Acrylic Solid Surface Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435623 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Acrylic Solid Surface Market Size

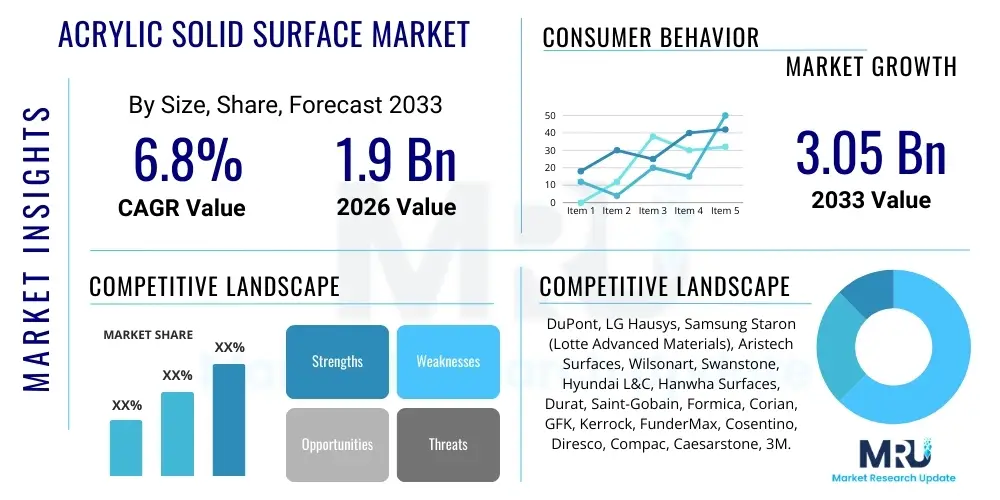

The Acrylic Solid Surface Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.9 Billion in 2026 and is projected to reach USD 3.05 Billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by rising global construction activities, particularly in the residential remodeling and commercial infrastructure sectors, where the demand for high-performance, aesthetically versatile, and hygienic surfacing materials is escalating. The inherent characteristics of acrylic solid surfaces, such as seamless integration, non-porous nature, and repairability, position them favorably against traditional materials like granite and laminate, contributing significantly to this upward trajectory.

Acrylic Solid Surface Market introduction

The Acrylic Solid Surface Market encompasses the manufacturing, distribution, and application of composite materials made primarily from acrylic polymers (polymethyl methacrylate or PMMA) combined with alumina trihydrate (ATH) fillers and pigments. This unique composition yields a non-porous, homogenous material that can be thermoformed into complex shapes, offering unparalleled design flexibility compared to conventional surfacing options. Major applications span high-traffic commercial environments, including healthcare facilities, hospitality venues, and retail spaces, alongside widespread use in premium residential kitchens and bathrooms. Key benefits driving adoption include superior hygienic properties (resistance to mold and mildew), durability, and the ability to be seamlessly repaired and renewed, addressing the long-term maintenance needs of modern infrastructure projects. Driving factors include increasing consumer awareness regarding sustainable and repairable building materials, coupled with a surge in infrastructure development in developing economies, necessitating high-quality, long-lasting interior finishes. The material's capacity to emulate natural stone aesthetics while offering enhanced performance attributes is central to its growing market penetration across diverse end-use sectors globally.

Acrylic Solid Surface Market Executive Summary

The global Acrylic Solid Surface Market exhibits robust business trends characterized by intense competition focused on product innovation, particularly the development of recycled content and specialized antibacterial formulations targeted at the healthcare sector. Regional trends show Asia Pacific as the fastest-growing market, driven by massive urbanization and burgeoning middle-class disposable income, boosting residential renovation spending, while North America and Europe maintain dominance in adoption rates for sophisticated commercial applications. Segment trends highlight the increasing preference for pure acrylic solid surfaces due to their superior thermoforming capabilities and UV stability, making them ideal for complex architectural designs. Furthermore, the commercial segment, specifically hospitality and institutional infrastructure (schools and government buildings), remains the largest revenue contributor, consistently demanding hygienic, low-maintenance finishes. Strategic initiatives, including capacity expansion and establishing localized supply chains to mitigate high logistics costs, are defining corporate strategies among leading manufacturers, ensuring market resilience against volatile raw material pricing.

AI Impact Analysis on Acrylic Solid Surface Market

User queries regarding AI's impact on the Acrylic Solid Surface Market frequently center on themes of optimizing manufacturing efficiency, enhancing design capabilities, and forecasting demand fluctuations. Users are keenly interested in how AI can streamline the complex polymerization and casting processes to reduce waste and improve material consistency. Another critical area of inquiry involves AI-driven generative design tools that can automate the creation of complex, thermoformable shapes, pushing the boundaries of architectural possibilities for acrylic surfaces. Furthermore, questions address AI's role in predictive maintenance within large-scale installations, using sensor data to anticipate wear and tear or structural failure in high-traffic commercial applications, thereby extending the product lifecycle and justifying the initial investment for end-users. This collective interest underscores an expectation that AI will primarily serve as an optimization and innovation accelerator, transforming both the supply chain management and the artistic/functional application of the surfaces.

- AI-powered predictive maintenance models optimize surface longevity in commercial settings, reducing costly downtimes for replacement or repair by anticipating structural stress points based on usage patterns.

- Generative Design AI assists architects and fabricators in rapidly prototyping and visualizing complex, seamless acrylic installations, maximizing material utilization and minimizing fabrication errors.

- Supply Chain Optimization through Machine Learning (ML) algorithms enhances inventory management for raw materials (PMMA, ATH), providing precise demand forecasting and mitigating price volatility risks.

- Quality Control automation utilizes computer vision and AI inspection systems to detect minute inconsistencies or defects in the surface sheets during the manufacturing process, ensuring uniform product quality at high throughput.

- AI-driven personalized design interfaces enable consumers to digitally customize colors, patterns, and embedded features of acrylic surfaces, facilitating mass customization in the residential sector.

DRO & Impact Forces Of Acrylic Solid Surface Market

The Acrylic Solid Surface Market is propelled by robust drivers, including a global increase in healthcare facility construction demanding non-porous, antibacterial surfaces, and substantial growth in residential remodeling projects focused on high-end, customizable kitchen and bathroom countertops. However, the market faces significant restraints, primarily the high cost of raw materials, specifically acrylic polymers, and the strong competitive presence of natural stone and quartz surfacing alternatives which often offer a lower initial purchase price perception. Opportunities abound in technological advancements enabling thinner, lighter sheets for vertical cladding applications and the expansion into niche markets such as marine interiors and laboratory casework, where the chemical resistance and seamless nature of the product are highly valued. These dynamics culminate in powerful impact forces, including the intense pressure from substitute materials and the critical need for continuous innovation in fabrication techniques and aesthetics to maintain premium positioning and market share growth against evolving consumer preferences and regulatory standards.

Key impact forces shaping the competitive environment include the increasing stringency of international building codes emphasizing fire safety and low VOC emissions, pushing manufacturers towards advanced, compliant formulations. Furthermore, the impact force of customer education is crucial; market penetration is heavily reliant on successfully conveying the total cost of ownership (TCO) benefits, highlighting repairability and long-term durability over the lower upfront costs of competing materials. Economic cycles also exert a significant impact, as large-scale commercial and luxury residential projects are highly sensitive to fluctuating economic stability and interest rates, influencing large-volume material procurement decisions. The confluence of these forces necessitates strategic investments in R&D to diversify product lines and expand application areas beyond traditional countertop uses, ensuring market resilience and sustainable growth trajectory.

- Drivers: Growing demand from the healthcare sector for hygienic, non-porous surfaces; increasing residential renovation and remodeling activities globally; inherent design flexibility and thermoformability of acrylic materials.

- Restraints: High volatility and cost associated with primary raw materials (PMMA); intense competition from quartz and modified polyester solid surfaces; perceived high initial installation costs compared to laminates.

- Opportunity: Expansion into new applications such as exterior cladding and furniture design; development of sustainable and recycled acrylic formulations; technological advancements in seamless jointing and customization.

- Impact Forces: Intense pressure from substitute materials (Quartz, Granite); regulatory requirements regarding fire rating and indoor air quality (VOC standards); economic sensitivity affecting commercial construction investments.

Segmentation Analysis

The segmentation of the Acrylic Solid Surface Market is essential for understanding targeted growth areas and product penetration strategies. The market is primarily segmented by Type (Pure Acrylic Solid Surface and Modified Acrylic Solid Surface), Application (Residential and Commercial), and End-Use Industry (Kitchen & Bathroom Countertops, Wall Cladding, Hospitality, Healthcare, and Others). The dominance of the Commercial application segment is attributable to large-scale projects requiring high durability and hygiene standards, particularly in the institutional and hospitality sectors. Conversely, the Residential segment is seeing rapid growth spurred by customization trends and the desire for premium, easy-to-maintain kitchen and bath finishes. The Modified Acrylic segment, while offering a lower price point, maintains substantial market share due to cost-sensitive projects, but the Pure Acrylic segment continues to grow faster due to its superior performance characteristics like better thermoforming and longevity.

Within the type segmentation, Pure Acrylic Solid Surfaces are favored for high-performance applications where complex shapes and outdoor stability are crucial, leveraging the superior qualities of PMMA. The modified variety, which incorporates polyester resins, offers cost advantages suitable for basic, straight-run installations. The application analysis confirms that Kitchen & Bathroom Countertops remain the dominant end-use, forming the foundation of market revenue globally. However, the fastest-growing application is Wall Cladding, driven by architectural trends favoring sleek, monolithic wall systems in corporate and public spaces. Analyzing these segments allows manufacturers to tailor marketing efforts and R&D towards developing specific product attributes, such as specialized color ranges for the hospitality sector or antimicrobial properties for clinical environments, thereby maximizing profitability across diverse market verticals.

- By Type:

- Pure Acrylic Solid Surface

- Modified Acrylic Solid Surface

- By Application:

- Residential (New Construction and Renovation)

- Commercial (Healthcare, Hospitality, Retail, Corporate Offices)

- By End-Use Industry:

- Kitchen and Bathroom Countertops

- Wall Cladding and Vertical Surfaces

- Furniture and Fixtures (Tables, Sinks, Receptacles)

- Healthcare and Laboratory Casework

- Retail and Hospitality Design Elements

Value Chain Analysis For Acrylic Solid Surface Market

The value chain for the Acrylic Solid Surface Market begins with upstream analysis centered on the sourcing and processing of core raw materials: acrylic polymers (methyl methacrylate monomer, PMMA), alumina trihydrate (ATH) fillers, and specialized pigments/catalysts. This upstream stage is highly capital-intensive and concentrated, with reliance on petrochemical industries for polymer supply, leading to significant price sensitivity and potential supply chain bottlenecks. Manufacturers must maintain strategic relationships with chemical suppliers to ensure quality control and stable pricing, as raw material costs constitute a substantial portion of the final product cost. Effective backward integration or long-term sourcing contracts are crucial strategies employed by major players to secure input materials and achieve cost leadership in the highly competitive surfacing market.

Downstream analysis focuses on the fabrication, distribution, and installation of the solid surface sheets. Distribution channels are typically bifurcated into direct sales to large commercial contractors and indirect sales through specialized distributors and dealer networks that service smaller fabricators and the residential remodeling market. Direct distribution is favored for high-volume commercial projects where technical support and customized logistical solutions are required. Fabricators play a critical role, as the quality of the final installation—including seamless jointing and thermoforming accuracy—significantly impacts end-user satisfaction. The final step involves professional installation, often managed by certified or licensed fabricators, underscoring the necessity of robust training and certification programs within the channel to maintain brand integrity and product performance standards throughout the entire consumption cycle.

Acrylic Solid Surface Market Potential Customers

Potential customers for the Acrylic Solid Surface Market are diverse, spanning both the Business-to-Business (B2B) and Business-to-Consumer (B2C) segments, defined primarily by their end-use application needs and procurement volumes. Key B2B buyers include commercial architects, interior designers, general contractors, and specialized commercial millwork companies involved in large-scale institutional projects such as hospitals, universities, airports, and luxury hotels. These customers prioritize durability, compliance with hygiene standards (especially non-porosity and ease of cleaning), fire ratings, and the material’s ability to create monolithic, highly customized interior environments. Their purchasing decisions are often based on performance specifications, certifications, and established supply relationships with proven manufacturers capable of handling large, complex orders consistently over project timelines.

The B2C segment, consisting mainly of residential homeowners undertaking kitchen and bathroom remodeling or custom home builders, represents a significant growth driver, particularly in developed markets. These buyers are motivated by aesthetic versatility, perceived luxury, the availability of specific color palettes, and the unique selling proposition of repairability (the ability to sand out scratches). Although procurement occurs through local fabricators, dealers, or big-box retail channels, the ultimate buyer sensitivity revolves around achieving a high-end look with materials that offer practical, long-term maintenance benefits. Furthermore, the burgeoning custom furniture and yacht manufacturing sectors represent niche but high-value customer segments requiring superior water resistance and thermoformability for unique marine and luxury applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.9 Billion |

| Market Forecast in 2033 | USD 3.05 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont, LG Hausys, Samsung Staron (Lotte Advanced Materials), Aristech Surfaces, Wilsonart, Swanstone, Hyundai L&C, Hanwha Surfaces, Durat, Saint-Gobain, Formica, Corian, GFK, Kerrock, FunderMax, Cosentino, Diresco, Compac, Caesarstone, 3M. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Acrylic Solid Surface Market Key Technology Landscape

The technological landscape of the Acrylic Solid Surface Market is characterized by continuous refinement in manufacturing processes, focusing on enhancing material properties and fabrication ease. The primary technology involves continuous casting or batch molding processes utilizing a precisely controlled mixture of acrylic resin (PMMA), alumina trihydrate (ATH), pigments, and initiators, followed by a carefully managed curing cycle. Recent advancements focus heavily on optimizing the mixing process to ensure homogenous dispersion of fillers, thereby improving the surface finish and minimizing internal stress points. Furthermore, vacuum degassing technology is crucial during casting to eliminate microscopic air bubbles, which significantly enhances the density, strength, and non-porosity of the final sheet, meeting stringent performance requirements for clinical environments.

Beyond core manufacturing, the fabrication technology—particularly thermoforming and seamless jointing—is critical for market differentiation. Advanced thermoforming ovens allow for greater manipulation of the material at lower temperatures, facilitating the creation of complex three-dimensional curves and shapes without compromising structural integrity. Jointing technology relies on sophisticated, color-matched adhesive systems that chemically bond the acrylic pieces, creating monolithic installations that eliminate visible seams, a key aesthetic advantage over competing materials. Finally, sustainability technology is gaining prominence, involving the incorporation of recycled PMMA content and the development of bio-based resins to reduce the environmental footprint, aligning with global green building standards and capturing the growing demand for eco-friendly surfacing solutions.

Regional Highlights

The global Acrylic Solid Surface Market demonstrates significant regional variation in growth drivers and maturity levels. North America and Europe currently represent the most established markets, characterized by high disposable income, stringent building regulations promoting hygienic materials (especially in healthcare), and a robust remodeling industry. North America, driven by the strong presence of major manufacturers and a sophisticated architectural community, continues to lead in the adoption of innovative, high-end applications like custom corporate reception desks and advanced clinical casework. Europe emphasizes sustainability and design integration, pushing demand for recycled content surfaces and innovative color palettes suitable for modern minimalist aesthetics in both residential and commercial sectors.

Asia Pacific (APAC) is projected to be the fastest-growing region throughout the forecast period, owing to rapid urbanization, exponential growth in infrastructure spending (particularly in China, India, and Southeast Asian nations), and the expansion of the hospitality and retail sectors. The growing middle class in APAC is increasingly opting for durable, premium interior finishes over cheaper, short-lifecycle materials, fueling significant consumption growth. Conversely, Latin America and the Middle East & Africa (MEA) markets show potential, primarily concentrated around major economic hubs and large-scale government development projects (e.g., smart cities, tourism infrastructure), relying heavily on imports but gradually developing localized fabrication capabilities to service the construction boom.

- Asia Pacific (APAC): Leads in market growth due to rapid urbanization, extensive new residential construction, and significant government investment in commercial infrastructure, making it a critical region for future sales volume.

- North America: Mature market characterized by high consumer spending on kitchen and bath renovation, stringent health safety standards driving demand in the healthcare sector, and strong market presence of key global players.

- Europe: Focuses on aesthetic integration, high-quality fabrication, and sustainability mandates; strong demand from the hospitality and high-end retail sectors in Western Europe.

- Latin America: Emerging market demonstrating substantial growth potential in countries like Brazil and Mexico, driven by increasing foreign investment in commercial real estate and manufacturing facilities.

- Middle East and Africa (MEA): Growth tied to mega-project development in the UAE and Saudi Arabia, where premium materials are specified for high-profile hotels, commercial towers, and airports demanding superior durability and aesthetic performance in harsh climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Acrylic Solid Surface Market.- DuPont (Corian)

- LG Hausys (HI-MACS)

- Samsung Staron (Lotte Advanced Materials)

- Aristech Surfaces LLC

- Wilsonart LLC

- Swanstone

- Hyundai L&C

- Hanwha Surfaces

- Durat

- Saint-Gobain

- Formica Group

- GFK

- Kerrock (Kolpa)

- FunderMax

- Cosentino S.A.

- Diresco

- Compac The Surfaces Company

- Caesarstone Ltd.

- 3M Company

- Chongqing Polycomp International Corp. (CPIC)

Frequently Asked Questions

Analyze common user questions about the Acrylic Solid Surface market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Pure Acrylic and Modified Acrylic Solid Surfaces?

Pure Acrylic Solid Surfaces are composed entirely of acrylic polymers (PMMA) and mineral fillers, offering superior thermoformability, UV resistance, and excellent seamless joint performance. Modified Acrylic Surfaces often incorporate polyester resins, which typically lower the cost but reduce flexibility and may affect UV stability, making them less suitable for intricate curved designs or outdoor applications.

Why is the Acrylic Solid Surface Market experiencing strong growth in the Healthcare sector?

Growth in healthcare is driven by the material's non-porous nature, which prevents the penetration of liquids and inhibits the growth of bacteria, mold, and mildew. Furthermore, the ability to create seamlessly joined surfaces eliminates crevices where pathogens can accumulate, crucial for maintaining stringent sanitary standards in hospitals, clinics, and laboratories.

How do acrylic solid surfaces compare in cost and durability to quartz or granite?

While the initial purchase cost of acrylic solid surfaces may be higher than some grades of granite or laminate, their total cost of ownership is often favorable due to superior durability, ease of repair (scratches can be sanded out), and renewable finish. Unlike stone, acrylic is non-porous and does not require periodic sealing, offering excellent long-term performance and hygiene.

What are the main regional growth drivers for the Acrylic Solid Surface Market?

The Asia Pacific region is the primary growth driver, fueled by high volumes of new commercial and residential construction and rapid infrastructure development. North America and Europe maintain strong demand based on renovation activities, stringent hygiene standards in commercial spaces, and a mature market for sophisticated, custom architectural applications.

Is the manufacturing of acrylic solid surfaces incorporating sustainable practices?

Yes, sustainability is a growing focus. Manufacturers are increasingly utilizing recycled content, particularly post-consumer and post-industrial PMMA, in their formulations. Furthermore, operational improvements are aimed at reducing waste and energy consumption during the casting process, aligning with green building certifications and environmental regulatory expectations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Corian Acrylic Solid Surface Market Size Report By Type (Casting Molding Solid Surface, Extrusion Molding Solid Surface), By Application (Hospitals, Hotels, Private Households, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Acrylic Solid Surface Market Statistics 2025 Analysis By Application (Hospitals, Hotels, Private Households, Other), By Type (Casting Molding Solid Surface, Extrusion Molding Solid Surface), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Acrylic Solid Surface Market Statistics 2025 Analysis By Application (Hospitals, Hotels, Private Households), By Type (Casting Molding Solid Surface, Extrusion Molding Solid Surface), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager