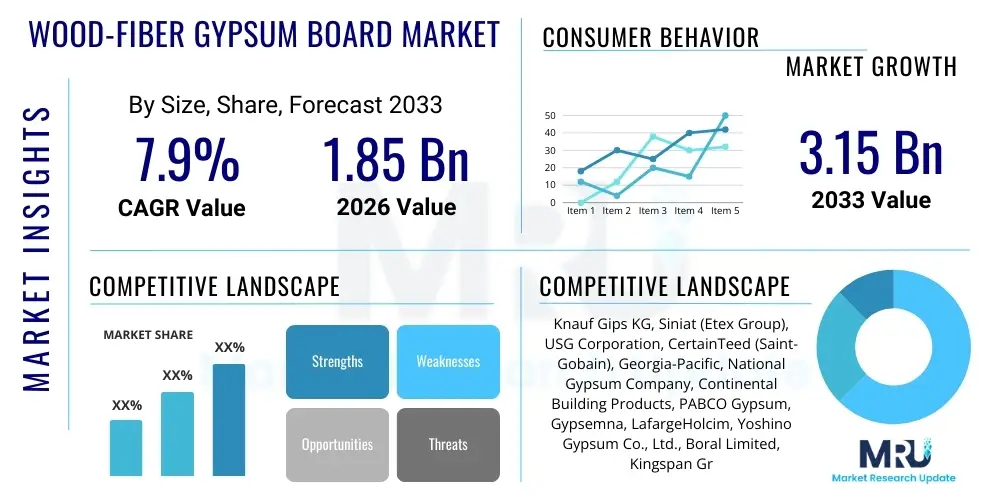

The Wood-Fiber Gypsum Board Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.9% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $3.15 Billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the global shift towards sustainable construction practices and stringent environmental regulations promoting the use of bio-based and recycled building materials. The intrinsic properties of wood-fiber gypsum board, such as enhanced fire resistance, superior thermal insulation, and exceptional acoustic performance, are making it an increasingly preferred choice over traditional gypsum boards in high-specification commercial and residential projects worldwide. Market penetration is accelerating across developed economies in North America and Europe, where green building certification standards mandate high material sustainability metrics.

Wood-Fiber Gypsum Board Market introduction

The Wood-Fiber Gypsum Board Market encompasses the production and distribution of specialized drywall panels manufactured using calcined gypsum, recycled paper fiber, or virgin wood fiber, and often reinforced with fiberglass or mineral fillers. Unlike conventional gypsum board, the inclusion of wood fibers provides greater density, enhanced structural integrity, and superior dimensional stability, making these boards highly resistant to warping and cracking, particularly beneficial in areas exposed to moderate humidity fluctuations. This product is defined by its ability to combine the benefits of mineral-based fire resistance with the tensile strength offered by organic fibers, resulting in a durable and eco-friendly construction material that meets demanding modern building codes globally.

Major applications of wood-fiber gypsum boards span across high-performance interior wall and ceiling systems, modular construction units, and specialized structural sheathing, predominantly utilized in residential, commercial, and institutional building sectors. Key driving factors fueling market growth include the rising imperative for energy-efficient buildings, which leverages the material’s high thermal mass and excellent insulation capabilities, coupled with consumer preference for non-combustible and non-toxic building products. Furthermore, advancements in manufacturing technology, which allow for lower cost production and wider availability of specialized wood-fiber formulations, are expanding the material’s competitive advantage against alternatives like oriented strand board (OSB) and standard plasterboard, ensuring its sustained market trajectory in the global construction landscape.

Wood-Fiber Gypsum Board Market Executive Summary

The Wood-Fiber Gypsum Board Market is poised for robust expansion, characterized by significant momentum in sustainable construction initiatives and technological innovations improving product versatility. Current business trends indicate a strong focus on supply chain resilience and the integration of highly automated production lines to meet the accelerating demand, particularly from the pre-fabricated and modular housing industries which rely heavily on high-specification, dimensionally stable materials. Furthermore, strategic alliances between raw material suppliers (especially recycled wood fiber providers) and major manufacturers are becoming common, aimed at securing consistent, high-quality input materials and adhering to circular economy principles. This collaborative approach minimizes volatility in raw material costs and enhances the overall sustainability footprint of the final product, directly appealing to ESG-focused investors and large construction firms.

Regional trends reveal that North America and Europe currently dominate consumption, driven by well-established green building frameworks such as LEED and BREEAM, and rigorous fire safety standards which wood-fiber boards inherently satisfy. However, the Asia Pacific region, particularly emerging economies like India and China, represents the fastest-growing segment, fueled by rapid urbanization, substantial investments in public infrastructure, and a nascent but quickly evolving awareness regarding energy efficiency in buildings. Segment trends highlight that thicker boards (15mm and above) designed for load-bearing or high-impact areas are experiencing higher value growth compared to standard partition boards. Additionally, the residential renovation sector is proving to be a highly lucrative segment, benefiting from the easy installation and superior finish quality that wood-fiber gypsum boards offer to homeowners undertaking sustainable upgrades.

AI Impact Analysis on Wood-Fiber Gypsum Board Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Wood-Fiber Gypsum Board Market frequently revolve around optimizing manufacturing efficiency, improving material composition quality control, and streamlining construction logistics. Users are keen to understand how AI-driven predictive maintenance can reduce downtime in capital-intensive production plants, and how machine learning algorithms can analyze sensor data to precisely control the mixing ratios of gypsum, water, and wood fibers, thereby guaranteeing consistent density and performance characteristics in every batch. Another dominant theme is AI's role in optimizing inventory management and dynamic supply chain routing, particularly concerning the just-in-time delivery of bulky construction materials to complex urban job sites. The expectation is that AI will enhance material yield, minimize waste, and enable highly customized product specifications tailored to specific architectural demands, transforming traditional manufacturing processes into predictive and adaptive systems.

- AI optimizes raw material sourcing by predicting supply chain disruptions and volatile pricing of wood fibers and gypsum.

- Machine learning enhances product quality control by analyzing real-time sensor data during the drying and curing phases to detect density and moisture inconsistencies.

- Predictive maintenance algorithms reduce factory downtime by forecasting equipment failures in high-speed board production lines.

- AI-driven generative design assists architects in selecting optimal wood-fiber board specifications (thickness, density) for structural and acoustic performance requirements.

- Automation powered by computer vision systems streamlines sorting and packaging, reducing labor costs and improving operational efficiency.

DRO & Impact Forces Of Wood-Fiber Gypsum Board Market

The Wood-Fiber Gypsum Board Market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces shaping its trajectory. The primary driver is the accelerating global mandate for sustainable and green building materials, placing wood-fiber gypsum board—known for its use of recycled content and lower carbon footprint compared to cementitious alternatives—at the forefront of compliant construction. This is significantly amplified by stringent fire safety and energy efficiency regulations implemented across major industrialized nations. Conversely, the market faces restraints predominantly related to the relatively higher initial cost compared to conventional gypsum wallboard, which can deter adoption in price-sensitive developing markets. Additionally, the dependence on a steady supply of high-quality wood fiber waste or specialized virgin fiber sources introduces volatility and logistical complexities into the supply chain, occasionally constraining large-scale production expansion.

Significant opportunities abound through technological advancements focused on improving water resistance and simplifying installation procedures, which could unlock substantial growth in exterior sheathing applications currently dominated by other materials. Furthermore, the growing trend of modular and prefabricated construction offers a fertile ground for market penetration, as wood-fiber boards are highly suitable for off-site manufacturing due to their dimensional stability and ease of precision cutting. The market’s impact forces are currently skewed toward positive growth, driven by environmental mandates and performance superiority, overshadowing persistent cost barriers. The strongest impact force is the regulatory push towards carbon neutrality in the built environment, compelling developers and builders globally to prioritize materials with verifiable environmental product declarations (EPDs), a category where wood-fiber gypsum board excels.

The long-term outlook suggests that successful navigation of these forces will depend on manufacturers' ability to achieve economies of scale, thereby narrowing the price gap between wood-fiber and standard gypsum products. Investing in regional production hubs close to reliable fiber sources and developing specialized, high-margin products tailored for extreme weather resistance or specific acoustic performance will be critical strategic moves. The increasing global focus on Indoor Air Quality (IAQ) also acts as an opportunity, as these boards typically contain fewer volatile organic compounds (VOCs) than many alternatives, providing a distinct competitive advantage in health-conscious building projects, further solidifying their positioning as premium, performance-driven materials.

Segmentation Analysis

The Wood-Fiber Gypsum Board Market is comprehensively segmented based on various critical parameters including thickness, application, end-user type, and geographical region. Segmentation by thickness is crucial as it directly relates to the board's structural and performance capabilities, distinguishing between standard interior partitions and heavy-duty fire-rated or sound-insulating assemblies. Segmentation by application allows the market to be analyzed based on the specific end-use environment, such as wall partitions, ceilings, or specialized external sheathing. The end-user segment differentiates demand patterns between high-volume residential construction, demanding commercial projects (offices, retail), and highly specialized institutional facilities (hospitals, schools), each having unique requirements regarding fire rating, durability, and acoustic performance.

- By Thickness:

- Standard Thickness (9.5 mm – 12.5 mm)

- Thick Board (15 mm – 25 mm)

- By Application:

- Interior Wall Partitions

- Ceiling Systems

- Structural Sheathing

- Acoustic Panels

- By End-User:

- Residential Construction (New Builds and Renovation)

- Commercial Infrastructure (Offices, Retail, Hospitality)

- Institutional Buildings (Hospitals, Educational Facilities)

- Industrial Construction

- By Region:

- North America (US, Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain)

- Asia Pacific (China, India, Japan, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA)

Value Chain Analysis For Wood-Fiber Gypsum Board Market

The value chain for the Wood-Fiber Gypsum Board Market begins with robust upstream analysis focusing on the secure and sustainable sourcing of key raw materials: calcined gypsum (both natural and synthetic), recycled wood fibers or cellulose materials, and necessary chemical additives (starch, foam, emulsifiers). Upstream efficiency is paramount, especially regarding the utilization of industrial waste gypsum (flue-gas desulfurization gypsum) and recycled paper/wood waste, which significantly lowers production costs and enhances the product’s environmental profile. Strong relationships with reliable gypsum mining operations or industrial waste generators, coupled with efficient logistics for transporting bulky fibrous materials, define competitive advantage at this stage. Manufacturers employing advanced pulping and mixing technologies to ensure fiber consistency gain a quality edge, as inconsistent fiber distribution can compromise the final board’s mechanical performance, specifically its resistance to impact and bending.

The core manufacturing process, involving blending, continuous forming, precise cutting, and energy-intensive drying, is where value addition is maximized. Downstream analysis focuses on effective distribution channels and end-user engagement. Distribution channels are typically dual: direct sales to major construction developers, large prefabricated housing companies, and national hardware chains (indirect), and direct sales to specialized contractors or architectural specification firms seeking tailored solutions. The complexity of logistics is high due to the product's large size, fragility, and weight, necessitating specialized warehousing and transportation infrastructure capable of minimizing breakage and handling costs. Effective downstream strategy also includes rigorous technical support and training for installers, ensuring proper application which is critical for maximizing the high-performance features of wood-fiber boards.

The interplay between direct and indirect distribution relies heavily on regional market maturity. In mature markets like Western Europe, indirect channels dominate through extensive networks of specialized building material distributors who offer financing and localized stockholding. Conversely, in emerging Asian markets or for highly bespoke projects globally, manufacturers often utilize direct sales to manage quality assurance and control pricing. Successful firms optimize their value chain by vertically integrating key processes, such as securing long-term supply agreements for recycled inputs and investing in highly automated production facilities that minimize energy consumption during the drying phase, addressing both cost efficiency and sustainability concerns simultaneously. This strategic focus ensures that the premium product attributes are delivered efficiently to the final point of consumption, maximizing profitability and market reach.

Wood-Fiber Gypsum Board Market Potential Customers

The potential customers for Wood-Fiber Gypsum Board products are diverse, primarily spanning three major categories within the construction ecosystem: large-scale general contractors specializing in high-end commercial projects, residential developers focused on sustainable and energy-efficient housing, and governmental/institutional bodies funding public infrastructure. General contractors are primary buyers, driven by the material’s ability to meet stringent fire-rating, acoustic isolation, and durability specifications required in high-traffic or specialized commercial spaces like data centers, hotels, and high-rise office towers. Their purchasing decision is heavily influenced by verified performance data, supply reliability, and compliance with specific regional building codes, making them highly technical and quality-focused buyers who value long-term material integrity over marginal initial cost savings.

Residential developers, particularly those operating in markets subject to high environmental regulatory scrutiny, constitute a rapidly expanding customer base. These developers prioritize materials that contribute positively to green building certifications (e.g., Passive House or zero-energy standards) and offer improved insulation capabilities, which translates directly into lower long-term operating costs for homeowners. For this segment, the material's excellent dimensional stability and superior surface quality, facilitating easier finishing and aesthetic integration, are key selling points. The increasing demand for prefabricated and modular residential units further elevates this segment’s importance, as wood-fiber boards are highly suitable for precision manufacturing processes required in off-site construction, demanding reliable and consistent product quality.

Institutional purchasers, including government agencies managing school construction or healthcare facility expansion, represent another critical end-user group. These buyers prioritize non-toxic materials with exceptional longevity and proven resistance to mold and moisture, alongside critical fire safety credentials. Their procurement cycles are often long and rely on public tenders and detailed product specifications. Successful engagement with this customer segment requires comprehensive documentation, compliance with public procurement guidelines, and evidence of substantial lifespan performance. Ultimately, the end-user/buyer decision across all segments is migrating away from simple commodity pricing toward a holistic assessment of lifecycle cost, safety features, environmental stewardship, and building performance optimization, benefiting the premium positioning of wood-fiber gypsum board.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $3.15 Billion |

| Growth Rate | 7.9% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Knauf Gips KG, Siniat (Etex Group), USG Corporation, CertainTeed (Saint-Gobain), Georgia-Pacific, National Gypsum Company, Continental Building Products, PABCO Gypsum, Gypsemna, LafargeHolcim, Yoshino Gypsum Co., Ltd., Boral Limited, Kingspan Group, Eko-Light Gypsum, Vogl Deckensysteme |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wood-Fiber Gypsum Board Market Key Technology Landscape

The manufacturing technology underpinning the Wood-Fiber Gypsum Board Market is characterized by continuous innovation aimed at optimizing material homogenization, reducing energy consumption during the extensive drying process, and enhancing the physical properties of the final product. A key technological focus is on advanced blending systems that ensure a uniform dispersion of wood fibers within the gypsum slurry. This uniformity is critical for achieving consistent density, fire resistance, and superior bending strength. Modern production facilities utilize high-shear mixers and advanced pumping mechanisms to prevent fiber clumping, which would otherwise lead to structural weaknesses. Furthermore, the integration of specialized chemical additives, including proprietary binders and accelerators, is constantly being refined to improve the reaction kinetics of gypsum setting, allowing for faster processing speeds without compromising the mechanical integrity of the final board, thereby improving overall throughput and lowering unit costs substantially.

Another crucial area of technological advancement is in the drying kilns. Since wood-fiber gypsum board often has a higher moisture content requirement than standard gypsum board during forming, the drying phase is extremely energy-intensive. Manufacturers are increasingly adopting highly efficient, multi-zone drying systems that utilize waste heat recovery (WHR) and advanced moisture monitoring sensors. These systems allow for precise control over temperature and humidity gradients, minimizing the risk of internal stresses and cracks developing in the board while simultaneously drastically reducing the natural gas or electricity required for the process. This shift towards sustainable, energy-saving drying technology not only addresses operational costs but also aligns with the inherent environmental mandate of the product itself, reinforcing its market position as a green building solution.

The contemporary technology landscape also includes significant investment in robotics and automation for handling and finishing processes. Precision cutting using laser or waterjet technology ensures perfectly square edges and custom dimensions with minimal material waste, which is particularly vital for the modular construction industry. Furthermore, surface treatment technologies are evolving, allowing for the application of enhanced moisture barriers or specialized acoustic coatings directly on the board during the final stages of production. These technological enhancements enable manufacturers to produce highly specialized, value-added products (e.g., boards with integrated thermal insulation layers or high-impact resistance) that command premium pricing and penetrate niche markets such as high-performance sound studios and laboratories, thereby ensuring sustained profitability and market differentiation in an increasingly competitive environment.

Regional Highlights

The global distribution and consumption patterns of Wood-Fiber Gypsum Board are highly disparate, largely driven by regional regulatory environments, construction material preferences, and economic development levels. North America and Europe stand out as the mature markets, characterized by high adoption rates stemming from decades of focus on energy efficiency and standardized building codes prioritizing non-combustible, sustainable materials. The rapid adoption of green building standards and the robust demand from the renovation sector ensure stable, high-value growth in these regions. Conversely, the Asia Pacific region is the projected high-growth engine, driven by massive urbanization projects and infrastructure investments, coupled with increasing environmental awareness which is starting to influence material selection in large metropolitan areas.

- North America (US & Canada): Dominant market share due to stringent fire codes, particularly in high-rise commercial structures, and strong consumer demand for certified green building materials (LEED). High levels of modular construction adoption further boost demand for dimensionally stable boards.

- Europe (Germany, UK, France): Characterized by highly mature markets with established preference for high-performance acoustic and thermal insulation. Strong governmental subsidies for energy efficient retrofitting programs actively drive product usage in the renovation sector. Germany and Scandinavia are key innovators in sustainable building materials.

- Asia Pacific (China, India, Japan): Fastest-growing region. Growth is driven by rapid infrastructural expansion, government initiatives promoting sustainable construction practices, and increasing disposable incomes leading to higher expectations for indoor air quality and structural durability in new residential complexes.

- Latin America: Emerging market with increasing penetration, primarily focused on seismic resilience and cost-effective structural solutions. Market growth is heavily dependent on economic stability and harmonization of building standards across key economies like Brazil and Mexico.

- Middle East & Africa (MEA): Niche but growing market, predominantly confined to large commercial and governmental projects in the GCC states (UAE, Saudi Arabia) requiring premium, high-specification materials to withstand extreme temperatures and meet luxury interior finish standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wood-Fiber Gypsum Board Market.- Knauf Gips KG

- Siniat (Etex Group)

- USG Corporation

- CertainTeed (Saint-Gobain)

- Georgia-Pacific

- National Gypsum Company

- Continental Building Products

- PABCO Gypsum

- Gypsemna

- LafargeHolcim

- Yoshino Gypsum Co., Ltd.

- Boral Limited

- Kingspan Group

- Eko-Light Gypsum

- Vogl Deckensysteme

- Fermacell GmbH (James Hardie Industries)

- Etex Building Performance

- Gyproc (Saint-Gobain)

- ACG Materials

- Sto SE & Co. KGaA

Frequently Asked Questions

Analyze common user questions about the Wood-Fiber Gypsum Board market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes Wood-Fiber Gypsum Board from standard drywall?

Wood-Fiber Gypsum Board is fundamentally distinct due to the incorporation of wood or cellulose fibers, which provides superior structural integrity, enhanced density, and greater resistance to impact and warping compared to conventional gypsum board. This composition also often results in better acoustic and fire performance ratings, making it ideal for high-specification construction projects requiring durability and high performance.

What are the primary applications and benefits of using Wood-Fiber Gypsum Boards?

The primary applications include interior wall partitions, ceiling systems, and structural sheathing, particularly in projects focused on sustainability and energy efficiency. Key benefits are superior fire resistance, excellent sound insulation (acoustic dampening), high durability, non-toxic composition, and contribution to green building certifications due to its recycled content and lower carbon footprint.

Which geographical region exhibits the fastest growth potential in this market?

The Asia Pacific (APAC) region, driven primarily by rapid urbanization and massive infrastructure investment in countries like China and India, is projected to exhibit the fastest Compound Annual Growth Rate (CAGR). The increasing adoption of international building standards and rising environmental awareness are fueling this accelerated market expansion in Asia Pacific.

How does the cost of Wood-Fiber Gypsum Board compare to traditional gypsum products?

Wood-Fiber Gypsum Board generally carries a higher initial unit cost compared to traditional standard drywall. This premium is justified by its superior performance characteristics, including enhanced density, durability, and better fire and acoustic ratings. However, when assessing total lifecycle costs, the long-term benefits in terms of reduced maintenance and energy savings often offset the higher upfront expenditure.

What role does sustainability play in the market growth of Wood-Fiber Gypsum Board?

Sustainability is a critical driver for market growth. These boards typically utilize recycled wood or paper fibers, aligning with circular economy principles. Furthermore, their non-combustible and low-VOC nature makes them compliant with strict green building standards (e.g., LEED, BREEAM), making them highly attractive to developers targeting environmentally responsible and healthy building certifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager