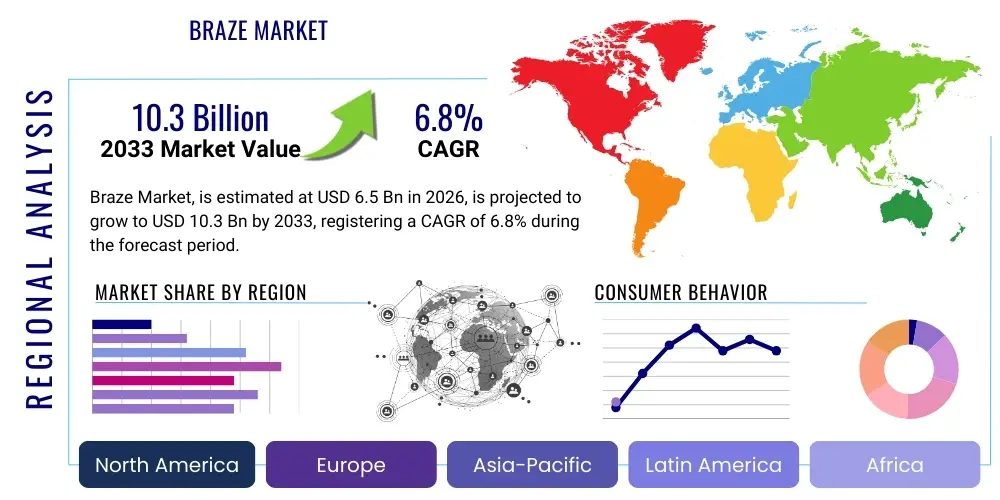

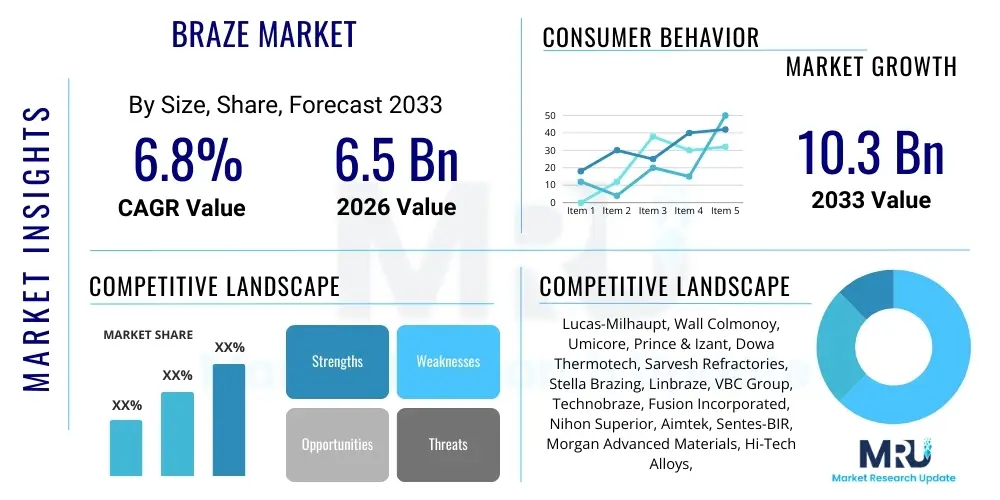

Braze Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440160 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Braze Market Size

The Braze Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 7.2 Billion in 2026 and is projected to reach USD 11.3 Billion by the end of the forecast period in 2033.

Braze Market introduction

The Braze Market encompasses the global industry for materials, equipment, and services related to brazing, a high-temperature metal-joining process that utilizes a filler metal with a lower melting point than the base materials. This intricate process is critical for creating robust, leak-tight, and electrically conductive joints in a wide array of demanding applications across various industrial sectors. The market includes a diverse range of braze alloys, such as silver-based, copper-based, nickel-based, and aluminum-based alloys, each tailored to specific material combinations and operational environments. Specialized fluxes, pastes, and automation equipment, including induction brazing systems, vacuum furnaces, and robotic brazing cells, also form integral components of this market. The choice of brazing method and materials is heavily dependent on the base metals, joint design, service temperature, and desired mechanical properties.

The primary applications of brazing are extensive and span critical industries globally. In the automotive sector, brazing is indispensable for manufacturing heat exchangers, radiators, air conditioning components, and catalytic converters, where its ability to create strong, vibration-resistant joints is paramount. The aerospace industry relies on brazing for fabricating lightweight, high-strength components such as engine parts, heat shields, and fuel lines that must withstand extreme temperatures and pressures. Electronics and electrical engineering utilize brazing for connecting conductors, heat sinks, and vacuum tubes, ensuring reliable electrical conductivity and thermal management. Furthermore, the HVAC&R (heating, ventilation, air conditioning, and refrigeration) industry, medical devices, and even jewelry production are significant consumers of brazing solutions. Each application benefits from brazing's capacity to join dissimilar metals, minimize distortion, and offer superior joint integrity compared to other joining methods.

The benefits of brazing are manifold, making it a preferred joining technique for many complex assemblies. It allows for the joining of a wide variety of dissimilar metals and non-metals (with metallization), offering significant design flexibility. Brazed joints are typically strong, ductile, and hermetic, providing excellent resistance to pressure and leaks, which is crucial for vacuum and fluid systems. The process generally results in minimal distortion to the base metals due to lower operating temperatures compared to welding, preserving the metallurgical properties of the parent materials. Key driving factors for the Braze Market include the increasing demand for lightweight and high-performance materials in automotive and aerospace industries, the continuous expansion of the electronics sector, growing adoption of advanced HVAC&R systems, and the imperative for energy efficiency in industrial processes. The technological advancements in braze alloy development and automation also play a pivotal role in market expansion, offering more efficient and reliable joining solutions.

Braze Market Executive Summary

The Braze Market is currently experiencing robust growth, driven by an escalating demand for high-performance and reliable joining solutions across diversified industrial applications. Business trends indicate a significant shift towards advanced, specialty braze alloys designed for specific high-temperature and corrosive environments, moving beyond conventional general-purpose materials. There is an increasing emphasis on automation in brazing processes, with manufacturers investing in robotic systems, induction brazing, and vacuum furnaces to enhance efficiency, consistency, and reduce labor costs. This automation trend is also fueled by the need for higher precision and quality control, especially in critical sectors like aerospace and medical devices. Furthermore, sustainability initiatives are influencing product development, leading to the emergence of lead-free and cadmium-free braze alloys that comply with stringent environmental regulations and offer safer operational profiles. The market is also seeing a surge in partnerships and collaborations aimed at innovation in new material development and process optimization, fostering a competitive yet progressive landscape.

Regionally, the Braze Market exhibits dynamic growth patterns, with Asia Pacific emerging as a dominant force, primarily due to rapid industrialization, burgeoning manufacturing sectors in countries like China, India, and South Korea, and robust growth in automotive and electronics production. North America and Europe represent mature markets, characterized by stable demand from established aerospace, automotive, and general industrial sectors, alongside a strong focus on advanced research and development for niche applications. These regions are increasingly adopting high-value, specialized brazing solutions. Latin America, the Middle East, and Africa are showing promising growth potential, driven by infrastructure development, expanding energy sectors, and increasing foreign investments in manufacturing capabilities. Each region's unique industrial landscape and regulatory environment significantly shape the adoption rates and types of brazing technologies employed, influencing localized market strategies and investment flows.

Segmentation trends within the Braze Market highlight critical shifts in demand and technological focus. By product type, nickel-based and silver-based alloys continue to hold significant market shares due to their versatility and performance in high-temperature applications, though copper-based and aluminum-based alloys are gaining traction for cost-effective and lightweight solutions, respectively. Equipment segmentation reveals a growing preference for automated and semi-automated brazing systems over manual techniques, reflecting the industry's drive for efficiency and precision. Applications across automotive, aerospace, HVAC&R, and electronics remain the cornerstone of market demand, with each sector presenting unique requirements that stimulate innovation in both materials and processes. The medical and dental sectors, while smaller, are high-value segments demanding extremely high precision and biocompatible solutions. The continuous evolution of these segments is fostering a market where customization and specialized solutions are becoming increasingly important for competitive differentiation and meeting diverse end-user needs.

AI Impact Analysis on Braze Market

Common user questions regarding the impact of AI on the Braze Market often revolve around how artificial intelligence can enhance process efficiency, improve joint quality, and optimize material usage. Users are particularly interested in AI's role in predictive maintenance for brazing equipment, real-time process monitoring, and the development of new, smarter braze alloys. Concerns frequently include the initial investment costs, the complexity of integrating AI systems into existing manufacturing lines, and the need for a skilled workforce capable of managing AI-driven processes. There is a clear expectation that AI will lead to more consistent results, reduce waste, and accelerate innovation in brazing technology, ultimately contributing to higher productivity and cost savings across various industries utilizing brazing. The key themes highlight a strong desire for automation and data-driven insights to overcome traditional brazing challenges.

- AI-driven predictive maintenance for brazing furnaces and equipment, reducing downtime and operational costs.

- Real-time quality control and anomaly detection in brazed joints using machine vision and AI algorithms, minimizing defects.

- Optimization of brazing parameters (temperature, time, atmosphere, filler amount) through AI models for enhanced joint strength and consistency.

- Accelerated development of novel braze alloys and fluxes using AI for material discovery and property prediction.

- Automated robotic brazing systems integrated with AI for adaptive path planning and precise filler material deposition.

- Supply chain optimization for brazing consumables and equipment through AI-powered demand forecasting and inventory management.

- Enhanced worker safety through AI-monitored hazardous environments and automated task execution in brazing operations.

DRO & Impact Forces Of Braze Market

The Braze Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping its trajectory. A primary driver is the accelerating demand for advanced materials and sophisticated joining solutions in high-growth industries such as automotive, aerospace, and electronics. The increasing emphasis on lightweighting in vehicles and aircraft to improve fuel efficiency and reduce emissions mandates the use of brazing for joining dissimilar and advanced alloys that are difficult to weld. Furthermore, the miniaturization of electronic components requires precise and reliable joining methods that brazing adeptly provides, ensuring both electrical conductivity and structural integrity. The inherent ability of brazing to create hermetic, strong, and aesthetically pleasing joints with minimal distortion makes it indispensable for applications where performance and precision are paramount, continuously driving its adoption over alternative joining techniques.

However, the market also faces notable restraints. The high initial capital investment required for advanced brazing equipment, particularly vacuum furnaces and automated systems, can be a barrier for small and medium-sized enterprises (SMEs). The technical complexity and skill required for effective brazing, including precise control over temperature profiles, atmosphere, and material selection, necessitate a highly trained workforce, which can be a challenge given global skill shortages in specialized manufacturing. Furthermore, environmental regulations concerning certain traditional braze alloy compositions (e.g., those containing cadmium or lead) are prompting a transition to more expensive, environmentally friendly alternatives, which can impact overall project costs and slow adoption in some regions. Competition from alternative joining methods such as welding, adhesive bonding, and mechanical fastening, while often less suitable for specific applications, also presents a persistent restraint by offering lower-cost or simpler solutions in certain contexts.

Despite these challenges, significant opportunities exist within the Braze Market. The continuous innovation in material science, leading to the development of novel braze alloys with enhanced properties, such as higher temperature resistance, improved corrosion resistance, and lead-free compositions, opens new application areas and strengthens brazing's competitive edge. The growing adoption of Industry 4.0 principles, including automation, IoT, and AI, offers immense potential for optimizing brazing processes, improving quality control, and reducing operational costs. Emerging markets in Asia Pacific, Latin America, and Africa present untapped potential as industrialization accelerates, driving demand for manufacturing and assembly solutions. Moreover, the increasing complexity of modern product designs and the need to join a broader array of advanced materials will continue to drive the demand for versatile and high-performance joining techniques like brazing, ensuring its sustained relevance and growth in specialized and critical applications across diverse industries. The shift towards electrification in automotive and aerospace also presents new opportunities for brazing in battery thermal management and power electronics.

Segmentation Analysis

The Braze Market is broadly segmented based on several key parameters, including product type, heating method, application, and end-use industry. This detailed segmentation allows for a granular understanding of market dynamics, specific demand drivers, and technological preferences within different sub-markets. Each segment represents distinct characteristics in terms of material composition, process requirements, and performance expectations, influencing purchasing decisions and market share distribution across regions. The diverse nature of brazing applications necessitates a comprehensive segmentation approach to accurately capture the market's intricate structure and growth potential. Understanding these segments is crucial for manufacturers, suppliers, and investors to identify lucrative opportunities and tailor their strategies effectively.

- By Product Type:

- Filler Metals (Alloys)

- Silver-based Alloys

- Copper-based Alloys

- Nickel-based Alloys

- Aluminum-based Alloys

- Gold-based Alloys

- Other Alloys (e.g., Palladium-based, Magnesium-based)

- Fluxes & Pastes

- Brazing Equipment

- Furnaces (Vacuum, Atmosphere)

- Induction Brazing Systems

- Torch Brazing Equipment

- Resistance Brazing Equipment

- Robotic Brazing Cells

- Other Equipment (e.g., Laser Brazing)

- Filler Metals (Alloys)

- By Heating Method:

- Furnace Brazing

- Induction Brazing

- Torch Brazing

- Resistance Brazing

- Dip Brazing

- Vacuum Brazing

- Other Heating Methods (e.g., Laser Brazing)

- By Application:

- Heat Exchangers

- HVAC&R Components

- Automotive Components (e.g., Radiators, Exhaust Systems)

- Aerospace Components (e.g., Engine Parts, Fuel Lines)

- Electrical & Electronic Components (e.g., Connectors, Heat Sinks)

- Medical & Dental Devices

- Tooling & Cutting Applications

- Piping & Tubing

- Jewelry

- Other Industrial Applications

- By End-Use Industry:

- Automotive

- Aerospace & Defense

- HVAC&R

- Electrical & Electronics

- Medical

- Construction

- Energy

- Consumer Goods

- Jewelry

- General Industrial

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Braze Market

The value chain for the Braze Market is a complex ecosystem beginning with the extraction and refining of raw materials, such as various metals used in filler alloys, and extending through manufacturing, distribution, and end-use application. Upstream activities involve the mining of base metals like copper, silver, nickel, aluminum, and gold, followed by their refining and purification. This stage is critical as the purity and quality of these raw materials directly impact the performance and characteristics of the final braze alloys. Specialized chemical companies also contribute by supplying fluxing agents and other chemical additives essential for the brazing process. The efficiency and environmental impact of these initial stages have a cascading effect on the entire value chain, influencing cost structures, supply stability, and the environmental footprint of the final brazing solution.

Midstream activities primarily encompass the manufacturing of braze filler metals, fluxes, pastes, and brazing equipment. Filler metal manufacturers transform refined raw materials into various forms such as wire, foil, preforms, and powders, often blending them into specific alloy compositions designed for different applications and base metals. Flux and paste manufacturers develop formulations that facilitate wetting and protect joints from oxidation during brazing. Concurrently, equipment manufacturers design and produce a range of brazing systems, from manual torches to highly automated vacuum furnaces and induction brazing machines. This manufacturing phase involves significant R&D investment to innovate new alloys, develop more efficient equipment, and improve process controls. Quality control and adherence to industry standards are paramount at this stage to ensure product reliability and performance.

Downstream activities focus on the distribution and application of brazing products. Distribution channels can be direct, where major manufacturers supply directly to large industrial end-users, or indirect, involving a network of distributors, wholesalers, and specialized retailers who cater to a broader customer base, including SMEs and repair shops. Direct channels are often preferred for customized solutions and large-volume orders, facilitating closer collaboration between supplier and end-user for technical support and process optimization. Indirect channels provide wider market reach and availability, particularly for standard products and consumables. The end-users, including automotive, aerospace, HVAC&R, and electronics manufacturers, integrate these brazing solutions into their production processes to join components. Post-sales services, technical support, and training are crucial aspects of the downstream value chain, ensuring that end-users maximize the effectiveness and efficiency of their brazing operations and achieve desired joint quality. The strength of the value chain relies on seamless coordination and collaboration among all stakeholders to deliver high-quality, cost-effective, and sustainable brazing solutions.

Braze Market Potential Customers

The Braze Market serves a highly diverse and extensive customer base, primarily consisting of manufacturing companies across various industrial sectors that require robust and reliable metal-joining solutions. These end-users, or buyers, range from large multinational corporations engaged in mass production to specialized niche manufacturers focusing on high-precision components. The core demand stems from industries where traditional welding might not be suitable due to material sensitivity, complex geometries, or the need for minimal heat input and distortion. Key characteristics of these potential customers include a strong emphasis on product performance, component longevity, and stringent quality control standards for their assemblies. They seek brazing solutions that offer superior joint strength, hermetic sealing capabilities, and excellent electrical or thermal conductivity, depending on their specific application requirements.

Major end-user segments include the automotive industry, where brazing is critical for manufacturing heat exchangers, radiators, air conditioning systems, and exhaust components, particularly with the rise of electric vehicles and lightweighting initiatives. The aerospace and defense sector relies heavily on brazing for engine components, hydraulic systems, and structural parts that operate under extreme temperatures and pressures, demanding high integrity and reliability. The HVAC&R (heating, ventilation, air conditioning, and refrigeration) industry is a significant consumer, utilizing brazing for evaporator and condenser coils, compressors, and piping systems to ensure leak-proof and efficient fluid transfer. Furthermore, the electrical and electronics sector depends on brazing for joining conductors, semiconductor packages, and heat sinks, where precise, reliable electrical and thermal connections are paramount for device performance and durability.

Beyond these primary sectors, potential customers also include manufacturers in the medical device industry, producing instruments and implants that require biocompatible and corrosion-resistant joints; the tooling industry, for bonding carbide tips to steel shanks; and the energy sector, for components in power generation and distribution. Each of these segments presents unique technical challenges and regulatory requirements that drive specific demands for braze alloys, fluxes, and equipment. For instance, medical device manufacturers require materials that meet stringent biocompatibility standards, while aerospace companies prioritize high-temperature performance and fatigue resistance. The diversity of these applications underscores the broad applicability and continued relevance of brazing as a crucial manufacturing process, making these various industries the primary and ongoing targets for braze market suppliers and service providers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.2 Billion |

| Market Forecast in 2033 | USD 11.3 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lucas-Milhaupt, Wall Colmonoy, Umicore, Oerlikon Metco, Prince & Izant Co., VBC Group, Morgan Advanced Materials, Technobraze, Alloy Custom Products, Hoganas AB, SAXONIA Technical Materials GmbH, Johnson Matthey, Fusion Inc., Sarin Industries, Tokyo Braze Co., Ltd., Superior Flux & Mfg. Co., Castolin Eutectic, Solvay S.A., Materion Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Braze Market Key Technology Landscape

The Braze Market is characterized by a dynamic and evolving technology landscape, continuously driven by the demand for enhanced joint performance, increased efficiency, and automation. A foundational technology revolves around the development of advanced braze filler metals and fluxes. Innovations include lead-free and cadmium-free alloys that meet stringent environmental regulations, high-temperature nickel-based and cobalt-based alloys for demanding aerospace and energy applications, and active braze alloys capable of joining ceramics to metals directly. Research into nanotechnology and composite filler materials is also expanding, aiming to improve joint strength, ductility, and resistance to corrosion or oxidation. Furthermore, the development of specialized pastes and foils allows for more precise application and reduces material waste, contributing to both cost efficiency and quality control in complex assemblies.

Equipment technology forms another critical pillar of the Braze Market, with significant advancements in heating methods and process control. Vacuum brazing furnaces continue to evolve, offering precise temperature control, clean environments, and the ability to braze reactive materials without the need for fluxes, producing exceptionally strong and clean joints. Induction brazing technology has seen progress in terms of energy efficiency, faster heating cycles, and localized heating capabilities, making it ideal for automated production lines and specific component joining. Robotic brazing systems, integrating sophisticated vision systems and precise motion control, are becoming increasingly prevalent, enabling high-volume, repeatable, and highly accurate brazing of complex parts, minimizing human error and improving overall throughput. Laser brazing is also gaining traction for its precision, minimal heat input, and ability to join very thin or delicate components with high aesthetic quality.

Beyond materials and core equipment, the integration of Industry 4.0 technologies is profoundly shaping the braze market's technological landscape. Sensor technology, coupled with data analytics and artificial intelligence, is being deployed for real-time monitoring of brazing processes, allowing for immediate adjustments to parameters and predictive maintenance of equipment. This leads to higher consistency, reduced defects, and optimized energy consumption. Simulation software for joint design and process modeling helps engineers predict performance and refine parameters before physical prototyping, significantly cutting down development time and costs. The shift towards digital manufacturing and smart factories emphasizes interconnected brazing cells, enabling seamless integration into broader production workflows and enhancing overall operational intelligence. These technological advancements collectively contribute to making brazing a more reliable, efficient, and versatile joining solution for future industrial requirements.

Regional Highlights

- North America: A mature market characterized by robust demand from the aerospace and defense, automotive, and medical industries. Strong emphasis on high-performance, specialized brazing solutions and advanced manufacturing technologies. The presence of major research institutions and a focus on innovation drive the adoption of new braze alloys and automated systems.

- Europe: Another key mature market, driven by its strong automotive, industrial manufacturing, and energy sectors. Stringent environmental regulations, particularly regarding lead and cadmium, propel the adoption of eco-friendly braze alloys. Germany, France, and the UK are major contributors, with a focus on advanced engineering and high-quality production.

- Asia Pacific (APAC): The largest and fastest-growing market, fueled by rapid industrialization, massive automotive production, burgeoning electronics manufacturing, and expanding infrastructure in countries like China, India, Japan, and South Korea. Cost-effectiveness, coupled with increasing demand for quality, drives both volume and technological upgrades.

- Latin America: An emerging market experiencing steady growth due to increasing industrialization, particularly in Brazil and Mexico. Expansion in the automotive, construction, and general manufacturing sectors contributes to the demand for brazing products and services. Investments in infrastructure and manufacturing capabilities are driving market potential.

- Middle East & Africa (MEA): A developing market with significant potential, driven by investments in oil and gas, construction, and power generation sectors. Economic diversification initiatives and increasing industrial activity are expected to boost the demand for brazing solutions, especially for high-temperature and corrosion-resistant applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Braze Market.- Lucas-Milhaupt (A Handy & Harman Company)

- Wall Colmonoy Corporation

- Umicore N.V.

- Oerlikon Metco (A Division of Oerlikon Surface Solutions AG)

- Prince & Izant Co.

- VBC Group

- Morgan Advanced Materials

- Technobraze

- Alloy Custom Products

- Hoganas AB

- SAXONIA Technical Materials GmbH

- Johnson Matthey

- Fusion Inc.

- Sarin Industries

- Tokyo Braze Co., Ltd.

- Superior Flux & Mfg. Co.

- Castolin Eutectic (A Groupe Air Liquide Company)

- Solvay S.A.

- Materion Corporation

- Shantian Braze Alloy Materials Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Braze market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is brazing and how does it differ from welding?

Brazing is a metal-joining process that uses a filler metal with a melting point lower than the base metals, which are not melted themselves. The filler metal flows into the joint by capillary action. Welding, conversely, melts and fuses the base metals, often with a filler material, at higher temperatures. Brazing offers less distortion, ability to join dissimilar metals, and creates clean, strong joints, whereas welding typically produces stronger joints at the cost of higher heat input and potential material distortion.

What are the primary advantages of using brazing over other joining techniques?

Brazing offers several key advantages including the ability to join dissimilar metals, create strong and leak-tight joints, minimize thermal distortion to base materials due to lower process temperatures, and achieve precise, repeatable results, especially with automated systems. It is also effective for joining complex assemblies and delicate components, preserving their original metallurgical properties and surface finish.

Which industries extensively utilize brazing technology?

Brazing technology is extensively utilized across a wide range of industries including automotive (for heat exchangers, radiators), aerospace & defense (engine components, fuel lines), HVAC&R (coils, compressors), electrical & electronics (connectors, heat sinks), medical devices (instruments, implants), and general industrial applications for piping, tooling, and consumer goods. Its versatility makes it indispensable for critical, high-performance applications.

What are the key types of braze filler metals and their applications?

Key types of braze filler metals include silver-based (versatile, lower melting point for general applications), copper-based (strong, good conductivity, often for steel/copper), nickel-based (high temperature, corrosion resistance for aerospace/energy), and aluminum-based (for aluminum alloys, lightweighting). The selection depends on base materials, operating temperature, and required joint properties.

How is AI impacting the future of the Braze Market?

AI is set to revolutionize the Braze Market by enabling predictive maintenance for equipment, enhancing real-time quality control through machine vision, optimizing brazing parameters for improved consistency and reduced waste, and accelerating the development of new, advanced braze alloys. AI will drive greater automation, efficiency, and innovation, leading to more reliable and cost-effective brazing solutions across all applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Braze Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- High Frequency Induction Heating Machine Market Size Report By Type (The Welding Equipment, Heat Treatment Equipment, Annealing Equipment, Other), By Application (Heating (Hot Forging, Hot Fitting and Smelting), Heat Treatment (Surface Quench), Welding (Braze Welding, Silver Soldering and Brazing), Annealing (Tempering and Modulation)), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Nickel Base Brazing Materials Market Statistics 2025 Analysis By Application (Appliance Industry, Transportation Industry, Electrical and Electronic Industry, Construction Industry, Medical Industry), By Type (Braze Powder, Braze Paste, Braze Tape, Braze Rod and Wire), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Aluminum Base Brazing Materials Market Statistics 2025 Analysis By Application (HVAC, Automotive, Aerospace), By Type (Braze Powder, Braze Paste, Braze Tape, Braze Rod and Wire), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Silver Base Brazing Materials Market Statistics 2025 Analysis By Application (HVAC, Automotive, Aerospace), By Type (Braze Powder, Braze Paste, Braze Tape, Braze Rod and Wire), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager