Boron Trichloride Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439647 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Boron Trichloride Market Size

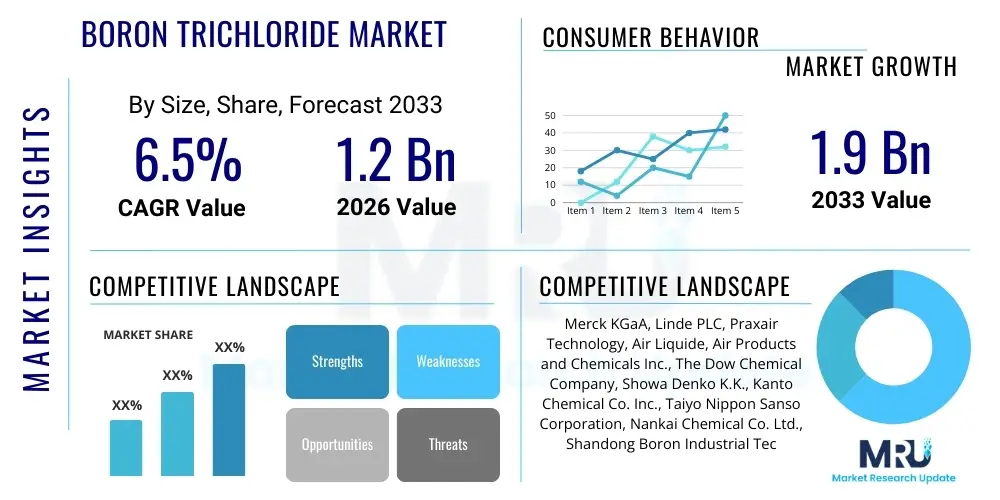

The Boron Trichloride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 285.5 million in 2026 and is projected to reach USD 454.2 million by the end of the forecast period in 2033.

Boron Trichloride Market introduction

The Boron Trichloride (BCl3) market is a critical segment within the specialty chemicals and industrial gases sector, driven primarily by its indispensable role in advanced manufacturing processes. Boron trichloride is a colorless, fuming liquid or gas with a pungent odor, characterized by its strong Lewis acidic properties and high reactivity. This unique chemical profile makes it exceptionally valuable across a diverse array of industrial applications. Its primary utility stems from its effectiveness as an etchant in semiconductor manufacturing, a chlorinating agent in organic and inorganic synthesis, and a crucial component in the production of high-purity boron compounds and advanced materials. The market's trajectory is intrinsically linked to the performance and innovation within these key downstream industries, highlighting its foundational importance to technological progress.

Boron trichloride serves a multitude of functions, ranging from the precise etching of silicon wafers in the electronics industry to its use as a catalyst in polymerization reactions and as a raw material for boron fibers and refractory materials. Its high reactivity with various compounds, including water and organic substances, necessitates specialized handling and storage, which in turn influences its supply chain and distribution dynamics. The demand for high-purity BCl3 is particularly pronounced in the semiconductor sector, where even trace impurities can compromise the performance of integrated circuits. This requirement for ultra-high purity drives continuous advancements in production and purification technologies, pushing market players to invest heavily in research and development to meet evolving industry standards and expand product applications.

The benefits of Boron Trichloride are multifaceted, including its efficiency as a halogenating agent, its strong electron-accepting properties for catalytic applications, and its ability to facilitate precise material removal in microfabrication. These advantages are significant driving factors for market growth, particularly as industries increasingly demand materials with specific properties and processes that offer greater control and efficiency. The ongoing technological evolution in electronics, the expansion of the chemical synthesis industry towards more complex molecules, and the increasing adoption of advanced materials in aerospace and defense sectors are robustly fueling the demand for Boron Trichloride. Moreover, the global push for renewable energy solutions and lightweight materials further contributes to the market's expansion, underscoring BCl3's critical role in diverse innovation landscapes.

Boron Trichloride Market Executive Summary

The Boron Trichloride market is currently undergoing significant transformation, characterized by several prominent business trends. Strategic collaborations, mergers, and acquisitions are becoming increasingly common as key players seek to consolidate market share, expand their technological capabilities, and strengthen their global distribution networks. There is a discernible trend towards vertical integration, with some manufacturers extending their operations from raw material sourcing to the production of high-purity BCl3 and its delivery to end-users, ensuring stringent quality control and supply chain stability. Furthermore, sustainability initiatives are gaining traction, prompting companies to explore more environmentally friendly production methods and waste management solutions, despite the inherent challenges associated with BCl3's hazardous nature. This focus on sustainability is not only driven by regulatory pressures but also by growing corporate responsibility and investor demand for greener industrial practices, influencing investment decisions and R&D priorities across the value chain.

From a regional perspective, the market exhibits considerable dynamism, with Asia Pacific emerging as the dominant region due to its expansive semiconductor and electronics manufacturing bases, particularly in countries like China, South Korea, Taiwan, and Japan. This region benefits from significant governmental support for high-tech industries and a burgeoning consumer electronics market that continuously fuels demand for integrated circuits, directly translating into higher consumption of Boron Trichloride. North America and Europe, while representing mature markets, are characterized by their strong emphasis on research and development, advanced materials science, and niche applications in aerospace and defense. These regions are focal points for innovation in BCl3 production and application technologies, driving advancements in ultra-high purity grades and specialized delivery systems. Emerging economies in Latin America and the Middle East & Africa are showing nascent growth, driven by industrialization efforts and increasing foreign investments in manufacturing capabilities, though their market share remains comparatively smaller.

Segmentation trends within the Boron Trichloride market underscore the importance of purity and application-specific requirements. The semiconductor grade segment continues to command the largest market share, driven by the relentless miniaturization and increasing complexity of electronic devices, which demand BCl3 of exceptional purity (typically 5N to 7N). There is a growing demand for customized grades tailored for specific etching processes or chemical reactions, reflecting the precision required in modern manufacturing. In terms of application, chemical synthesis remains a robust segment, with BCl3 serving as a versatile chlorinating agent and Lewis acid catalyst in the production of pharmaceuticals, agrochemicals, and other specialty chemicals. The optical fiber manufacturing segment is also experiencing steady growth, propelled by the global expansion of high-speed internet infrastructure. These trends highlight a market that is highly responsive to technological advancements and specialized industrial needs, with innovation in product purity and application specificity being key differentiators for market players.

AI Impact Analysis on Boron Trichloride Market

Users frequently inquire about the transformative potential of Artificial Intelligence (AI) across the Boron Trichloride market, seeking to understand how this technology might enhance production efficiency, improve product quality, optimize supply chains, and mitigate operational risks. Key themes consistently revolve around the application of AI in predictive maintenance for complex BCl3 manufacturing facilities, its role in accelerating research and development for novel applications and purification techniques, and its capacity to revolutionize quality control through advanced sensor data analysis. Users are particularly interested in AI's ability to analyze vast datasets from chemical processes to identify subtle anomalies, predict equipment failures before they occur, and ultimately reduce downtime and improve safety in handling this hazardous substance. There are also significant expectations regarding AI's contribution to process optimization, enabling manufacturers to fine-tune reaction parameters and purification steps for maximum yield and purity, which is paramount in high-stakes industries like semiconductor manufacturing. Furthermore, the potential for AI to model and simulate new chemical reactions involving BCl3, thereby accelerating the discovery of new applications or more sustainable synthetic routes, is a recurring point of interest, indicating a strong desire for innovation-driven growth supported by intelligent systems.

- Process Optimization and Control: AI algorithms can analyze real-time operational data from BCl3 manufacturing plants, including temperature, pressure, flow rates, and reactant concentrations, to identify optimal parameters for yield and purity. This leads to more efficient resource utilization, reduced energy consumption, and minimized waste generation, directly impacting production costs and environmental footprint. Machine learning models can predict deviations from desired conditions and suggest corrective actions autonomously, ensuring consistent product quality and operational stability.

- Predictive Maintenance of Equipment: AI-powered predictive maintenance systems leverage sensor data from pumps, reactors, compressors, and purification units to forecast potential equipment failures. By analyzing vibration, temperature, acoustic, and other operational data, AI can identify patterns indicative of impending breakdowns, allowing maintenance teams to intervene proactively. This minimizes unplanned downtime, extends the lifespan of critical machinery, and significantly enhances safety protocols in facilities handling hazardous BCl3.

- Enhanced Quality Control and Purity Assurance: In high-purity applications, especially for semiconductors, even minute impurities can be detrimental. AI can integrate data from advanced analytical instruments (e.g., mass spectrometry, gas chromatography) to detect and quantify trace impurities with unprecedented accuracy and speed. Machine learning models can identify complex impurity signatures that might be missed by traditional methods, ensuring that BCl3 batches consistently meet stringent specifications and reducing the risk of costly product recalls or manufacturing defects.

- Accelerated Research and Development: AI can dramatically accelerate the discovery and optimization of new BCl3 applications or more efficient synthesis routes. By analyzing vast chemical databases and simulating molecular interactions, AI can predict the reactivity of BCl3 with various compounds, identify promising catalysts, or design novel materials incorporating boron. This computational approach reduces the need for extensive experimental trials, cutting down R&D costs and significantly shortening time-to-market for innovative BCl3-based solutions.

- Supply Chain Optimization and Risk Management: AI can analyze global supply and demand patterns, geopolitical events, and logistics data to optimize the BCl3 supply chain. This includes forecasting demand fluctuations, optimizing inventory levels, selecting the most efficient transportation routes, and identifying potential supply disruptions before they occur. For a hazardous material like BCl3, AI can also enhance risk management by modeling the impact of various scenarios (e.g., transportation accidents, regulatory changes) and recommending proactive strategies to ensure continuous and secure supply.

DRO & Impact Forces Of Boron Trichloride Market

The Boron Trichloride market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces that collectively dictate its growth trajectory and competitive landscape. The market's robust expansion is primarily driven by the relentless growth of the global semiconductor industry, where BCl3 is an indispensable etching agent for silicon wafers and other semiconductor materials. The increasing demand for advanced electronic devices, from smartphones to high-performance computing components and IoT devices, directly translates into a surging need for high-purity BCl3. Concurrently, the expanding chemical synthesis sector, particularly in the production of specialty chemicals, pharmaceuticals, and agrochemicals, relies heavily on BCl3 as a versatile chlorinating agent and Lewis acid catalyst. Technological advancements in optical fiber manufacturing, driven by the global build-out of 5G networks and high-speed internet infrastructure, also contribute significantly to market demand. These factors underscore BCl3's foundational role in numerous high-growth, technology-driven industries.

Despite these powerful drivers, the market faces notable restraints. The high production cost associated with manufacturing ultra-high purity BCl3, necessitated by stringent industry requirements (especially in semiconductors), poses a significant barrier. The raw materials and specialized equipment required, coupled with energy-intensive processes, contribute to these elevated costs. Furthermore, Boron Trichloride is a highly corrosive and toxic substance, presenting considerable challenges in terms of safe handling, storage, and transportation. This hazardous nature necessitates strict adherence to rigorous environmental, health, and safety (EHS) regulations globally, which can add to operational complexities and costs for manufacturers. The availability of alternative etching gases or catalytic agents, though often less effective or more expensive for specific applications, could also present a competitive restraint, pushing manufacturers to continuously innovate and demonstrate BCl3's superior performance and cost-effectiveness in its niche applications.

Opportunities for market growth primarily lie in the emergence of new applications in advanced materials science, such as the development of novel boron-containing compounds for ceramics, composites, and energy storage solutions. There is a growing focus on green chemistry initiatives, which could spur innovation in more sustainable BCl3 production methods or closed-loop recycling systems, potentially reducing its environmental footprint and improving public perception. Technological advancements in purification techniques, enabling the production of even higher purity grades at more competitive costs, will unlock new possibilities in ultra-sensitive applications. Moreover, the expanding industrial base in emerging economies, particularly in Asia Pacific and Latin America, presents untapped markets for BCl3 as these regions invest in their own semiconductor, chemical, and telecommunications infrastructure. The market is also influenced by impact forces such as the bargaining power of buyers (driven by a concentrated customer base in semiconductors) and suppliers (influenced by the availability of raw materials like boron and chlorine), the threat of new entrants (high capital investment and regulatory hurdles), the threat of substitutes (continuous R&D into alternative chemicals), and intense industry rivalry among established players.

Segmentation Analysis

The Boron Trichloride market is comprehensively segmented to provide granular insights into its diverse applications, varying purity requirements, and wide-ranging end-use industries. This segmentation is crucial for understanding specific market dynamics, identifying high-growth areas, and developing targeted strategies for different product offerings. The primary segmentation categories include Purity, Application, and End-use Industry, each reflecting distinct value propositions and demand drivers within the market landscape. Analyzing these segments helps stakeholders appreciate the specialized nature of Boron Trichloride, where subtle differences in chemical specifications or intended use can lead to significant variations in market value and competitive intensity. The demand for ultra-high purity grades, for instance, exhibits different growth patterns and requires more sophisticated manufacturing processes compared to industrial-grade BCl3, directly impacting pricing structures and market competition.

- By Purity:

- Semiconductor Grade: This segment includes BCl3 with extremely high purity levels, typically ranging from 5N (99.999%) to 7N (99.99999%), essential for critical applications in semiconductor manufacturing where trace impurities can cause device defects. The demand in this segment is driven by the continuous advancement and miniaturization of integrated circuits, requiring stringent quality control and specialized purification techniques.

- High Purity Grade: Encompasses BCl3 with purity levels suitable for sensitive chemical synthesis, optical fiber manufacturing, and other advanced material applications where lower impurity levels than industrial grade are required but not as critical as semiconductor grade. This segment supports various high-tech industries requiring precise chemical reactions and material properties.

- Industrial Grade: Refers to BCl3 used in broader industrial applications where ultra-high purity is not the primary concern. This includes uses as a chlorinating agent, in metallurgical processes, and in the production of boron compounds where impurity tolerances are more flexible. This segment generally has lower production costs and serves a wider array of industrial users.

- By Application:

- Semiconductor Etching: The largest and most critical application, involving the precise removal of material from semiconductor wafers during the fabrication of integrated circuits. BCl3 is valued for its ability to create anisotropic etches and remove metal and metal oxide layers with high selectivity.

- Chemical Synthesis: Utilizes BCl3 as a powerful Lewis acid catalyst and chlorinating agent in organic and inorganic reactions, crucial for producing pharmaceuticals, agrochemicals, polymers, and various specialty chemicals. Its versatility makes it indispensable in complex synthetic pathways.

- Optical Fiber Manufacturing: BCl3 is used as a dopant source in the production of optical fibers, specifically for introducing boron into silica glass to modify its refractive index and enhance light transmission properties, vital for telecommunications infrastructure.

- Doping Agent: Beyond optical fibers, BCl3 acts as a doping agent in semiconductor manufacturing to introduce boron atoms into silicon, altering its electrical properties to create p-type semiconductors.

- Plasma Etching: A sub-segment of semiconductor etching, BCl3 is a key component in plasma-based etching processes for precise pattern transfer in microfabrication, offering superior control and uniformity.

- Pharmaceutical Intermediates: In the pharmaceutical industry, BCl3 is used to synthesize various boron-containing compounds that serve as intermediates for drug development, leveraging boron's unique chemical properties.

- Other Industrial Applications: Includes niche uses such as the production of high-strength boron fibers for aerospace composites, refractory materials, and specialized metallurgical applications where boron's properties are advantageous.

- By End-use Industry:

- Electronics & Semiconductor: This is the dominant end-use sector, driven by the global demand for integrated circuits, memory chips, microprocessors, and other electronic components. The continuous innovation in consumer electronics and advanced computing sustains high demand for BCl3.

- Chemical: Encompasses specialty chemical manufacturers, pharmaceutical companies, and agrochemical producers that utilize BCl3 for various synthetic processes. This sector relies on BCl3 for its reactivity and catalytic properties in creating complex molecules.

- Telecommunications: Driven by the expansion of broadband networks, 5G infrastructure, and data centers, this industry demands BCl3 for the production of high-quality optical fibers essential for high-speed data transmission.

- Medical: Beyond pharmaceutical intermediates, BCl3 may find niche applications in medical device manufacturing or research, particularly where boron-containing materials offer unique biocompatibility or functional properties.

- Automotive: BCl3's role here is indirect, primarily through the electronics in vehicles (ECUs, sensors) and potentially in advanced lightweight materials research (boron composites) aimed at improving fuel efficiency and safety.

- Aerospace & Defense: Boron fibers, produced using BCl3, are incorporated into advanced composites for lightweight, high-strength components in aircraft, satellites, and defense systems, reducing weight and enhancing performance.

- Energy: Potential applications in developing new materials for batteries, solar cells, or nuclear technologies, where boron's unique properties can contribute to improved efficiency or safety.

Value Chain Analysis For Boron Trichloride Market

The value chain for Boron Trichloride is a complex, multi-stage process beginning with the extraction and purification of raw materials and culminating in the delivery of highly specialized BCl3 to diverse end-use industries. The upstream segment of the value chain is primarily concerned with the sourcing and initial processing of elemental boron or boron-containing minerals, alongside the production of high-purity chlorine gas. Boron is typically obtained from borate ores, which undergo various refining steps to yield boron oxide or elemental boron. Chlorine gas is produced through electrolysis of brine, requiring significant energy input. These raw materials are fundamental to the synthesis of BCl3, and their availability, purity, and cost directly impact the overall production economics. Suppliers in this segment face challenges related to geological resource distribution, energy price volatility, and stringent environmental regulations associated with chemical production. Ensuring a stable and high-quality supply of these precursors is paramount for BCl3 manufacturers, often leading to long-term supply agreements or backward integration strategies.

Moving downstream, the manufacturing process of Boron Trichloride itself is highly specialized, involving sophisticated chemical reactions such as the direct chlorination of boron carbide or the reaction of boric acid with carbon and chlorine at high temperatures. Following synthesis, the crude BCl3 undergoes rigorous purification steps, often involving fractional distillation, adsorption, and specialized filtration, to achieve the ultra-high purity levels demanded by critical applications like semiconductor manufacturing. This purification stage is capital-intensive and requires advanced technological expertise, representing a significant value-add in the chain. After purification, the BCl3 is typically compressed and stored in specialized containers, often cylinders or isotanks, designed to safely handle its hazardous and corrosive properties. The logistics involved in packaging and storing BCl3 are crucial, as maintaining purity and preventing contamination or leakage during storage and transportation is essential for product integrity and safety. Innovators in this segment focus on developing more efficient and cost-effective synthesis and purification technologies to gain a competitive edge.

The distribution channel for Boron Trichloride is bifurcated into direct sales and indirect channels, depending on the volume, specificity, and relationship with the end-user. Direct sales are common for large-volume customers, particularly major semiconductor manufacturers or large chemical synthesis plants, where direct contractual agreements allow for customized delivery schedules, technical support, and stringent quality assurance. This direct relationship fosters strong partnerships and allows for tailored solutions. Indirect channels involve a network of specialized industrial gas distributors or chemical suppliers who manage smaller orders, regional deliveries, and provide logistical support to a wider array of smaller and medium-sized enterprises. These distributors often maintain specialized facilities for handling hazardous materials and possess expertise in local regulations and customer needs. Both channels are critical, but the increasing complexity of end-user requirements and the hazardous nature of BCl3 mean that all distribution partners must adhere to the highest safety and quality standards, from packaging and labeling to transportation and delivery protocols, ensuring product integrity and mitigating risks throughout the entire journey from manufacturer to the final application site.

Boron Trichloride Market Potential Customers

The potential customers for Boron Trichloride span a diverse range of high-technology and industrial sectors, each leveraging BCl3's unique chemical properties for specific, critical applications. At the forefront are semiconductor manufacturers, who represent the largest and most demanding segment of end-users. These companies rely on ultra-high purity BCl3 as a primary etching agent for creating intricate patterns on silicon wafers, essential for the production of microprocessors, memory chips, and various integrated circuits that power modern electronics. Their stringent requirements for purity, consistency, and supply reliability make them key strategic partners for BCl3 producers. The relentless drive for miniaturization, higher performance, and increased computational power in the electronics industry ensures a continuous and growing demand for top-grade Boron Trichloride. These customers often engage in long-term supply contracts, seeking secure and stable partnerships with manufacturers capable of meeting their exacting specifications and delivering just-in-time solutions to maintain their high-volume production schedules.

Another significant customer base comprises specialty chemical and pharmaceutical companies. In the chemical synthesis domain, BCl3 serves as a powerful Lewis acid catalyst and a versatile chlorinating agent, integral to the production of a wide array of organic and inorganic compounds. This includes the synthesis of various pharmaceutical intermediates, agrochemicals, polymers, and advanced materials. These end-users seek BCl3 for its high reactivity and selectivity in complex chemical reactions, enabling them to create novel compounds or optimize existing synthetic pathways. The pharmaceutical sector, in particular, requires BCl3 of high purity for drug discovery and development, where the integrity of chemical reactions is paramount to ensure the efficacy and safety of new medications. Manufacturers catering to this segment must not only provide high-quality BCl3 but also offer comprehensive technical support and adhere to rigorous quality management systems to meet the strict regulatory standards prevalent in these industries.

Beyond semiconductors and chemical synthesis, other important potential customers include manufacturers of optical fibers and companies involved in advanced materials production. Optical fiber manufacturers utilize BCl3 as a critical dopant to precisely control the refractive index of silica glass, which is fundamental to creating high-performance communication cables for telecommunications networks, data centers, and global internet infrastructure. The ongoing expansion of 5G technology and increased demand for high-speed data transmission worldwide fuel this segment. Furthermore, industries focusing on advanced materials, such as aerospace and defense, seek BCl3 for the production of high-strength boron fibers and other boron-containing composites. These materials offer superior strength-to-weight ratios, making them invaluable for lightweight components in aircraft, missiles, and other high-performance applications. Research institutions and academic laboratories also constitute a segment of potential customers, albeit smaller in volume, as they utilize BCl3 for exploratory research in chemistry, materials science, and physics, driving future innovations and applications for this versatile chemical compound.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 285.5 million |

| Market Forecast in 2033 | USD 454.2 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linde plc, Air Products and Chemicals, Inc., Praxair Technology, Inc. (now part of Linde), Taiyo Nippon Sanso Corporation, Dupont de Nemours, Inc., The Dow Chemical Company, Versum Materials (now part of Merck KGaA), Shin-Etsu Chemical Co., Ltd., Sumitomo Chemical Co., Ltd., SK Materials Co., Ltd., REC Silicon ASA, American Elements, Gelest, Inc., Voltaix LLC (now part of Air Liquide), Central Glass Co., Ltd., H.C. Starck GmbH, Solvay S.A., AGC Inc., Mitsubishi Chemical Corporation, Sichuan Xinyang Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Boron Trichloride Market Key Technology Landscape

The Boron Trichloride market is characterized by a sophisticated technological landscape that spans its entire lifecycle, from synthesis and purification to safe handling and application. At the core are the various manufacturing processes for BCl3. The most common industrial methods include the direct chlorination of boron carbide (B4C) or boron oxide (B2O3) in the presence of carbon, or the reaction of boric acid (H3BO3) with carbon and chlorine gas at high temperatures. Each method requires precise control over reaction parameters such as temperature, pressure, and reactant stoichiometry to maximize yield and minimize impurities. Innovations in this area focus on developing more energy-efficient synthesis routes, utilizing advanced catalysts to accelerate reactions, and designing reactors that can withstand the corrosive nature of reactants and products, thereby improving overall process safety and economic viability. The goal is to achieve higher conversion rates and produce crude BCl3 with fewer byproducts, streamlining subsequent purification steps and reducing the environmental footprint of the manufacturing process.

Critical to the market, especially for high-end applications like semiconductor manufacturing, are the advanced purification technologies employed to achieve ultra-high purity BCl3. These technologies often involve a multi-stage approach, combining various physical and chemical separation techniques. Fractional distillation, a widely used method, leverages differences in boiling points to separate BCl3 from volatile impurities. However, for semiconductor-grade purity (typically 5N to 7N), more advanced methods are essential. These include adsorption processes using specialized adsorbents to selectively remove trace metal impurities and organic compounds, and chemical purification techniques where specific reagents are used to convert impurities into non-volatile or easily separable forms. Membrane separation and cryogenic distillation are also being explored for their potential to achieve even higher levels of purity with improved efficiency. Continuous monitoring and in-line analytical techniques, such as gas chromatography-mass spectrometry (GC-MS) and Fourier-transform infrared (FTIR) spectroscopy, are integrated into the purification lines to ensure real-time quality control and validate the purity of the final product, preventing contamination and ensuring stringent specifications are met for critical end-use applications.

Beyond production and purification, the technological landscape also encompasses advanced materials for BCl3 handling, storage, and precise delivery systems. Given its highly corrosive and reactive nature, BCl3 requires specialized materials for containers, piping, valves, and seals, typically nickel alloys, Monel, or specific fluoropolymers, to prevent corrosion and leakage. Innovations in materials science are crucial for developing more resistant and cost-effective containment solutions, enhancing safety and extending equipment lifespan. Furthermore, the precise delivery of BCl3 to application sites, particularly in semiconductor fabrication, relies on sophisticated gas delivery systems that ensure accurate flow control, minimal dead space, and prevention of contamination. These systems often incorporate advanced flow controllers, pressure regulators, and highly inert tubing, along with integrated safety features like leak detection and automatic shutdown mechanisms. The development of intelligent sensors and automation systems plays a vital role in enhancing the safety and efficiency of BCl3 handling, minimizing human exposure, and ensuring seamless integration into complex manufacturing environments, thereby underpinning the reliability and consistency of Boron Trichloride supply across all its critical applications.

Regional Highlights

- North America: This region is characterized by a mature market with a strong emphasis on research and development, particularly in advanced electronics, aerospace, and defense sectors. The United States, in particular, is a hub for semiconductor innovation and advanced materials research, driving demand for high-purity Boron Trichloride. Companies here focus on high-value applications and technological advancements in BCl3 production and delivery systems, maintaining a competitive edge through intellectual property and specialized expertise. Robust regulatory frameworks ensure high safety standards in manufacturing and handling.

- Europe: Europe represents a significant market driven by its strong chemical industry, pharmaceutical manufacturing, and growing investment in R&D for advanced materials. Countries like Germany, France, and the UK are key contributors, focusing on specialty chemical synthesis and niche applications where BCl3 acts as a crucial reagent or catalyst. The region also adheres to stringent environmental and safety regulations (e.g., REACH), which influence production practices and promote innovation in safer handling and sustainable synthesis methods for Boron Trichloride.

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region in the Boron Trichloride market, primarily due to the massive presence of semiconductor and electronics manufacturing hubs in countries such as China, South Korea, Taiwan, and Japan. These countries are global leaders in consumer electronics production, driving an insatiable demand for high-purity BCl3 for wafer etching. Government initiatives supporting high-tech industries, coupled with lower manufacturing costs and a large skilled workforce, have fueled rapid industrial expansion and increased BCl3 consumption across the region.

- Latin America: This region is an emerging market for Boron Trichloride, with nascent growth driven by increasing industrialization and foreign investment in manufacturing sectors, particularly in Brazil and Mexico. While the market share is smaller compared to developed regions, there is potential for growth as local industries expand their capabilities in electronics assembly, chemical production, and infrastructure development. The market is largely dependent on imports, but local distribution networks are gradually strengthening to meet rising industrial demand for BCl3.

- Middle East and Africa (MEA): The MEA region currently holds a relatively smaller share of the Boron Trichloride market, with demand primarily stemming from emerging chemical industries, petrochemical complexes, and limited electronics manufacturing activities. Countries in the GCC are investing in diversifying their economies beyond oil and gas, which could lead to increased industrial output and a gradual rise in BCl3 consumption for specialty chemicals and advanced materials. However, challenges related to industrial infrastructure and technological adoption persist.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Boron Trichloride Market.- Linde plc

- Air Products and Chemicals, Inc.

- Praxair Technology, Inc. (now part of Linde)

- Taiyo Nippon Sanso Corporation

- Dupont de Nemours, Inc.

- The Dow Chemical Company

- Versum Materials (now part of Merck KGaA)

- Shin-Etsu Chemical Co., Ltd.

- Sumitomo Chemical Co., Ltd.

- SK Materials Co., Ltd.

- REC Silicon ASA

- American Elements

- Gelest, Inc.

- Voltaix LLC (now part of Air Liquide)

- Central Glass Co., Ltd.

- H.C. Starck GmbH

- Solvay S.A.

- AGC Inc.

- Mitsubishi Chemical Corporation

- Sichuan Xinyang Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Boron Trichloride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Boron Trichloride (BCl3) and what are its primary industrial uses?

Boron Trichloride (BCl3) is a colorless, fuming chemical compound known for its strong Lewis acidic properties and high reactivity. Industrially, its primary applications include its indispensable role as an etching agent in semiconductor manufacturing for creating intricate patterns on silicon wafers. It is also extensively used as a versatile chlorinating agent and a Lewis acid catalyst in various chemical synthesis processes for pharmaceuticals, agrochemicals, and specialty chemicals. Furthermore, BCl3 serves as a crucial dopant in the manufacturing of optical fibers to modify their refractive index, and it finds applications in the production of high-strength boron fibers and advanced materials for the aerospace and defense sectors, highlighting its foundational importance across high-technology industries.

What factors are driving the growth of the Boron Trichloride market?

The Boron Trichloride market's growth is predominantly driven by the robust expansion of the global semiconductor industry, which relies on BCl3 for precise etching in microchip fabrication. The increasing demand for advanced electronic devices, 5G infrastructure, and data centers directly fuels this segment. Additionally, the growing demand for specialty chemicals and pharmaceuticals, where BCl3 acts as a key reagent for complex syntheses, significantly contributes to market expansion. Advancements in optical fiber technology, continuous innovation in advanced materials science (e.g., boron composites for lightweight structures), and increasing investments in high-tech manufacturing across emerging economies further propel market growth. The imperative for higher purity materials in these industries mandates the use of high-quality BCl3, solidifying its market position.

What are the main challenges faced by the Boron Trichloride market?

The Boron Trichloride market faces several significant challenges. Foremost among these is the high production cost associated with manufacturing ultra-high purity BCl3, which requires specialized equipment, energy-intensive processes, and expensive raw materials. Its hazardous and highly corrosive nature presents considerable difficulties in safe handling, storage, and transportation, necessitating stringent adherence to rigorous environmental, health, and safety (EHS) regulations globally. These regulatory burdens can increase operational complexities and costs for manufacturers. Additionally, the continuous research into alternative etching gases or catalytic agents, while currently limited in effectiveness for specific niche applications, poses a potential long-term competitive restraint, pushing BCl3 producers to innovate and maintain a superior performance-to-cost ratio for their products.

Which regions are key players in the Boron Trichloride market and why?

The Asia Pacific (APAC) region stands out as the dominant and fastest-growing market for Boron Trichloride, primarily due to its expansive semiconductor and electronics manufacturing bases in countries like China, South Korea, Taiwan, and Japan. These nations are global leaders in consumer electronics production, driving immense demand for high-purity BCl3 in wafer etching. North America and Europe are also significant players, characterized by their strong focus on research and development, advanced materials science, and niche applications in aerospace, defense, and specialty chemicals. These regions prioritize innovation in production technologies and customized BCl3 grades. Latin America and the Middle East & Africa represent emerging markets with nascent growth, driven by increasing industrialization and foreign investments in manufacturing capabilities.

How does the purity of Boron Trichloride impact its applications and market segmentation?

The purity of Boron Trichloride critically impacts its suitability for various applications and forms a fundamental basis for market segmentation. Semiconductor Grade BCl3, with purity levels typically ranging from 5N to 7N (99.999% to 99.99999%), is essential for microelectronics manufacturing, where even trace impurities can compromise integrated circuit performance and yield. This segment commands the highest prices and requires advanced purification technologies. High Purity Grade BCl3, while slightly less stringent, is vital for sensitive chemical synthesis and optical fiber manufacturing, ensuring product integrity and desired material properties. In contrast, Industrial Grade BCl3, with lower purity specifications, is used for broader applications where precise impurity control is less critical, such as general chlorination or metallurgical processes, leading to different pricing structures and market dynamics across these segments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Boron Trichloride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Boron Trichloride Market Statistics 2025 Analysis By Application (Semiconductor Industry for Plasma Etching, Gas for CVD, Raw Material for Boron Nitride (BN), Raw Material for Pharmaceutical And Agrochemicals, Raw Material for Catalysts), By Type (Electronic Grade, Industrial Grade), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager