Zircon and Derivative Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436664 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Zircon and Derivative Market Size

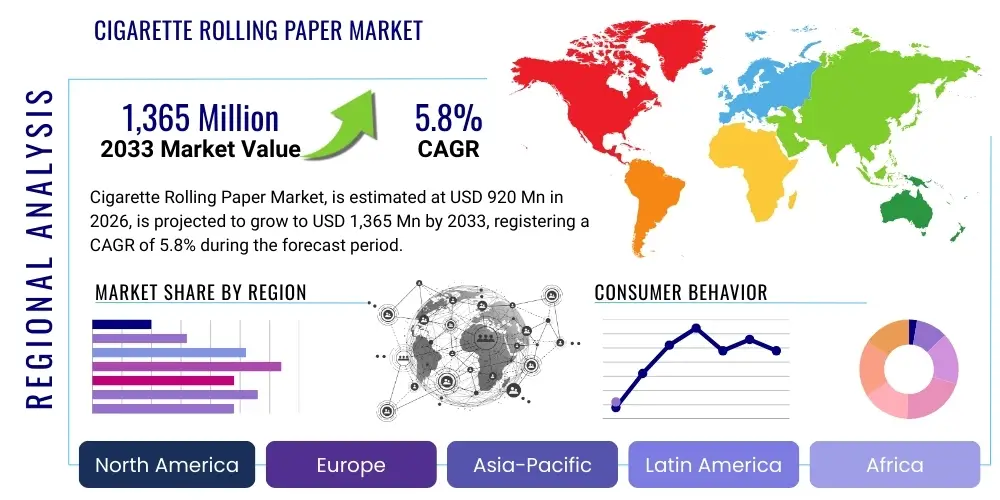

The Zircon and Derivative Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 2.87 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by the escalating global demand for high-performance materials in extreme conditions, particularly within the ceramics, refractories, and foundry industries, where zircon’s chemical stability and thermal resistance are irreplaceable. Furthermore, the increasing adoption of advanced zircon derivatives, such as high-purity zirconium dioxide and specialized zirconium chemicals, across the electronics, automotive, and nuclear sectors, is significantly bolstering market expansion across key industrialized and developing economies.

Zircon and Derivative Market introduction

The Zircon and Derivative Market encompasses the extraction, processing, and application of zircon mineral (zirconium silicate, ZrSiO4) and its chemically derived compounds, which are essential raw materials for numerous high-specification industrial processes. Zircon is recognized for its exceptional characteristics, including high melting point, remarkable hardness, chemical inertness, and low thermal expansion, making it indispensable in environments requiring extreme durability. The primary derivatives include zirconium dioxide (zirconia), opacifiers, zirconium chemicals (such as zirconium oxychloride and zirconium basic carbonate), and specialized refractory materials. Major applications are concentrated in the manufacturing of ceramic tiles and sanitaryware, where zircon sand and flour act as powerful opacifiers and vitrifying agents; in the foundry industry for producing high-quality molds; and in the production of high-performance refractories used in lining steel and glass furnaces. The overall market growth is fundamentally propelled by rapid urbanization, particularly in the Asia Pacific region, leading to booming construction and ceramic production, coupled with the rising industrial requirement for energy-efficient, high-temperature insulation materials, ensuring zircon remains a critical component in the modern industrial landscape.

Zircon and Derivative Market Executive Summary

The Zircon and Derivative Market is characterized by robust resilience fueled by consistent industrial demand, despite fluctuations in mining output and commodity pricing. Current business trends indicate a strategic shift by major players toward vertical integration, securing high-quality upstream supply chains to mitigate risks associated with geopolitical instabilities and regulatory changes in key producing nations like Australia and South Africa. A critical trend involves the growing emphasis on high-purity derivatives, such as stabilized zirconia (yttria-stabilized zirconia), which are achieving premium pricing due to their essential role in cutting-edge applications like dental implants, solid oxide fuel cells (SOFCs), and thermal barrier coatings in aerospace engines. The market is also experiencing heightened M&A activity focused on acquiring specialized processing technologies capable of maximizing yields and purity levels. Regional trends highlight the sustained dominance of the Asia Pacific (APAC) market, driven overwhelmingly by China and India, where massive infrastructure and residential construction projects necessitate vast volumes of ceramic products and foundry materials. Conversely, North America and Europe demonstrate mature market characteristics, focusing less on volume and more on value-added applications, particularly advanced refractories and specialty zirconium chemicals used in high-tech manufacturing, catalysis, and nuclear power generation. Segment trends confirm that ceramics remain the largest application segment by volume, but the fastest growth rate is observed in the chemical and electronic segments due to the expanding commercialization of next-generation devices and energy storage solutions requiring highly specific zirconium compounds.

AI Impact Analysis on Zircon and Derivative Market

Common user questions regarding AI's influence on the Zircon and Derivative Market predominantly revolve around optimizing complex mineral processing and ensuring supply chain transparency. Users frequently inquire about how AI can predict variations in ore grade quality during mining operations, optimize the energy-intensive separation and calcination processes to reduce operational costs and environmental footprint, and forecast volatile pricing models for raw zircon sand and refined derivatives. Furthermore, significant interest lies in leveraging machine learning models for accelerated materials discovery, specifically designing novel, stable zirconium compounds for use in advanced technical ceramics or high-efficiency catalysts, thereby shortening R&D cycles. The core concern centers on integrating sophisticated, data-heavy AI platforms with traditional, often antiquated, industrial processing equipment without incurring prohibitive initial investment costs, emphasizing predictive analytics for equipment maintenance and quality control as immediate value generators.

- AI-driven optimization of mineral separation and heavy media processing to enhance zircon yield rates and purity from ore concentrates.

- Predictive maintenance analytics applied to kiln operations and milling equipment, minimizing unplanned downtime and extending asset life in high-wear environments.

- Machine learning models utilized for real-time demand forecasting and strategic inventory management, smoothing price volatility and securing just-in-time delivery for large ceramic manufacturers.

- Application of computational materials science and AI algorithms to discover and synthesize new, customized zirconium derivative chemistries for specialized electronic or medical applications.

- Enhanced quality control systems through computer vision and sensor fusion, ensuring derivative specifications (e.g., particle size distribution, phase stability) meet stringent end-user requirements, particularly in high-purity zirconia production.

DRO & Impact Forces Of Zircon and Derivative Market

The dynamics of the Zircon and Derivative Market are primarily dictated by a confluence of structural drivers and resource-related restraints, coupled with significant technological opportunities that shape long-term industry viability. Key drivers include persistent global infrastructure investment, particularly in emerging economies, which necessitates consistent supplies of ceramics and refractories, and the increasing stringency of environmental regulations prompting manufacturers to utilize high-quality, durable materials that reduce replacement frequency. However, the market faces considerable restraints, notably the geopolitical concentration of primary zircon supply in a limited number of countries, creating vulnerability to trade disputes and export restrictions, alongside the high energy intensity required for processing raw zircon into refined derivatives like stabilized zirconia, which directly impacts production costs. Opportunities reside in the proliferation of new high-tech applications, such as the deployment of zirconium derivatives in advanced energy storage systems (e.g., solid-state batteries), catalysts for pollution abatement, and specialized coatings in the aerospace and defense sectors, allowing for diversification away from traditional, volume-based construction applications. These various forces exert a collective impact, leading to cyclical market volatility governed by construction cycles but simultaneously promoting innovation and efficiency improvements in resource management and derivative manufacturing techniques.

Segmentation Analysis

The Zircon and Derivative Market is comprehensively segmented based on the type of product derived from the raw mineral and the ultimate industrial application where these materials are deployed. Product segmentation allows stakeholders to differentiate between commodities like zircon sand and highly processed, value-added chemicals, reflecting vast differences in manufacturing complexity and profitability margins. Application segmentation provides a clear understanding of the market's reliance on major industrial sectors, predominantly ceramics and refractories, while simultaneously highlighting fast-growing niches such as nuclear components and high-performance electronics. Analyzing these segments is crucial for strategic planning, enabling companies to allocate resources effectively toward high-growth, high-margin areas like advanced zirconia production rather than solely focusing on maintaining volume in mature markets like conventional foundry applications, thereby optimizing overall revenue generation and market penetration strategies across diverse geographical areas.

- By Product Type:

- Zircon Sand/Flour

- Zircon Opacifier

- Zirconium Dioxide (Zirconia)

- Zircon Chemicals (Zirconium Oxychloride, Zirconium Basic Carbonate, Zirconium Sulfate)

- Fused Zirconia

- By Application:

- Ceramics and Tiles

- Refractories (Monolithic and Shaped)

- Foundry and Casting

- Chemicals and Pigments

- Nuclear Applications (Fuel Cladding)

- Electronics and Electrical Components

- Others (Medical, Aerospace Coatings)

- By Grade:

- Standard Grade Zircon

- Premium Grade Zircon

- Chemical Grade Zircon

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Zircon and Derivative Market

The value chain for the Zircon and Derivative Market begins at the upstream stage with the exploration and mining of heavy mineral sands, primarily concentrated in coastal dune environments in countries such as Australia, South Africa, and Indonesia. This is followed by initial concentration processes, including wet gravity separation and magnetic separation, which isolate the crude zircon sand from other valuable minerals like rutile and ilmenite. The midstream processing stage is where significant value accretion occurs, involving the chemical treatment of zircon sand to produce refined derivatives such as opacifiers, high-purity zirconia, and various specialty zirconium chemicals. This conversion process is energy-intensive and highly dependent on technological expertise, influencing the final quality and cost structure of the end product.

Downstream analysis focuses on the transformation of these derivatives into final consumer goods across diverse industrial applications. For instance, high-purity zirconia is used by technical ceramics manufacturers for complex components, while zircon opacifiers are consumed in large quantities by the tile and sanitaryware industries. The distribution channel is crucial, relying heavily on specialized logistics providers capable of handling bulk mineral shipments and chemical transport. Distribution pathways are bifurcated into direct sales to large, established industrial buyers (e.g., major refractory producers) and indirect distribution through networks of regional distributors and chemical suppliers who service smaller end-users and specialty manufacturers, particularly in the complex European and North American markets.

The interplay between these stages highlights specific points of leverage: securing long-term supply contracts upstream minimizes procurement risk, while technological differentiation in the midstream (producing ultra-high purity materials) maximizes profit margins. The efficiency and reliability of the distribution network ultimately determine market responsiveness, especially in geographically dispersed end-user markets like Asia Pacific, where localized supply centers are critical for maintaining competitive pricing and timely delivery to the burgeoning construction sector.

Zircon and Derivative Market Potential Customers

Potential customers for the Zircon and Derivative Market span a highly diversified range of heavy and specialized industries, all relying on the material's unique thermal and chemical properties to achieve high-performance outcomes. The largest volume buyers are consistently the ceramic and tile manufacturers, who utilize zircon sand and opacifiers extensively to achieve the white, opaque finish and structural integrity required for floor tiles, wall tiles, and sophisticated sanitaryware products, particularly within the booming residential and commercial construction sectors across Asia and the Middle East. Equally critical customers are companies specializing in refractories, which require high-grade zircon, zirconia, and fused derivatives to line furnaces, kilns, and ladles in the steel, cement, glass, and non-ferrous metal industries, ensuring operational longevity and temperature resistance in extreme heat processing environments.

Another significant customer base includes the global foundry industry, where zircon flour is employed as a key component in mold and core washes due to its low thermal expansion, which prevents cracking and ensures the production of highly accurate metal castings, particularly for high-value components in the automotive and aerospace sectors. Furthermore, the market targets highly specialized buyers in the chemical and electronics segments, which require ultra-high purity zirconium chemicals (such as zirconium oxychloride) for use as catalysts, stabilizers, precursors for advanced ceramics (MLCCs and thermal barrier coatings), and increasingly, in emerging fields like nuclear power generation, where specific zirconium alloys are essential for fuel cladding applications requiring exceptional neutron transparency and corrosion resistance, representing premium, high-value customer segments demanding stringent quality control and long-term contractual security.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 2.87 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Iluka Resources Limited, Tronox Holdings plc, Kenmare Resources plc, Eramet, Doral Mineral Sands, Alkane Resources Ltd., Luxfer Holdings PLC, Guangdong Orient Zirconic Ind Sci & Tech Co., Ltd., Zircoa, Inc., Imerys S.A., Cristal Mining Australia Ltd., Indian Rare Earths Limited (IREL), Universal Minerals Development Co., Ltd., Astron Corporation Limited, Murray Zircon Pty Ltd, Reactive Metals & Alloys Corp., Saint-Gobain, TAM Ceramics LLC, Lixing Chemical, Orient Abrasives Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zircon and Derivative Market Key Technology Landscape

The technology landscape governing the Zircon and Derivative Market is characterized by continuous innovation focused on improving purity, yield, and energy efficiency across the processing chain. Upstream, modern mining operations heavily employ advanced magnetic and electrostatic separation techniques, integrated with optical sorting technology, to maximize the recovery of high-quality zircon from heavy mineral sands, minimizing waste and tailings. Midstream refinement involves sophisticated chemical and thermal processes. For the production of high-purity zirconium dioxide (zirconia), key technologies include plasma melting and stabilization techniques (e.g., plasma torches used to stabilize the monoclinic phase into cubic or tetragonal forms with yttria or magnesia), as well as complex chemical precipitation and solvent extraction methods crucial for producing the ultra-pure, nuclear-grade zirconium compounds required for sensitive applications.

Furthermore, significant technological advancements are centered on reducing the environmental impact and energy consumption inherent in the calcination and fusion stages. Optimized furnace designs, utilizing advanced insulation and process control systems, are being adopted to achieve the high temperatures required for producing fused zirconia and high-quality opacifiers with reduced energy input. The development of advanced ceramic milling and particle size control technologies, such as ultrafine grinding and micronization, is essential for meeting the stringent particle size specifications demanded by the electronics and technical ceramics industries, where homogeneity and extremely fine particle distributions are paramount for product performance and sintering quality, driving overall technological investment in advanced quality control and processing automation.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market volume due to unprecedented growth in construction activities, coupled with the region being the world's primary manufacturing hub for ceramic tiles, sanitaryware, and foundry operations. China and India are the pivotal markets, driving massive demand for standard and premium grade zircon sand and opacifiers.

- North America: Characterized by a high-value, low-volume consumption pattern, focusing heavily on specialty applications such as nuclear fuel cladding (zircaloy), high-performance thermal barrier coatings for aerospace, and specialized zirconium chemicals for catalyst manufacturing and pollution control systems, demanding ultra-high purity and technical specifications.

- Europe: A mature market defined by rigorous environmental standards and technological leadership in advanced ceramics and specialized refractories. Key countries like Germany and Italy prioritize premium-grade derivatives and innovative zirconia compounds for high-end automotive components, fine porcelain, and specialized industrial linings, emphasizing R&D intensity and sustainable sourcing.

- Middle East and Africa (MEA): Emerging as a major supply hub, particularly South Africa, which holds substantial zircon reserves. Demand within the region is growing, spurred by domestic infrastructure projects and investments in local ceramic production capabilities, though much of the mined resource is exported for further processing elsewhere.

- Latin America: Shows steady growth driven by expanding domestic construction markets, especially in Brazil and Mexico, leading to increased localized demand for zircon-based opacifiers and refractory materials used in steel and glass production, although the overall market penetration remains lower than APAC or Europe.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zircon and Derivative Market.- Iluka Resources Limited

- Tronox Holdings plc

- Kenmare Resources plc

- Eramet

- Doral Mineral Sands

- Alkane Resources Ltd.

- Luxfer Holdings PLC

- Guangdong Orient Zirconic Ind Sci & Tech Co., Ltd.

- Zircoa, Inc.

- Imerys S.A.

- Cristal Mining Australia Ltd.

- Indian Rare Earths Limited (IREL)

- Universal Minerals Development Co., Ltd.

- Astron Corporation Limited

- Murray Zircon Pty Ltd

- Reactive Metals & Alloys Corp.

- Saint-Gobain

- TAM Ceramics LLC

- Lixing Chemical

- Orient Abrasives Ltd.

- TiZir Titanium & Iron (Eramet/Tronox Joint Venture)

- Prayon S.A.

- Jiangxi Kingan Hi-Tech

- Nippon Denko Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Zircon and Derivative market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the current growth in the Zircon and Derivative Market?

The primary growth drivers are the ceramics industry, particularly in Asia Pacific, demanding zircon opacifiers for tiles and sanitaryware, and the refractory segment, which requires high-grade zircon and zirconia for lining high-temperature furnaces in steel and glass manufacturing due to zircon's exceptional thermal resistance and chemical stability.

How is the Zircon Market affected by geopolitical factors and supply concentration?

The Zircon Market is highly susceptible to geopolitical instability because key mining and supply are concentrated in a few jurisdictions, notably Australia, South Africa, and Indonesia. Any trade restrictions, export quotas, or regulatory changes in these regions can lead to significant price volatility and supply chain disruptions globally, forcing end-users to secure long-term contracts.

What is the main difference between zircon sand and zirconium dioxide (zirconia)?

Zircon sand (zirconium silicate) is the raw mineral concentrate used mainly as a foundry material and opacifier base. Zirconium dioxide (zirconia, ZrO2) is a highly refined derivative produced through complex chemical processing of zircon sand, possessing far superior thermal, electrical, and mechanical properties, making it essential for technical ceramics, dental materials, and specialized refractories.

Which technological innovation holds the most promise for the future of zircon derivatives?

The most promising innovation involves advanced stabilization techniques for zirconia, particularly plasma melting and chemical precipitation methods used to produce high-purity, phase-stabilized zirconia powders. These materials are crucial for next-generation solid oxide fuel cells (SOFCs), high-performance sensors, and thermal barrier coatings, enabling applications in renewable energy and aerospace.

What role does the nuclear industry play in the demand for zirconium derivatives?

The nuclear industry is a critical, high-value consumer of specialized zirconium alloys, primarily Zircaloy, which is required for cladding nuclear fuel rods. This application demands extremely high purity and stringent quality control due to the need for low neutron absorption and high corrosion resistance under reactor conditions, driving demand for chemical-grade zirconium chemicals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager