Zirconium and Hafnium Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437111 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Zirconium and Hafnium Market Size

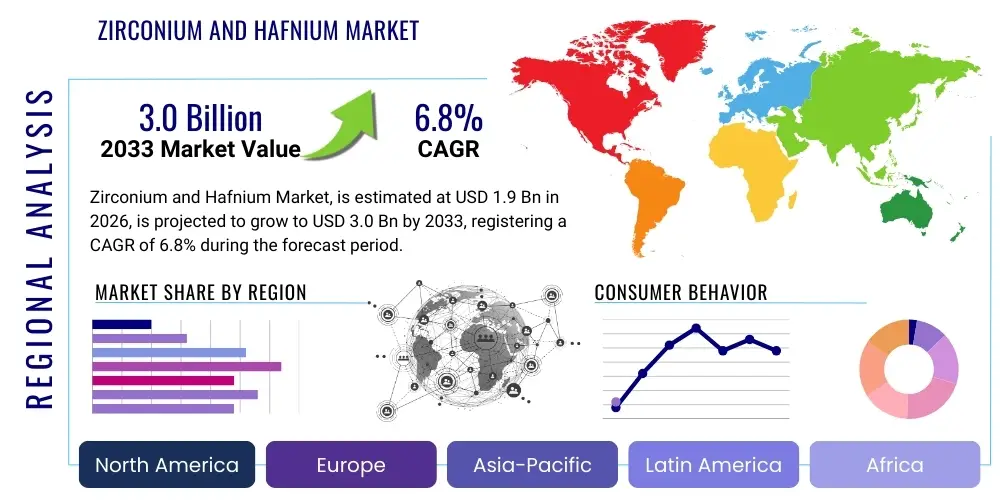

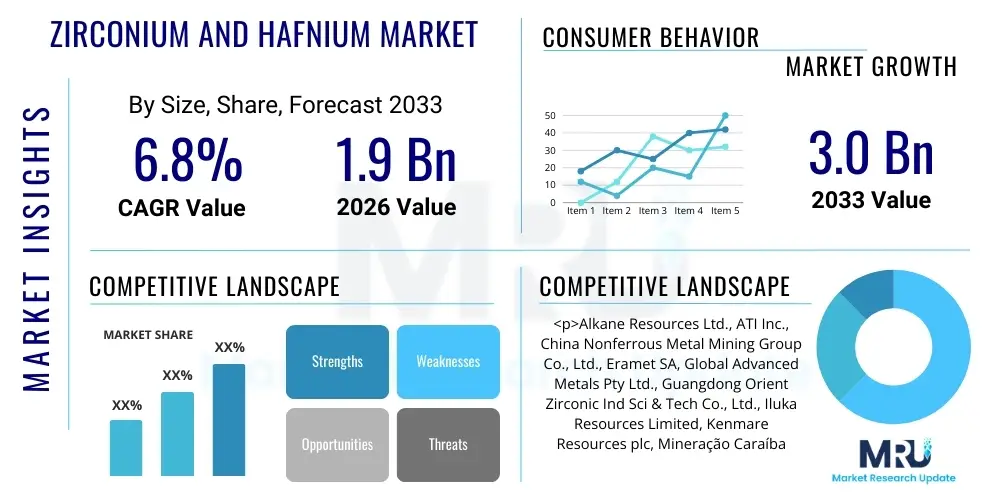

The Zirconium and Hafnium Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $1.9 Billion in 2026 and is projected to reach $3.0 Billion by the end of the forecast period in 2033.

Zirconium and Hafnium Market introduction

The Zirconium and Hafnium Market encompasses the extraction, separation, processing, and distribution of these chemically similar, yet functionally distinct, refractory metals and their compounds. Zirconium, primarily derived from zircon sands, is renowned for its exceptional corrosion resistance, low neutron absorption cross-section, and high melting point, making it indispensable in the nuclear energy sector for fuel cladding, and extensively utilized in ceramics, refractories, and foundry applications, largely through its compounds Zirconium Dioxide (Zirconia) and Zirconium Silicate. Conversely, Hafnium is nearly always found alongside Zirconium, requiring complex separation techniques; its high neutron absorption capacity makes it critical for control rods in nuclear reactors, while its high permittivity oxides are fundamental components in advanced microelectronics, particularly in high-k dielectrics for modern semiconductor manufacturing. The expansion of global nuclear power infrastructure, alongside persistent demand from high-performance ceramics and the burgeoning advanced electronics sector, are the primary drivers sustaining substantial growth and strategic investment across the entire market value chain, necessitating continuous innovation in extraction and purification methodologies.

Zirconium and Hafnium Market Executive Summary

The market exhibits strong business trends driven by the resurgence of interest in nuclear power globally, significantly boosting demand for reactor-grade Zirconium alloys and Hafnium control rods, countered partially by volatile pricing stemming from complex and energy-intensive separation processes inherent to these sister elements. Regionally, the Asia Pacific (APAC) dominates in terms of consumption and refinement capacity, particularly due to its robust ceramics, electronics, and burgeoning nuclear construction sectors in countries like China and India, while North America and Europe remain pivotal for high-specification nuclear and aerospace applications, emphasizing stringent quality control and supply chain stability. Segment trends indicate accelerated growth in the Hafnium segment, especially its high-purity oxides used in advanced logic chip fabrication, overshadowing the more established, yet steady, Zirconium refractory and ceramic segments, thereby shifting the technological focus toward optimization of ultra-pure material synthesis and maximizing material performance in extreme environments, such as Gen III and IV nuclear reactors and next-generation semiconductors.

AI Impact Analysis on Zirconium and Hafnium Market

Common user inquiries concerning the influence of Artificial Intelligence (AI) on the Zirconium and Hafnium market frequently center on three primary areas: optimizing the energy-intensive separation process, predicting material performance under extreme operating conditions (especially within nuclear reactors), and enhancing quality control and anomaly detection during high-purity synthesis. Users anticipate that machine learning algorithms will revolutionize solvent extraction and plasma processing techniques, significantly reducing operational costs and material waste associated with the historical challenges of separating these two chemically analogous elements. Furthermore, AI-driven simulations and digital twin technologies are expected to accelerate the development of new Zirconium alloys and Hafnium compounds by accurately modeling microstructure evolution and failure mechanisms, leading to faster innovation cycles and greater material reliability in aerospace and nuclear applications. Finally, the integration of deep learning models into sensor networks is poised to establish real-time, zero-defect manufacturing standards for critical reactor-grade and electronic-grade materials, ensuring unparalleled consistency and regulatory compliance throughout the supply chain.

- AI-driven optimization of solvent extraction parameters for efficient Zirconium/Hafnium separation, reducing energy consumption and operational expenditures.

- Predictive modeling using machine learning to forecast long-term structural integrity and corrosion resistance of Zirconium alloys in extreme nuclear environments.

- Enhanced supply chain risk mitigation through AI analysis of global geopolitical events, resource availability, and refining bottlenecks.

- Automated defect detection and quality assurance in high-purity Hafnium oxide film deposition for semiconductor fabrication.

- Simulation of novel compound synthesis and performance using generative adversarial networks (GANs) to accelerate R&D timelines for advanced ceramics.

DRO & Impact Forces Of Zirconium and Hafnium Market

The Zirconium and Hafnium market dynamics are fundamentally shaped by the delicate balance between robust industrial demand and inherent supply chain complexities, establishing a critical set of interconnected Drivers, Restraints, and Opportunities (DRO). The primary market driver is the global commitment to carbon neutrality, translating into accelerated deployment of new nuclear power plants and the subsequent elevated need for reactor-grade Zirconium cladding and Hafnium control rods, complemented by sustained growth in high-temperature ceramic applications across industrial and defense sectors. Concurrently, the market faces significant restraints, chiefly the formidable technical and economic challenges associated with the highly sensitive and energy-intensive chemical separation of Zirconium from Hafnium, alongside stringent regulatory requirements and limited geographical concentration of processing facilities which create supply vulnerability and price volatility. However, substantial opportunities arise from technological advancements, specifically the development of smaller, modular nuclear reactors (SMRs) which require specialized materials, and the pervasive expansion of advanced microelectronics demanding ultra-pure Hafnium oxides for next-generation logic chips, presenting avenues for market participants to innovate in processing efficiency and high-value material production.

Segmentation Analysis

The Zirconium and Hafnium Market is structurally segmented based primarily on product form and end-use application, reflecting the divergence in performance requirements across nuclear, industrial, and high-tech sectors. Product segmentation distinguishes between the foundational raw materials, intermediate compounds, and final refined metals or alloys, with Zirconium Silicate representing the largest volume segment due to its widespread use in refractories and foundry operations, while high-purity Hafnium metal commands the highest value due to its indispensable role in aerospace and nuclear safety mechanisms. Application segmentation clearly delineates the market into the capital-intensive Nuclear Industry, the high-volume Ceramics and Refractories sector, and the technologically critical Advanced Electronics sector, with each segment exhibiting distinct growth trajectories influenced by global infrastructure investment cycles and technological shifts toward miniaturization and enhanced material performance.

- By Product Type:

- Zirconium Silicate/Sand

- Zirconium Dioxide (Zirconia)

- Zirconium Chemicals (e.g., Zirconium Oxychloride)

- Zirconium Metal and Alloys (e.g., Zircaloy)

- Hafnium Metal

- Hafnium Oxide and Compounds

- By Application:

- Nuclear Power (Fuel Cladding, Control Rods, Structural Components)

- Ceramics and Refractories (High-Temperature Furnaces, Ceramic Coatings)

- Foundry and Casting

- Advanced Electronics (High-k Dielectrics, Microprocessors)

- Chemical Processing and Aerospace

- By Purity Grade:

- Commercial Grade

- Nuclear Grade (High Separation Purity)

- Electronic Grade (Ultra-High Purity)

Value Chain Analysis For Zirconium and Hafnium Market

The Zirconium and Hafnium value chain commences with the upstream extraction phase, predominantly involving the mining of heavy mineral sands, where Zirconium is found primarily as Zircon (Zirconium Silicate), inherently containing small percentages of Hafnium. The most critical and cost-intensive stage is the midstream processing, involving chemical separation techniques—such as solvent extraction or fractional crystallization—necessary to isolate reactor-grade Zirconium (Hafnium-free) and high-purity Hafnium metal, which determines the material's final value and suitability for demanding applications like nuclear cladding or semiconductor components. Downstream activities involve specialized fabrication, where processed Zirconium and Hafnium are converted into final forms, such as high-precision tubes, powder coatings, or sputtering targets, distributed through a highly selective channel network, often favoring direct, long-term contracts with nuclear facility operators and major electronics manufacturers, bypassing broad indirect channels due to strict quality and traceability mandates.

Zirconium and Hafnium Market Potential Customers

The core customer base for Zirconium and Hafnium materials is defined by industries requiring superior refractory characteristics, corrosion resistance, and specific neutron characteristics, positioning the Nuclear Power Industry as the single largest and most strategically important buyer, demanding high volumes of reactor-grade Zircaloy for fuel assembly cladding and Hafnium for critical control rods used in reactor operation and safety. Secondary but highly substantial customers include the Ceramics and Refractory Manufacturing sector, which utilizes Zirconium Dioxide extensively for high-temperature furnace lining, thermal barriers, and specialized industrial coatings requiring exceptional hardness and thermal stability. Furthermore, the burgeoning Advanced Electronics Manufacturing industry, particularly semiconductor fabrication companies, represents a high-growth customer segment for ultra-pure Hafnium oxide precursors, critical for integrating advanced high-k gate dielectrics necessary for the continued miniaturization and performance enhancement of modern microprocessor technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.9 Billion |

| Market Forecast in 2033 | $3.0 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Alkane Resources Ltd., ATI Inc., China Nonferrous Metal Mining Group Co., Ltd., Eramet SA, Global Advanced Metals Pty Ltd., Guangdong Orient Zirconic Ind Sci & Tech Co., Ltd., Iluka Resources Limited, Kenmare Resources plc, Mineração Caraíba SA, Pacer International, RZ Refractories Pty Ltd., Tronox Holdings plc, Ucimco, Western Zirconium, AEM, CeramTec GmbH, Materion Corporation, Tosoh Corporation, VSMPO-AVISMA Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zirconium and Hafnium Market Key Technology Landscape

The technological landscape dominating the Zirconium and Hafnium market is fundamentally centered on achieving ultra-high purity and cost-effective separation, utilizing sophisticated hydrometallurgical and pyrometallurgical processes. Central to this is solvent extraction, which remains the industrial workhorse for separating Zirconium from Hafnium by exploiting slight differences in their chemical behavior across immiscible liquid phases, though this technique is highly resource-intensive and requires continuous optimization through process engineering advancements. Furthermore, the production of nuclear-grade Zirconium alloys necessitates specialized vacuum arc melting and electron beam melting processes to ensure homogeneity and precise control over alloy composition and microstructure, critical for enduring the severe radiation and temperature stresses within reactor cores. In the Hafnium segment, particularly for electronic applications, advanced chemical vapor deposition (CVD) and atomic layer deposition (ALD) technologies are paramount for producing thin-film Hafnium oxide gate dielectrics with atomic-scale precision, driving the market toward increased investment in high-throughput, clean-room compatible processing equipment and material handling systems.

Regional Highlights

- Asia Pacific (APAC): Dominates both consumption and production capacity, propelled by massive industrialization, rapid expansion in the Chinese ceramics and refractory sectors, and extensive investment in new nuclear power generation infrastructure, making it the central hub for midstream processing and downstream material conversion, especially for commercial-grade materials.

- North America: A critical market emphasizing high-specification, nuclear-grade materials, driven by the replacement and maintenance of existing reactor fleets, significant defense applications requiring stringent material quality standards, and leading innovation in advanced reactor designs such as Small Modular Reactors (SMRs).

- Europe: Characterized by strong historical reliance on nuclear power and a robust aerospace sector, demanding high-performance Zirconium alloys; the region is heavily focused on regulatory compliance and sustainable sourcing, with a growing emphasis on high-purity Hafnium consumption for advanced semiconductor manufacturing within its established technology centers.

- Latin America (LATAM): Primarily a source region for Zirconium mineral sands (e.g., Brazil), but downstream processing remains limited; consumption is concentrated in basic refractories and chemicals, with future growth linked to regional infrastructure projects and resource exploitation.

- Middle East and Africa (MEA): Emerging market primarily acting as a raw material supplier (e.g., South Africa, Kenya) for zircon sands; domestic consumption is nascent, focused on regional industrial growth, oil and gas processing refractory lining, and nascent nuclear energy program developments in key regional states.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zirconium and Hafnium Market.- Alkane Resources Ltd.

- ATI Inc.

- China Nonferrous Metal Mining Group Co., Ltd.

- Eramet SA

- Global Advanced Metals Pty Ltd.

- Guangdong Orient Zirconic Ind Sci & Tech Co., Ltd.

- Iluka Resources Limited

- Kenmare Resources plc

- Mineração Caraíba SA

- Pacer International

- RZ Refractories Pty Ltd.

- Tronox Holdings plc

- Ucimco

- Western Zirconium

- AEM

- CeramTec GmbH

- Materion Corporation

- Tosoh Corporation

- VSMPO-AVISMA Corporation

Frequently Asked Questions

Analyze common user questions about the Zirconium and Hafnium market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for nuclear-grade Zirconium?

The central driver is the global renewed commitment to developing and maintaining nuclear energy infrastructure as a reliable, low-carbon power source. Nuclear-grade Zirconium alloys, particularly Zircaloy, are indispensable for fuel cladding because they exhibit high structural integrity, exceptional corrosion resistance in pressurized water environments, and crucially, possess a very low thermal neutron absorption cross-section, ensuring maximum reactor efficiency and safety across the operational life cycle of the fuel rods.

How do Hafnium oxides contribute to advancements in the semiconductor industry?

Hafnium oxides are fundamental to modern semiconductor technology, specifically serving as high-k (high-dielectric constant) gate dielectrics in complementary metal-oxide-semiconductor (CMOS) transistors. By replacing conventional silicon dioxide gates, Hafnium oxide films, deposited using precise techniques like Atomic Layer Deposition (ALD), significantly reduce gate leakage current and enhance transistor scaling, enabling faster processing speeds, lower power consumption, and the continued miniaturization of microprocessors in alignment with Moore's Law objectives.

What are the main technical challenges in separating Zirconium and Hafnium?

The main technical challenge stems from the chemical similarity of the two elements, a consequence of the Lanthanide contraction, which results in nearly identical ionic radii and chemical properties, making traditional separation techniques ineffective. Industrial separation relies heavily on complex, multi-stage solvent extraction processes or fractional crystallization, which are extremely energy-intensive, require precise control over chemical parameters, and represent a significant portion of the material's final cost, often leading to supply bottlenecks for ultra-high purity grades.

Which geographical region holds the largest processing capacity and why?

The Asia Pacific (APAC) region, particularly China, holds the largest processing capacity due to extensive investment in large-scale chemical processing plants and lower operational costs compared to North America and Europe. This dominance is supported by a robust internal demand from the region's massive manufacturing bases for ceramics, refractories, and high-volume industrial applications, solidifying its role in refining Zirconium compounds from globally sourced mineral sands and preparing intermediate products for high-purity final processing elsewhere.

How is the adoption of Small Modular Reactors (SMRs) expected to impact Zirconium demand?

The rising adoption and projected deployment of Small Modular Reactors (SMRs) are anticipated to positively impact Zirconium demand, particularly for specialized, advanced alloys. While SMRs are smaller, their design often involves higher operating temperatures and pressures, requiring Zirconium-based materials with enhanced performance characteristics, such as higher corrosion resistance or specific neutronics properties, potentially accelerating R&D into next-generation Zircaloys and related materials optimized for these unique, high-efficiency nuclear systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager