Zeolite Membrane Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439021 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Zeolite Membrane Market Size

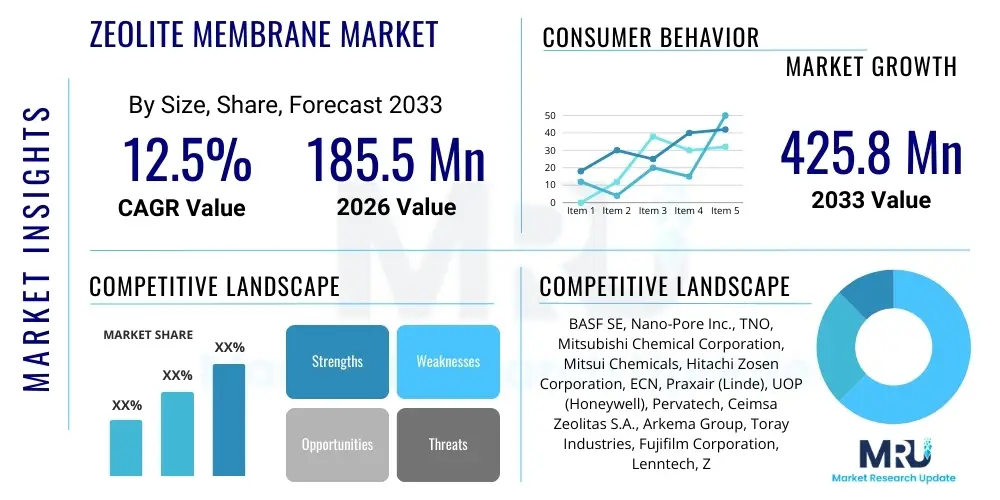

The Zeolite Membrane Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at $185.5 Million in 2026 and is projected to reach $425.8 Million by the end of the forecast period in 2033.

Zeolite Membrane Market introduction

The Zeolite Membrane Market encompasses advanced separation technology utilizing crystalline aluminosilicate materials known as zeolites, which possess highly uniform pore sizes, typically ranging from 0.3 to 1.0 nanometers. These porous structures enable molecular sieving mechanisms, making zeolite membranes exceptionally effective for high-precision separations that are energy-intensive or difficult to achieve using conventional methods like distillation or solvent extraction. Zeolite membranes are primarily synthesized onto porous supports (such as ceramics or metals) to ensure mechanical stability, creating a selective layer that facilitates processes like gas separation, liquid purification, and catalysis. The foundational advantage of these membranes lies in their ability to achieve high selectivity at elevated temperatures and in harsh chemical environments, differentiating them significantly from polymer-based alternatives.

Major applications driving the commercialization of zeolite membrane technology include the dehydration of organic solvents through pervaporation, particularly in the chemical and pharmaceutical industries where purity is paramount, and the separation of permanent gases, such as hydrogen recovery from refinery streams and CO2 capture. Furthermore, these membranes are increasingly utilized in petrochemical processing for isomer separation and in environmental applications for volatile organic compound (VOC) removal. The increasing global focus on energy efficiency and sustainable manufacturing practices directly accelerates the adoption of zeolite membrane systems, as they significantly reduce the thermal energy required for separation compared to traditional heat-driven processes.

The primary benefits fueling market expansion include superior thermal and chemical stability, enabling operation under conditions where polymeric membranes fail; high molecular selectivity due to their uniform pore structure; and the potential for substantial reductions in operational energy costs. Driving factors center on stringent environmental regulations necessitating efficient carbon capture and solvent recovery, the booming demand for ultra-pure gases in electronics and industrial sectors, and continuous research breakthroughs enhancing membrane reproducibility and scale-up capabilities. As manufacturing costs decrease and long-term performance data validates their reliability, zeolite membranes are transitioning from niche laboratory tools to essential industrial separation components.

Zeolite Membrane Market Executive Summary

The Zeolite Membrane Market is positioned for robust growth, underpinned by escalating industrial demand for energy-efficient separation technologies, particularly within the petrochemical, refining, and environmental sectors. Current business trends indicate a strong shift towards commercial-scale deployment, moving beyond pilot projects. Key market players are concentrating their efforts on improving the mechanical stability of supported membranes and reducing synthesis time and cost, targeting processes like hydrogen purification and ethanol dehydration. Regional trends show Asia Pacific leading in consumption and manufacturing capacity, driven by rapid industrial expansion and governmental mandates for cleaner production methods, while North America and Europe prioritize the development of advanced CO2 capture technologies using these membranes.

Segmentation analysis highlights the dominance of the pervaporation segment, primarily due to established applications in solvent recovery and bio-fuel dehydration. However, the gas separation segment is anticipated to exhibit the fastest growth, propelled by the urgent need for cost-effective natural gas processing (e.g., nitrogen rejection, moisture removal) and enhanced efficiency in hydrogen production streams. The segment trends also reflect a preference for LTA and MFI type zeolites, valued for their proven performance in water separation and specific molecular sieving capabilities, respectively. Investment in novel zeolite structures, such such as DDR and Chabazite, is also increasing, focusing on challenging separations like CO2/CH4 and C3 isomer separation.

Overall, the market trajectory is highly dependent on standardization and scalability. While the performance of zeolite membranes is superior in specific applications, high capital expenditure and the complexity of synthesizing large-area defect-free membranes remain critical adoption barriers. Successful commercial strategies involve strategic collaborations between academic researchers, membrane fabricators, and end-users to tailor membrane properties to specific industrial needs, accelerating technology readiness levels and broadening market acceptance across diverse separation fields requiring high throughput and extreme stability.

AI Impact Analysis on Zeolite Membrane Market

User inquiries regarding AI's influence on the Zeolite Membrane Market frequently revolve around optimizing material discovery, predicting membrane performance under varied industrial conditions, and automating complex synthesis protocols. Users are primarily concerned with how Artificial Intelligence can streamline the costly and time-consuming process of finding novel zeolite frameworks suitable for specific separations, such as highly efficient CO2 capture or complex hydrocarbon fractioning. Key themes include the use of machine learning (ML) for structure-property relationship prediction, generative AI for proposing new synthetic pathways, and deep learning models for quality control during large-scale membrane fabrication to ensure defect-free layers. Expectations are high that AI will drastically cut R&D cycles and improve the reliability and reproducibility required for mass commercialization.

- AI-Driven Material Discovery: Utilizing machine learning algorithms to screen virtual libraries of thousands of hypothetical zeolite structures, predicting their separation performance (selectivity and flux) for target molecules before experimental synthesis, thereby drastically accelerating the R&D pipeline.

- Synthesis Optimization: Employing AI models to optimize complex hydrothermal synthesis parameters (temperature, pH, concentration, time) to consistently produce large-area, defect-free zeolite films, ensuring industrial scalability and reducing batch-to-batch variation.

- Predictive Maintenance and Performance Monitoring: Integrating sensors and AI into commercial membrane units to continuously monitor performance degradation, predict fouling events, and optimize operating conditions in real-time to maximize membrane lifespan and efficiency in harsh environments.

- Automated Quality Control (AQC): Using computer vision and deep learning for rapid, non-destructive inspection of synthesized membrane surfaces to detect micro-defects or cracks that compromise separation selectivity, enhancing manufacturing throughput.

- Process Modeling and Simulation: Leveraging AI to create highly accurate simulation models that predict the complex mass transfer dynamics within membrane modules, optimizing system design and reducing the need for extensive physical prototyping in pilot plants.

DRO & Impact Forces Of Zeolite Membrane Market

The dynamics of the Zeolite Membrane Market are shaped by a complex interplay of stringent environmental drivers pushing adoption, technical limitations hindering rapid scale-up, and lucrative opportunities emerging from niche, high-value industrial applications. The primary drivers revolve around the global mandate for carbon neutrality and the necessity for lower energy consumption in chemical processes. Restraints often center on the high initial capital investment required for fabrication facilities, the challenge of achieving reproducibility in large-scale synthesis, and the current limitations in producing durable, high-flux membranes that can withstand prolonged, aggressive industrial use without degradation. Opportunities are substantial, particularly in the realm of advanced petrochemical separations (e.g., xylene separation) and in the emerging hydrogen economy, where highly selective separation of H2 is critical.

The driving force for market growth is fundamentally linked to regulatory pressure, especially mandates enforcing lower VOC emissions and increased energy efficiency in chemical and refining plants. Zeolite membranes offer a revolutionary path to achieving these goals by replacing energy-intensive distillation columns with passive, molecular-level separation processes. Furthermore, the increasing complexity of feedstocks, such as sour natural gas or complex bio-fuel mixtures, necessitates separation methods with ultra-high selectivity that conventional technologies cannot match. This performance gap is uniquely addressed by the molecular sieving capabilities of zeolites, acting as a major pull factor for industrial adoption.

Conversely, the key restraint remains the technological hurdle of scaling up synthesis while maintaining quality control. The deposition of a thin, continuous, and defect-free zeolite layer over large substrate areas remains scientifically challenging and expensive, limiting widespread implementation in massive industrial plants where cost-per-area is a major constraint. However, the immense opportunity lies in addressing global environmental crises, such as providing effective, low-cost CO2 capture solutions for industrial flue gases, which could fundamentally transform the energy sector and establish zeolite membranes as a trillion-dollar technology if the scale-up challenge is overcome. The five impact forces—customer needs, technology development speed, regulatory environment, manufacturing costs, and competitive intensity—collectively determine the speed and trajectory of market penetration.

Segmentation Analysis

The Zeolite Membrane Market is comprehensively segmented based on separation mechanism, zeolite type, application, and end-user industry, providing a granular view of specific market dynamics and growth potential. The separation mechanism segmentation clearly defines the primary uses, with pervaporation and gas separation being the most commercially relevant technologies today, while vapor permeation and liquid phase separation hold promise for future growth. Understanding the market by zeolite type (e.g., MFI, LTA, FAU) is crucial, as performance is inextricably linked to the specific crystal structure and pore size, dictating suitability for targeted molecules. Application segmentation reveals the breadth of industrial utility, ranging from traditional solvent dehydration to emerging uses in flue gas cleanup and specialized petrochemical processing.

The market's structure is heavily influenced by end-user demand, with the chemical and petrochemical industries dominating due to their continuous need for high-purity feedstocks and energy optimization. The pharmaceutical industry, requiring sterile and high-purity solvent recovery, also constitutes a high-value, albeit smaller, segment. Analyzing these segments helps stakeholders target R&D efforts towards structures that solve the most pressing industrial challenges, such as developing high-performance membranes for olefin/paraffin separation, which currently relies on cryogenic and energy-intensive methods. The forecasted fastest-growing segments typically align with areas of highest regulatory pressure, such as carbon capture and sustainable energy production.

- Separation Mechanism:

- Pervaporation (Liquid Separation/Dehydration)

- Gas Separation (H2 recovery, CO2/CH4 separation, O2/N2 separation)

- Vapor Permeation

- Liquid Phase Separation (e.g., Desalination, Organic-Organic Separation)

- Zeolite Type:

- MFI (ZSM-5) Type

- LTA (Zeolite A) Type

- FAU (Zeolite X, Y) Type

- DDR Type

- Chabazite (CHA) Type

- Other Types (MOR, BEA, etc.)

- Application:

- Solvent Dehydration and Recovery

- Hydrogen Purification and Recovery

- Natural Gas Processing and Upgrade (CO2, N2 removal)

- Air Separation

- Petrochemical Separation (e.g., Isomer separation, Olefin/Paraffin separation)

- Environmental Control (VOC removal)

- End-User Industry:

- Chemical and Petrochemical

- Oil and Gas (Refining and Natural Gas)

- Pharmaceutical and Life Sciences

- Environmental Management and Waste Water Treatment

- Electronics and Semiconductor

Value Chain Analysis For Zeolite Membrane Market

The value chain for the Zeolite Membrane Market begins with complex upstream activities involving the synthesis and sourcing of raw materials, primarily silica and alumina precursors, which dictate the ultimate crystal structure and purity of the resulting zeolite powder. This upstream segment is highly specialized, relying on chemical manufacturers and material science companies focused on high-purity inorganic chemistry. Efficient upstream operations, including precise control over the hydrothermal synthesis of the zeolite precursor, are foundational to minimizing defects in the final membrane layer, directly influencing performance and cost.

Midstream activities involve the critical process of membrane fabrication, where the synthesized zeolite material is deposited onto porous supports (ceramic, metal, or carbon). This stage includes support manufacturing, often involving extrusion or sintering, followed by the complex coating and crystallization processes necessary to form a thin, selective zeolite film. Key stakeholders in this stage include specialized membrane fabricators and R&D divisions within large chemical companies. The midstream focus is heavily centered on scalability, uniformity, and adherence testing, as manufacturing defects here directly translate into poor separation efficiency and module failure.

Downstream distribution channels typically involve two major paths: Direct sales to large petrochemical or refining corporations who integrate the membranes into their existing plants, and indirect sales through specialized engineering, procurement, and construction (EPC) firms that design and install custom separation systems incorporating the membrane modules. Potential customers primarily look for established case studies and performance guarantees, favoring suppliers that offer complete system integration, including peripheral equipment like pumps, heat exchangers, and control units. The complexity of integration means that comprehensive technical support and long-term service agreements are crucial components of the final offering, extending the value chain far beyond the simple sale of the membrane unit.

Zeolite Membrane Market Potential Customers

Potential customers for zeolite membranes are predominantly industrial entities grappling with the challenges of achieving high-purity separations, reducing energy consumption, and complying with strict environmental mandates. The primary buyers fall within the chemical and petrochemical manufacturing sectors, particularly operators of large facilities involved in solvent recovery, isomer separation (e.g., xylene production), and the management of high-volume gas streams. These customers prioritize membranes based on operational longevity, resistance to aggressive chemical environments, and the ability to operate at high temperatures, offering substantial operational expenditure (OpEx) savings compared to thermal separation techniques.

The second major group includes companies in the natural gas and oil refining sectors, which require highly efficient means to upgrade raw gas streams by removing contaminants like CO2, H2S, and water vapor (dehydration). These applications demand robust membranes that can handle high pressure and fluctuating feed compositions. The emerging hydrogen economy also designates industrial gas companies and clean energy producers as key future customers, as selective separation is critical for producing fuel-cell grade hydrogen from various sources, including steam methane reforming (SMR) or water electrolysis. These buyers seek membranes optimized for H2/CO2 and H2/N2 separations.

Furthermore, the pharmaceutical and fine chemical industries represent high-value buyers, especially for pervaporation applications requiring ultra-pure solvent dehydration—a critical step in drug manufacturing and crystallization processes. While their consumption volume might be lower than petrochemicals, the necessity for flawless separation and the high cost of alternative methods make zeolite membranes an attractive solution. Lastly, environmental service companies and municipal water treatment facilities are emerging customers, focusing on specialized applications like VOC stripping from industrial waste streams and advanced water purification where conventional filters are inadequate, showcasing the breadth of applicability of this molecular sieving technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.5 Million |

| Market Forecast in 2033 | $425.8 Million |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Nano-Pore Inc., TNO, Mitsubishi Chemical Corporation, Mitsui Chemicals, Hitachi Zosen Corporation, ECN, Praxair (Linde), UOP (Honeywell), Pervatech, Ceimsa Zeolitas S.A., Arkema Group, Toray Industries, Fujifilm Corporation, Lenntech, Zeochem AG, Saint-Gobain, Applied Materials Inc., LiqTech International, Rota-Chem. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zeolite Membrane Market Key Technology Landscape

The technology landscape of the Zeolite Membrane Market is dominated by advanced synthesis and fabrication techniques aimed at minimizing defects and maximizing the active membrane area. The primary method utilized is Secondary (or Seeded) Growth, where a uniform layer of pre-synthesized zeolite nanocrystals (seeds) is first applied to a porous support, followed by hydrothermal treatment to induce continuous crystal growth. This approach significantly lowers the required crystallization time and improves the likelihood of forming a defect-free, interlocking zeolite layer compared to traditional primary crystallization methods. The choice of support material—ranging from porous stainless steel and alumina to more cost-effective polymer-based supports (for lower-temperature applications)—is a critical technological decision influencing mechanical stability and system cost.

Current technological innovations are heavily focused on three main areas: reducing membrane thickness to enhance flux (permeation rate), engineering novel zeolite frameworks (e.g., hierarchical porous structures) to achieve highly specific separations, and developing scalable coating methods. Techniques such as microwave-assisted hydrothermal synthesis and vapor-phase transport methods are being explored to accelerate crystallization kinetics and enable highly reproducible production runs suitable for commercial scaling. Furthermore, the integration of 3D printing and additive manufacturing techniques is starting to emerge, allowing for the creation of complex, customized membrane module geometries that maximize surface area per unit volume, ultimately improving system compactness and efficiency.

A critical technical challenge being addressed involves mitigating the trade-off between selectivity and flux. Researchers are tackling this by synthesizing Ultra-Thin Zeolite Membranes (UTZMs), often less than 1 micrometer thick, which maintain high selectivity while offering drastically improved permeation rates. Parallel efforts are directed towards robust module design and sealing technologies, which are essential for industrial deployment, particularly in high-pressure gas separation systems. The technology landscape is thus characterized by ongoing material science refinement combined with sophisticated engineering efforts to transition these lab-scale breakthroughs into robust, commercially viable industrial separation systems capable of operating reliably for decades.

Regional Highlights

- Asia Pacific (APAC): APAC is the leading and fastest-growing region, primarily driven by massive investments in petrochemical refining capacity, rapid industrialization, and strong governmental initiatives in countries like China, India, and South Korea focused on sustainable manufacturing and energy independence. The demand for solvent dehydration in the booming pharmaceutical and chemical manufacturing sectors, combined with the necessity for natural gas processing, fuels the high adoption rate of zeolite membrane technology here.

- North America: North America holds a significant share, characterized by high R&D spending and early adoption of advanced separation technologies, particularly in the Oil & Gas sector for natural gas upgrading (removal of CO2 and N2) and in the developing hydrogen economy. Regulatory environments, especially related to carbon capture and storage (CCS) in the US and Canada, provide strong incentives for membrane development and deployment.

- Europe: Europe is a mature market focusing heavily on sustainability and compliance with strict environmental regulations (e.g., REACH). The market growth is centered around high-value applications, including solvent recovery in specialty chemicals and pharmaceuticals, and extensive efforts in developing zeolite membrane reactors for integrated chemical synthesis and separation, maximizing process efficiency.

- Middle East and Africa (MEA): Growth in MEA is highly concentrated within the oil and gas sector. The primary application is the removal of contaminants from natural gas streams to meet pipeline specifications and maximize LNG production. Investments in large-scale refining and petrochemical projects in Saudi Arabia, UAE, and Qatar are driving the need for durable, high-performance separation membranes.

- Latin America: This region presents moderate growth, largely focused on industrial modernization. Key drivers include the processing of biofuels (ethanol dehydration) and optimization in existing petrochemical operations. Market penetration is steadily increasing as local industries seek cost-effective alternatives to traditional energy-intensive separation techniques.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zeolite Membrane Market.- BASF SE

- Nano-Pore Inc.

- TNO (Netherlands Organization for Applied Scientific Research)

- Mitsubishi Chemical Corporation

- Mitsui Chemicals

- Hitachi Zosen Corporation

- ECN (Energy research Centre of the Netherlands - now part of TNO)

- Praxair (Linde)

- UOP (Honeywell)

- Pervatech

- Ceimsa Zeolitas S.A.

- Arkema Group

- Toray Industries

- Fujifilm Corporation

- Lenntech

- Zeochem AG

- Saint-Gobain

- Applied Materials Inc.

- LiqTech International

- Rota-Chem

Frequently Asked Questions

Analyze common user questions about the Zeolite Membrane market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a zeolite membrane and how does it achieve separation?

A zeolite membrane is a selective separation layer composed of crystalline aluminosilicate materials with uniform, molecular-sized pores (typically 0.3-1.0 nm). Separation is achieved through a molecular sieving mechanism, where molecules smaller than the pore size pass through, while larger molecules are rejected, offering extremely high selectivity compared to conventional methods.

Which application segment drives the highest demand for zeolite membranes?

The pervaporation segment, specifically solvent dehydration and recovery in the chemical and pharmaceutical industries, currently drives the highest commercial demand. This application capitalizes on the membrane’s exceptional stability and selectivity for separating water from organic solvents, which is difficult and energy-intensive via distillation.

What are the primary technical challenges hindering widespread adoption of zeolite membranes?

The major technical challenges include the difficulty and high cost associated with scaling up synthesis to produce large-area, defect-free membranes consistently; ensuring long-term mechanical and chemical stability under aggressive industrial operating conditions; and the high initial capital investment required for industrial implementation.

How do zeolite membranes contribute to environmental sustainability goals?

Zeolite membranes enhance sustainability by enabling highly energy-efficient separations, drastically reducing the thermal energy footprint compared to conventional distillation processes. They are also critical in environmental control applications, such as efficient carbon dioxide (CO2) capture and the recovery of volatile organic compounds (VOCs) from waste streams.

Which geographical region is projected to be the fastest-growing market for zeolite membranes?

The Asia Pacific (APAC) region is projected to be the fastest-growing market, driven by rapid expansion in chemical manufacturing, petrochemical refining capacity, and supportive government policies emphasizing industrial energy efficiency and regulatory compliance across major economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager