XRF Analysers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435484 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

XRF Analysers Market Size

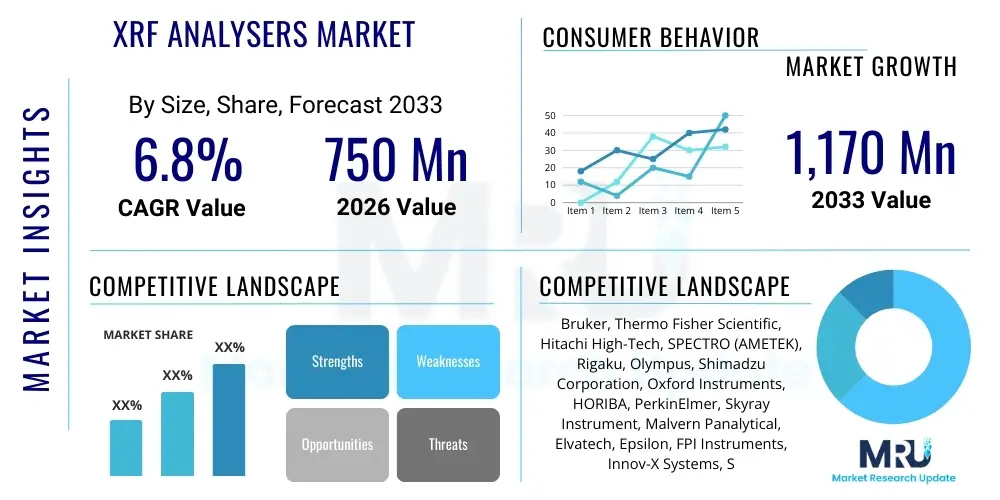

The XRF Analysers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,170 Million by the end of the forecast period in 2033.

XRF Analysers Market introduction

X-ray Fluorescence (XRF) analysers are sophisticated spectroscopic instruments crucial for non-destructive elemental analysis across a vast range of industries. These devices determine the elemental composition of materials by irradiating a sample with X-rays, causing the atoms to emit characteristic secondary (or fluorescent) X-rays. The intensity and energy of these emitted X-rays are measured to quantify the concentration of specific elements, making XRF analysis indispensable for quality control, regulatory compliance, and process optimization in highly technical environments. The core utility of XRF systems lies in their ability to provide rapid, precise, and multi-element analysis with minimal sample preparation, offering a significant advantage over traditional chemical testing methods that are often time-consuming and destructive.

Major applications of XRF analysers span diverse sectors, including mining and exploration for rapid grade control, environmental monitoring for heavy metal detection in soil and water, and materials science for alloy verification and coating thickness measurement. Furthermore, the petroleum and petrochemical industries rely on XRF for sulfur and catalyst analysis, while the electronics sector uses them for RoHS/WEEE compliance testing. The increasing global focus on product safety, material traceability, and stringent environmental regulations is primarily driving the adoption of these analytical instruments. As industries transition toward Industry 4.0 principles, the demand for portable and automated XRF solutions capable of real-time data integration is accelerating market growth.

Key benefits driving market momentum include the high accuracy and precision of elemental measurement, the suitability for analyzing solids, liquids, and powders, and the non-invasive nature of the testing process. Technological advancements, particularly in detector technology (e.g., Silicon Drift Detectors or SDDs) and miniaturization, have resulted in the widespread adoption of highly accurate handheld XRF devices. These portable units extend laboratory-grade capabilities into field operations, increasing efficiency and reducing turnaround times for critical decision-making processes. These combined factors solidify the XRF analyser's position as a cornerstone technology in modern analytical instrumentation.

XRF Analysers Market Executive Summary

The XRF Analysers market exhibits robust growth driven by escalating global quality standards and regulatory mandates across heavy industries such as mining, metallurgy, and environmental protection. Business trends emphasize miniaturization and integration, leading to significant uptake of handheld XRF (HHXRF) devices, which are transforming field analysis capabilities and on-site material verification. Manufacturers are heavily investing in advanced software for spectral analysis and calibration methodologies, enhancing accuracy and reducing operator dependency. The competitive landscape is characterized by innovation focused on detector sensitivity and the development of application-specific calibration standards to address complex matrices in niche areas like pharmaceuticals and food safety. Strategic partnerships aiming at broader geographical distribution and improved service networks are also pivotal in maintaining market share.

From a regional perspective, the Asia Pacific (APAC) region is projected to maintain the highest growth rate, fueled by aggressive infrastructural development, rapid industrial expansion, and increased scrutiny over raw material quality in manufacturing hubs like China and India. North America and Europe, while mature, continue to show stable demand, primarily driven by stringent environmental monitoring legislation (e.g., REACH, RoHS) and sophisticated research and development activities in materials science. Segment trends indicate that Energy Dispersive XRF (EDXRF) systems dominate the market owing to their faster analysis speed and lower operational complexity compared to the highly precise, yet more complex, Wavelength Dispersive XRF (WDXRF) technology. Benchtop systems retain dominance in laboratory settings requiring high throughput and ultimate precision, while handheld units capture growth in on-site inspection and rapid screening applications.

AI Impact Analysis on XRF Analysers Market

Common user questions regarding AI's influence on the XRF Analysers Market center on how artificial intelligence can overcome inherent analytical challenges, such as matrix effects and spectral overlaps, which traditionally require extensive manual calibration and specialized expertise. Users also frequently inquire about the potential for AI-driven automation in routine quality control workflows, asking if AI can autonomously identify material anomalies, perform complex data processing, and optimize instrument parameters in real time. The key thematic expectations revolve around achieving higher accuracy, reducing the dependence on highly skilled operators, and integrating XRF data seamlessly into larger industrial IoT and quality management systems, fundamentally transforming rapid decision-making processes based on elemental composition data.

- AI-Powered Spectral Deconvolution: Utilizes machine learning algorithms to resolve complex spectral overlaps, significantly improving accuracy in multi-element samples and complex matrices, thus enhancing quantitative analysis reliability.

- Automated Calibration and Drift Correction: Employs neural networks to continuously monitor system performance and environment, automatically adjusting calibration curves to compensate for temperature fluctuations, detector drift, or matrix variations without manual intervention.

- Enhanced Anomaly Detection: Machine learning models analyze vast datasets of XRF spectra to identify subtle deviations indicative of contamination, incorrect grading, or unexpected impurities faster and more reliably than traditional limit-checking methods.

- Predictive Maintenance and Diagnostics: AI algorithms analyze instrument operational data (e.g., X-ray tube output, detector noise) to predict component failure, scheduling maintenance proactively and maximizing instrument uptime, especially crucial for field deployment.

- Data Integration and Interpretation: Facilitates the seamless integration of elemental data into larger manufacturing execution systems (MES) or laboratory information management systems (LIMS), providing instant, contextualized insights for non-expert users and speeding up compliance reporting.

DRO & Impact Forces Of XRF Analysers Market

The XRF Analysers market is shaped by powerful driving forces centered on regulatory compliance, technological superiority, and operational efficiency. A primary driver is the accelerating requirement for rapid, non-destructive testing (NDT) across high-value materials, particularly in metallurgy and precious metals sectors where material authenticity and composition integrity are paramount. Global initiatives like RoHS (Restriction of Hazardous Substances) and specific industry regulations requiring the strict quantification of elements (e.g., sulfur in petroleum products or lead in consumer goods) necessitate the deployment of highly reliable, precise analytical tools like XRF analysers. Furthermore, the inherent efficiency of XRF—providing results in seconds or minutes versus hours for traditional wet chemistry methods—makes it an essential tool for high-throughput quality control and process monitoring, directly impacting operational bottom lines.

Restraints, however, pose critical challenges to widespread market adoption. The most significant restraints include the high initial capital expenditure associated with purchasing high-performance XRF systems, particularly WDXRF instruments, which can be prohibitive for smaller laboratories or mining operations. Additionally, the complex phenomenon of matrix effects, where the composition of the bulk material significantly influences the signal intensity of the target element, requires specialized software, skilled operators, and robust calibration standards, adding to operational complexity and potential measurement uncertainty. While XRF excels at heavier elements, its poor sensitivity to lighter elements (such as C, N, O) in air-path systems limits its utility in specific organic chemistry and light materials analysis, forcing users to rely on more complex vacuum or helium purging systems.

Opportunities in the market are largely driven by continued miniaturization and the push towards specialized application development. The ongoing advancement in detector technology, leading to more sensitive and less expensive Silicon Drift Detectors (SDDs), is enabling the development of powerful, yet affordable, handheld XRF devices, opening up new markets in recycling, scrap metal sorting, and field geology. Furthermore, the burgeoning demand for forensic material analysis, specialized pharmaceutical quality control (analyzing trace contaminants), and advanced battery material research presents highly lucrative niche segments. The seamless integration of XRF data with cloud computing platforms and the rise of IoT-enabled analytical instruments are key impact forces, allowing for centralized data management, remote diagnostics, and automated reporting, thus significantly enhancing the strategic value of XRF technology in smart manufacturing and Industry 4.0 environments.

Segmentation Analysis

The XRF Analysers market is primarily segmented based on the core technology (Type), physical form factor (Portability), and the specific industry application, reflecting the diverse operational needs and analytical requirements across the global economy. Understanding these segments is crucial as the choice between different XRF modalities directly impacts precision, speed, initial cost, and suitability for field versus laboratory use. The segmentation highlights the underlying technological advancements and the shifting demand patterns, particularly the rapid expansion in the handheld market fueled by convenience and mobility, contrasting with the sustained laboratory demand for high-precision, benchtop WDXRF systems. This market structure allows key players to tailor instrument performance and software packages to specific end-user environments, maximizing penetration in both industrial quality control and high-end research applications.

- By Type: Energy Dispersive XRF (EDXRF), Wavelength Dispersive XRF (WDXRF), Total Reflection XRF (TXRF)

- By Portability: Benchtop, Handheld/Portable

- By Application: Mining & Metallurgy, Cement, Environmental Monitoring, Pharmaceuticals, Petroleum and Petrochemicals, Semiconductors & Electronics, Research & Education

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA)

Value Chain Analysis For XRF Analysers Market

The value chain for XRF Analysers starts with upstream analysis focusing on the procurement and development of highly specialized components, primarily the X-ray tube and the detector technology (like SDDs or SiPIN detectors), alongside high-purity materials for manufacturing shielding and system housings. Key activities in this stage include R&D expenditure to improve detector efficiency, maximize tube life, and develop robust power supply systems. Suppliers of these critical components hold substantial leverage as their technological capabilities directly determine the performance parameters (sensitivity and speed) of the final XRF instrument. Maintaining a stable and high-quality supply of these complex analytical components is vital for ensuring consistency in instrument manufacturing and final product performance.

The core manufacturing and assembly phase involves integrating the X-ray source, detector, advanced electronics, and specialized analytical software. This mid-stream segment requires significant engineering expertise to minimize noise, ensure precise calibration, and guarantee instrument stability across varying operational environments. Distribution channels are complex and bifurcated. Direct sales are common for high-end, customized laboratory WDXRF systems, where direct interaction with customers ensures precise configuration and post-sale support. Indirect distribution, leveraging a network of specialized dealers, distributors, and value-added resellers (VARs), is particularly prevalent for standard benchtop and, crucially, high-volume handheld XRF units, enabling broader geographical reach and localized technical service delivery.

Downstream analysis involves the direct relationship with end-users, encompassing installation, operator training, application support, and ongoing maintenance. The post-sales service phase, including annual calibration services, software updates, and repair of expensive components, constitutes a significant long-term revenue stream and a crucial differentiator for manufacturers. Potential customers evaluate vendors not just on instrument specifications but heavily on the reliability of the support network and the availability of application-specific calibration standards. The effectiveness of the indirect distribution channel in providing timely local service directly influences customer retention and brand reputation, completing the value cycle through sustained end-user operational performance.

XRF Analysers Market Potential Customers

The primary potential customers and end-users of XRF analysers are organizations and professionals requiring rapid, accurate elemental characterization for quality assurance, compliance, or research purposes. In the industrial sector, this includes large mining corporations that utilize portable XRF units for real-time geological mapping and ore grade control at the pit face, and metallurgical plants that deploy benchtop units for rapid verification of alloy composition and melt chemistry. The cement and construction industries are also major buyers, using XRF to monitor raw meal composition and final product quality, ensuring structural integrity and compliance with building standards. These heavy industrial segments prioritize ruggedness, speed, and reliability in harsh operational environments.

Beyond traditional heavy industries, the market is expanding significantly into highly regulated and specialized domains. Environmental agencies and consulting firms use XRF for rapid screening of toxic elements (e.g., lead, arsenic, mercury) in contaminated sites, soil, and consumer waste to meet stringent governmental safety standards. The pharmaceutical industry is increasingly adopting XRF, particularly Total Reflection XRF (TXRF), for ultra-trace element analysis, ensuring compliance with heavy metal impurity limits specified by pharmacopoeias. Furthermore, recycling operations and scrap metal dealers represent a high-volume customer base for handheld XRF, relying on these instruments for instant identification and sorting of various materials for efficient revenue optimization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,170 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bruker, Thermo Fisher Scientific, Hitachi High-Tech, SPECTRO (AMETEK), Rigaku, Olympus, Shimadzu Corporation, Oxford Instruments, HORIBA, PerkinElmer, Skyray Instrument, Malvern Panalytical, Elvatech, Epsilon, FPI Instruments, Innov-X Systems, SGS, Applied Rigaku Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

XRF Analysers Market Key Technology Landscape

The core technology landscape of the XRF Analysers market is defined by continuous improvements in three primary areas: X-ray source efficiency, detector sensitivity, and computational capabilities for data processing. The transition from older proportional counters to Silicon Drift Detectors (SDDs) has been instrumental in modern XRF, particularly in handheld units. SDDs offer significantly improved energy resolution and high count rates, allowing for faster analysis times and better separation of adjacent elemental peaks, minimizing spectral overlap issues. Furthermore, advancements in miniaturized, low-power micro-focus X-ray tubes enable the high performance and long battery life required by portable devices, expanding their applicability in remote locations and non-laboratory settings.

Beyond the fundamental hardware, software and computational technologies are rapidly shaping the market. Modern XRF instruments rely heavily on sophisticated fundamental parameters (FP) software methods for calibration. These FP models mathematically correct for matrix effects, allowing operators to analyze a wider variety of materials without needing numerous physical calibration standards. This enhances the versatility and accuracy of the instruments, especially for unknown samples. The latest technological wave involves integrating IoT connectivity and edge computing capabilities, allowing instruments to transmit data in real-time, perform initial analysis locally, and receive remote diagnostic and calibration updates, moving XRF technology into the interconnected industrial ecosystem.

Regional Highlights

-

North America: North America represents a mature yet highly innovative market segment for XRF analysers, characterized by high adoption rates in research, advanced manufacturing, and stringent regulatory environments. The demand is heavily concentrated in the oil and gas sector for elemental analysis of fuels and lubricants, and in the semiconductor and electronics industries for RoHS compliance and quality control of complex microcomponents. The region benefits from substantial research and development investment, particularly in materials science and nanotechnology, driving the demand for high-end WDXRF and TXRF systems. Stringent environmental protection laws, such as those governing soil and water purity, ensure consistent growth in the environmental monitoring application segment, often favoring the deployment of highly mobile, fast handheld XRF units for field screening.

The US market leads regional growth, supported by a robust infrastructure for analytical equipment maintenance and technical expertise. Regulatory bodies play a critical role; for example, the enforcement of lead limits in consumer goods necessitates widespread use of XRF for screening at ports and manufacturing facilities. Competitive dynamics focus on providing highly reliable instruments integrated with advanced data management software, catering to pharmaceutical and aerospace industries where data integrity and traceability are non-negotiable requirements. The focus on integrating XRF data into centralized cloud systems for auditing and compliance reporting further solidifies North America’s demand for sophisticated analytical solutions.

Key drivers include expansion in material recycling initiatives and the modernization of infrastructure projects. Companies in the region leverage XRF technology to rapidly identify and sort specialized alloys and plastics, optimizing recycling processes. Furthermore, ongoing research into new energy materials, such as battery components, demands precise elemental mapping and quantification, keeping the high-precision XRF segment resilient and growing.

-

Europe: The European XRF market is characterized by strict adherence to comprehensive safety and environmental regulations, most notably the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, which mandates extensive chemical analysis and reporting throughout the supply chain. This regulatory framework necessitates widespread use of XRF analysers for screening incoming raw materials, monitoring intermediate production stages, and verifying final product compliance. The region demonstrates strong demand in the automotive sector for quality control of metal components and catalytic converters, ensuring material longevity and emission standards are met.

Germany, with its strong manufacturing base (Industry 4.0 adoption) and sophisticated chemical sector, is a key consumer, prioritizing automated benchtop systems integrated into production lines for continuous quality monitoring. Demand is also significant in the cultural heritage sector, where the non-destructive nature of XRF makes it ideal for analyzing historical artifacts, pigments, and materials without causing damage. The push for sustainability and circular economy models further boosts the use of XRF in scrap metal sorting and waste management facilities, where rapid identification of material grades is crucial for profitability.

Technological trends in Europe focus on developing specialized accessories and software for difficult matrices, particularly in food safety and complex polymer analysis. European manufacturers often emphasize low detection limits and excellent spectral resolution to meet the demands of highly sensitive research applications. Market growth is sustained by regulatory pressure and the ongoing need for advanced material characterization in high-tech manufacturing and academic research institutes.

-

Asia Pacific (APAC): The APAC region is the fastest-growing market globally, driven by rapid industrialization, massive infrastructural investments, and an increasing shift of global manufacturing capabilities into countries like China, India, and Southeast Asia. The primary driver is the sheer volume of construction and manufacturing activity, demanding efficient quality control tools, especially in the mining, cement, and basic metals industries. Mining operations in Australia and Southeast Asia extensively use handheld XRF for rapid resource exploration and on-site grade reconciliation, optimizing excavation and processing decisions.

As economies in the region mature, there is an increasing shift toward implementing stricter environmental and safety standards, often mimicking European or North American regulations. This regulatory transition forces local manufacturers to invest in analytical instruments to ensure product quality and market access. China's enormous electronics manufacturing sector requires significant deployment of XRF analysers for compliance with global regulations concerning hazardous substances in electronic waste and finished goods (e.g., China RoHS). The large market size coupled with lower labor costs makes the deployment of high-throughput automated XRF systems economically viable in many APAC production facilities.

The competitive landscape in APAC is characterized by intense price sensitivity, yet a growing recognition of the value of high-precision analytical tools. Local manufacturers are emerging, challenging established global players, especially in the mid-range and entry-level benchtop market. However, high-end applications, particularly those requiring WDXRF precision in advanced materials research and petroleum analysis, still rely heavily on imports from Western and Japanese manufacturers. The substantial infrastructural growth and tightening quality mandates ensure that APAC remains the powerhouse for future XRF market expansion, particularly in the portable segment.

-

Latin America, Middle East, and Africa (MEA): These regions are characterized by significant activity in primary resource extraction (mining, oil, and gas) and expanding infrastructure. In Latin America, countries like Chile and Brazil, rich in mineral resources, are substantial markets for portable XRF analysers, which are critical for geological exploration and mine site operational efficiency. The focus here is on rugged, reliable instruments that can withstand harsh field conditions and provide immediate, actionable elemental data to minimize operational delays. The establishment of local laboratories and the standardization of quality checks are gradually increasing demand for benchtop systems.

The Middle East market is dominated by the petroleum and petrochemical industries. XRF analysers are essential for accurately measuring sulfur content in crude oil and refined products, ensuring compliance with global shipping and environmental emission standards. Investment in new refineries and petrochemical complexes drives demand for sophisticated, often automated, XRF systems for continuous process monitoring. Regulatory enforcement regarding fuel quality is a primary driver in this highly capitalized sector.

In Africa, the market growth is intrinsically linked to mining and large-scale infrastructure projects. XRF technology provides crucial, cost-effective solutions for initial resource assessment and elemental analysis in areas lacking extensive fixed laboratory infrastructure. While price sensitivity is high, the increasing pressure from international trade partners to meet defined quality standards is compelling adoption across resource-rich nations. The long-term trajectory is positive, supported by foreign investment in resource development and capacity building in local analytical capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the XRF Analysers Market.- Bruker

- Thermo Fisher Scientific

- Hitachi High-Tech

- SPECTRO (AMETEK)

- Rigaku

- Olympus

- Shimadzu Corporation

- Oxford Instruments

- HORIBA

- PerkinElmer

- Skyray Instrument

- Malvern Panalytical

- Elvatech

- Epsilon

- FPI Instruments

- Innov-X Systems

- SGS

- Applied Rigaku Technologies

- PANalytical (A Spectris company)

- Zetium

Frequently Asked Questions

Analyze common user questions about the XRF Analysers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between EDXRF and WDXRF analysers?

Energy Dispersive XRF (EDXRF) systems use a solid-state detector (like SDD) to measure the energy of all fluorescent X-rays simultaneously, offering rapid analysis and high portability. Wavelength Dispersive XRF (WDXRF) systems use a crystal and goniometer to separate X-rays by wavelength before detection, providing superior energy resolution and higher precision, especially for light elements, making them ideal for complex, high-accuracy laboratory work.

How significant is the adoption of handheld XRF (HHXRF) in the market?

Handheld XRF adoption is highly significant, constituting the fastest-growing portability segment. HHXRF devices offer non-destructive, near real-time elemental analysis capabilities outside the lab, revolutionizing quality control in scrap metal recycling, mining exploration (ore grade control), and immediate compliance screening (e.g., Positive Material Identification or PMI).

What major regulatory factors influence the demand for XRF analysers?

Key regulatory factors include the Restriction of Hazardous Substances (RoHS) directives, which mandate screening for heavy metals in electronics, and petroleum regulations requiring precise sulfur quantification. Environmental mandates, particularly those controlling toxic element levels in soil and water, also drive significant demand for compliant XRF analytical instrumentation.

What are the main technical limitations of XRF analysis?

The primary technical limitations include matrix effects, where the bulk composition of the sample interferes with the signal of the target element, and poor sensitivity for ultra-light elements (e.g., hydrogen, carbon, oxygen, nitrogen) when operating without expensive vacuum or helium purge systems. This requires advanced calibration or supplementary analysis techniques.

In which application segment is XRF projected to see the highest growth?

The highest growth is projected in the Environmental Monitoring and Recycling segments. Increasing global focus on sustainable practices, waste material recovery, and strict enforcement of environmental pollution limits necessitate the rapid and accurate elemental identification capabilities uniquely offered by portable and benchtop XRF systems, especially for analyzing electronic waste and industrial effluent.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager