Zirconia Powders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434312 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Zirconia Powders Market Size

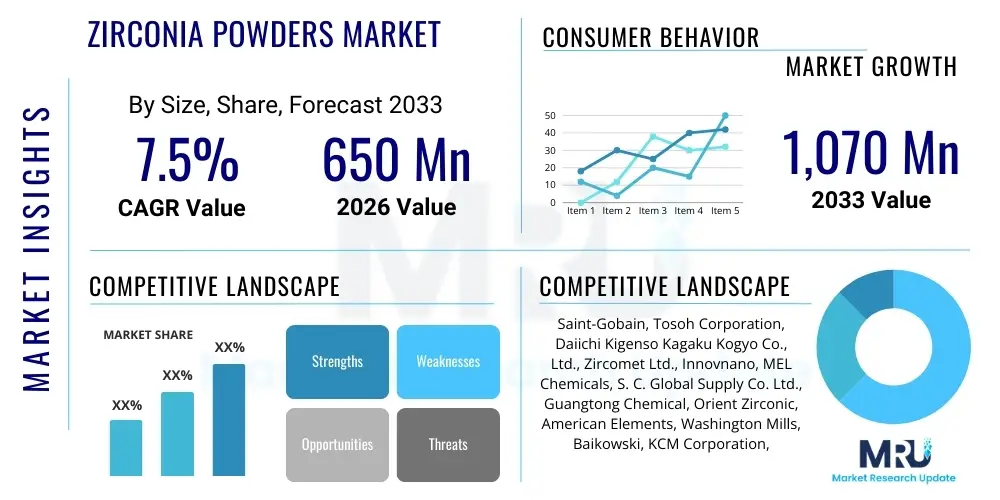

The Zirconia Powders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,070 Million by the end of the forecast period in 2033.

Zirconia Powders Market introduction

Zirconia powders, chemically known as zirconium dioxide (ZrO2), represent a crucial category of advanced ceramic materials highly valued for their exceptional physical and chemical properties, including high strength, fracture toughness, thermal stability, and corrosion resistance. These characteristics position them as essential components across various high-performance industrial applications. The market encompasses a range of purity levels and stabilization methods, such as Yttria-Stabilized Zirconia (YSZ) and Magnesia-Stabilized Zirconia (MgSZ), tailored to meet specific functional requirements in demanding environments like aerospace, medical devices, and electronics manufacturing.

The product description highlights zirconia as an extremely versatile ceramic. Its unique properties, such as its bio-compatibility, make it indispensable in dental and orthopedic implants, where longevity and resistance to wear are paramount. Furthermore, in the energy sector, particularly in Solid Oxide Fuel Cells (SOFCs), stabilized zirconia acts as a highly effective electrolyte due to its ability to conduct oxygen ions at elevated temperatures. This dual utility across healthcare and energy underscores its strategic importance within the broader specialty chemicals and advanced materials landscape.

Major applications of zirconia powders span structural ceramics (e.g., thermal barrier coatings, cutting tools), electronics (e.g., oxygen sensors, capacitors), and, most significantly, bioceramics (e.g., crowns, bridges, hip joint replacements). The primary benefits driving market demand include enhanced mechanical performance, superior wear resistance compared to traditional materials, and inertness in corrosive media. Key driving factors accelerating market expansion are the rapid growth in dental aesthetics, increasing global demand for energy-efficient SOFC technology, and the continuous need for lightweight, high-temperature materials in the automotive and aerospace industries.

Zirconia Powders Market Executive Summary

The Zirconia Powders Market is characterized by robust business trends centered on technological advancements in powder synthesis and processing, aimed at achieving ultra-fine particle sizes and narrow size distributions to enhance final product performance. Leading manufacturers are heavily investing in hydrothermal synthesis and chemical precipitation methods to produce high-purity, tailor-made zirconia grades necessary for sophisticated applications like medical devices and high-definition electronic components. A significant business trend involves strategic partnerships between powder producers and downstream manufacturers (e.g., dental laboratories, SOFC stack assemblers) to ensure consistent supply chain quality and co-develop next-generation ceramic formulations with improved functionality, focusing on lowering sintering temperatures and increasing overall component durability.

Regionally, Asia Pacific (APAC) dominates the Zirconia Powders Market, driven primarily by massive industrial expansion, booming electronics manufacturing, and rapidly improving healthcare infrastructure in countries such as China, India, and South Korea. Europe and North America maintain high market shares in value terms, specializing in high-end, tightly regulated applications like aerospace thermal coatings and premium dental implants, where established quality standards and regulatory compliance mandate the use of the highest purity zirconia grades. Emerging regional trends indicate accelerating demand in Latin America and the Middle East for infrastructure projects and localized dental manufacturing capabilities, fostering new opportunities for market penetration by international suppliers.

In terms of segment trends, the Yttria-Stabilized Zirconia (YSZ) segment holds the largest market share due to its excellent combination of strength, toughness, and stability, making it the material of choice for dental ceramics and SOFC electrolytes. Application trends reveal that bioceramics and structural ceramics are the fastest-growing segments, propelled by the rising prevalence of age-related orthopedic issues and the ongoing automotive trend toward lightweighting and efficient engine design utilizing advanced thermal barrier coatings (TBCs). The electronics segment, particularly oxygen sensors used in pollution control and engine management systems, provides steady, substantial demand, emphasizing the need for high-density, defect-free zirconia components.

AI Impact Analysis on Zirconia Powders Market

User inquiries regarding AI's influence on the Zirconia Powders Market predominantly focus on optimizing material synthesis processes, enhancing quality control, and accelerating new product development cycles. Users are keen to understand how machine learning (ML) models can predict optimal sintering parameters to minimize defects in final ceramic components, thereby reducing manufacturing costs and improving batch consistency. Key concerns revolve around the integration cost of AI systems into existing legacy manufacturing environments and the need for highly specialized data scientists familiar with materials science. The consensus expectation is that AI will revolutionize R&D by enabling high-throughput screening of various dopants and stabilization chemistries, predicting material behavior under extreme stress, and ultimately shortening the time-to-market for novel, high-performance zirconia formulations necessary for advanced technologies like next-generation Solid Oxide Electrolysis Cells (SOECs) and ultra-strong structural components.

- AI-driven optimization of hydrothermal and chemical precipitation methods for precise particle size control.

- Machine learning algorithms predict defect formation during sintering, enhancing manufacturing yield and component reliability.

- Accelerated discovery of novel zirconia-based composites and dopant combinations through high-throughput computational screening.

- Implementation of smart sensors and vision systems for real-time, automated quality inspection of powder morphology and purity.

- Supply chain predictability and demand forecasting for precursor materials (e.g., zircon sand, yttrium oxide) improved via predictive analytics.

- Robotics and AI-guided automation in handling high-purity powder batches, minimizing contamination risks.

DRO & Impact Forces Of Zirconia Powders Market

The Zirconia Powders Market is shaped by a compelling interplay of drivers, restraints, and opportunities that dictate its growth trajectory and competitive landscape. Key drivers include the escalating global demand for high-quality dental prosthetics and orthopedic implants, fueled by demographic shifts towards an aging population and increasing discretionary spending on healthcare. Furthermore, stringent environmental regulations globally necessitate improved emissions control technologies, substantially boosting the requirement for zirconia-based oxygen sensors in automotive and industrial sectors. The expansion of the energy sector, particularly the widespread adoption of clean energy technologies like SOFCs, provides a long-term structural driver for stabilized zirconia demand, solidifying its role as a strategic material.

However, the market faces significant restraints. The primary challenge is the high cost associated with producing high-purity zirconia powders, particularly those stabilized with expensive rare earth elements like yttria. This elevated cost structure, combined with complex and energy-intensive manufacturing processes, limits its adoption in price-sensitive applications. Additionally, the fluctuating supply and pricing of the raw material, zircon sand, introduce volatility and uncertainty into the supply chain, requiring manufacturers to implement sophisticated risk management strategies to mitigate unexpected operational costs and maintain competitive pricing globally.

Opportunities within the market largely revolve around material innovation and market diversification. The development of advanced processing techniques, such as plasma synthesis or micronization, offers avenues to reduce production costs while maintaining or improving powder characteristics. Significant opportunities exist in the military and aerospace sectors for lightweight, ultra-high-temperature resistant zirconia coatings for turbine blades. Furthermore, expanding the application scope into consumer electronics (e.g., ceramic casings for high-end devices) and developing new low-temperature SOFC electrolytes represent major opportunities that could sustain double-digit growth in specialized market niches, leveraging the unique combination of strength and electrical properties zirconia offers.

Segmentation Analysis

The Zirconia Powders Market is comprehensively segmented based on product type, application, and end-use industry, reflecting the diverse requirements of various high-tech sectors. This granular segmentation allows manufacturers to tailor their product offerings, focusing on specific particle size distributions and stabilization chemistries required for optimal performance in demanding applications, ranging from biomedical implants to complex electronic components. Understanding these segments is crucial for strategic planning and resource allocation, enabling companies to target the fastest-growing and highest-value market niches effectively.

- By Product Type:

- Yttria-Stabilized Zirconia (YSZ)

- Fully Stabilized Zirconia (FSZ)

- Magnesia-Stabilized Zirconia (MgSZ)

- Ceria-Stabilized Zirconia (CeSZ)

- Partially Stabilized Zirconia (PSZ)

- Others (Calcium-Stabilized Zirconia, etc.)

- By Application:

- Bioceramics and Dental

- Structural Ceramics (e.g., Cutting Tools, Wear Parts)

- Electronics and Electrical Components (e.g., Oxygen Sensors, Capacitors)

- Refractories and Insulation

- Energy and Environmental (e.g., Solid Oxide Fuel Cells (SOFCs), Catalysts)

- Thermal Barrier Coatings (TBCs)

- By End-Use Industry:

- Healthcare and Medical Devices

- Automotive and Transportation

- Aerospace and Defense

- Chemical Processing and Metallurgy

- Electronics and Telecommunications

- Energy and Power Generation

Value Chain Analysis For Zirconia Powders Market

The value chain for the Zirconia Powders Market begins with the upstream segment, dominated by the mining and processing of zircon sand, the primary raw material source of zirconium. Key activities in the upstream include sand purification, chemical extraction, and initial conversion into intermediate zirconium chemicals like zirconium oxychloride (ZOC) or zirconium sulphate. The cost and quality of these intermediate chemicals heavily influence the final price and performance characteristics of the zirconia powder. A small number of specialized chemical companies control this crucial phase, making supply security and long-term contracts vital for powder manufacturers.

The core manufacturing stage involves converting these zirconium intermediates into high-purity zirconia powders using advanced synthesis techniques such as chemical precipitation, hydrothermal methods, or plasma processing. This stage is highly technology-intensive, focusing on achieving precise control over particle size, morphology, and stabilization chemistry (doping). Quality assurance and regulatory compliance, especially for medical-grade powders, are paramount here. Direct distribution channels often involve supplying large volumes to integrated ceramics manufacturers or specialized component fabricators (e.g., dental milling centers), ensuring technical support and tight specification adherence.

The downstream analysis focuses on the final consumption and integration of the zirconia powder into finished goods. End-users include manufacturers of structural ceramic components, dental laboratories that mill custom prosthetics, and energy companies assembling fuel cell stacks. Indirect distribution involves specialized technical distributors and agents who manage logistics, provide local stockholding, and cater to smaller, diverse customers across various regions. The efficiency of the downstream segment is highly dependent on effective collaboration between the powder supplier and the end-user to optimize sintering and processing parameters for the final product.

Zirconia Powders Market Potential Customers

The primary consumers and end-users of Zirconia Powders are highly specialized manufacturers operating in high-precision, high-reliability sectors where material failure is unacceptable. Dental laboratories and orthopedic implant manufacturers constitute a major segment, prioritizing biocompatibility, aesthetic qualities, and long-term mechanical strength for crowns, bridges, and joint replacements. These customers demand extremely fine, high-purity, and consistently stabilized powders, predominantly YSZ, often sourced under strict regulatory certifications such as ISO 13485.

Another critical customer base includes automotive and industrial Original Equipment Manufacturers (OEMs), particularly those specializing in exhaust systems and engine component manufacturing. These customers utilize zirconia for oxygen sensors to manage emissions effectively and as thermal barrier coatings (TBCs) to protect metallic parts from extreme heat in turbine engines, demanding powders with high thermal shock resistance and low thermal conductivity. Furthermore, manufacturers of Solid Oxide Fuel Cells (SOFCs) are high-volume purchasers of specific YSZ grades optimized for ionic conductivity at elevated operating temperatures, representing a significant strategic growth area for the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,070 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Saint-Gobain, Tosoh Corporation, Daiichi Kigenso Kagaku Kogyo Co., Ltd., Zircomet Ltd., Innovnano, MEL Chemicals, S. C. Global Supply Co. Ltd., Guangtong Chemical, Orient Zirconic, American Elements, Washington Mills, Baikowski, KCM Corporation, Cumi Murugappa, Reade International, H.C. Starck Solutions, Showa Denko (Resonac), Inframat Advanced Materials. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zirconia Powders Market Key Technology Landscape

The technological landscape of the Zirconia Powders Market is primarily defined by the precision required in synthesizing ultra-fine, highly pure, and uniform ceramic materials. The dominant manufacturing technologies employed include chemical methods such as co-precipitation, sol-gel processing, and hydrothermal synthesis. Hydrothermal synthesis is particularly favored for producing nano-sized powders with narrow particle size distributions and high crystallinity, which are crucial for achieving dense, high-performance ceramic parts with superior mechanical properties, especially important in biomedical applications where mechanical reliability is critical.

Another crucial set of technologies revolves around stabilization techniques. Zirconia undergoes volume changes during phase transitions (monoclinic to tetragonal), which must be managed by introducing stabilizers like yttria (YSZ) or magnesia (MgSZ). Advanced doping and mixing technologies ensure homogenous incorporation of these stabilizers at the atomic level, optimizing the resulting material’s phase stability across wide temperature ranges. Furthermore, plasma spray technology is essential for applying zirconia-based Thermal Barrier Coatings (TBCs) onto metallic substrates in aerospace and energy applications, demanding high-flowability powders with specific morphological characteristics suitable for high-velocity application processes.

In terms of processing, recent innovations focus on reducing the energy intensity and cost of production. Techniques like microwave-assisted sintering and flash sintering are being explored to lower the required processing temperatures and cycle times, making zirconia component manufacturing more economically viable. Furthermore, advanced characterization tools, including high-resolution electron microscopy and sophisticated surface area analysis, are indispensable for quality control, ensuring the manufactured powders meet the rigorous specifications required by sophisticated end-users in electronics and medical device manufacturing.

Regional Highlights

The global Zirconia Powders Market exhibits distinct regional dynamics, influenced by local industrial base, regulatory environment, and healthcare expenditure.

- Asia Pacific (APAC): Dominates the market both in terms of volume consumption and production capacity. Fueled by exponential growth in electronics manufacturing (especially in China and South Korea), rapid expansion of the automotive sector, and increasing demand for high-quality dental and medical ceramics driven by improving living standards and medical tourism. China is a major hub for both raw material processing and finished powder production.

- North America: Characterized by high-value, specialized demand, particularly from the aerospace and defense sectors for Thermal Barrier Coatings (TBCs) and advanced military applications. The region also maintains robust demand for high-purity medical-grade zirconia due to strict regulatory standards and mature orthopedic and dental markets. Innovation and R&D activities are strongly funded, focusing on new stabilization chemistries.

- Europe: A mature market defined by strong regulatory frameworks and a focus on premium, high-performance applications, especially in the automotive industry (emission control sensors) and advanced dental prosthetics. Germany, Italy, and France are key consumers. Strict environmental norms promote the use of zirconia in catalysts and filtration systems, ensuring steady demand.

- Latin America (LATAM): Exhibits accelerating growth, primarily in the dental and construction sectors. Expanding healthcare accessibility and increasing investment in local manufacturing capabilities are driving regional demand, though reliance on imports of high-purity grades remains significant.

- Middle East and Africa (MEA): A smaller but growing market, largely driven by infrastructure investments, localized petrochemical processing, and rapidly developing healthcare sectors in the Gulf Cooperation Council (GCC) countries. Demand is focused on refractories and components for high-temperature industrial environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zirconia Powders Market.- Saint-Gobain

- Tosoh Corporation

- Daiichi Kigenso Kagaku Kogyo Co., Ltd.

- Zircomet Ltd.

- Innovnano

- MEL Chemicals

- S. C. Global Supply Co. Ltd.

- Guangtong Chemical

- Orient Zirconic

- American Elements

- Washington Mills

- Baikowski

- KCM Corporation

- Cumi Murugappa

- Reade International

- H.C. Starck Solutions

- Showa Denko (Resonac)

- Inframat Advanced Materials

- Jiangxi Kingan Hi-Tech

- Treibacher Industrie AG

Frequently Asked Questions

Analyze common user questions about the Zirconia Powders market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for high-purity Zirconia Powders?

The primary factor driving the demand for high-purity zirconia is the rapid expansion of the global healthcare sector, specifically the increasing utilization of Yttria-Stabilized Zirconia (YSZ) in dental crowns, bridges, and orthopedic implants due to its superior biocompatibility, strength, and aesthetic qualities.

How does Yttria-Stabilized Zirconia (YSZ) differ from Fully Stabilized Zirconia (FSZ) in application?

YSZ (Partially Stabilized Zirconia) is prized for its high fracture toughness, making it ideal for structural and biomedical applications. FSZ, stabilized across the full temperature range, typically offers better ionic conductivity, making it the preferred electrolyte material for high-temperature Solid Oxide Fuel Cells (SOFCs) and oxygen sensors.

Which region dominates the Zirconia Powders Market and why?

The Asia Pacific (APAC) region currently dominates the market, driven by substantial investment in electronics manufacturing, a booming automotive sector requiring emission control components, and accelerated industrial growth leading to high consumption in structural and refractory applications.

What are the main technological challenges in the production of nano-sized Zirconia Powders?

Key technological challenges include maintaining precise control over particle size distribution during synthesis (e.g., hydrothermal methods), preventing particle agglomeration during drying and processing, and ensuring cost-effective production methods while achieving extremely high purity levels required for advanced ceramics.

What role do Zirconia Powders play in the clean energy transition?

Zirconia powders are critical components in the clean energy transition, primarily serving as the electrolyte material in Solid Oxide Fuel Cells (SOFCs) and Solid Oxide Electrolysis Cells (SOECs), enabling highly efficient conversion of chemical energy into electrical energy and hydrogen production, respectively, at high temperatures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Zirconia Powders Market Statistics 2025 Analysis By Application (Medical, Paints & Coatings, Electronics, Zirconium Metal Production, Other), By Type (Purity: 99%, Purity: 99.9%, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Zirconia Powders Market Statistics 2025 Analysis By Application (Biomaterials, Mechanical Components, Automotive Exhaust Treatment, Wear-Resistant Products, Special Tool), By Type (Hydrothermal Method Zirconia Powders, Precipitation Method Zirconia Powders), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager