Xylylene Diisocyanate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440609 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Xylylene Diisocyanate Market Size

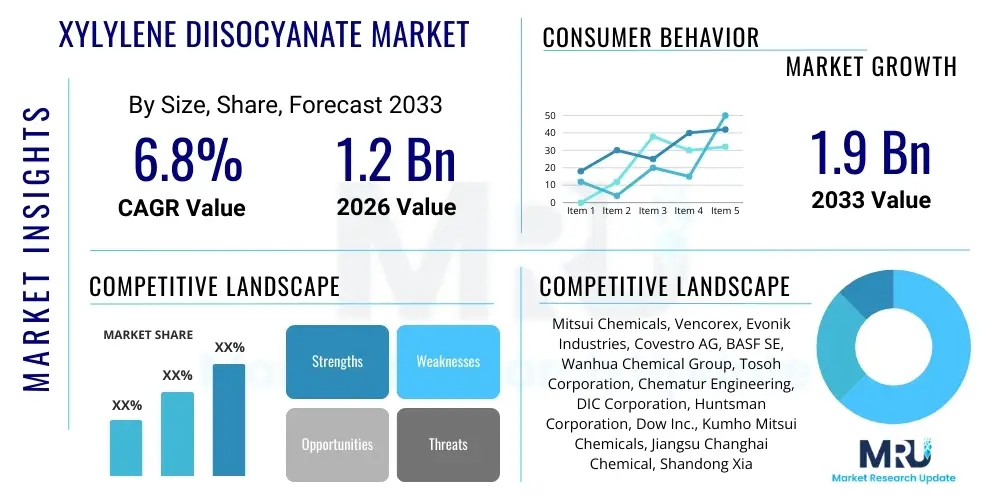

The Xylylene Diisocyanate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 2.15 Billion in 2026 and is projected to reach USD 4.05 Billion by the end of the forecast period in 2033.

Xylylene Diisocyanate Market introduction

Xylylene Diisocyanate (XDI) represents a class of aromatic diisocyanates characterized by the presence of isocyanate groups attached to xylylene moieties, offering unique chemical structures that impart superior performance attributes to a wide array of end products. Primarily, m-Xylylene Diisocyanate (m-XDI) and p-Xylylene Diisocyanate (p-XDI) are the commercially relevant isomers, with m-XDI being more widely utilized due to its advantageous reactivity and handling characteristics. These specialty diisocyanates are crucial building blocks in the synthesis of high-performance polyurethanes, which are polymers known for their exceptional physical and mechanical properties. The distinct structure of XDI, featuring a benzene ring separating the isocyanate groups, provides enhanced flexibility, excellent mechanical strength, and superior resistance to yellowing and degradation from UV radiation, making it an indispensable component in advanced material formulations.

The major applications of XDI span across diverse industries, predominantly within coatings, adhesives, elastomers, and sealants. In the coatings sector, XDI-based polyurethanes are highly valued for their ability to form tough, durable, and weather-resistant films that maintain their aesthetic appeal and protective functions over extended periods, particularly in outdoor environments. Automotive finishes, industrial protective coatings, and high-performance wood coatings are prime examples where XDI's benefits are extensively leveraged. For adhesives and sealants, XDI contributes to formulations that offer strong bonding capabilities, flexibility, and resistance to environmental factors, which are critical in demanding applications within construction, electronics, and general assembly. The elastomeric applications benefit from XDI's contribution to materials exhibiting high resilience, wear resistance, and excellent mechanical properties, making them suitable for specialized components and thermoplastic polyurethanes (TPUs).

The primary benefits of incorporating XDI into polyurethane systems include exceptional UV stability, which significantly reduces yellowing and chalking over time, thereby preserving the appearance and structural integrity of materials exposed to sunlight. Furthermore, XDI imparts excellent mechanical properties, such as high tensile strength, elongation at break, and abrasion resistance, ensuring the longevity and reliability of the end products. Its unique molecular structure also contributes to improved chemical resistance, flexibility at low temperatures, and enhanced adhesion to various substrates. These superior performance characteristics are key driving factors for the Xylylene Diisocyanate market, as industries continuously seek advanced materials that can withstand harsher operating conditions and deliver extended service life. The increasing demand for high-performance materials in sectors such as automotive, electronics, and construction, coupled with a growing emphasis on product longevity and aesthetics, continues to fuel the adoption and market expansion of XDI globally.

Xylylene Diisocyanate Market Executive Summary

The Xylylene Diisocyanate market is currently experiencing robust growth, driven by an escalating demand for high-performance materials across several critical industries. Business trends indicate a strong focus on innovation, with manufacturers investing heavily in research and development to optimize production processes, improve product purity, and explore novel applications. This includes the development of more sustainable and bio-based XDI alternatives to meet growing environmental regulations and consumer preferences for eco-friendly products. Strategic partnerships and collaborations between XDI producers and end-use formulators are becoming more prevalent, aimed at developing customized solutions that address specific application requirements and accelerate market penetration. Furthermore, an emphasis on vertical integration within the supply chain is observed, as key players seek to gain better control over raw material sourcing and enhance operational efficiency, thereby mitigating supply chain risks and ensuring cost competitiveness.

Regionally, the Asia Pacific (APAC) market continues to dominate the Xylylene Diisocyanate landscape, primarily due to the rapid industrialization, burgeoning manufacturing sector, and increasing demand from automotive, construction, and electronics industries in countries like China, India, Japan, and South Korea. This region benefits from a robust manufacturing infrastructure and a large consumer base, driving significant demand for coatings, adhesives, and elastomers. North America and Europe, while mature markets, are also witnessing steady growth, largely propelled by stringent environmental regulations necessitating high-performance, durable, and low-VOC (Volatile Organic Compound) solutions. These regions are also hubs for innovation, with a focus on specialty applications and advanced material development. Emerging economies in Latin America and the Middle East & Africa are showing promising growth potential, attributed to infrastructure development projects and increasing industrial output, creating new avenues for XDI adoption.

In terms of segmentation, the coatings application segment holds a significant share of the Xylylene Diisocyanate market, driven by the demand for highly durable, weather-resistant, and UV-stable polyurethane coatings in automotive, industrial, and architectural applications. The adhesives and sealants segments are also exhibiting strong growth, fueled by the need for high-strength, flexible, and long-lasting bonding solutions in construction, electronics, and packaging. Within end-use industries, the automotive sector remains a major consumer, leveraging XDI for interior and exterior coatings, adhesives, and elastomers that enhance vehicle aesthetics, performance, and longevity. The construction industry is another key segment, utilizing XDI-based materials for protective coatings, flooring, and sealants that offer superior durability and resistance to environmental elements. Furthermore, the electronics sector is increasingly adopting XDI for its insulating and protective properties in various components, reflecting a broader trend towards high-performance materials in advanced technological applications.

AI Impact Analysis on Xylylene Diisocyanate Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize various stages of the Xylylene Diisocyanate market, from raw material procurement and production optimization to demand forecasting and application development. Key themes revolve around improving manufacturing efficiency, reducing operational costs, enhancing product quality through predictive analytics, and accelerating research and development cycles for novel XDI-based materials. There is significant interest in AI's potential to address supply chain complexities, optimize inventory management, and facilitate dynamic pricing strategies. Concerns often include the initial investment costs for AI implementation, the need for specialized data infrastructure, and ensuring data security and privacy within the chemical industry. Expectations are high for AI to unlock new levels of precision, efficiency, and innovation, ultimately leading to more sustainable and cost-effective XDI production and its broader adoption in advanced applications.

- AI-driven process optimization for XDI synthesis, improving reaction yields and energy efficiency.

- Predictive maintenance for manufacturing equipment, minimizing downtime and extending asset lifespan.

- Enhanced quality control through real-time data analysis and anomaly detection in XDI production.

- Optimized supply chain management, including raw material sourcing and logistics, reducing costs and lead times.

- Advanced demand forecasting using machine learning algorithms to anticipate market needs and production planning.

- Accelerated R&D for novel XDI-based polyurethanes by simulating material properties and performance.

- Development of smart sensor technologies for real-time monitoring of application performance and material degradation.

- Personalized product development and formulation recommendations based on specific customer requirements.

- Improved safety protocols in chemical plants through AI-powered risk assessment and predictive analytics.

- Automated market trend analysis to identify emerging applications and competitive landscapes.

- Enhanced sustainability through AI-optimized resource utilization and waste reduction strategies.

- Digital twins of production facilities for scenario planning and operational efficiency improvements.

- Robotics and automation integration in XDI handling and packaging for increased safety and precision.

- Data-driven insights for strategic decision-making across the entire XDI value chain.

- AI-powered predictive modeling for raw material price fluctuations, enabling better procurement strategies.

DRO & Impact Forces Of Xylylene Diisocyanate Market

The Xylylene Diisocyanate market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces that shape its trajectory and competitive landscape. Key drivers include the ever-increasing global demand for high-performance materials in diverse end-use industries such as automotive, construction, and electronics, where XDI’s superior properties like UV stability, flexibility, and mechanical strength are highly valued. The continuous technological advancements in polyurethane chemistry, which allow for the development of innovative XDI-based formulations with enhanced properties, further propel market expansion. Additionally, the growing consumer preference for durable, long-lasting, and aesthetically pleasing products, coupled with stringent performance requirements in various industrial applications, acts as a significant catalyst for XDI adoption. The trend towards lightweighting in automotive and aerospace sectors also supports demand, as XDI contributes to materials that offer an optimal strength-to-weight ratio.

However, several restraints pose challenges to the market’s growth. The volatility of raw material prices, particularly for key precursors like p-xylene and toluene, directly impacts production costs and profit margins for XDI manufacturers. This price unpredictability can lead to supply chain disruptions and financial instability within the market. Stringent environmental regulations and health and safety concerns associated with the handling and production of isocyanates, including XDI, necessitate significant investments in compliance, safety equipment, and waste management, adding to operational expenses. Furthermore, competition from alternative diisocyanates and substitute materials, which may offer similar performance at lower costs or fewer regulatory hurdles, presents a constant challenge. The need for specialized handling and processing infrastructure due to the reactivity and toxicity of isocyanates also acts as a barrier to entry for new players and can limit adoption in less equipped facilities.

Opportunities for growth in the Xylylene Diisocyanate market are emerging from various fronts. The growing demand for bio-based and sustainable chemical solutions is prompting research and development into green XDI alternatives, which could unlock new market segments and appeal to environmentally conscious consumers and industries. The expansion into new and niche application areas, such as specialized textiles, medical devices, and advanced optical materials, offers significant untapped potential. Furthermore, continuous innovation in catalyst technologies and non-phosgene production routes promises to enhance production efficiency, reduce environmental impact, and improve the overall cost-effectiveness of XDI manufacturing. The rapid industrialization and infrastructure development in emerging economies, particularly in Asia Pacific and Latin America, present substantial growth opportunities as these regions seek advanced materials for their burgeoning manufacturing and construction sectors. The increasing adoption of 3D printing and additive manufacturing techniques, which can benefit from XDI’s unique material properties, also represents a promising avenue for future market expansion.

Beyond these direct factors, broader impact forces also shape the XDI market. The bargaining power of raw material suppliers is moderately high due to the specialized nature of some precursors and the limited number of suppliers for certain intermediates, which can influence pricing and supply stability for XDI manufacturers. Conversely, the bargaining power of buyers is also significant, especially for large-volume purchasers in the automotive and construction industries, who often demand competitive pricing and customized product specifications. The threat of new entrants into the XDI market is relatively low due to the high capital investment required for manufacturing facilities, complex technological expertise, stringent regulatory compliance, and established intellectual property. However, the threat of substitutes, particularly from other diisocyanates or entirely different polymer systems, remains a constant concern, driving continuous innovation and product differentiation among XDI producers. Competitive rivalry among existing market players is intense, characterized by continuous product development, strategic pricing, and regional market expansion initiatives, all aimed at gaining and maintaining market share.

Segmentation Analysis

The Xylylene Diisocyanate market is comprehensively segmented to provide a detailed understanding of its diverse applications, end-use industries, product types, and grades. This segmentation allows for precise market analysis, identifying key growth drivers, challenges, and opportunities within specific sub-markets. The primary segmentation categories include application, end-use industry, and geographic region, with further granular distinctions made within these categories to reflect the multifaceted nature of XDI demand and supply. Understanding these segments is crucial for market participants to tailor their strategies, optimize product portfolios, and target specific customer bases effectively. The versatile chemical properties of XDI enable its integration into a wide range of products, catering to various performance requirements across different sectors, thereby supporting its extensive segmentation.

- By Application:

- Coatings

- Polyurethane Coatings

- Automotive Coatings

- Wood Coatings

- Industrial Coatings

- Protective Coatings

- Adhesives

- Structural Adhesives

- Pressure-Sensitive Adhesives

- Reactive Adhesives

- Elastomers

- Thermoplastic Polyurethanes

- Cast Elastomers

- Sealants

- Other Applications (Textiles, Medical Devices, Optical Materials)

- Coatings

- By End-Use Industry:

- Automotive

- Construction

- Electronics

- Industrial

- Medical

- Packaging

- Others

- By Type:

- Para-Xylylene Diisocyanate (p-XDI)

- Meta-Xylylene Diisocyanate (m-XDI)

- By Grade:

- Industrial Grade

- Specialty Grade

Value Chain Analysis For Xylylene Diisocyanate Market

The value chain for the Xylylene Diisocyanate market is a complex network of activities, starting from the sourcing of raw materials and extending through various stages of manufacturing, formulation, distribution, and ultimately, to the end-user applications. Understanding this chain is crucial for identifying key players, potential bottlenecks, and areas for value addition or cost optimization. The upstream segment involves the production and supply of essential chemical precursors, which are foundational to XDI synthesis. These raw materials undergo intricate chemical reactions in the manufacturing phase to yield the final XDI product, which then moves downstream for further processing and integration into specialized materials.

In the upstream analysis, the primary raw materials for XDI production typically include p-xylene or m-xylene, which are petroleum-derived aromatic hydrocarbons, along with phosgene (or alternative non-phosgene reactants) and other catalysts. Suppliers of these base chemicals form the initial link in the value chain, and their pricing, quality, and reliability significantly impact the cost-effectiveness and consistency of XDI manufacturing. Chemical intermediate suppliers also play a crucial role, providing specialized components required for specific XDI isomer production or purification steps. Relationships with these upstream suppliers are critical, as secure and stable access to high-quality raw materials is paramount for maintaining uninterrupted production and competitive pricing within the XDI market. Volatility in crude oil prices directly impacts the cost of xylene, thereby influencing the overall profitability of XDI manufacturers.

The downstream analysis of the XDI value chain focuses on the transformation of XDI into finished products and its subsequent distribution. Once XDI is manufactured, it is typically supplied to formulators and compounders who integrate it into various polyurethane systems, such as polyols and other additives, to create specific coatings, adhesives, elastomers, and sealants. These formulators often customize their products to meet the precise technical specifications and performance requirements of diverse end-use industries, adding significant value through their expertise in material science and application development. The distribution channel then facilitates the movement of these finished or semi-finished XDI-based products to a wide array of end-users. Direct sales involve manufacturers selling directly to large industrial clients or strategic partners, allowing for close technical collaboration and tailored solutions. Indirect channels, on the other hand, utilize a network of distributors, agents, and wholesalers who provide market access, logistics, and technical support to smaller businesses or geographically dispersed customers. This multi-channel approach ensures broad market penetration and efficient delivery of XDI-based solutions to various segments globally.

Xylylene Diisocyanate Market Potential Customers

The Xylylene Diisocyanate market serves a broad and diverse range of potential customers across multiple industrial sectors, all of whom seek high-performance materials that offer superior durability, UV stability, flexibility, and mechanical strength. These customers are primarily manufacturers and formulators who incorporate XDI into their proprietary product formulations to enhance the quality, longevity, and functional properties of their end products. The extensive application scope of XDI-based polyurethanes means that its potential customer base spans from global chemical conglomerates to specialized material developers and smaller-scale manufacturers focused on niche markets. Understanding the distinct needs and technical specifications of these varied customer segments is essential for XDI producers to effectively market their products and foster long-term partnerships.

Key end-users and buyers of XDI include manufacturers in the coatings industry, particularly those specializing in automotive OEM and refinish coatings, industrial protective coatings, wood coatings, and high-performance architectural coatings. These customers value XDI for its ability to prevent yellowing, resist abrasion, and withstand harsh environmental conditions, thereby extending the lifespan and aesthetic appeal of painted surfaces. Another significant customer segment comprises companies in the adhesives and sealants sector, ranging from producers of structural adhesives for construction and automotive assembly to manufacturers of specialized sealants for electronics and packaging. These buyers rely on XDI to provide strong, flexible, and durable bonds that can resist moisture, chemicals, and temperature fluctuations, ensuring product integrity and reliability.

Furthermore, manufacturers of elastomers, including thermoplastic polyurethanes (TPUs) and cast elastomers, represent a crucial customer base for XDI. These companies utilize XDI to produce materials with exceptional resilience, tear strength, and abrasion resistance, finding applications in diverse products such as industrial rollers, footwear components, sports equipment, and medical devices. The electronics industry also emerges as a growing area, with manufacturers seeking XDI-based encapsulants and protective coatings for sensitive components, valuing its electrical insulation properties and environmental resistance. Beyond these major segments, other potential customers include textile manufacturers developing specialized fabrics with enhanced durability and UV protection, medical device companies requiring biocompatible and robust materials, and producers of optical materials where high clarity and resistance to yellowing are critical. Each of these customer groups presents unique technical challenges and opportunities, requiring XDI suppliers to offer not just a raw material, but often technical support and formulation expertise to ensure successful product development and application.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 Billion |

| Market Forecast in 2033 | USD 4.05 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mitsui Chemicals, Inc., Vencorex, Covestro AG, BASF SE, Wanhua Chemical Group Co., Ltd., DIC Corporation, Asahi Kasei Corporation, Huntsman Corporation, Dow Inc., Tosoh Corporation, UBE Corporation, Evonik Industries AG, Cargill, Incorporated, SABIC, Formosa Plastics Corporation, KURARAY CO., LTD., Sumitomo Chemical Co., Ltd., Shanghai Huafon Polyurethane Co., Ltd., Jiangsu Taihu New Materials Co., Ltd., Kumho Mitsui Chemicals, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Xylylene Diisocyanate Market Key Technology Landscape

The Xylylene Diisocyanate market is underpinned by a sophisticated and evolving technological landscape that encompasses various aspects of its production, purification, and application. At the core of XDI manufacturing are complex chemical synthesis routes, primarily involving the phosgenation of xylylenediamines. This traditional phosgene-based route requires specialized infrastructure and stringent safety measures due to the highly toxic nature of phosgene. Continuous efforts are being made to optimize this process for higher yields, purity, and energy efficiency, leveraging advanced catalytic systems and process control technologies to ensure consistent product quality and cost-effectiveness. The development of high-purity XDI is crucial, as even minor impurities can significantly impact the performance of final polyurethane products, particularly in demanding applications like optical materials and high-end coatings.

Beyond traditional phosgenation, a key area of technological innovation focuses on developing non-phosgene routes for XDI synthesis. These alternative pathways aim to reduce environmental impact, enhance operational safety, and potentially lower production costs by avoiding the use of highly hazardous phosgene. Research efforts in this domain explore various methods, such as carbonate chemistry, reductive carbonylation, and other catalytic approaches that utilize less toxic and more sustainable reagents. While still facing challenges in terms of economic viability and scalability compared to established phosgene routes, advancements in non-phosgene technologies represent a significant future trend. These innovations are driven by increasing regulatory pressures and a global push towards greener chemistry, potentially opening new opportunities for XDI manufacturers to meet sustainability goals and broaden market acceptance.

Furthermore, the technology landscape extends to the formulation and application of XDI-based polyurethanes. This includes the development of novel polyol systems, chain extenders, and catalysts that work synergistically with XDI to achieve desired material properties. Advances in polymer science enable formulators to fine-tune properties like cure speed, adhesion, flexibility, and chemical resistance, expanding XDI’s utility in new and challenging environments. Techniques such as solvent-free and high-solids formulations are gaining traction, driven by regulations limiting volatile organic compounds (VOCs) and the desire for more environmentally friendly products. Continuous innovation in coating and adhesive application technologies, such as spray methods, roller coating, and reactive hot melt systems, also plays a crucial role in maximizing the performance benefits of XDI. The integration of digital tools for process simulation, quality control, and predictive modeling is also becoming increasingly important, enabling manufacturers to optimize operations, accelerate product development cycles, and maintain a competitive edge in the evolving Xylylene Diisocyanate market.

Regional Highlights

- Asia Pacific (APAC): The APAC region stands as the largest and fastest-growing market for Xylylene Diisocyanate, primarily driven by robust industrial growth, rapid urbanization, and significant investments in infrastructure and manufacturing sectors in countries like China, India, Japan, South Korea, and Southeast Asian nations. This region benefits from a burgeoning automotive industry, escalating construction activities, and a flourishing electronics sector, all of which are major consumers of XDI-based coatings, adhesives, and elastomers. The presence of numerous manufacturing hubs and a large consumer base further fuels demand, while increasing disposable incomes contribute to the uptake of high-performance products requiring XDI.

- North America: North America represents a mature yet steadily growing market for XDI, characterized by a strong emphasis on advanced materials, stringent environmental regulations, and a focus on high-performance applications. The automotive sector, particularly for premium vehicles, and the aerospace industry are significant end-users, demanding durable and UV-resistant coatings and adhesives. The region's robust construction sector, coupled with ongoing renovation and infrastructure projects, also contributes to demand for XDI in sealants and protective coatings. Innovation in specialty chemicals and the development of sustainable XDI solutions are key trends in this region.

- Europe: Europe is another mature market for XDI, driven by a strong focus on sustainability, stringent regulatory frameworks (such as REACH), and a high demand for advanced, eco-friendly materials. The European automotive industry, known for its high-quality standards, is a major consumer of XDI for durable coatings and adhesives. The region also sees significant demand from the construction, industrial, and electronics sectors, particularly for applications requiring excellent UV stability and mechanical properties. Research and development in bio-based XDI and non-phosgene production methods are prominent in this region.

- Latin America: The Latin American XDI market is an emerging region with considerable growth potential, primarily driven by increasing industrialization, expanding construction activities, and a growing automotive manufacturing base, especially in countries like Brazil and Mexico. Economic development and rising foreign investments in manufacturing and infrastructure projects are creating new opportunities for XDI adoption. While still smaller than other regions, the demand for performance materials is expected to grow as these economies mature and industrial output increases.

- Middle East and Africa (MEA): The MEA region exhibits nascent but promising growth in the XDI market, propelled by ongoing infrastructure development projects, diversification of economies away from oil, and increasing industrialization in countries like Saudi Arabia, UAE, and South Africa. The demand for durable coatings and sealants in the construction sector is a significant driver. While the market is relatively smaller, the push for local manufacturing capabilities and the development of new industries are expected to boost XDI consumption in the long term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Xylylene Diisocyanate Market.- Mitsui Chemicals, Inc.

- Vencorex

- Covestro AG

- BASF SE

- Wanhua Chemical Group Co., Ltd.

- DIC Corporation

- Asahi Kasei Corporation

- Huntsman Corporation

- Dow Inc.

- Tosoh Corporation

- UBE Corporation

- Evonik Industries AG

- Cargill, Incorporated

- SABIC

- Formosa Plastics Corporation

- KURARAY CO., LTD.

- Sumitomo Chemical Co., Ltd.

- Shanghai Huafon Polyurethane Co., Ltd.

- Jiangsu Taihu New Materials Co., Ltd.

- Kumho Mitsui Chemicals, Inc.

Frequently Asked Questions

Analyze common user questions about the Xylylene Diisocyanate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Xylylene Diisocyanate (XDI) and what are its primary uses?

Xylylene Diisocyanate (XDI) is an aromatic diisocyanate used as a crucial building block in high-performance polyurethane systems. It is primarily utilized in the manufacturing of durable coatings, strong adhesives, resilient elastomers, and robust sealants due to its excellent UV stability, flexibility, and mechanical strength, making products resistant to yellowing and degradation.

What are the key advantages of using XDI over other diisocyanates in polyurethane formulations?

The main advantages of XDI include superior UV resistance, which prevents yellowing and maintains aesthetic appeal, along with enhanced mechanical properties such as high tensile strength, elongation, and abrasion resistance. It also offers good chemical resistance and flexibility at low temperatures, making it ideal for demanding applications where durability and longevity are critical.

Which industries are the major consumers of XDI?

The major industries consuming XDI are automotive (for coatings and adhesives), construction (for protective coatings, sealants, and flooring), electronics (for encapsulants and protective layers), and various industrial applications requiring high-performance elastomers and coatings. The medical and textile sectors are also emerging as significant end-users due to specific material requirements.

What are the main factors driving the growth of the Xylylene Diisocyanate market?

The market growth for XDI is primarily driven by the increasing global demand for high-performance materials in key end-use industries, particularly those requiring superior UV stability and mechanical strength. Technological advancements in polyurethane chemistry, continuous innovation in application areas, and a growing emphasis on product durability and longevity also act as significant drivers.

What are the primary challenges or restraints faced by the XDI market?

Key challenges for the XDI market include the volatility of raw material prices, which can impact production costs and profitability. Additionally, stringent environmental regulations and health and safety concerns associated with the handling and production of isocyanates pose regulatory hurdles and necessitate significant investments in compliance and safety measures, alongside competition from alternative materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager