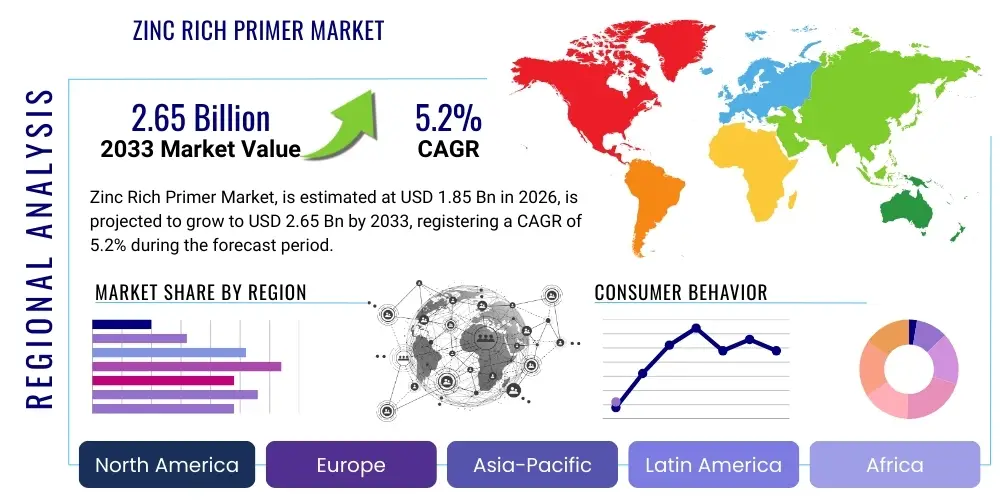

Zinc Rich Primer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439018 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Zinc Rich Primer Market Size

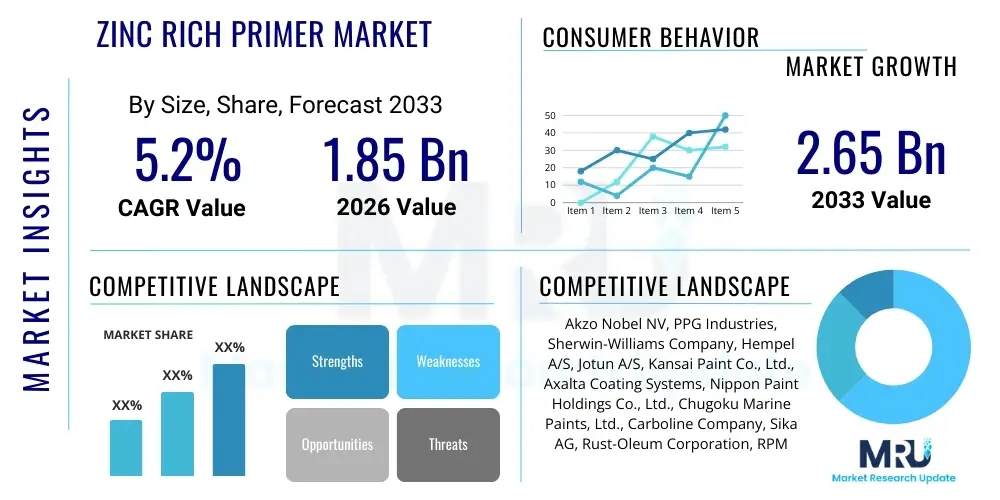

The Zinc Rich Primer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% between 2026 and 2033. The market is estimated at $1.85 Billion USD in 2026 and is projected to reach $2.65 Billion USD by the end of the forecast period in 2033.

Zinc Rich Primer Market introduction

The Zinc Rich Primer market encompasses high-performance protective coatings specifically engineered to prevent the corrosion of steel substrates through cathodic protection. These primers typically contain a high loading of zinc dust pigment, which acts sacrificially when the coating is compromised, shielding the underlying steel from environmental degradation. The primary applications for these sophisticated coatings are concentrated in heavy-duty sectors such as marine vessels and offshore structures, industrial plants, oil and gas pipelines, and large-scale infrastructure projects like bridges and power generation facilities, where long-term durability and resistance to harsh weather conditions are paramount requirements. The market features both inorganic (silicate-based) and organic (epoxy or polyurethane-based) formulations, each tailored for specific service environments and application characteristics. The increasing global focus on asset integrity management and the extension of operational lifespans for critical infrastructure are fundamentally driving the adoption of these premium anti-corrosion solutions across all major geographic regions, particularly in rapidly industrializing economies.

Zinc Rich Primers are distinguished by their exceptional adhesion to prepared steel surfaces and their robust chemical resistance, making them essential components in multi-coat protective systems. Their operational benefit lies primarily in significantly reducing maintenance costs associated with corrosion damage over the asset’s lifetime. The zinc content must meet stringent industry standards (often 85% or higher by weight in the dry film) to ensure effective galvanic action. Product development in this sector is heavily focused on enhancing Volatile Organic Compound (VOC) compliance, improving cure times, and developing single-component systems to simplify application procedures in the field. Furthermore, advancements in nano-technology are being explored to improve the dispersion of zinc particles, thus boosting efficiency and coverage without compromising protection standards. The demand correlation is strongly tied to global investment cycles in energy, transportation, and industrial expansion.

Zinc Rich Primer Market Executive Summary

The Zinc Rich Primer market is currently undergoing significant transformation, driven by robust business trends centered on global infrastructure development and stringent environmental regulations. Demand growth is particularly pronounced in Asia Pacific (APAC), fueled by massive investment in urbanization, maritime transport, and energy infrastructure, positioning APAC as the dominant regional market and the primary engine of future expansion. Segment trends indicate a sustained preference for epoxy-based zinc rich primers due to their versatility, excellent adhesion properties, and ease of use in diverse climatic conditions, though inorganic silicate primers maintain a critical role in high-temperature or extreme chemical environments. Furthermore, a key trend involves the market's gradual shift towards high-solids, low-VOC formulations to comply with evolving global environmental mandates, pushing manufacturers to innovate extensively in product chemistry and application technology. Competitive dynamics are characterized by intense R&D efforts aimed at reducing cure times and enhancing the service life of the coatings, ensuring differentiation in a technically demanding marketplace.

The core business trend influencing market trajectory is the increasing global emphasis on preventative maintenance over reactive repairs, especially concerning aging infrastructure in North America and Europe. This shift generates stable, long-term demand for high-performance coatings like zinc rich primers. Regionally, while APAC leads in volume growth due to new construction, established markets like Europe are pioneering regulatory changes that incentivize the adoption of sustainable, low-VOC products. The segment analysis reveals that the marine and protective coatings application segment remains the largest consumer, reflecting the essential nature of cathodic protection in saltwater environments. Economic volatility, particularly concerning the price fluctuations of raw materials like zinc, epoxy resins, and solvents, continues to pose a persistent challenge to market profitability, requiring sophisticated supply chain management and pricing strategies among key industry participants.

AI Impact Analysis on Zinc Rich Primer Market

Common user questions regarding AI's impact on the Zinc Rich Primer market frequently revolve around how artificial intelligence and machine learning (ML) can optimize complex formulation processes, predict coating performance, and enhance quality control in manufacturing. Users are keen to understand if AI can accelerate the development of novel, environmentally friendly formulations (e.g., non-isocyanate or low-VOC primers) and how predictive maintenance models, leveraging AI, can more accurately determine the optimal time for re-coating critical assets, thereby maximizing the protective lifespan of the primer. The key themes consistently highlighted are the potential for AI to dramatically reduce material waste, improve batch consistency, and refine application techniques through real-time data analytics, leading to superior product reliability and more efficient operations in both the factory and the field.

The integration of AI and machine learning platforms is beginning to revolutionize the R&D and manufacturing phases within the Zinc Rich Primer industry. AI algorithms are being deployed to analyze vast datasets concerning raw material compositions, reaction kinetics, and empirical performance results under various climatic conditions. This capability allows researchers to rapidly screen thousands of potential formulations, identifying optimal combinations that meet stringent performance criteria (such as adhesion, flexibility, and accelerated corrosion resistance) while simultaneously adhering to regulatory requirements regarding VOC emissions. This data-driven approach significantly shortens the product development cycle, moving away from traditional, lengthy trial-and-error methods towards precise predictive modeling, thus ensuring a faster time-to-market for specialized or bespoke primer solutions required by major industrial clients.

In the operational and application domains, AI is impacting quality control and asset management. During manufacturing, ML systems monitor mixing parameters, temperature profiles, and dispersion characteristics in real-time, instantly flagging deviations that could affect final product quality or consistency across batches. For end-users, AI-powered digital twins and predictive analytics are used to assess the integrity of coated structures (like offshore platforms or bridges) by processing sensor data, environmental inputs, and historical corrosion rates. This predictive ability allows asset managers to transition from time-based maintenance scheduling to condition-based monitoring, optimizing the timing of recoating activities and thereby reducing overall operational expenditure while maximizing the effective corrosion protection afforded by the zinc rich primer system.

- AI optimizes formulation R&D by predicting performance characteristics of new coating combinations.

- Machine learning enhances manufacturing consistency and quality control through real-time process monitoring.

- Predictive maintenance models, enabled by AI, optimize asset recoating schedules, extending primer life.

- Data analytics improves supply chain forecasting for raw materials, particularly zinc powder.

- AI-driven image recognition aids automated inspection systems for applied primer thickness and coverage uniformity.

DRO & Impact Forces Of Zinc Rich Primer Market

The Zinc Rich Primer market is significantly driven by escalating global investments in infrastructure maintenance and expansion, particularly in the oil and gas, marine, and transportation sectors, where the need for durable, long-lasting anti-corrosion protection is non-negotiable. However, the market faces considerable restraints, primarily the high cost and volatility of key raw materials, especially zinc metal, which directly affects the final product price and profitability margins for manufacturers. Opportunities are emerging through the development of environmentally compliant, high-performance formulations, such specifically low-VOC and waterborne zinc primers, addressing increasingly stringent global environmental legislation. The overarching impact force influencing this market is the nexus between increasing regulatory pressure for environmental compliance and the economic necessity of maximizing the service life of capital assets, pushing the industry towards sophisticated, yet sustainable, cathodic protection solutions.

Key drivers include rapid urbanization and industrial growth in emerging economies, necessitating new infrastructure development (bridges, ports, industrial complexes) that relies heavily on protective coatings. Additionally, the replacement and refurbishment of aging infrastructure in developed nations contribute substantial demand for high-quality zinc primers capable of offering decades of protection. Conversely, the complexity of application for certain zinc-rich systems, particularly inorganic silicates requiring highly specialized surface preparation (blast cleaning), acts as a restraint, occasionally favoring less durable but easier-to-apply conventional epoxy primers in less demanding applications. The skilled labor required for proper application further constrains rapid deployment in some geographical areas.

The primary opportunities lie in the technological refinement of existing products, focusing on ease of application and reduced environmental impact. Developing single-component organic zinc primers that offer performance close to two-component systems simplifies logistics and reduces on-site mixing errors. Furthermore, the expansion of renewable energy infrastructure, such as offshore wind farms, presents a lucrative new application segment where extreme durability against marine corrosion is essential. Impact forces are also shaped by technological substitution threats, although currently minor, such as high-performance barrier coatings not containing zinc. However, the established track record and superior cathodic protection mechanism of zinc rich primers maintain their dominance in critical protective applications globally, necessitating continuous innovation in formulation science to maintain market leadership.

Segmentation Analysis

The Zinc Rich Primer market is segmented primarily based on technology (Organic and Inorganic), type (Epoxy, Silicate, and others), application method, and end-use industry. The dominance of organic zinc rich primers, particularly those based on epoxy resins, stems from their application flexibility, better compatibility with various topcoats, and enhanced tolerance to varied field conditions compared to their inorganic counterparts. Conversely, inorganic zinc rich primers, typically utilizing ethyl silicate binders, maintain a strong position in highly corrosive, often high-temperature environments, such as chemical processing plants and exhaust stacks, due to their superior thermal and solvent resistance. Analyzing these segments reveals that the marine and protective coatings sector remains the most significant consumer, dictating demand for high-solids, durable formulations, while the geographic distribution shows a clear bifurcation between maintenance-driven demand in developed regions and new construction-driven demand in emerging economies.

Further segmentation by end-use highlights distinct requirements across major industries. The oil and gas sector demands specialized primers resistant to aggressive chemicals and high pressures for pipelines and refineries, favoring robust epoxy systems. The infrastructure sector, covering bridges and roads, prioritizes primers offering very long service life and resistance to cyclic weather stress. The overall market dynamics show a steady increase in demand for two-component systems due to their generally superior performance metrics compared to single-component options. Understanding these intricate segmentation layers is crucial for manufacturers to tailor their R&D efforts and marketing strategies, ensuring their product portfolio aligns with the specific performance and regulatory needs of high-value industrial applications worldwide.

- By Technology:

- Organic Zinc Rich Primer (Epoxy, Polyurethane)

- Inorganic Zinc Rich Primer (Ethyl Silicate, Waterborne Inorganic)

- By Application:

- Marine & Offshore

- Oil & Gas (Pipelines, Refineries)

- Infrastructure (Bridges, Highways, Rail)

- Industrial & Manufacturing (Chemical Plants, Power Generation)

- Automotive & Transportation

- By Type:

- Epoxy Zinc Rich Primer (Two-Component, Single-Component)

- Inorganic Silicate Zinc Rich Primer

- Others (Modified Alkyds, Waterborne Systems)

- By Form:

- Solvent-Based

- Water-Based (Lower VOC)

Value Chain Analysis For Zinc Rich Primer Market

The value chain for the Zinc Rich Primer market begins with the upstream segment, dominated by suppliers of critical raw materials, primarily metallic zinc powder, specialized resins (epoxy, ethyl silicate), solvents, and performance additives. The quality and stable supply of high-purity zinc dust are paramount, as this ingredient dictates the core protective function and cost structure of the final product. Upstream price volatility, particularly concerning zinc, has a direct and immediate impact on manufacturing costs. The midstream manufacturing phase involves sophisticated chemical processing, grinding, blending, and quality assurance, where manufacturers focus on achieving the required zinc loading, dispersion uniformity, and viscosity specifications for varied application methods. Efficiency in manufacturing and adherence to global quality standards (e.g., ISO certifications) are key differentiators at this stage.

The distribution channel represents the transition from manufacturer to end-user. Distribution involves both direct and indirect routes. Direct sales are common for large-scale, complex projects in sectors like marine shipbuilding and major infrastructure, where technical consultation, specialized training, and just-in-time delivery are essential services provided directly by the coating manufacturer or their large regional branch network. Indirect sales utilize an established network of regional distributors, specialized chemical wholesalers, and local dealers who handle smaller volumes, offer local stockholding, and cater to smaller maintenance contractors and industrial end-users. The choice of channel often depends on the project size, geographical remoteness, and the technical complexity of the required coating system.

The downstream segment consists of the end-users and professional application contractors. Successful application requires highly skilled labor, specialized equipment (e.g., airless sprayers, plural component pumps), and rigorous surface preparation (e.g., abrasive blasting to Sa 2.5 standard). The performance of the zinc rich primer is heavily dependent on correct surface preparation and precise adherence to application specifications (such as film thickness and cure time). Therefore, the quality of the downstream application service is a critical component of the overall value delivered. Contractors often require continuous technical support and certification from manufacturers, making strong post-sales service a crucial competitive advantage in the highly specialized protective coatings market.

Zinc Rich Primer Market Potential Customers

Potential customers for Zinc Rich Primers are predominantly found in industries where steel structures are constantly exposed to aggressive corrosive environments, necessitating superior long-term cathodic protection. The primary end-users or buyers are large asset owners and operators, including national oil companies, maritime shipping lines, port authorities, governmental transportation departments responsible for bridges and highways, and major utility companies managing power plants and transmission towers. These entities purchase high volumes and prioritize product reliability, documented long-term performance, and supplier technical support over simple cost considerations. The procurement process for these high-value applications often involves rigorous product qualification and vendor approval based on historical performance data and compliance with specifications like SSPC or ISO standards.

Beyond these large institutional buyers, significant demand originates from specialized industrial coating applicators and contractors who serve smaller manufacturing facilities, storage tank farms, and localized infrastructure projects. These contractors act as key intermediaries, often selecting and purchasing the primer based on their deep understanding of application logistics, site conditions, and client performance mandates. Furthermore, the shipbuilding and ship repair industry forms a constant and high-volume customer base, requiring large quantities of zinc rich primers for hull protection during construction and routine dry-dock maintenance cycles. The decision to purchase is usually a collaborative process involving asset integrity managers, coating specifiers, and procurement teams, all focused on achieving the lowest lifetime cost of protection.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion USD |

| Market Forecast in 2033 | $2.65 Billion USD |

| Growth Rate | 5.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Akzo Nobel NV, PPG Industries, Sherwin-Williams Company, Hempel A/S, Jotun A/S, Kansai Paint Co., Ltd., Axalta Coating Systems, Nippon Paint Holdings Co., Ltd., Chugoku Marine Paints, Ltd., Carboline Company, Sika AG, Rust-Oleum Corporation, RPM International Inc., BASF SE, KCC Corporation, Beckers Group, Wacker Chemie AG, Zinga Metall BV, Teknos Group, and Tikkurila Oyj. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zinc Rich Primer Market Key Technology Landscape

The technological landscape of the Zinc Rich Primer market is characterized by continuous innovation focused on optimizing anti-corrosion performance, reducing environmental impact, and simplifying application procedures. A major technological focus remains on the development of high-solids epoxy zinc rich primers. These systems utilize minimal or no conventional volatile organic solvents, achieving compliance with increasingly restrictive VOC regulations globally while maintaining the high zinc loading required for effective cathodic protection. High-solids technology often requires advanced rheology modifiers and specialized dispersants to handle the high pigment volume concentration (PVC) without compromising sprayability or film build characteristics, representing a significant area of current R&D investment across leading manufacturers.

Another pivotal area of technological advancement is the refinement of waterborne zinc rich primers, particularly those based on inorganic silicate binders. Traditional solvent-based ethyl silicates offer outstanding protection but require highly specialized handling and application due to solvent emission. Waterborne inorganic primers address these issues by eliminating or dramatically reducing solvent use, offering a safer and more environmentally conscious alternative, suitable for increasingly stringent shipyard and industrial coating mandates in regions like Western Europe and North America. Achieving comparable performance characteristics—especially rapid cure and resistance to early water exposure—to their solvent-borne counterparts remains a technical hurdle, driving ongoing development in binder chemistry and curing agents.

Furthermore, advancements in nanoparticle technology are beginning to influence primer formulation. The use of nano-zinc or hybrid metallic/non-metallic pigments, while still emerging, aims to improve the efficiency of the cathodic protection mechanism. By utilizing smaller, more uniformly distributed zinc particles, manufacturers seek to enhance conductivity and coverage, potentially allowing for the reduction of the total zinc content without sacrificing protection, thus managing raw material costs and improving flexibility. Lastly, specialized anti-settling agents and stabilizers are continually being developed to extend the pot life and shelf stability of two-component systems, improving user convenience and reducing material waste on large-scale construction sites.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, primarily driven by massive infrastructure investments across China, India, and Southeast Asian nations. The region's extensive coastline, coupled with robust shipbuilding and repair activities, generates immense demand for high-performance marine zinc primers. Rapid industrialization and the expansion of the oil and gas processing infrastructure further solidify APAC's dominance in terms of consumption volume.

- North America: This region is characterized by steady, maintenance-driven demand, focusing on the preservation and rehabilitation of aging transportation infrastructure (bridges, pipelines) and offshore oil and gas platforms. Strict environmental regulations, particularly regarding VOC emissions, highly favor the adoption of advanced high-solids and waterborne zinc rich primer systems, compelling manufacturers to adhere to highly specialized regional certifications.

- Europe: Europe is a mature market focused intensely on regulatory compliance and sustainable coating solutions. Demand is driven by the region's sophisticated marine industry, petrochemical sector, and significant investment in renewable energy infrastructure, such as North Sea wind farms. The market sees strong uptake of cutting-edge, low-VOC epoxy and inorganic silicate primers, often leading global trends in environmental technology adoption.

- Middle East & Africa (MEA): Growth is tied heavily to the expansion of the petrochemical and maritime sectors, characterized by highly corrosive desert and coastal environments. Large-scale oil and gas pipeline projects and refinery construction generate substantial, specialized demand for extremely robust, high-film-build zinc primers capable of withstanding extreme temperatures and chemical exposure.

- Latin America: This region presents moderate growth, linked to fluctuating commodity prices, particularly in the mining and oil production sectors in Brazil and Mexico. Infrastructure development and maintenance requirements offer localized growth opportunities, though economic volatility can sometimes hinder large capital expenditure on premium coating systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zinc Rich Primer Market.- Akzo Nobel NV

- PPG Industries

- Sherwin-Williams Company

- Hempel A/S

- Jotun A/S

- Kansai Paint Co., Ltd.

- Axalta Coating Systems

- Nippon Paint Holdings Co., Ltd.

- Chugoku Marine Paints, Ltd.

- Carboline Company

- Sika AG

- Rust-Oleum Corporation

- RPM International Inc.

- BASF SE

- KCC Corporation

- Beckers Group

- Wacker Chemie AG

- Zinga Metall BV

- Teknos Group

- Tikkurila Oyj

Frequently Asked Questions

Analyze common user questions about the Zinc Rich Primer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between inorganic and organic zinc rich primers?

Inorganic zinc rich primers, typically silicate-based, offer superior heat and solvent resistance and cure quickly, making them ideal for high-temperature chemical environments, but require specialized surface preparation. Organic primers, mainly epoxy-based, are more flexible, easier to apply, have better overcoating compatibility, and dominate general marine and heavy industrial applications.

How does the zinc rich primer provide effective corrosion protection?

Zinc rich primers function through cathodic protection. The zinc metal in the coating acts as a sacrificial anode; when moisture or damage exposes the steel, the zinc corrodes preferentially instead of the steel substrate, effectively protecting the structure against rust propagation until the zinc layer is fully depleted.

Which end-use industry drives the highest demand for zinc rich primers globally?

The Marine and Offshore sector consistently drives the highest demand, requiring primers for ship hulls, ballast tanks, and offshore platforms due to the extremely corrosive nature of saltwater environments. Infrastructure, including bridges and oil and gas facilities, also constitutes a major consumption segment.

What major regulatory factors are currently impacting the formulation of zinc rich primers?

The most impactful regulatory factors are global and regional limits on Volatile Organic Compound (VOC) emissions. This pushes manufacturers towards developing high-solids, solvent-free, or advanced waterborne primer formulations to ensure environmental compliance while maintaining necessary performance standards.

What role does the zinc loading percentage play in primer performance?

High zinc loading (typically 85% or more by weight in the dry film) is essential for ensuring effective electrical conductivity and establishing robust cathodic protection. Lower zinc content can compromise the galvanic action, reducing the primer's ability to sacrificially protect the steel substrate against corrosion over time.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Organic Zinc Rich Primer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Zinc Rich Primer Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Organic(Mainiy Epoxy Zinc Rich Primer), Inorganic(Mainly Inorganic Zinc Silicate Primer)), By Application (Ship & Offshore, Chemical Plant, Oil and Gas, Industrial Machinery, Construction, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager