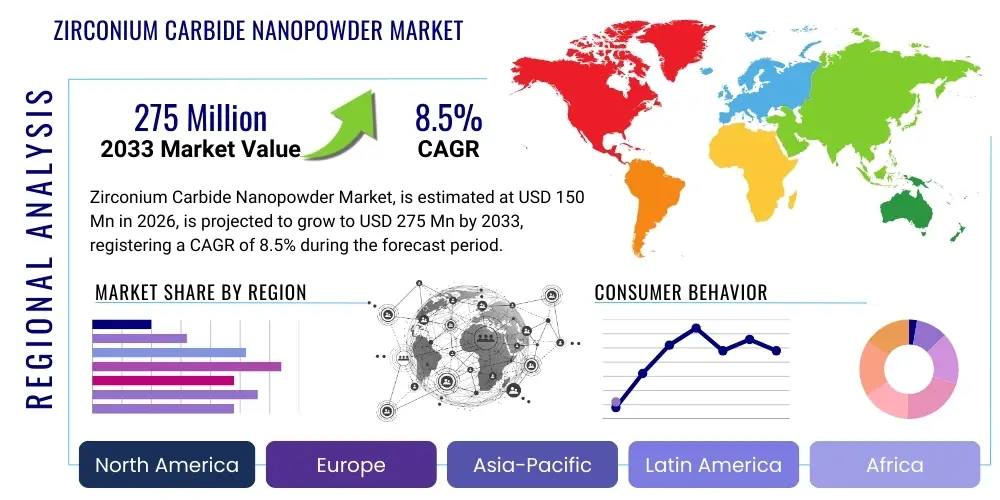

Zirconium Carbide Nanopowder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438274 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Zirconium Carbide Nanopowder Market Size

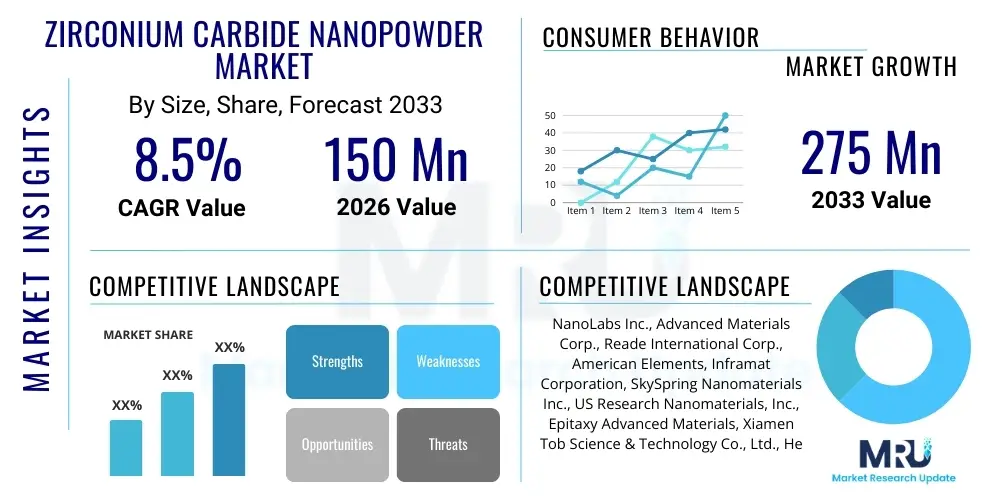

The Zirconium Carbide Nanopowder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 150 Million in 2026 and is projected to reach USD 275 Million by the end of the forecast period in 2033.

Zirconium Carbide Nanopowder Market introduction

Zirconium Carbide Nanopowder (ZrC) is a refractory ceramic material recognized for its exceptional physical properties, making it indispensable in high-performance applications. Characterized by an extremely high melting point (approaching 3530°C), superior hardness, chemical inertness, and excellent thermal conductivity, ZrC nanopowders offer significant advantages over traditional carbide materials, particularly when incorporated into advanced composites or coatings. The material's nanoscale structure dramatically enhances mechanical properties, enabling the development of components capable of withstanding extreme environmental conditions, such as ultra-high temperatures and corrosive chemical exposure, which are prevalent in aerospace, nuclear, and specialized industrial sectors.

The product is primarily manufactured through sophisticated chemical vapor deposition (CVD), plasma synthesis, or carbothermal reduction techniques, focusing on achieving tight control over particle size distribution and purity, which are critical determinants of final product performance. Major applications span the development of hard coatings for cutting tools, matrices for nuclear fuel cladding due to its low neutron cross-section, structural materials in hypersonic vehicles, and as an electrode material in various energy storage devices. The unique combination of refractory characteristics and high surface area intrinsic to nanopowder form allows for innovation in material science that was previously unattainable with conventional micron-sized ZrC.

Market growth is predominantly driven by the escalating demand for advanced ceramics in the global defense and aerospace sectors, where component reliability and operational efficiency at extreme temperatures are paramount. Furthermore, the accelerating adoption of advanced manufacturing processes, such as additive manufacturing (3D printing) of complex ceramic parts, heavily relies on high-quality, flowable ceramic nanopowders like ZrC. The inherent benefits, including enhanced wear resistance, superior strength-to-weight ratio, and long operational lifetimes, position Zirconium Carbide Nanopowder as a cornerstone material for next-generation material engineering across several high-technology industries aiming for improved performance and durability.

Zirconium Carbide Nanopowder Market Executive Summary

The Zirconium Carbide Nanopowder market is currently undergoing significant transformation, driven by robust investment in high-performance material science and the persistent push for operational efficiency across critical infrastructure and defense applications. Key business trends indicate a strong move toward tailored manufacturing solutions, where specialized grades of ZrC nanopowder, optimized for specific synthesis methods like selective laser sintering (SLS) or thermal spraying, command premium pricing. Mergers, acquisitions, and strategic collaborations focused on securing proprietary synthesis technology are defining the competitive landscape, especially as manufacturers seek to overcome scalability challenges associated with maintaining high purity in nanoscale production. Innovation is centered around developing composite materials that leverage ZrC’s properties alongside polymers or other ceramics to create novel functions, such as enhanced ballistic resistance or superior thermoelectric performance.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrial expansion, massive governmental investment in nuclear energy programs, and a growing domestic aerospace and defense manufacturing base, particularly in China and India. North America and Europe maintain strong market shares, focusing predominantly on high-value, application-specific R&D, and premium military-grade material supply. Regulatory trends in these Western economies, particularly concerning occupational safety and nanomaterial handling, are influencing production standards, pushing firms toward encapsulated or suspended nanopowder forms to mitigate risk. Investment in R&D facilities specializing in advanced ceramics across the European Union is bolstering demand in the non-tooling industrial sector.

Segment trends reveal that the application of Zirconium Carbide Nanopowder in wear-resistant and thermal barrier coatings is experiencing the highest growth trajectory due to its versatility and efficacy in extending the lifespan of industrial machinery components. The nuclear segment, though smaller in volume, remains critical and high-value, driven by long-term strategic energy planning involving accident-tolerant fuels (ATF) development. Furthermore, the segment categorized by high-purity grades (99.9% and above) is forecasted to outpace the growth of standard industrial grades, reflecting the stringent quality requirements mandated by the aerospace and semiconductor manufacturing industries. Overall, the market remains technologically driven, with success heavily reliant on consistent quality and the ability to scale specialized production processes efficiently.

AI Impact Analysis on Zirconium Carbide Nanopowder Market

Common user questions regarding AI's influence in the Zirconium Carbide Nanopowder market revolve primarily around three core areas: how AI can accelerate the discovery of new ZrC-based composites, whether AI can optimize energy-intensive synthesis processes to lower production costs, and the role of machine learning in ensuring consistent quality control and predicting potential defects in the final material. Users are keenly interested in predictive maintenance models for production equipment and the possibility of utilizing advanced algorithms to simulate material behavior under extreme operational conditions, thereby reducing the need for expensive and time-consuming physical testing. There is a clear expectation that AI will be the key enabler for transitioning laboratory-scale nanomaterial synthesis into reliable, industrial-scale production, specifically addressing the notorious challenge of achieving uniform particle distribution and high purity at volume.

The integration of Artificial Intelligence and Machine Learning (ML) platforms is fundamentally transforming the synthesis and application of Zirconium Carbide Nanopowder. AI models are being deployed to analyze complex thermodynamic and kinetic data generated during synthesis processes, such as plasma torch reactions or fluidized bed reactors, allowing manufacturers to identify optimal process parameters—including temperature gradients, precursor flow rates, and reaction times—that maximize yield while minimizing energy consumption. This optimization not only reduces production costs, which have historically been a significant restraint in the nanomaterials market but also directly improves the quality consistency of the resultant nanopowder, addressing major supply chain reliability concerns from end-users.

Furthermore, AI accelerates material innovation by performing high-throughput virtual screening of potential ZrC composite formulations. Generative AI tools and physics-informed neural networks (PINNs) simulate how doping agents or different particle morphologies interact within a composite matrix, predicting resultant properties such as thermal expansion coefficients or fracture toughness without physical experimentation. This capability drastically shortens the material development cycle, enabling companies to quickly tailor ZrC nanopowder products for highly niche applications, such as specialized armor plating or high-efficiency catalysts. The ability to model nanoscale behavior under conditions impossible to replicate in standard labs positions AI as a strategic asset for market leaders seeking a competitive edge in product innovation and speed to market.

- AI optimizes energy consumption in carbothermal reduction processes, leading to reduced production costs.

- Machine learning enhances real-time quality control by predicting and correcting particle size deviations during synthesis.

- Generative algorithms accelerate the design of novel ZrC-based composite materials for aerospace and nuclear applications.

- Predictive maintenance models increase uptime and efficiency of specialized synthesis reactors and grinding equipment.

- AI-driven simulation tools reduce the reliance on costly physical testing for high-temperature and high-pressure performance verification.

- Advanced data analytics optimize logistics and inventory management for sensitive nanopowder supply chains.

DRO & Impact Forces Of Zirconium Carbide Nanopowder Market

The Zirconium Carbide Nanopowder market is influenced by a dynamic interplay of factors that both propel and restrict its growth, establishing a landscape rich with high-risk, high-reward opportunities. The primary driver is the unparalleled demand from critical infrastructure sectors—namely aerospace, defense, and nuclear power—which require materials capable of surviving extremely harsh environments where conventional metals or ceramics fail. ZrC's exceptional thermal shock resistance, high strength retention at temperatures exceeding 2000°C, and neutron transparency are non-negotiable requirements for these demanding applications. Simultaneously, the market faces significant restraints, chiefly concerning the high cost of production due to energy-intensive synthesis methods and the associated technological complexity required to achieve high-purity, uniform nanoscale particles. Furthermore, growing regulatory scrutiny and safety concerns surrounding the handling and potential environmental impact of airborne ceramic nanoparticles pose ongoing challenges that necessitate substantial investment in safe handling and encapsulation technologies.

Opportunities for expansion are fundamentally linked to technological advances in neighboring industries, particularly the maturation of additive manufacturing techniques for ceramics. The ability to 3D print complex geometries using ZrC-polymer slurries or suspensions opens up new market avenues in customized tooling, high-precision nozzles, and complex thermal management components. Furthermore, the global push toward sustainable energy sources presents an opportunity within the Solid Oxide Fuel Cell (SOFC) segment, where ZrC is investigated for enhanced electrode performance and longevity. The long-term impact forces shaping the market include the geopolitical instability that drives defense spending, thus creating persistent demand for advanced materials, and the pace of innovation in competing ultra-high-temperature ceramics (e.g., hafnium carbide), which could potentially erode ZrC's market share if cost-effective alternatives emerge.

Ultimately, the market's trajectory is highly sensitive to technological breakthroughs in synthesis and dispersion techniques. If manufacturers successfully transition from batch processing to continuous, high-volume production with guaranteed quality consistency, the primary restraint (high cost/low scalability) will diminish, unlocking massive latent demand in the industrial tooling and general wear-protection markets. Conversely, failure to adequately address the inherent safety and regulatory hurdles associated with nanomaterials could slow adoption rates, regardless of the technological benefits. The current environment indicates that the impact forces favoring specialized, high-performance applications (Defense/Aerospace R&D funding) currently outweigh the forces of restraint, signaling continued, albeit specialized, high-value growth.

Segmentation Analysis

The Zirconium Carbide Nanopowder market is systematically segmented based on key criteria including purity level, synthesis method, and end-use application, reflecting the material’s diversity in functionality and cost structures. Segmentation by purity is crucial, dividing the market into high-purity grades (99.9% and above) often used in nuclear and semiconductor applications where trace impurities are intolerable, and industrial grades (99.0%–99.8%) suitable for thermal coatings and general wear resistance. Purity directly correlates with production cost and complexity, establishing clear pricing tiers across the market. Segmentation by application helps delineate the market's core drivers, with the Aerospace and Defense sector consistently holding the largest market share due to critical reliance on ZrC for components subject to extreme mechanical and thermal stresses.

The segmentation based on the synthesis method highlights the technological diversity within the production landscape. Key methods include Chemical Vapor Deposition (CVD), Plasma Synthesis, and Carbothermal Reduction (CTR). CVD and Plasma techniques typically yield finer particles with narrower size distribution and superior morphology, fetching higher prices and serving niche, ultra-high-performance segments. Conversely, CTR is often utilized for bulk production of industrial grades due to its relative cost-effectiveness and scalability, although it often results in broader particle size ranges. This technological segmentation is pivotal for investment strategy, as manufacturers must choose processes optimized for the target market segment's quality and volume requirements.

Furthermore, segmentation by form (e.g., dry powder, slurry/dispersion, or sintered components) reflects how the product is delivered to the end-user. The increasing adoption of ZrC nanopowder in liquid dispersions or pre-sintered forms is a growing trend, driven by end-users seeking enhanced handling safety, improved dispersion stability in composite fabrication, and greater convenience in additive manufacturing processes. These tailored forms reduce the risk of nanoparticle inhalation and simplify integration into complex production lines, thus stimulating adoption in heavily regulated environments like Europe. Overall market performance is increasingly tied to the ability of suppliers to customize particle characteristics based on the specific end-user fabrication technique.

- By Purity Level:

- Industrial Grade (99.0% - 99.8%)

- High Purity Grade (99.9% and above)

- By Synthesis Method:

- Chemical Vapor Deposition (CVD)

- Carbothermal Reduction

- Plasma Synthesis

- Other Methods (e.g., Self-Propagating High-Temperature Synthesis - SHS)

- By Application:

- Aerospace and Defense (Thermal Protection Systems, Nozzles)

- Nuclear Energy (Fuel Cladding, Accident-Tolerant Fuels - ATF)

- Cutting Tools and Wear Parts

- Metallurgy (Cermets and Composites)

- Energy Storage (Electrodes, Solid Oxide Fuel Cells)

- Catalysis and Chemical Processing

- By Form:

- Dry Nanopowder

- Slurries and Dispersions

Value Chain Analysis For Zirconium Carbide Nanopowder Market

The value chain for Zirconium Carbide Nanopowder is characterized by high complexity and technological intensity, commencing with the sourcing and preparation of specialized precursor materials. Upstream activities predominantly involve the supply of high-grade Zirconia (ZrO2) and various carbon sources (e.g., carbon black or specialized organic precursors). The purity and cost of these raw materials critically influence the final product quality and price. Suppliers specializing in high-purity Zirconia often hold significant leverage, given the demanding requirements of the final ZrC product. The core manufacturing stage—the conversion of precursors into uniform nanopowder via methods like plasma synthesis or carbothermal reduction—represents the highest value-addition point, requiring substantial capital investment in specialized, high-temperature reactors and stringent process control to ensure nanoscale consistency.

Midstream activities focus on post-synthesis processing, including washing, drying, deagglomeration, and dispersion stabilization. Nanopowders often exhibit strong agglomeration tendencies; thus, effective milling and surface treatment techniques are crucial to prepare the material for integration into composites or coatings. Distribution channels are highly specialized, often bypassing traditional commodity chemical distributors. Due to the niche nature and high cost, sales are frequently direct-to-manufacturer (DTM) for large aerospace or nuclear OEMs, ensuring technical support and strict quality traceability. Indirect distribution involves specialized chemical and materials distributors that handle smaller orders for R&D institutions or highly dispersed industrial users, often dealing with pre-prepared slurries rather than dry powders to mitigate handling risks.

Downstream analysis centers on the integration of ZrC nanopowder into final products. This stage is dominated by end-users in highly sophisticated manufacturing environments, such as companies producing cutting-edge ceramic matrix composites (CMCs), advanced thermal spray coatings, or specialized nuclear fuel pellets. The success of ZrC in the downstream application depends heavily on effective dispersion and integration techniques, ensuring that the nanoscale benefits are transferred to the macroscopic component. Major risks in the downstream segment include poor integration leading to composite failure and stringent performance qualification protocols (e.g., MIL-SPECs or nuclear safety standards), which create high barriers to entry for new materials and suppliers. This high level of integration complexity solidifies the necessity for strong, collaborative relationships between the nanopowder producer and the final product manufacturer.

Zirconium Carbide Nanopowder Market Potential Customers

The potential customer base for Zirconium Carbide Nanopowder is highly specialized, concentrated within sectors demanding extreme material performance where cost is secondary to reliability and function. Primary end-users fall into three major categories: the aerospace and defense industry, the nuclear energy sector, and advanced industrial tooling manufacturers. Aerospace OEMs, particularly those involved in hypersonic flight technology, rocket propulsion systems, and atmospheric re-entry vehicles, are critical buyers. They utilize ZrC for thermal protection shields, highly durable nozzle throats, and components that must maintain structural integrity under combustion temperatures and intense mechanical stress, classifying them as high-volume, continuous buyers of high-purity grades.

The nuclear energy sector represents a growing, high-value segment. Research institutions and fuel fabrication companies are increasingly focusing on Zirconium Carbide Nanopowder for the development of Accident-Tolerant Fuels (ATF) and next-generation fuel cladding materials. ZrC’s low neutron absorption cross-section and superior resistance to high-temperature steam oxidation make it a foundational material for improving reactor safety and efficiency. These customers typically engage in long-term procurement contracts, often requiring the highest levels of material purity and extensive documentation regarding material sourcing and process controls to meet regulatory mandates.

Furthermore, advanced industrial manufacturers, specifically those producing high-performance cutting tools, grinding media, and wear-resistant coatings (via thermal spray or physical vapor deposition), constitute another significant consumer group. These buyers leverage ZrC nanopowder to enhance the hardness, abrasion resistance, and operational lifespan of tools used in machining hard alloys, ceramics, and composites. While these transactions may involve less stringent purity requirements compared to the aerospace or nuclear segments, the demand for consistently sized, well-dispersed nanopowder to ensure coating uniformity and performance is paramount, driving a large segment of the industrial-grade market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150 Million |

| Market Forecast in 2033 | USD 275 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | NanoLabs Inc., Advanced Materials Corp., Reade International Corp., American Elements, Inframat Corporation, SkySpring Nanomaterials Inc., US Research Nanomaterials, Inc., Epitaxy Advanced Materials, Xiamen Tob Science & Technology Co., Ltd., Hefei Kaier Nano Technology Co., Ltd., Nanochemazone, Materion Corporation, Treibacher Industrie AG, Goodfellow Corporation, Zibo Honghe Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Zirconium Carbide Nanopowder Market Key Technology Landscape

The technological landscape of the Zirconium Carbide Nanopowder market is defined by continuous evolution aimed at achieving superior control over particle morphology, size distribution, and purity while simultaneously reducing the substantial energy footprint associated with high-temperature processing. Carbothermal Reduction (CTR) remains a foundational method, utilizing the reaction between Zirconia and carbon precursors at temperatures exceeding 1800°C. Technological advancements in CTR focus on using novel, highly reactive carbon sources and optimizing furnace design (e.g., vacuum or inert gas atmospheres) to lower reaction temperatures and minimize unwanted oxygen contamination, which is critical for achieving nuclear-grade purity levels required for accident-tolerant fuels.

More sophisticated synthesis techniques, such as non-transferred arc plasma synthesis and laser ablation, are gaining prominence, particularly for creating ultra-fine powders with extremely narrow size distributions (typically below 50 nm). Plasma synthesis offers high reaction rates and rapid cooling, which effectively prevents grain growth and agglomeration, yielding superior nanoscale morphology essential for high-strength composites. However, these methods require extremely specialized equipment and have higher operational costs, positioning them for high-end, low-volume applications like R&D and precision electronics components. A significant recent trend involves the integration of in-situ monitoring technologies, often supported by AI, to modulate plasma parameters in real-time, ensuring consistent material quality across production runs.

Beyond the synthesis phase, the focus of technological innovation is heavily weighted toward effective dispersion and surface functionalization. Due to the high surface energy of ZrC nanopowders, preventing re-agglomeration in liquid systems (slurries or solvents) is a persistent challenge that directly impacts the quality of the final composite or coating. Innovations in ultrasonic dispersion, mechanical milling coupled with proprietary surfactants, and advanced encapsulation techniques are key areas of intellectual property development. These surface modification technologies ensure the nanopowder can be uniformly integrated into polymer matrices or ceramic composite systems, thereby realizing the full potential of the material’s nanoscale properties in practical applications, such as large-scale thermal barrier coatings applied via high-velocity oxy-fuel (HVOF) spraying.

Regional Highlights

The global Zirconium Carbide Nanopowder market exhibits distinct regional dynamics, largely reflective of defense spending, industrial growth rates, and technological maturity in advanced material manufacturing. North America, driven primarily by the United States, commands a substantial share of the high-value market, characterized by significant investment in defense and aerospace R&D. Demand here is exceptionally high for materials used in next-generation military hardware, including hypersonic missile components and advanced jet engine coatings. The presence of major research institutions and leading aerospace OEMs ensures consistent, stringent demand for high-purity, tailor-made ZrC nanopowders, often procured under long-term federal contracts. This region is also a pioneer in applying ZrC in ceramic additive manufacturing, further fueling technological demand.

Asia Pacific (APAC) represents the fastest-growing market, propelled by rapid industrialization, massive infrastructure development, and substantial governmental backing for domestic advanced materials production in countries like China, Japan, and South Korea. China, in particular, is witnessing robust growth in its nuclear power capacity and an expanding domestic aerospace industry, leading to increased consumption of industrial-grade and intermediate-purity ZrC nanopowder for conventional thermal barriers and specialized tooling. The lower manufacturing costs and increasing domestic technological capability within APAC allow this region to serve both internal and global supply chains for standard industrial applications, placing intense competitive pressure on Western suppliers regarding volume and price.

Europe, while mature, maintains a strong presence, emphasizing high-quality, niche applications, and adherence to rigorous safety and environmental standards. Key demand segments include specialized automotive components (e.g., high-performance braking systems), industrial precision tooling, and nuclear research facilities, particularly within France and Germany. The European market tends to favor encapsulated or dispersed forms of the nanopowder to comply with strict REACH regulations concerning nanomaterial handling. Latin America, the Middle East, and Africa (MEA) currently hold smaller market shares, with demand primarily centered on oil and gas infrastructure (wear-resistant coatings for drilling equipment) and initial nuclear energy development projects, relying heavily on imports from North America and APAC for specialized material supply.

- North America: Dominant in high-value defense, aerospace, and advanced materials R&D; leader in ceramic 3D printing applications.

- Asia Pacific (APAC): Fastest growing region due to industrial expansion, massive nuclear energy investment (China, India), and large-scale manufacturing capacity.

- Europe: Focus on regulated, high-performance industrial applications, specialized tooling, and nuclear research, with strong emphasis on nanomaterial safety compliance.

- Latin America: Emerging market with niche demand driven by mining and energy sector applications.

- Middle East and Africa (MEA): Growth tied to infrastructure projects and nascent nuclear energy programs requiring thermal and wear resistance materials.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Zirconium Carbide Nanopowder Market.- NanoLabs Inc.

- Advanced Materials Corp.

- Reade International Corp.

- American Elements

- Inframat Corporation

- SkySpring Nanomaterials Inc.

- US Research Nanomaterials, Inc.

- Epitaxy Advanced Materials

- Xiamen Tob Science & Technology Co., Ltd.

- Hefei Kaier Nano Technology Co., Ltd.

- Nanochemazone

- Materion Corporation

- Treibacher Industrie AG

- Goodfellow Corporation

- Zibo Honghe Chemical Co., Ltd.

- H.C. Starck GmbH (Parent Company Involvement)

- Stanford Advanced Materials

- Cenosphere Corp.

- Saint-Gobain (Advanced Ceramics Division)

Frequently Asked Questions

Analyze common user questions about the Zirconium Carbide Nanopowder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary challenges in the large-scale production of Zirconium Carbide Nanopowder?

The main challenges involve achieving consistent particle size distribution and high purity levels at industrial scale. Synthesis methods are highly energy-intensive, leading to elevated production costs, and effective deagglomeration of the resulting ultra-fine powder without introducing contaminants remains a significant technical hurdle for mass production.

In which specific aerospace applications is Zirconium Carbide Nanopowder most critical?

ZrC nanopowder is critical in ultra-high-temperature aerospace applications such as rocket motor nozzles, thermal protection systems (TPS) for re-entry vehicles, and leading edges of hypersonic aircraft, where its extreme melting point and thermal shock resistance are essential for mission success and structural integrity.

How does the purity of ZrC nanopowder affect its end-use market?

Higher purity grades (99.9%+) are mandated for highly sensitive, strategic sectors like nuclear energy (Accident-Tolerant Fuels) and advanced electronics, where trace elements can compromise performance. Industrial grades (99.0%–99.8%) are typically sufficient for hard coatings, cutting tools, and general thermal barriers, offering a balance of performance and cost.

What role does Zirconium Carbide Nanopowder play in the nuclear energy sector?

ZrC is increasingly vital in nuclear energy for developing Accident-Tolerant Fuels (ATF). Its primary advantage is its chemical stability and low neutron cross-section, which helps prevent fuel cladding degradation and oxidation in high-temperature steam environments, thereby significantly enhancing reactor safety margins.

Is Zirconium Carbide Nanopowder safe to handle, and what are the compliance requirements?

Handling ZrC nanopowder requires strict adherence to occupational safety standards due to the potential health risks associated with inhaling fine nanoparticles. Manufacturers are increasingly producing ZrC in encapsulated forms or stable liquid dispersions (slurries) to improve safety and meet stringent environmental and health regulations, such as the European Union’s REACH guidelines for nanomaterials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager