X-Ray Diffraction Instrument Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431523 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

X-Ray Diffraction Instrument Market Size

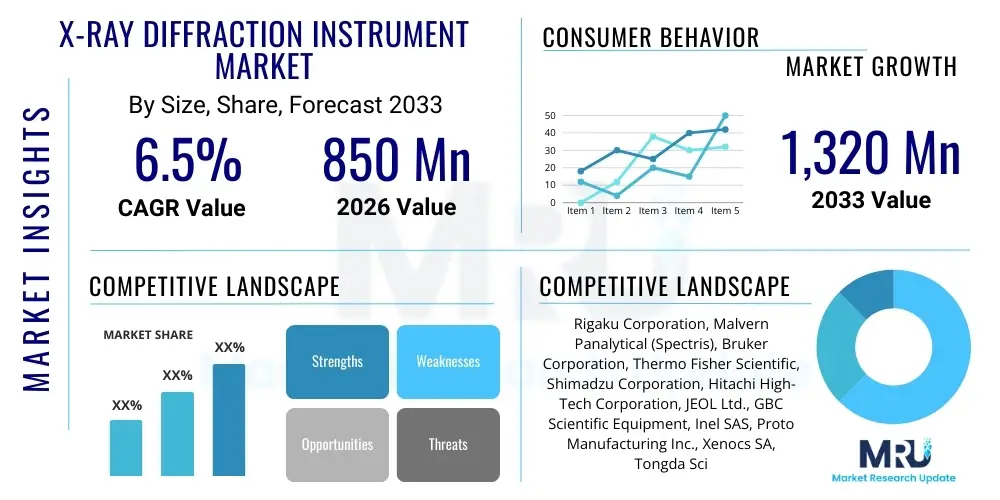

The X-Ray Diffraction Instrument Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,320 Million by the end of the forecast period in 2033.

X-Ray Diffraction Instrument Market introduction

The X-Ray Diffraction (XRD) Instrument Market encompasses sophisticated analytical equipment primarily utilized for determining the crystal structure, chemical composition, and physical properties of materials, ranging from crystalline solids to semi-crystalline and amorphous substances. These instruments operate by directing a beam of X-rays onto a sample and measuring the intensity and angle of the diffracted X-rays, providing unique spectral fingerprints crucial for material identification and quality control. The primary applications span across diverse sectors including pharmaceuticals for polymorphism analysis, geological sciences for mineral identification, materials science for thin-film and bulk material characterization, and semiconductor manufacturing for quality assurance of epitaxial layers and device components. The high precision and non-destructive nature of XRD analysis solidify its position as an indispensable tool in both academic research and industrial quality assurance laboratories globally.

Product descriptions within this market vary significantly, covering systems such as Powder X-Ray Diffraction (PXRD), which is the most common for bulk materials and phase identification, and Single-Crystal X-Ray Diffraction (SCXRD), used for determining the absolute structure of novel chemical compounds. Additionally, specialized systems like High-Resolution X-Ray Diffraction (HRXRD) cater specifically to advanced semiconductor and thin-film characterization, demanding high angular resolution to study lattice mismatch and strain. The continuous technological evolution, particularly the integration of faster detectors, automated sample changers, and improved software algorithms, enhances the throughput and analytical capabilities of modern XRD systems, addressing the growing demand for rapid, high-quality material analysis in high-volume research and production environments.

Major benefits derived from utilizing XRD instruments include precise phase identification, quantification of crystalline components, determination of lattice parameters, measurement of residual stress and texture, and analysis of crystallite size and strain. These capabilities are driving factors for market expansion, particularly in emerging economies where industrialization necessitates stringent material quality standards and advanced research capabilities. The increasing focus on nanotechnology, the development of advanced battery materials for electric vehicles, and the rigorous regulatory environment in the pharmaceutical sector further propel the adoption of reliable and advanced XRD technology, making these instruments critical investments for industries focused on innovation and material performance optimization.

X-Ray Diffraction Instrument Market Executive Summary

The X-Ray Diffraction Instrument Market is characterized by steady growth, driven primarily by robust research and development activities across materials science, pharmaceutical, and semiconductor industries, coupled with stringent quality control requirements for advanced materials. Business trends indicate a strong focus on automation and integration, with manufacturers prioritizing modular designs, user-friendly interfaces, and multi-functional systems capable of performing various techniques (e.g., SAXS, WAXS, and CT) on a single platform. Key market players are heavily investing in detector technology, moving towards hybrid photon counting (HPC) detectors and silicon drift detectors (SDD) to achieve faster data acquisition and improved signal-to-noise ratios, enhancing the overall efficiency and sensitivity of the instruments, which directly impacts customer acquisition and retention in competitive research environments.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market due to massive investments in electronics manufacturing, battery technology, and academic research infrastructure, particularly in countries like China, Japan, and South Korea, which are global hubs for advanced material production. North America and Europe, while mature, maintain dominant market shares driven by well-established pharmaceutical R&D centers and high adoption rates of advanced HRXRD systems in semiconductor and aerospace applications. Segmentation analysis reveals that Powder X-Ray Diffraction (PXRD) instruments maintain the largest market share owing to their versatility and applicability in fundamental research and industrial QC, while the services segment is experiencing high growth, attributed to the increasing complexity of instruments requiring specialized maintenance, calibration, and training.

Segment trends highlight a noticeable shift toward specialized applications and higher-throughput systems. The increasing complexity of new materials, such as metal-organic frameworks (MOFs) and perovskites, demands instruments with enhanced capabilities for in-situ and operando studies, driving demand for specialized accessories like high/low-temperature chambers and reaction cells. Furthermore, the rising need for non-ambient testing to simulate real-world conditions (e.g., high pressure, specific atmospheres) is fueling innovation in sample environment control systems. This emphasis on application-specific customization ensures that XRD instruments remain relevant and essential tools in cutting-edge scientific endeavors, reinforcing the market's long-term stability and growth trajectory.

AI Impact Analysis on X-Ray Diffraction Instrument Market

Common user inquiries regarding the impact of Artificial Intelligence (AI) on the X-Ray Diffraction Instrument Market center on how AI can accelerate data processing, improve phase identification accuracy, automate complex measurement protocols, and assist in structure solution and refinement, particularly for challenging novel materials. Users are highly concerned about the integration of machine learning algorithms for predictive maintenance and real-time anomaly detection during experimentation, seeking solutions that minimize downtime and optimize instrument performance. Key expectations revolve around AI reducing the reliance on manual expertise for routine analysis, thereby increasing laboratory throughput and democratizing the use of sophisticated XRD techniques. Users anticipate that AI-driven data analysis will move beyond simple peak matching to complex pattern simulation and crystal structure prediction, thereby opening up new avenues for materials discovery and optimization. The integration of AI for automated experimental design using robotics is also a major theme of user interest.

- AI integration significantly accelerates data processing speed and reduces analysis time, particularly for large datasets generated by high-throughput screening.

- Machine learning algorithms enhance the accuracy of phase identification and quantification, especially in complex, multi-component mixtures where traditional methods struggle with peak overlap.

- Deep learning models facilitate automated crystal structure solution and refinement, minimizing manual intervention and accelerating the discovery process for novel compounds.

- AI enables predictive maintenance of XRD instruments by analyzing operational parameters and predicting potential hardware failures, thereby maximizing uptime and reducing maintenance costs.

- Automated experimental design (Autonomous Synthesis Labs) utilizing AI optimizes measurement parameters and sample environment controls, ensuring consistent and reproducible data collection.

- AI improves indexing and determination of unit cells for novel materials, overcoming challenges associated with low-symmetry structures and complex diffraction patterns.

- Natural Language Processing (NLP) tools integrated with XRD databases allow researchers to quickly cross-reference experimental data with millions of known crystal structures and research publications.

DRO & Impact Forces Of X-Ray Diffraction Instrument Market

The X-Ray Diffraction Instrument Market is fundamentally driven by escalating investments in material science research and development, particularly in emerging sectors like battery technology, advanced ceramics, and specialized alloys, all of which require precise structural analysis for performance optimization. Restraints primarily involve the high initial cost of advanced HRXRD systems and the necessity for highly skilled personnel to operate and interpret complex data, limiting adoption in smaller academic institutions and industries with limited budgets. Opportunities abound in the development of benchtop and portable XRD systems, which offer reduced cost and complexity, making the technology accessible for routine quality control in diverse industrial settings. Impact forces, such as the increasing global emphasis on nanotechnology and sustainable material development, strongly push the demand for high-resolution, in-situ characterization techniques, while regulatory standards in pharmaceuticals necessitate strict crystalline polymorph control, further embedding XRD as a mandatory analytical tool.

Specific drivers include rapid technological advancements in X-ray sources (like micro-focus sources and rotating anodes) and detection systems (HPC detectors), significantly enhancing instrument performance, speed, and efficiency. The expansion of government funding for scientific research in materials, chemistry, and physics globally creates a stable demand base for high-end analytical equipment. Conversely, the market faces restraints due to the inherent technical limitations related to sample preparation, where non-uniformity or amorphous content can significantly complicate data collection and interpretation. Furthermore, the dominance of established players with proprietary software and data formats can create integration challenges for users seeking multi-vendor solutions or open-source analysis platforms, slowing down broad technological adoption in certain research ecosystems.

The most compelling opportunities lie in integrating XRD instruments with complementary analytical techniques, such as X-ray fluorescence (XRF) or computed tomography (CT), into hybrid systems, offering comprehensive structural and elemental analysis simultaneously from a single sample, thereby increasing the value proposition for end-users. Additionally, expansion into non-traditional markets, such as industrial process monitoring and forensic science, represents new revenue streams. The collective impact forces—technological obsolescence pressure driving users to upgrade, coupled with the critical need for advanced material characterization to meet global energy transition goals—ensure sustained innovation and necessitate continuous capital investment in this market, maintaining a positive long-term growth trajectory despite cost-related restraints.

Segmentation Analysis

The X-Ray Diffraction Instrument Market is comprehensively segmented based on technology type, material type, application, and end-user, providing a granular view of market dynamics and adoption patterns across various industrial and research verticals. Technology segmentation is vital as it distinguishes between the prevalent Powder XRD (PXRD), which serves the bulk market, and the more specialized Single Crystal XRD (SCXRD) and High-Resolution XRD (HRXRD) systems crucial for advanced scientific endeavors and semiconductor quality control. Analyzing material type segmentation, which includes crystalline, semi-crystalline, and amorphous materials, helps identify the specific analytical challenges and required instrumental capabilities for different industries. This structural analysis allows market participants to tailor their offerings, focusing on instrument ruggedness and automation for industrial applications versus ultimate resolution and flexibility for academic research environments, ensuring maximum market penetration and client satisfaction across the diverse end-user spectrum.

- Technology Type:

- Powder X-Ray Diffraction (PXRD)

- Single-Crystal X-Ray Diffraction (SCXRD)

- High-Resolution X-Ray Diffraction (HRXRD)

- Stress & Texture Analysis Systems

- Material Type:

- Crystalline Materials (Metals, Minerals, Ceramics)

- Semi-Crystalline Materials (Polymers)

- Amorphous Materials Analysis

- Thin Films and Coatings

- Application:

- Phase Identification and Quantification

- Lattice Parameter Determination

- Structural Analysis (Crystal Structure Solution)

- Residual Stress Measurement

- In-situ and Operando Studies

- Quality Control (QC)

- End User:

- Academic & Research Institutions

- Pharmaceutical & Biotechnology Companies

- Semiconductor & Electronics Industry

- Chemical & Petrochemical Industry

- Mining & Metallurgy

- Government & Forensic Laboratories

Value Chain Analysis For X-Ray Diffraction Instrument Market

The value chain for the X-Ray Diffraction Instrument Market begins with the upstream segment, encompassing the critical sourcing of highly specialized components, most notably the X-ray tube (source), advanced detectors (such as hybrid photon counting or scintillation detectors), high-precision goniometers, and sophisticated vacuum and temperature control systems. This stage is characterized by intense R&D investment by component suppliers, ensuring technological superiority, reliability, and miniaturization of key elements, which directly influences the final instrument's performance specifications. Key manufacturers typically maintain strong, long-term relationships with a limited number of specialized component providers to ensure quality consistency and adherence to strict manufacturing tolerances required for high-precision analytical equipment, thereby stabilizing the initial cost structure and minimizing supply chain disruptions.

Midstream activities involve the design, manufacturing, assembly, and integration of these components into complete XRD systems, including the development of proprietary control and analysis software that often constitutes a significant portion of the instrument's intellectual property and competitive advantage. Distribution channels are predominantly indirect, utilizing specialized regional distributors and value-added resellers (VARs) who possess the necessary technical expertise to install, commission, and provide basic training on these complex instruments, especially in geographically dispersed markets. However, high-end systems and strategic governmental tenders are often handled through direct sales channels to ensure optimal technical support and service contract negotiations, reflecting the high value and complexity of the equipment.

Downstream activities center on post-sales service, technical support, application training, calibration, and long-term maintenance contracts, which are crucial for ensuring sustained instrument performance and generating predictable recurring revenue for manufacturers. The success of the downstream segment relies heavily on maintaining a global network of specialized field service engineers capable of handling complex hardware and software issues efficiently. The high service requirement, due to the sensitive nature of the equipment, makes the aftermarket services segment highly profitable and a vital differentiator for market leaders, ultimately influencing customer satisfaction and repeat purchases within the research and industrial communities.

X-Ray Diffraction Instrument Market Potential Customers

Potential customers for X-Ray Diffraction instruments span a wide array of scientific, industrial, and governmental entities that require precise characterization of material structure and composition at the atomic level, making the market highly diversified yet specialized. The largest segment of end-users includes Academic and Research Institutions, encompassing universities and national laboratories, which utilize XRD systems for fundamental research in physics, chemistry, geology, and materials science, often driving the demand for cutting-edge, high-resolution and specialized in-situ capabilities. These institutions are characterized by budget cycles tied to grant funding and often prioritize instrument flexibility and educational utility over high-throughput industrial performance.

The Pharmaceutical and Biotechnology industry represents a high-value customer base, utilizing XRD instruments extensively for polymorph screening, quantitative phase analysis, determining crystallinity percentage in drug formulations, and ensuring regulatory compliance regarding solid-state forms of Active Pharmaceutical Ingredients (APIs). Precision and regulatory traceability are paramount for these customers. Simultaneously, the Semiconductor and Electronics Industry heavily relies on High-Resolution XRD (HRXRD) for non-destructive characterization of epitaxial layers, measurement of strain in device structures, and quality control of advanced substrates, demanding extremely high precision and automation capabilities suitable for cleanroom environments and production line integration.

Furthermore, industrial sectors such as Mining, Metallurgy, and Chemicals constitute a significant customer segment, using Powder XRD for quality control, phase identification in raw materials, process optimization, and failure analysis of manufactured components. Government and Forensic Laboratories also rely on XRD for regulatory enforcement, mineral identification, and forensic analysis of material evidence. These diverse end-users collectively drive demand for systems ranging from entry-level benchtop models for routine quality control to highly sophisticated, multi-axis goniometer systems required for advanced research and manufacturing control.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,320 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rigaku Corporation, Malvern Panalytical (Spectris), Bruker Corporation, Thermo Fisher Scientific, Shimadzu Corporation, Hitachi High-Tech Corporation, JEOL Ltd., GBC Scientific Equipment, Inel SAS, Proto Manufacturing Inc., Xenocs SA, Tongda Science & Technology, RaySpec Ltd., Hubei Maxis, STOE GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

X-Ray Diffraction Instrument Market Key Technology Landscape

The X-Ray Diffraction Instrument market is dominated by several foundational and rapidly evolving technologies crucial for maximizing analytical power, speed, and accuracy. At the core are the X-ray sources, where traditional sealed tubes and rotating anode generators remain prevalent, but there is a growing trend toward micro-focus X-ray sources, which provide higher flux density and smaller focal spots, crucial for high-resolution measurements and small sample analysis. This evolution in source technology directly enhances the signal-to-noise ratio and reduces measurement times, making high-throughput analysis feasible. Coupled with advanced sources, the goniometer technology, which precisely controls the angle of the incident beam and the detector, continues to advance, offering multi-axis movement (e.g., four-circle goniometers) necessary for complex texture and residual stress measurements in single crystals and thin films, enabling more comprehensive material characterization previously achievable only at synchrotron facilities.

A major technological leap involves X-ray detectors. The market is shifting rapidly from older scintillation and proportional counter detectors to advanced high-speed detectors such, as 0D/1D/2D detectors based on technologies like Hybrid Photon Counting (HPC) and Silicon Drift Detectors (SDD). HPC detectors, in particular, offer superior spatial resolution, virtually zero background noise, and exceptional counting rate capability, enabling rapid data collection in dynamic experiments like in-situ heating or reaction monitoring. This capability is pivotal for industries requiring real-time analysis, such as catalysts and battery research, where observing kinetic processes is essential. Furthermore, the development of integrated sample environment chambers—including high-vacuum systems, cryostats, and high-temperature furnaces—allows researchers to perform operando experiments that simulate real-world conditions, adding a new dimension to material analysis.

Software and automation are equally critical technological pillars. Modern XRD instruments utilize sophisticated software suites that manage instrument control, data processing, structure solution, and database referencing (e.g., ICDD Powder Diffraction File). The incorporation of automated sample handling systems, robotic arms, and high-capacity magazines (up to hundreds of samples) allows for unsupervised, high-throughput screening, driving efficiency in industrial quality control laboratories and large pharmaceutical screening facilities. The ongoing trend towards integrating AI and machine learning into these software platforms promises to further automate complex analytical tasks, such as phase identification in complex mixtures and structure prediction for novel compounds, thereby enhancing the instrument’s intelligence and reducing the expertise required for routine operation, which serves as a major market growth accelerator.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven by explosive growth in electronics manufacturing, particularly in advanced semiconductor devices and consumer electronics, which require stringent HRXRD quality control. Substantial governmental and private sector investment in battery technology research (lithium-ion and solid-state batteries) across China, South Korea, and Japan fuels demand for high-end analytical instruments for material optimization. Furthermore, the rapid expansion of academic research institutions and industrialization in India contributes significantly to the demand for foundational PXRD systems for quality assurance and educational purposes, making this region a global manufacturing and research powerhouse for advanced materials.

- North America: North America holds a dominant market share, characterized by high technological maturity, substantial R&D expenditure by leading pharmaceutical and biotechnology firms, and a robust aerospace and defense manufacturing sector. The presence of major analytical instrument manufacturers and early adoption of cutting-edge technologies like synchrotron-based XRD techniques and advanced HRXRD for silicon wafer analysis ensures sustained market leadership. Strong regulatory frameworks, especially concerning pharmaceutical polymorphism and material safety, mandate the constant use and upgrading of high-precision XRD instruments, maintaining high market value despite slower population growth compared to APAC.

- Europe: Europe represents a significant, mature market, driven by powerful research consortia and strict environmental and material safety standards enforced by the European Union. Countries like Germany, France, and the UK are leaders in automotive material science, advanced ceramics, and chemical production, leading to sustained demand for PXRD and specialized stress and texture analysis systems. The strong presence of international key market players and a focused commitment to green technology research, including new energy materials and catalysts, ensures continuous investment in sophisticated XRD technology for performance optimization and failure analysis across diverse industrial applications.

- Latin America (LATAM): The LATAM region presents moderate growth potential, primarily focused on applications within the mining, metallurgy, and petrochemical sectors, where XRD is essential for mineral exploration, quality control of ore concentrates, and catalyst characterization. Market adoption is often constrained by budget limitations and reliance on imported technology, but increasing foreign direct investment in research infrastructure, particularly in Brazil and Mexico, suggests a gradual expansion of the user base for both new and refurbished analytical equipment.

- Middle East and Africa (MEA): The MEA market is niche but growing, largely concentrated in oil and gas exploration (petrochemical catalyst characterization), mining, and governmental research initiatives focused on renewable energy and materials security. Investment in Saudi Arabia and the UAE for establishing world-class research universities and technological hubs is driving demand for advanced analytical instruments, although overall market size remains smaller compared to other regions due to infrastructure maturity and geopolitical volatility impacting investment cycles.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the X-Ray Diffraction Instrument Market.- Rigaku Corporation

- Malvern Panalytical (Spectris)

- Bruker Corporation

- Thermo Fisher Scientific

- Shimadzu Corporation

- Hitachi High-Tech Corporation

- JEOL Ltd.

- GBC Scientific Equipment

- Inel SAS

- Proto Manufacturing Inc.

- Xenocs SA

- Tongda Science & Technology

- RaySpec Ltd.

- Hubei Maxis

- STOE GmbH

- Applied Rigaku Technologies, Inc.

- Huber Diffraktionstechnik GmbH

- PANalytical (now part of Malvern Panalytical)

- AXT Pty Ltd.

Frequently Asked Questions

Analyze common user questions about the X-Ray Diffraction Instrument market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for High-Resolution X-Ray Diffraction (HRXRD) systems?

The primary driver for HRXRD demand is the exponential growth and complexity of the semiconductor and electronics industries, which require non-destructive, atomic-level characterization of thin films, epitaxial layers, and device structures for stringent quality control and advanced material research.

How are X-Ray Diffraction instruments utilized within the pharmaceutical industry?

Pharmaceutical companies utilize XRD instruments, particularly PXRD, for essential quality control processes such as phase identification, polymorph screening, determining the degree of crystallinity in Active Pharmaceutical Ingredients (APIs), and ensuring patent protection and regulatory compliance for solid-state forms of drugs.

Which geographical region is expected to exhibit the fastest growth in the XRD Instrument Market?

The Asia Pacific (APAC) region is projected to register the fastest growth rate, fueled by massive regional investments in electronics manufacturing, advanced battery research, expanding academic infrastructure, and industrialization across key economies like China, South Korea, and India.

What technological advancements are most significantly impacting the performance of modern XRD systems?

Key technological advancements include the transition to high-speed, low-noise detectors like Hybrid Photon Counting (HPC) detectors, the development of micro-focus X-ray sources for increased flux, and the integration of sophisticated AI/machine learning software for automated data analysis and structural refinement.

What are the main segments of the X-Ray Diffraction Instrument Market by end-user?

The main end-user segments are Academic and Research Institutions, Pharmaceutical and Biotechnology Companies, the Semiconductor and Electronics Industry, and various Industrial applications including Mining, Metallurgy, and Chemicals, each demanding specific instrument capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager