Wood Lathe Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431684 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Wood Lathe Market Size

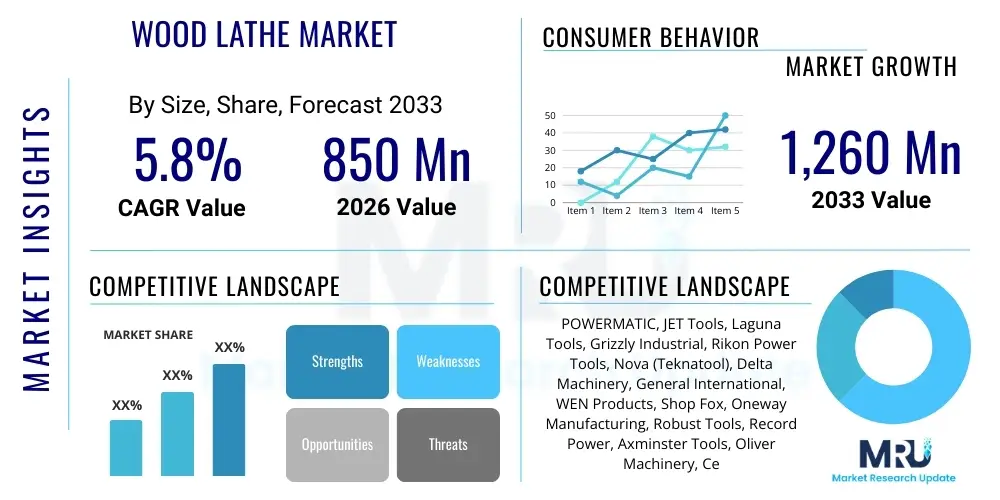

The Wood Lathe Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,260 Million by the end of the forecast period in 2033.

Wood Lathe Market introduction

The Wood Lathe Market encompasses the manufacturing, distribution, and sales of machinery designed to rotate a piece of wood (the workpiece) around an axis of rotation, allowing for operations such as cutting, sanding, knurling, drilling, or deformation using specialized tools. These machines are fundamental to woodturning, which transforms rough lumber into symmetrical objects like bowls, spindles, chair legs, and decorative items. The core product categories include benchtop lathes, midi lathes, and heavy-duty floor-standing lathes, catering to varying levels of usage intensity, from amateur hobbyists and educational institutions to large-scale industrial furniture and fixture producers. Market growth is closely tied to the global resurgence in artisanal crafts, DIY (Do-It-Yourself) activities, and continued industrial demand from construction and interior design sectors.

The primary applications of wood lathes span across custom woodworking, furniture manufacturing, decorative arts, and educational vocational training. Key benefits of using modern wood lathes include high precision, repeatability of complex shapes, improved surface finish quality, and enhanced safety features such as electronic braking systems and robust construction. The evolution of variable speed controls, digital readouts (DROs), and computer numerical control (CNC) integration is significantly enhancing the capabilities and accessibility of these machines, widening the scope of intricate projects that can be undertaken. Furthermore, specialized accessories, including steady rests, faceplates, and specific chuck systems, contribute substantially to the versatility and overall value proposition of contemporary wood lathe equipment.

Driving factors propelling the expansion of the Wood Lathe Market include increasing disposable income leading to higher spending on home improvement and hobby equipment, the growing popularity of woodworking as a recreational activity across developed nations, and the consistent demand from the established cabinetmaking and customized architectural millwork industries. Technological advancements focused on making machines quieter, more powerful, and easier to use—such as incorporating smart features for operational feedback and maintenance alerts—are attracting a newer generation of woodworkers. Additionally, the replacement cycle for older, less efficient industrial equipment is contributing to sustained demand for high-performance, precision-engineered wood lathes globally.

Wood Lathe Market Executive Summary

The Wood Lathe Market is experiencing robust growth driven by converging trends in both industrial automation and consumer-focused DIY segments. Business trends indicate a shift towards specialized, high-precision CNC wood lathes for mass production, especially in large-scale furniture manufacturing centers in Asia Pacific, focusing on maximizing throughput and minimizing material waste. Concurrently, the consumer segment is driving demand for compact, feature-rich midi and benchtop lathes, characterized by easy setup, robust safety features, and comprehensive accessory availability. Key players are focusing intensely on developing proprietary vibration dampening technologies and enhancing digital interfaces to maintain a competitive edge and optimize the user experience across all product tiers. The market structure remains fragmented, though consolidation is anticipated among manufacturers specializing in high-end industrial machinery.

Regionally, North America and Europe remain mature markets characterized by high adoption rates of premium, digitally enabled machinery for both industrial and hobbyist applications, driven by strong consumer interest in bespoke furniture and handcrafted goods. Asia Pacific, particularly China and India, presents the highest growth potential, fueled by massive infrastructure development, burgeoning furniture export industries, and the rapid establishment of vocational training centers requiring reliable, cost-effective equipment. Regional trends also highlight regulatory scrutiny regarding dust extraction and noise reduction, compelling manufacturers to integrate advanced environmental and safety compliance features, which influences the average selling price and design complexity of new models.

Segmentation trends indicate that variable speed lathes are rapidly dominating fixed speed counterparts due to their versatility and efficiency in handling different wood types and turning styles. Within the application segment, the consumer/hobbyist category, encompassing small workshops and individual enthusiasts, holds a significant volume share, while the industrial segment, driven by large manufacturers, accounts for the majority of market value due to the purchase of high-capacity, heavy-duty machinery. Material and build quality remain paramount, with cast iron body construction continuing to be the standard benchmark for minimizing vibration and ensuring long-term durability, even as composite materials are explored for weight reduction in portable models.

AI Impact Analysis on Wood Lathe Market

Common user questions regarding AI's impact on the Wood Lathe Market frequently revolve around potential automation levels, how AI can assist beginners in achieving professional results, and the role of predictive maintenance in minimizing industrial downtime. Users are concerned about whether AI integration will lead to the obsolescence of traditional skills but are simultaneously eager for tools that enhance precision and efficiency. Key themes summarize the desire for AI-powered diagnostics for optimal tool path generation, defect detection in finished pieces, and integrated machine learning algorithms that suggest ideal cutting speeds and feeds based on wood density and project specifications, effectively bridging the gap between highly skilled and novice users.

- AI-driven optimization of tool cutting parameters based on real-time acoustic and vibrational feedback.

- Predictive maintenance analytics for industrial CNC lathes, reducing unplanned downtime and optimizing component replacement cycles.

- Automated quality control systems using computer vision to detect subtle surface imperfections or dimensional deviations in mass-produced items.

- AI-assisted design generation for complex geometric woodturning projects, simplifying CAD-to-G-code conversion.

- Personalized training modules and feedback systems integrated into smart lathes for educational and hobbyist users.

- Enhanced safety protocols through AI monitoring of abnormal operational patterns that indicate potential hazards or machine failure.

- Optimized inventory management for industrial users by predicting tooling wear and usage rates.

DRO & Impact Forces Of Wood Lathe Market

The dynamics of the Wood Lathe Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively constitute the Impact Forces influencing market trajectory. The primary drivers include the global economic recovery bolstering construction and furniture sectors, the increasing demand for customizable and handcrafted wood products, and the rise of vocational education emphasizing practical woodworking skills. However, the market faces significant restraints, notably the high initial investment cost associated with professional-grade industrial lathes and the ongoing challenge of securing skilled labor proficient in operating and maintaining advanced CNC woodturning equipment. Opportunities arise from the rapidly expanding DIY and maker movement, the potential for incorporating advanced sensor technology for enhanced user safety, and the development of lightweight, powerful cordless options for mobile professionals.

The impact forces are substantial, particularly from technological innovation. The continuous integration of sophisticated digital controls, like high-resolution Digital Readouts (DROs) and closed-loop servo systems, significantly improves precision, thereby making the finished products more competitive in global markets. Simultaneously, economic volatility and supply chain disruptions, particularly regarding the sourcing of specialized cast iron and electronic components, act as significant impact forces that can constrain short-term manufacturing output and inflate retail prices. Furthermore, intense competition among regional manufacturers in Asia Pacific forces constant price adjustments, which puts downward pressure on margins, particularly in the lower-end benchtop segment.

The market's ability to capitalize on the opportunity presented by increasing consumer demand for personalized crafts is a critical determinant of future growth. Manufacturers are strategically positioning entry-level and mid-range products with aggressive pricing and bundled accessory offers to capture the expanding hobbyist base. Conversely, the restraint related to energy consumption and environmental regulations—especially concerning wood dust—demands continuous investment in sophisticated dust management systems, adding to the overall cost of ownership for both industrial and serious amateur users, thus acting as a counteracting force against rapid market expansion.

Segmentation Analysis

The Wood Lathe Market is comprehensively segmented based on product type, speed type, application, and distribution channel, allowing for targeted analysis of consumer behavior and industrial purchasing patterns. Product type segmentation distinguishes between high-capacity industrial machines and smaller, more accessible hobbyist equipment, each requiring different technological specifications and marketing strategies. Speed type differentiation highlights the shift towards variable speed controls, providing operators with greater flexibility and control over the turning process, which is essential for working with diverse materials ranging from softwoods to dense exotic hardwoods. Application segmentation clearly delineates the distinct needs of mass-production environments versus personalized artisanal creation, influencing machine size, power, and durability requirements across the board.

- By Product Type:

- Benchtop Lathes

- Midi Lathes

- Full-Size/Floor Standing Lathes

- CNC Wood Lathes

- By Speed Type:

- Variable Speed Lathes

- Fixed Speed Lathes

- By Application:

- Industrial Manufacturing (Furniture, Architectural Millwork)

- Hobbyist/Consumer Use

- Educational Institutions and Vocational Training

- By Distribution Channel:

- Online Retailers/E-commerce

- Specialty Stores/Hardware Stores

- Direct Sales (Industrial B2B)

Value Chain Analysis For Wood Lathe Market

The Wood Lathe Market value chain begins with upstream activities involving the sourcing and processing of raw materials, primarily high-grade cast iron, steel, specialized electronic components (motors, controllers, DRO systems), and precision bearings. Upstream analysis focuses on managing raw material price volatility and ensuring the quality and consistency of casting processes, which are critical for the vibration dampening properties of the lathe beds. Manufacturers must maintain robust relationships with specialized component suppliers, especially for sensitive electronic controls and high-efficiency motors, which drive the machine's performance specifications. Supply chain resilience, particularly post-global disruptions, has become a key strategic priority for manufacturers to ensure uninterrupted production schedules and competitive pricing structures.

Midstream activities encompass the core manufacturing, assembly, quality assurance, and branding processes. This stage involves sophisticated machining of precision parts, integration of complex electronics (especially for CNC and variable speed models), and rigorous testing protocols to meet global safety standards (e.g., CE, UL). Manufacturers increasingly invest in modular designs to simplify customization and assembly, allowing for efficient production of various models, from entry-level benchtop units to heavy-duty industrial machines. Key differentiation at this stage lies in proprietary technology integration, such as specialized spindle systems or vibration isolation techniques, which contribute significantly to the perceived quality and premium pricing of certain brands.

Downstream analysis covers the distribution channels, market reach, and after-sales support. Distribution is segmented into direct sales (crucial for large industrial clients purchasing bespoke CNC systems), specialty retailers (offering expert advice and hands-on demonstrations to serious hobbyists), and the rapidly expanding e-commerce platform (dominating the sale of entry-level and accessory products). The shift towards online sales necessitates robust logistics for handling heavy, bulky machinery and scalable, efficient customer support services. Effective after-sales support, including warranty services, parts availability, and technical training, is a crucial factor in customer satisfaction and brand loyalty, especially given the long operational life expectancy of quality wood lathes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,260 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | POWERMATIC, JET Tools, Laguna Tools, Grizzly Industrial, Rikon Power Tools, Nova (Teknatool), Delta Machinery, General International, WEN Products, Shop Fox, Oneway Manufacturing, Robust Tools, Record Power, Axminster Tools, Oliver Machinery, Central Machinery, Manta Woodworking Machinery, Scheppach, Charnwood, Steel City Tool Works |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Wood Lathe Market Key Technology Landscape

The Wood Lathe Market is increasingly defined by technological advancements centered on precision, safety, and user-friendliness, moving far beyond traditional belt-driven systems. A crucial technological shift is the widespread adoption of Electronic Variable Speed (EVS) controls utilizing VFDs (Variable Frequency Drives). This technology allows for seamless, instantaneous speed adjustments without physically changing belt positions, optimizing the cutting environment for different materials and project stages, which is critical for reducing vibration and improving material removal rates. Furthermore, the integration of high-definition Digital Readouts (DROs) provides woodturners with accurate real-time feedback on spindle speed and tool positioning, dramatically improving the repeatability and accuracy of complex, dimensionally critical turnings, thereby justifying the premium cost associated with these advanced features. The focus on motor technology has also intensified, with high-torque, brushless induction motors becoming standard in mid-to-high-range models, offering increased efficiency and reduced maintenance requirements compared to older AC motor designs.

The emergence of Computer Numerical Control (CNC) wood lathes represents the pinnacle of technological integration in the industrial segment. These highly sophisticated machines utilize multi-axis controls and complex software to execute repetitive, intricate designs with unparalleled precision and speed, transforming mass production capabilities for items like stair balusters and custom architectural elements. CNC systems require highly specialized programming interfaces and robust servo motor mechanisms capable of sustaining high load demands over extended operational periods. Beyond industrial applications, technology is also influencing safety and ease of use for hobbyists. Innovations include electronic safety features such as proximity sensors that immediately stop the spindle upon detecting excessive vibration or unusual force, integrated electronic braking systems that halt the workpiece much faster than mechanical brakes, and specialized vibration-dampening polymer compounds embedded within the cast iron bodies to ensure stable operation even under significant imbalance, significantly enhancing the operational safety profile of the machinery.

Furthermore, connectivity and IoT integration are beginning to penetrate the high-end industrial lathe sector, allowing for remote diagnostics, performance monitoring, and integration into broader manufacturing execution systems (MES). This integration facilitates predictive maintenance, where sensors track spindle temperature, motor load, and vibration levels to forecast potential failures before they occur, maximizing operational uptime. Another notable technological trend is the modular design philosophy, allowing users to easily expand their lathe's capacity—for instance, by adding bed extensions or outboard turning attachments—to accommodate larger or more irregular workpieces. This modularity ensures that the equipment remains relevant and adaptable as the user's skill set and project requirements evolve over time, offering superior long-term investment value compared to fixed-specification machinery.

Regional Highlights

The Wood Lathe Market exhibits distinct characteristics across major geographical regions, driven by localized economic conditions, consumer preferences, and industrial maturity.

- North America: A mature market characterized by high consumer spending on woodworking hobbies and a robust industrial sector focused on custom millwork and high-end furniture. The demand is heavily skewed towards high-quality, feature-rich midi and full-size lathes, with strong uptake of CNC technology for precision industrial applications. Safety compliance and ergonomic design are key purchasing criteria.

- Europe: Dominated by stringent quality standards and a strong tradition of precision engineering. Countries like Germany and Italy are major hubs for industrial machinery manufacturing and export. Demand is strong in both professional workshops and educational settings, with increasing interest in highly efficient, low-vibration machines and integrated dust extraction systems to comply with strict occupational safety regulations.

- Asia Pacific (APAC): The fastest-growing region due to rapid urbanization, increasing manufacturing output (particularly in China and Southeast Asia), and rising disposable incomes fueling demand for furniture. The region balances high-volume, cost-effective industrial lathe procurement with growing demand for entry-level hobbyist machines. China is a major producer and consumer, driving competitive pricing across the lower and mid-range segments.

- Latin America: Characterized by gradual market expansion, primarily focused on supporting local construction and furniture markets. Adoption of sophisticated CNC technology is slower compared to North America and Europe, with demand focusing mainly on reliable, moderately priced full-size lathes for small to medium-sized enterprises (SMEs).

- Middle East and Africa (MEA): A nascent market segment driven largely by large infrastructure projects and commercial interior design. Demand is specialized, often requiring heavy-duty industrial lathes for architectural millwork and hotel outfitting. Growth is uneven, concentrated in economically stable Gulf Cooperation Council (GCC) countries where significant construction activity occurs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Wood Lathe Market.- POWERMATIC

- JET Tools

- Laguna Tools

- Grizzly Industrial

- Rikon Power Tools

- Nova (Teknatool)

- Delta Machinery

- General International

- WEN Products

- Shop Fox

- Oneway Manufacturing

- Robust Tools

- Record Power

- Axminster Tools

- Oliver Machinery

- Central Machinery

- Manta Woodworking Machinery

- Scheppach

- Charnwood

- Steel City Tool Works

Frequently Asked Questions

Analyze common user questions about the Wood Lathe market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Wood Lathe Market?

The market is primarily driven by the increasing global interest in DIY projects and woodworking hobbies, sustained demand from the furniture and architectural millwork industries, and technological advancements such as the integration of variable speed controls and enhanced safety features. Economic growth supporting home improvement spending is also a key factor.

How does CNC technology impact industrial woodturning applications?

CNC technology significantly impacts industrial woodturning by enabling high-volume, high-precision production of complex, repetitive parts like balusters and spindles. It reduces reliance on highly specialized manual labor, minimizes material waste, and ensures unparalleled dimensional accuracy and repeatability across large batches.

Which geographical region exhibits the highest growth potential for wood lathe sales?

The Asia Pacific (APAC) region, driven by rapid urbanization, massive furniture manufacturing exports, and increasing vocational training initiatives in countries like China and India, holds the highest growth potential for the wood lathe market during the forecast period.

What key safety features should modern wood lathes include?

Modern wood lathes should integrate crucial safety features, including electronic braking systems for rapid spindle stop, robust cast iron construction for stability, safety switches, and optimized vibration dampening technology. Advanced models also incorporate electronic sensors to monitor imbalances and excessive tool pressure to prevent kickback.

What is the main distinction between benchtop and floor standing wood lathes?

The main distinction lies in size, capacity, and power. Benchtop lathes are smaller, portable, and generally used by hobbyists for smaller projects, offering lower swing and length capacities. Floor standing lathes are heavy-duty, permanent installations designed for industrial or professional use, offering much larger swing diameters, greater power, and enhanced stability necessary for turning large or heavy workpieces.

The extensive analysis of the Wood Lathe Market reveals a sophisticated ecosystem where traditional craftsmanship intersects seamlessly with modern technological integration. The robust growth projected across the forecast period underscores the enduring appeal of woodturning, catalyzed by market demand for customized wooden goods and the accessibility provided by advanced machinery. Industrial players continue to prioritize CNC adoption for efficiency gains, while the consumer segment drives innovation in compact, safe, and feature-rich midi and benchtop models. Maintaining strict quality control and investing in supply chain resilience remain paramount for market leaders to secure their competitive positions against emerging regional competitors. Furthermore, strategic integration of IoT and predictive maintenance capabilities will be crucial for capturing long-term value in the high-end industrial sector. The geographical disparity in market maturity, with rapid expansion in APAC contrasted by stable replacement cycles in North America and Europe, necessitates tailored product development and distribution strategies focused on regional compliance requirements and consumer purchasing power.

Future opportunities in the Wood Lathe Market are intrinsically linked to sustainable manufacturing practices and educational outreach. Manufacturers demonstrating commitment to developing energy-efficient motors and incorporating recycled or sustainably sourced materials in their construction will likely gain favor among environmentally conscious consumers and corporations. Moreover, the increasing adoption of virtual reality (VR) and augmented reality (AR) for machine operation training and troubleshooting represents a significant, yet nascent, opportunity to overcome the current restraint related to the shortage of skilled labor. By providing immersive, low-risk training environments, manufacturers can accelerate the proficiency curve for new users, thereby expanding the overall market base. The long-term trajectory is positive, supported by global cultural trends favoring bespoke, handcrafted items over mass-produced standardized alternatives, reinforcing the foundational demand for versatile and reliable woodturning equipment.

The complex interplay between technological forces, regulatory frameworks, and consumer dynamics shapes the competitive landscape. Innovation in tooling materials, aimed at increasing longevity and reducing friction, complements the advancements in machine design. Specialized carbide-tipped tools, for example, are gaining traction due to their ability to hold an edge significantly longer than traditional high-speed steel (HSS) tools, minimizing downtime for sharpening and improving overall productivity, especially in high-volume industrial environments. The focus on reducing noise and vibration, not only for regulatory compliance but also for user comfort, continues to drive engineering investments. As the market matures, product differentiation will increasingly rely on proprietary digital ecosystems, including exclusive training content, project libraries, and direct communication channels for personalized technical support, cementing customer loyalty and brand authority in a highly competitive global arena.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager