Calcium Chloride Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432712 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Calcium Chloride Powder Market Size

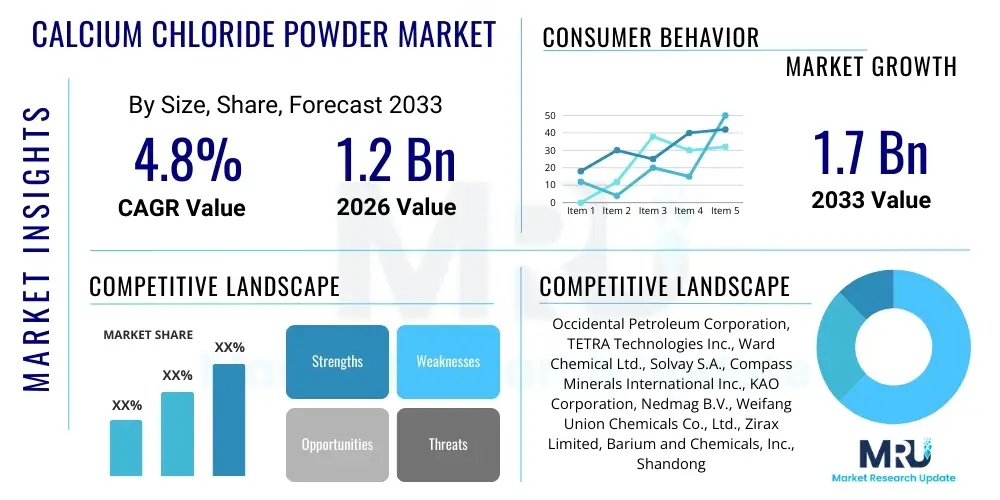

The Calcium Chloride Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.7 Billion by the end of the forecast period in 2033.

Calcium Chloride Powder Market introduction

Calcium chloride powder is a versatile inorganic salt characterized by its high solubility in water and highly hygroscopic nature, making it indispensable across numerous industrial and commercial applications globally. Produced primarily through the Solvay process as a byproduct of sodium carbonate manufacturing, or through direct neutralization of hydrochloric acid with calcium carbonate, this compound, represented by the chemical formula CaCl2, is widely valued for its powerful performance characteristics in lowering freezing points, controlling ambient moisture levels, and acting as an accelerating agent in construction materials. Its widespread utility ensures stable demand across diverse, critical infrastructure sectors.

Major applications of calcium chloride powder span crucial infrastructural, energy, and resource management sectors. In winter maintenance, it is the preferred de-icing agent due to its ability to function effectively at lower temperatures and its faster melting action compared to standard rock salt (sodium chloride), enhancing road safety in extreme weather conditions. Furthermore, its inherent hygroscopic properties are heavily leveraged in effective dust suppression on unpaved roads and as a high-capacity desiccant in various processing and packaging industries. The benefits derived from calcium chloride powder include superior efficacy in cold weather de-icing, improved environmental management through effective moisture and dust control, and significant operational cost-effectiveness when substituted for certain alternative chemicals, firmly establishing its vital market position.

Driving factors for the robust growth of the calcium chloride powder market include increasing global infrastructural development, particularly in emerging economies where construction projects demand high-performance accelerating admixtures to speed up curing processes. The stringent regulatory requirements for enhanced road safety and consistent maintenance in regions prone to heavy snowfall further bolster significant demand in the de-icing segment. Moreover, the expanding energy sector, particularly unconventional drilling activities like shale gas extraction, heavily relies on calcium chloride for clear brine fluids to manage downhole pressure and stabilize geological formations. These systemic drivers, combined with growing awareness and regulatory mandates regarding effective dust control solutions for both environmental protection and workplace safety, collectively propel the upward trajectory of the market size and valuation across all geographic regions.

Calcium Chloride Powder Market Executive Summary

The Calcium Chloride Powder Market is experiencing steady and consistent growth primarily fueled by the fundamental, non-substitutable requirements across critical applications such as winter road maintenance, oil and gas exploration, and specialized construction. Key business trends indicate a strategic movement towards optimizing and decentralizing supply chain logistics to ensure prompt product availability during highly seasonal peak demand periods, such as intense winter months across Northern hemisphere regions. Major producers are increasingly prioritizing vertical integration and investing heavily in technologies aimed at developing higher purity grades, most notably the food and pharmaceutical grade CaCl2, which command substantial premium pricing and unlock new, high-value avenues for market penetration, diversifying away from standard technical grade commodity sales.

From a regional perspective, North America maintains its historical position as the dominant market, driven by its extensive network of road infrastructure requiring mandatory winter maintenance and the substantial, ongoing activity within its domestic oil and gas sector, particularly operations utilizing advanced hydraulic fracturing and horizontal drilling techniques. Conversely, the Asia Pacific region is anticipated to record the highest compound annual growth rate over the forecast period, fueled by massive, centralized public investments in core infrastructure projects and rapid, continuous urbanization demanding superior concrete curing and effective dust control solutions for both public health and project longevity. European markets, while mature, maintain stable demand, which is increasingly steered by stringent environmental regulations prompting the use of efficient and ecologically sound dust suppressants and established food processing standards utilizing calcium chloride as an essential firming agent.

Analysis of segment trends confirms that the technical grade segment currently dominates overall consumption volume, a fact largely attributable to its overwhelming scale of use in de-icing and high-volume oilfield services globally. Nevertheless, the specialized food grade segment is witnessing accelerated expansion due to its increasing application in sophisticated food preservation techniques, specialized beverages (especially the craft brewing industry), and various medical sectors, necessitating specialized manufacturing processes that strictly adhere to exceptionally high purity and traceability standards. Furthermore, the application segment analysis confirms that De-icing and Oil & Gas collectively remain the largest revenue generators; however, the Dust Control segment is rapidly gaining traction and market share, significantly bolstered by governmental mandates concerning air quality preservation, road safety, and erosion control management in mining and agricultural areas.

AI Impact Analysis on Calcium Chloride Powder Market

User queries regarding the implications of Artificial Intelligence (AI) on the traditional Calcium Chloride Powder Market fundamentally concentrate on aspects of operational efficiency enhancement, predictive logistical planning, and rigorous quality assurance. Users are keen to understand precisely how advanced machine learning models can be deployed to systematically optimize complex chemical manufacturing processes, thereby leading to measurable reductions in energy consumption and waste generation during the energy-intensive Solvay process or direct neutralization reactions. Furthermore, there is significant analytical interest in applying AI for highly accurate predictive maintenance of large-scale, capital-intensive production facilities and, critically, utilizing sophisticated predictive analytics platforms to optimize inventory levels and distribution routes, which is essential for managing the acute, high-volume seasonal demand characterizing sectors like de-icing.

The influence of AI, while not directly altering the chemical composition of calcium chloride, is profound in refining operational performance and competitiveness. By analyzing massive streams of multivariate sensor data originating from reactors, evaporators, and crystallizers, AI algorithms can ensure optimal control over process variables such as temperature, pressure, and reactant concentration, leading directly to increased product yield and guaranteeing highly consistent product quality across all available grades (technical, food, pharmaceutical). This industry shift towards smart manufacturing practices minimizes inter-batch variation and substantially reduces the incidence of non-conforming product, which directly and positively impacts both profitability and overall supply reliability. The enhanced capability of AI to accurately model and predict complex crystallization patterns can enable the precise control of particle size distribution, a critical factor for specialized powder applications such as highly efficient desiccants or advanced, customizable construction mixtures.

Moreover, in the downstream elements of the supply chain, AI is fundamentally transforming logistics management, making it more resilient and responsive. Advanced predictive models can now forecast specific snowfall intensity and anticipated duration with greater geographical accuracy than traditional methods, consequently allowing manufacturers and distributors to strategically preposition vast amounts of inventory closer to high-demand areas. This strategic forecasting drastically reduces overall transportation costs, minimizes potential supply chain bottlenecks, and helps avoid critical public safety shortages during unforeseen severe weather events. In the high-demand oil and gas sector, AI-driven simulations are employed to optimize the chemical composition and precise usage rate of clear brine fluids in real-time drilling operations, ensuring minimal chemical wastage, maximizing wellbore stability, and accelerating overall drilling efficiency. This integration is paramount for maintaining a sustainable competitive advantage in what is intrinsically a high-volume, low-margin commodity chemical market, effectively translating raw data into actionable operational intelligence.

- AI-driven optimization of all critical manufacturing parameters, leading to demonstrable enhancements in yield and sustained purity levels in large-scale chemical production facilities.

- Implementation of rigorous predictive maintenance strategies utilizing machine learning models to minimize unscheduled equipment downtime and ensure continuous supply, thereby stabilizing overall market availability.

- Advanced supply chain forecasting and logistics optimization facilitated by utilizing real-time global weather and historical demand data, a capability critical for efficient seasonal de-icing product distribution networks.

- Enhanced quality control systems that deploy computer vision and sophisticated sensor analytics to monitor crucial attributes like particle size and moisture content in real-time, rigorously ensuring compliance with diverse grade specifications.

- Real-time simulation and optimization of drilling fluid density and chemical composition in the oil and gas sector, specifically guided by advanced AI algorithms for demonstrably improved operational efficiency and reduced material consumption.

- Development of smart inventory management systems that proactively mitigate spoilage risks associated with long-term storage of highly hygroscopic powder products under fluctuating environmental conditions.

DRO & Impact Forces Of Calcium Chloride Powder Market

The comprehensive dynamics of the Calcium Chloride Powder Market are critically governed by a complex and interacting array of Drivers, Restraints, and Opportunities (DRO), which collectively dictate the market’s trajectory and its breadth of penetration across various end-use applications. The principal market drivers include consistently increasing global infrastructural spending, particularly in emerging markets, the absolute necessity for effective road safety during seasonal winter months, and continued high-volume demand originating from the expansive, technically demanding oil and gas industry, specifically for high-performance drilling and completion fluids. However, the market faces significant structural constraints related to the highly corrosive nature of concentrated calcium chloride solutions, which poses substantial challenges to storage, distribution infrastructure, and the maintenance of road assets, alongside volatility in key raw material costs, particularly hydrochloric acid and calcium carbonate derivatives, which directly impact the operational profitability margins of producers.

Opportunities for strategic market expansion are substantial and are primarily centered on the accelerated development of specialized, low-corrosion calcium chloride formulations that are suitable for use on sensitive or high-value infrastructure like steel bridges and protected concrete surfaces. Additionally, significant potential lies in the growing application of high-purity food-grade calcium chloride in niche but rapidly expanding sectors such as molecular gastronomy, specialized vegan food production (where it acts as a non-dairy coagulant), and the manufacturing of nutritional supplements and isotonic beverages. Furthermore, the rising governmental and public emphasis on implementing sustainable and effective dust control solutions, particularly in large-scale mining regions, arid agricultural zones, and temporary construction sites, presents a substantial and largely untapped potential market segment that incentivizes specialized product development.

The major external impact forces that rigorously structure the competitive environment of the market include the constantly evolving regulatory landscape governing the usage, disposal, and environmental impact of road salts, which directly dictates product substitution rates and local market uptake. Continuous technological advancement in core manufacturing processes, specifically advanced crystallization and purification techniques required to achieve exceptionally higher purities and enhanced product stability, exerts a strong and positive influence on market pricing and product differentiation. Moreover, the inherent cyclical nature of the global oil and gas industry’s exploration budget and unpredictable global weather patterns (which dramatically impact de-icing demand) act as powerful, external macroeconomic impact forces that necessitate robust, highly flexible, and sophisticated supply chain planning to strategically mitigate sudden and severe shifts in localized demand and subsequent pricing volatility.

Segmentation Analysis

The Calcium Chloride Powder Market is comprehensively and systematically segmented based on Grade Type, Application, and Geographic Region, providing crucial data necessary for a granular analysis of market demand patterns, pricing strategies, and global competitiveness. Segmentation based on product grade is absolutely crucial as it determines the required complexity of purification and manufacturing processes and, consequently, dictates the final end-user pricing and regulatory compliance burden. The Technical Grade, due to its suitability for high-volume industrial uses like de-icing and construction, constitutes the largest volume segment globally, while the highly purified Food and Pharmaceutical Grades, which necessitate extensive quality control and certification, occupy valuable, high-margin niche markets. Analyzing the growth dynamics and consumption trends within these specialized segments provides critical strategic insights for manufacturers seeking to optimally fine-tune their product mix and accurately target specific, highly regulated markets globally.

Segmentation by application vividly reveals the extensive and diversified utility of calcium chloride powder, highlighting its foundational role across sectors far beyond traditional winter maintenance. The consistently robust consumption in the Oil & Gas sector, specifically for formulating dense brines used in high-pressure, high-temperature (HPHT) well drilling and completion operations, ensures this segment remains a major and resilient revenue generator despite industry cyclicality. Simultaneously, the burgeoning market demand for efficient and long-lasting dust suppression solutions, notably in expansive open-pit mining sites, unpaved governmental roads, and large military installations, is rapidly expanding, substantially driven by strict environmental and occupational health safety mandates implemented worldwide. Furthermore, the global construction industry utilizes calcium chloride powder extensively as an effective accelerating admixture to drastically speed up concrete setting times, a performance characteristic that is absolutely critical for time-sensitive, large-scale infrastructure projects, contributing consistently to stable, foundational market demand.

The granular analysis of sub-segments within key applications, such as the diverse use cases within the global Food & Beverage industry—including process enhancement in brewing, serving as a vegetable firming agent in canning operations, or its crucial role in cheesemaking—helps in the precise identification of minor but often rapidly growing pockets of high-margin demand. Understanding the unique requirements of these niche end-uses, coupled with a deep dive into differential regional consumption patterns—such as the massive, volume-driven de-icing demand in North America juxtaposed against the high construction and oilfield demand centered in the Middle East and Asia Pacific—is fundamentally important for developing highly effective global pricing and strategic distribution strategies, ensuring optimal resource allocation, minimizing logistics costs, and achieving comprehensive market coverage across the global supply chain efficiently.

- By Grade:

- Technical Grade (High-volume industrial applications, De-icing, Dust Control, Oil & Gas)

- Food Grade (Used as a Food Additive, Electrolyte source, Coagulant in Dairy and Vegan Production, Brewing process aid)

- Pharmaceutical Grade (Utilized in Medical solutions, Desiccants for Drug Formulation, Specialized cleanroom applications)

- By Application:

- De-icing and Anti-Icing (Essential for Roads, Airport Runways, Commercial Parking Lots, and Sidewalks)

- Dust Control and Road Stabilization (Critical for Unpaved roads, Mining areas, Quarries, and large Construction sites)

- Oil and Gas Industry (Core component of Drilling Fluids, High-density Completion Brines, and various Well Servicing operations)

- Construction (Primary role as a Concrete Accelerating Admixture, and specialized Curing Agent for concrete and cement)

- Food and Beverage (Acts as a Firming Agent, pH regulator, Electrolyte addition, and essential ingredient in Refrigeration Brines)

- Industrial Processing (Used as a powerful Drying Agent, High-capacity Desiccant, and intermediate in Chemical Synthesis processes)

- By Form:

- Powder/Flake (The dominant physical form utilized for high-volume industrial and de-icing applications)

- Pellets/Granules (Used for controlled release, precision applications, and specialized dust control formulations)

- By Region:

- North America (USA, Canada, Mexico)

- Europe (Germany, UK, France, Scandinavia, Russia)

- Asia Pacific (APAC) (China, India, Japan, South Korea)

- Latin America (LATAM) (Brazil, Argentina)

- Middle East and Africa (MEA) (Saudi Arabia, UAE, South Africa)

Value Chain Analysis For Calcium Chloride Powder Market

The highly complex value chain for the Calcium Chloride Powder Market is initiated with upstream activities that center intensely on secure and sustainable raw material sourcing, which is predominantly achieved through brine extraction from natural subterranean sources or the highly controlled procurement of limestone/calcium carbonate and essential hydrochloric acid for synthetic production pathways. The initial extraction and comprehensive processing of these vital raw materials necessitate specialized mining operations and advanced chemical handling capabilities to ensure consistent quality and supply. The subsequent manufacturing stage is inherently capital-intensive, involving complex and continuous chemical reactions, extensive purification sequences, energy-intensive evaporation, and critical crystallization processes, invariably followed by precise drying and professional packaging into the marketable powder or flake forms. Operational efficiency in this production stage, particularly optimizing energy consumption during the high-heat evaporation process, is the single most crucial determinant of maintaining competitive pricing and profitability in the global market.

Midstream activities primarily encompass sophisticated global logistics and the management of distribution channels, aspects that are especially critical given the pronounced seasonal volatility of demand (e.g., massive winter de-icing spikes) and the absolute necessity for proper, moisture-proof packaging due to the compound’s highly hygroscopic nature. Distribution channels are generally structured into a critical bifurcation: direct sales to extremely large industrial end-users, such as governmental road maintenance departments or major multinational oil and gas service companies, and indirect sales conducted through a network of specialized chemical distributors and regional agents who efficiently cater to the needs of smaller construction firms, local food processors, and varied agricultural sectors. Maintaining efficient, strategically located, and decentralized storage facilities, particularly near high-demand metropolitan areas or remote drilling sites, is absolutely essential to effectively serve immediate, localized demand and minimize supply lead times.

Downstream analysis meticulously focuses on the various end-user applications and how value is ultimately realized and captured. For high-volume technical grades, the value is predominantly derived from proven application performance metrics (e.g., de-icing efficacy speed, measurable dust control longevity, and superior concrete strength acceleration). In contrast, for the critical higher-purity Food and Pharmaceutical grades, the value is primarily secured from guaranteed compliance with extremely stringent national and international regulatory standards (such as FDA approval, USP compliance, and ISO certifications) and the assurance of uncompromising quality, safety, and comprehensive batch traceability. Direct, long-term engagement with key, strategically important end-users—such as international oilfield services giants or multinational food manufacturing corporations—allows leading producers to customize product specifications and secure lucrative, long-term supply contracts, thereby maximizing margin capture across the entirety of the complex value chain.

Calcium Chloride Powder Market Potential Customers

Potential customers for Calcium Chloride Powder are extraordinarily diverse, encompassing numerous sectors where precision temperature control, efficient moisture absorption, and accurate brine density management are absolutely critical operational prerequisites. The single largest volume consumers are generally governmental and large municipal entities responsible for extensive public road infrastructure maintenance, who utilize the powder as the primary, most effective de-icing and anti-icing agent throughout cold, severe weather seasons. Furthermore, private contracting firms heavily involved in large-scale civil engineering and commercial construction projects also represent highly significant customers, relying heavily on calcium chloride powder as a fast-acting concrete setting accelerator to meet extremely aggressive construction deadlines, particularly when working in cold or seasonally cool operating environments where setting time is inhibited.

The vast global Oil and Gas industry represents another monumental and crucial customer segment. Oilfield service companies, which specialize in complex directional drilling, well stimulation, and well completion procedures, are consistently heavy purchasers of high-density clear brine fluids, which are meticulously formulated using calcium chloride to effectively maintain crucial wellbore stability and control immense formation pressures in deep, challenging subsurface wells. Within this vital sector, the demand profile is typically cyclical but involves extremely high-volume purchases, driven fundamentally by global exploration and production activity levels. Furthermore, the global mining industry acts as a substantial and growing customer, using the product extensively for highly effective dust suppression on long haul roads, ore processing areas, and tailings facilities to drastically improve operational visibility, minimize wear and tear on expensive heavy equipment, and strictly comply with governmental environmental air quality regulations.

Finally, the specialized, higher-margin customer base includes the international Food and Beverage industry, where manufacturers across various segments utilize certified food-grade calcium chloride powder as a highly functional firming agent (e.g., for ensuring texture in canned tomatoes and pickled vegetables), as an essential electrolyte additive in specialized sports and energy drinks, and as a critical coagulant component in cheesemaking and the meticulous brewing process. Pharmaceutical companies and high-end chemical laboratories also constitute significant potential customers, although they require lower volume but demand an extremely high purity powder, used extensively in sophisticated desiccation processes, specialized sterile drug formulation, and the preparation of precision medical solutions. Effectively targeting these diverse and distinct customer needs requires highly specialized technical sales teams and the rigorous maintenance of customized regulatory compliance certifications across various jurisdictions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.7 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Occidental Petroleum Corporation, TETRA Technologies Inc., Ward Chemical Ltd., Solvay S.A., Compass Minerals International Inc., KAO Corporation, Nedmag B.V., Weifang Union Chemicals Co., Ltd., Zirax Limited, Barium and Chemicals, Inc., Shandong Haihua Group Co., Ltd., New Alliance Chemical Inc., Pioneer Chemical, Inc., Tangshan Sanyou Group, Tiger Calcium Services. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Calcium Chloride Powder Market Key Technology Landscape

The current technology landscape in the Calcium Chloride Powder Market strategically focuses less on revolutionary chemical innovation and more intensely on enhancing process efficiency, ensuring exceptional purity levels, and developing highly specialized formulation and particle engineering techniques. While the fundamental production methods—namely the Solvay process byproduct recovery and the direct hydrochloric acid neutralization method—remain industry standards, modern technological advancements are intensely concentrated on optimizing energy utilization during the critically high-heat evaporation and drying phases. Innovative technologies such as Mechanical Vapor Recompression (MVR) systems are being increasingly and widely employed to recycle latent heat effectively, which drastically reduces overall operational energy costs, significantly lowers the carbon footprint, and markedly improves the overall environmental profile of large-scale manufacturing facilities. This industry-wide shift towards sustainable and energy-efficient production methods constitutes a key competitive differentiator within this highly demanding commodity chemical market.

Furthermore, advanced process technology is absolutely vital in achieving and maintaining the ultra-high purity grades mandated by the extremely demanding food and pharmaceutical industries. State-of-the-art filtration, ion-exchange, and multi-stage crystallization techniques, which are often integrated with real-time spectroscopic analysis and advanced sensing, are deployed to meticulously ensure the near-complete removal of heavy metal contaminants and other common impurities, such as sodium or magnesium chlorides, thereby meeting stringent international regulatory benchmarks like USP or FCC specifications. Innovation in advanced particle engineering technology is also rapidly gaining strategic importance, enabling manufacturers to precisely control the final physical form (uniform powder, stable flake, or spherical pellet) and the exact particle size distribution. Controlled particle sizing is a critical performance parameter for specific applications, such such as maximizing the longevity of dust control treatments, where delayed solubility is beneficial, or in concrete acceleration, where near-instantaneous dissolution upon mixing is required for efficacy.

In the application technology sphere, the robust development of inhibited or low-corrosion calcium chloride formulations represents a major focus area for market development and differentiation. Manufacturers are actively integrating specialized corrosion inhibitors into the final powdered product, utilizing sophisticated chemical additives (such as specialized phosphates, organic compounds, or blends) to effectively mitigate the compound’s notorious corrosive impact on sensitive metals, vehicle underbodies, and concrete structures. This technological advancement significantly expands the product’s applicability for use on high-value, sensitive infrastructure like steel bridges, parking decks, and airport aircraft surfaces. Concurrently, advanced packaging technology, incorporating multi-layer barrier films and optimized sealing techniques, plays a critical technological role in ensuring the necessary shelf-stability of the highly hygroscopic powder, critically minimizing moisture absorption, preventing clumping, and maintaining the product’s physical integrity and performance during prolonged storage and long-haul international distribution cycles.

Regional Highlights

- North America: Market Dominance Driven by Winter Maintenance and Energy Sector

North America consistently holds the largest volume share of the global calcium chloride powder market, a position primarily driven by the extensive, mandatory need for comprehensive winter road maintenance across vast areas of the United States and Canada. Stringent de-icing protocols require massive annual volumes of calcium chloride due to its documented superior effectiveness at much lower temperatures compared to standard sodium chloride salts, ensuring higher levels of road safety. Furthermore, the region's robust and technologically advanced oil and gas sector, particularly high-volume shale drilling in the U.S. Permian and Appalachian Basins, provides a consistent, high-volume demand stream for dense clear brine fluids. Regulatory frameworks strictly emphasizing public road safety and continuous infrastructural investment solidify North America's position as the leading consumer, though its growth trajectory is characteristic of a mature, high-volume market compared to rapidly industrializing regions. The current focus here is increasingly shifting towards sustainable sourcing practices, logistical precision, and adopting inhibited low-corrosion products.

- Asia Pacific (APAC): Fastest Growth Due to Infrastructure Boom and Industrialization

The Asia Pacific region is emphatically projected to exhibit the fastest compound annual growth rate throughout the forecast period. This significant accelerated expansion is inextricably linked to the region’s unprecedented rate of rapid urbanization, coupled with massive and sustained public and private investment in essential construction and physical infrastructure development (driving demand for concrete accelerating and curing agents). Demand for essential dust control solutions is also soaring significantly, particularly across major industrialized nations like China and India, propelled by exponentially increasing mining activities, rapid industrial expansion, and increasingly stringent governmental air quality regulations requiring intervention. While de-icing demand is typically localized and minor (confined to high-altitude regions), the primary and most powerful drivers are high-volume industrial processing, the expanding regional food manufacturing sector, and large-scale, continuous civil engineering projects. Local manufacturers are rapidly expanding their production capacity and upgrading technological processes to efficiently meet this burgeoning domestic and regional demand, often focusing on export opportunities within the MEA region as well.

- Europe: Steady Demand and Focus on High-Purity Grades

The European market maintains a mature, predictable, yet fundamentally stable consumption profile for calcium chloride powder. Demand remains consistent and well-established across all major application sectors, including critical winter road maintenance in Northern and Central European nations, and diverse, steady industrial utilization. Europe exhibits a particularly strong and discernible emphasis on high-purity applications, driven by exceptionally strict regional food safety standards which mandate the utilization of certified food-grade calcium chloride in all dairy, brewing, and prepared beverage production processes. Regulatory pressures specifically concerning the environmental discharge of high concentrations of chloride ions are increasingly influencing product formulation strategies, prompting manufacturers towards developing and marketing more environmentally responsible and inherently low-corrosion product lines. The regional strategic focus remains fixed on maximizing operational efficiency, ensuring impeccable quality control, and achieving full regulatory compliance within its existing, advanced industrial frameworks.

- Middle East and Africa (MEA): Growth Tied to Oilfield Services and Desiccant Use

The robust demand trajectory in the Middle East and Africa region is intrinsically and fundamentally linked to the scale and intensity of ongoing activity within the immense global oil and gas exploration and production sector, primarily serving the crucial need for high-density drilling and specialized completion fluids required in challenging, high-pressure reservoirs. Additionally, the region’s predominantly arid climate necessitates the heavy utilization of calcium chloride powder as an exceptionally effective desiccant and high-performance dust control agent, particularly vital in large-scale remote construction sites (e.g., NEOM project), extensive military bases, and rapidly expanding solar power generation facilities. Continued massive investment in new large-scale conventional oil projects and ongoing infrastructural expansion across the Gulf Cooperation Council (GCC) countries and North African nations are the primary and most significant accelerators for market growth in this strategically and geographically important area, often relying heavily on imports from APAC and European suppliers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Calcium Chloride Powder Market.- Occidental Petroleum Corporation (OxyChem)

- TETRA Technologies Inc.

- Ward Chemical Ltd.

- Solvay S.A.

- Compass Minerals International Inc.

- Nedmag B.V.

- Weifang Union Chemicals Co., Ltd.

- Zirax Limited

- Barium and Chemicals, Inc.

- Shandong Haihua Group Co., Ltd.

- New Alliance Chemical Inc.

- Pioneer Chemical, Inc.

- Tangshan Sanyou Group

- Tiger Calcium Services

- ICL Group Ltd.

- Jost Chemical Co.

- Shenzhen Chem Source Co., Ltd.

- AkzoNobel N.V. (Salt Business)

- Qingdao Haijing Chemical Group

Frequently Asked Questions

Analyze common user questions about the Calcium Chloride Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers for the sustained growth of the Calcium Chloride Powder Market?

The primary drivers include mandatory regulatory road safety requirements necessitating effective de-icing agents during winter, rapid global infrastructure development requiring concrete accelerating admixtures for faster construction cycles, and consistent, high-volume demand from the oil and gas industry for clear brine fluids used extensively in drilling and well completion operations globally.

How does the technical grade Calcium Chloride differ from the food grade in terms of application and regulation?

Technical grade is utilized primarily for large-scale industrial applications like de-icing and dust control and adheres to general industrial chemical standards. Food grade, conversely, necessitates extremely high purity, minimal heavy metal content, and must rigorously comply with stringent international food safety regulations (such as FDA and EFSA standards) for its safe use as a firming agent, electrolyte, or preservative.

What is the main challenge faced by manufacturers in the Calcium Chloride Powder supply chain?

The primary challenge is successfully managing the highly seasonal and fundamentally unpredictable demand peaks, especially for the high-volume de-icing segment, coupled with the complex logistical hurdles of handling and storing a highly corrosive and highly hygroscopic chemical efficiently without suffering product degradation or excessive equipment corrosion.

Which application segment consumes the largest volume of Calcium Chloride Powder globally?

The De-icing and Anti-Icing application segment consumes the largest volume globally, significantly dominating market share, particularly across North America and key regions of Europe, due to the critical necessity of maintaining clear, safe, and navigable roadways and public thoroughfares during severe winter conditions.

How is technology being utilized to reduce the environmental impact of calcium chloride use?

Technological innovation is focused on developing new low-corrosion inhibited formulations to protect critical public and private infrastructure, alongside manufacturing process upgrades like Mechanical Vapor Recompression (MVR) which significantly reduces the operational energy intensity and lowers the overall carbon footprint associated with large-scale production, enhancing sustainability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager