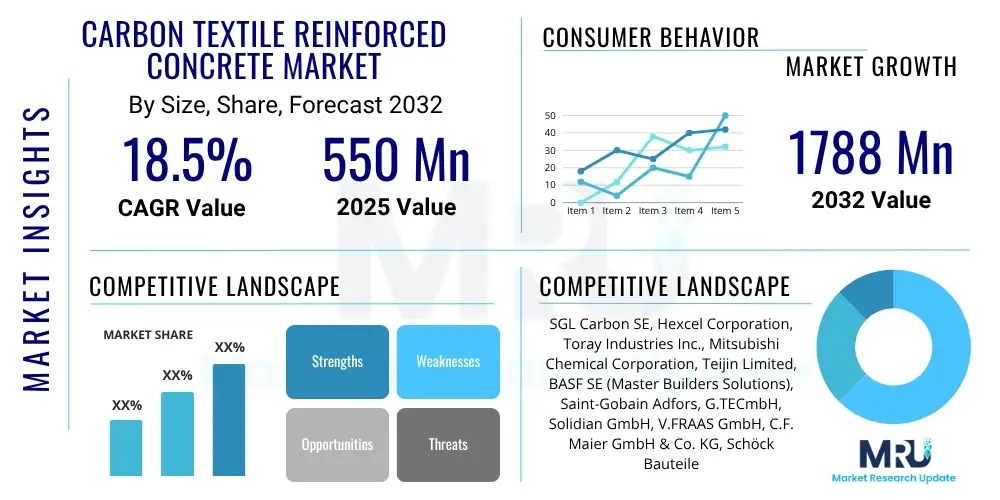

Carbon Textile Reinforced Concrete Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439676 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Carbon Textile Reinforced Concrete Market Size

The Carbon Textile Reinforced Concrete Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 17.5% between 2026 and 2033. The market is estimated at USD 155 Million in 2026 and is projected to reach USD 475 Million by the end of the forecast period in 2033. This robust growth is primarily attributed to the escalating global demand for high-performance, durable, and sustainable construction materials, particularly in critical infrastructure projects and the extensive renovation of aging structures worldwide. The inherent superior properties of Carbon Textile Reinforced Concrete (CTRC), such as its remarkably lightweight nature, exceptional tensile strength, and unparalleled corrosion resistance, position it as a revolutionary and increasingly preferred alternative to traditional steel-reinforced concrete, thereby driving its rapid adoption across a wide array of construction applications. Furthermore, heightened environmental consciousness, coupled with increasingly stringent regulatory frameworks promoting eco-friendly and resource-efficient building practices, are compelling construction firms, urban planners, and developers to invest significantly in advanced materials like CTRC, ensuring long-term structural integrity with a substantially reduced environmental footprint and enhanced resilience against climatic challenges. The market's expansion is also supported by continuous innovation in carbon fiber manufacturing processes, which are gradually improving cost-effectiveness and material accessibility.

Carbon Textile Reinforced Concrete Market introduction

Carbon Textile Reinforced Concrete (CTRC) represents a groundbreaking and transformative advancement in the field of civil engineering and construction, integrating high-strength, non-corrosive carbon fiber textiles into a specially formulated fine-grained concrete matrix. This innovative composite material offers a compelling suite of superior mechanical properties, significantly outperforming traditional steel-reinforced concrete across critical parameters such as durability, overall weight, and resistance to corrosion. The market for CTRC is characterized by its increasing relevance and pivotal role in modern construction paradigms, driven by the global imperative to build more resilient, sustainable, and long-lasting infrastructure capable of withstanding increasingly harsh environmental conditions, mitigating the effects of natural disasters, and substantially reducing long-term maintenance cycles and associated costs. CTRC's unique composition strategically leverages the exceptional tensile strength and stiffness inherent to carbon fibers, which are fundamentally non-corrosive and chemically inert. This fundamental property effectively eliminates the primary cause of degradation and failure in conventional concrete structures, namely steel corrosion, thereby dramatically extending the service life of newly constructed and rehabilitated assets.

Carbon Textile Reinforced Concrete Market Executive Summary

The Carbon Textile Reinforced Concrete (CTRC) market is currently undergoing a significant and transformative paradigm shift within the global construction industry, marking a decisive move towards the widespread adoption of advanced, sustainable, and high-performance materials. Current business trends indicate a strong and discernible inclination towards continuous innovation, with leading companies strategically focusing their research and development efforts on discovering and implementing more cost-effective production methods for carbon fibers and significantly improving the chemical and mechanical compatibility of carbon textile reinforcements with various concrete matrices. There is an observable and increasing trend of strategic partnerships, joint ventures, and collaborative agreements forming between major carbon fiber manufacturers, specialized textile producers, and large-scale construction companies. These collaborations are specifically designed to facilitate the seamless integration of CTRC solutions into mainstream construction projects, accelerate market penetration, and overcome existing adoption barriers. Furthermore, a growing emphasis on modular construction techniques and sophisticated prefabrication processes is substantially bolstering the demand for CTRC, as its inherently lightweight and high-strength properties render it an ideal material for efficient off-site manufacturing, which in turn leads to significantly faster construction times, reduced on-site labor requirements, and enhanced quality control. The market is also witnessing a noticeable rise in the availability of specialized engineering and consulting services exclusively dedicated to CTRC application, indicating the rapid maturation of an increasingly sophisticated ecosystem around this innovative material, consistently supported by ongoing academic and industrial research and development efforts aimed at expanding its functional applications and pushing the boundaries of its performance envelopes.

AI Impact Analysis on Carbon Textile Reinforced Concrete Market

The profound integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies is poised to revolutionize the Carbon Textile Reinforced Concrete (CTRC) market by comprehensively addressing common user concerns related to material optimization, stringent quality control, design complexity, and accurate predictive performance. Users frequently raise questions regarding how AI can significantly enhance the overall efficiency and reliability of CTRC production processes, improve the precision and accuracy of material property predictions across various environmental conditions, and substantially streamline the intricate design and demanding construction phases. There is a strong and growing interest in AI's inherent potential to minimize material waste, intelligently optimize complex concrete mix designs for highly specific application requirements, and ensure consistent, verifiable quality across large-scale, intricate projects. Furthermore, users are increasingly keen on understanding how AI can provide invaluable assistance in the non-destructive evaluation of existing CTRC structures, accurately predict their long-term structural behavior under dynamic loads, and facilitate adaptive design adjustments in real-time. The overarching expectation among industry stakeholders is that AI will unlock unprecedented new levels of efficiency, achieve greater cost-effectiveness, and deliver enhanced performance predictability throughout the entire CTRC lifecycle, thereby propelling the industry towards more intelligent, data-driven, and increasingly autonomous construction paradigms.

- Material Composition Optimization: AI algorithms possess the capability to meticulously analyze vast and complex datasets encompassing material properties, diverse environmental conditions, and critical performance metrics. This allows for the precise optimization of both the concrete mix design and the specific carbon textile specifications, leading to significantly enhanced strength, durability, and cost-efficiency tailored to highly specific application requirements. This intricate optimization process extends to the intelligent selection of the ideal carbon fiber type, precise fiber orientation within the textile, and the most effective impregnation techniques, thereby substantially reducing the time-consuming and costly trial-and-error phases in research and development and streamlining manufacturing processes.

- Predictive Performance Modeling: Sophisticated Machine Learning models can accurately and reliably predict the long-term structural behavior, creep deformation, shrinkage characteristics, and fatigue resistance of CTRC components when subjected to a wide range of static and dynamic loading and diverse environmental conditions. This advanced predictive capability empowers engineers to design structures with significantly higher confidence, proactively anticipate future maintenance needs, and strategically extend the overall service life of assets. This shift moves the industry from reactive maintenance strategies towards proactive, data-driven asset management and fosters preventative maintenance plans meticulously crafted based on robust data-driven insights, ensuring optimal performance over decades.

- Automated Quality Control and Inspection: AI-powered vision systems, integrated with advanced sensors, can continuously monitor the manufacturing process of carbon textiles and CTRC elements in real-time. These systems are capable of detecting even subtle defects, inconsistencies, and deviations from prescribed specifications with remarkably high precision and speed. This ensures uniform product quality, significantly reduces the potential for human error, and minimizes material waste by identifying and rectifying issues early in the production cycle. The outcome is a substantial improvement in overall product reliability and strict adherence to demanding engineering standards, leading to higher confidence in the finished product.

- Design and Simulation Acceleration: AI tools are instrumental in accelerating the often-iterative design process for complex CTRC structures by rapidly generating and exhaustively evaluating numerous design alternatives, intelligently optimizing intricate geometries, and performing advanced structural simulations with unparalleled speed. This dramatically reduces overall design time, facilitates the exploration and realization of more innovative and complex architectural forms, and allows for thorough performance analysis well before any physical prototyping commences. This capability ultimately facilitates the creation of exceptionally lightweight, structurally efficient, and aesthetically pleasing structures that push the boundaries of conventional design.

- Supply Chain and Logistics Optimization: AI can profoundly enhance the efficiency and resilience of the entire CTRC supply chain by accurately forecasting demand fluctuations, intelligently optimizing inventory levels across multiple warehouses, and streamlining complex logistics for both raw materials and finished products. This intelligent optimization leads to significantly reduced lead times, lower transportation costs, and improved overall operational efficiency across the value chain, ensuring the timely delivery of critical components to construction sites and minimizing potential project delays by expertly managing the intricate and globally distributed network of suppliers.

- Robotics and Autonomous Construction: AI plays a pivotal and enabling role in the advancement of robotic systems for the automated and precise placement of carbon textiles, controlled concrete pouring, and efficient finishing operations, particularly within controlled prefabrication plants. This not only dramatically increases the speed and precision of the construction process but also significantly enhances worker safety by automating hazardous, strenuous, or highly repetitive tasks. The result is consistently higher productivity, uniform application quality, and a reduced risk of human error in the precision-driven construction of high-performance CTRC elements, leading to higher quality and greater efficiency.

DRO & Impact Forces Of Carbon Textile Reinforced Concrete Market

The Carbon Textile Reinforced Concrete (CTRC) market is profoundly influenced by a complex and dynamic interplay of drivers, inherent restraints, significant opportunities, and broader impact forces that are collectively shaping the global construction and advanced materials sectors. Key drivers robustly propelling the market forward include the inherent superior material properties of CTRC, such as its remarkably lightweight nature, exceptional tensile strength, and unparalleled corrosion resistance, which collectively position it as an ideal and often superior replacement for traditional steel-reinforced concrete in a multitude of demanding and critical applications. The increasing global focus on highly sustainable construction practices and the growing adoption of stringent green building certifications also play a crucial role, as CTRC offers an extended service life and significantly reduced maintenance requirements over its operational lifespan, thereby leading to a substantially lower overall environmental footprint compared to conventional materials. Furthermore, the urgent and widespread need for comprehensive infrastructure upgrades and extensive renovations worldwide, particularly for aging bridges, roads, and buildings that are highly susceptible to corrosion and deterioration, is creating substantial and sustained demand for durable, high-performance, and long-lasting repair and strengthening solutions like CTRC. Continuous technological advancements in carbon fiber manufacturing processes, leading to improved material characteristics, enhanced mechanical properties, and progressively reduced production costs, are further enhancing its economic viability and broader market accessibility, making it increasingly competitive against established conventional materials.

Segmentation Analysis

The Carbon Textile Reinforced Concrete (CTRC) market is meticulously segmented across various crucial parameters to provide a highly nuanced and comprehensive understanding of its intricate dynamics, diverse adoption patterns, and significant growth potential across a wide array of applications and geographical regions. These detailed segmentation analyses are indispensable for allowing market stakeholders to precisely identify specific growth hotspots, accurately understand the competitive landscapes, and strategically tailor their product development and marketing strategies to effectively capitalize on emerging opportunities. The market is primarily bifurcated based on the type of carbon fiber utilized in the reinforcement, the specific form of the carbon textile reinforcement, the broad application areas within the construction and infrastructure sectors, and the distinct end-use industries that primarily drive demand. Furthermore, granular geographical segmentation offers critical insights into regional disparities in market demand, the influence of varying regulatory environments, and differential rates of technological adoption, accurately reflecting the diverse stages of market maturity across different parts of the world. A thorough understanding of these intricate segments is paramount for market participants to successfully develop highly targeted product offerings, optimize their distribution channels for maximum reach and efficiency, and refine their marketing approaches to resonate effectively with specific customer cohorts and market niches, ensuring sustained growth and competitive advantage.

- By Carbon Fiber Type:

- PAN-based Carbon Fiber: These fibers predominantly lead the market due to their exceptional balance of high strength-to-weight ratio, superior stiffness, and remarkable versatility. They are extensively utilized in a broad range of structural and non-structural applications where robust mechanical properties are critical for performance and longevity, forming the backbone of most CTRC products due to their established manufacturing processes and continuous advancements in their cost-effectiveness.

- Pitch-based Carbon Fiber: Known primarily for their ultra-high modulus (stiffness) and excellent thermal conductivity, pitch-based carbon fibers are typically reserved for highly specialized applications requiring extreme rigidity, dimensional stability under high temperatures, or specific heat dissipation characteristics. While a smaller segment, their unique properties make them indispensable for niche, high-performance CTRC solutions where standard PAN-based fibers may not suffice.

- By Textile Form:

- Grids/Meshes: This is the most common and widely adopted form of carbon textile reinforcement, offering excellent distribution of reinforcing elements within the concrete matrix and ease of integration during construction. They are extensively used for strengthening existing structures, new construction of lightweight elements, and general concrete reinforcement, providing multi-directional tensile capacity.

- Chopped Fibers: These are short, randomly dispersed carbon fibers integrated directly into the concrete mix to improve its ductility, increase crack resistance, and enhance overall matrix properties. Often used as a supplementary reinforcement or for non-structural applications, they contribute to the concrete's toughness and reduce micro-cracking.

- Non-woven Fabrics: Representing an emerging form of textile reinforcement, non-woven fabrics offer unique properties, such as isotropic reinforcement and flexibility, suitable for specific architectural applications, complex geometries, or delicate repair projects where traditional grids might be challenging to apply. Their development is driven by niche demands for customized performance.

- Other Forms (e.g., Mats, Braids): This category includes various specialized forms of carbon textiles, such as continuous mats for surface reinforcement or braided elements for localized strengthening. These forms are developed for particular engineering requirements, offering tailored performance characteristics and allowing for highly optimized solutions in advanced CTRC applications.

- By Application:

- Repair and Strengthening: This constitutes the largest and most critical segment, addressing the urgent global need for the rehabilitation, retrofitting, and seismic enhancement of aging or damaged concrete structures, including bridges, historical buildings, and critical infrastructure. CTRC's lightweight and durable properties make it ideal for extending service life without adding significant structural load.

- New Construction: A rapidly growing segment, utilizing CTRC for the creation of innovative, lightweight, and slender designs in a broad range of structures, from cutting-edge residential and commercial buildings to modern public infrastructure projects. This application leverages CTRC's strength and durability to enable more sustainable and aesthetically pleasing designs.

- Prefabrication: This involves the manufacturing of precast elements such as façade panels, beams, columns, and other structural components in controlled factory environments. CTRC is highly valued here for enabling lightweight, high-strength precast units that contribute to faster, more efficient, and higher-quality off-site construction, reducing on-site labor and project timelines.

- Other Applications (e.g., Architectural Elements, Tunnel Linings): This category includes niche but expanding areas where CTRC's aesthetic advantages, design flexibility, and structural capabilities are uniquely leveraged. Examples include intricate architectural features, durable tunnel linings, and specialized industrial applications where conventional materials fall short in performance or longevity.

- By End-Use Industry:

- Infrastructure (Bridges, Roads, Tunnels, Marine Structures): This is the dominant end-use segment due to the critical global need for long-lasting, corrosion-resistant, and low-maintenance materials in public works, where CTRC offers unparalleled performance against environmental degradation and heavy loads, ensuring the resilience and safety of critical assets over decades.

- Building and Construction (Residential, Commercial, Industrial Buildings): A significant and expanding segment, driven by the growing demand for sustainable, energy-efficient, and aesthetically appealing structures. CTRC is increasingly used in walls, floors, roofs, and facades to reduce weight, improve durability, and meet modern design requirements for both new builds and major renovations.

- Automotive and Aerospace: While still a relatively niche application compared to construction, CTRC and its underlying composite technologies are finding emerging uses in lightweight components for the automotive sector (e.g., body panels, chassis elements) and aerospace industries (e.g., interior structures, non-load-bearing elements) where weight reduction directly translates to fuel efficiency and performance gains.

- Other Industrial Applications: This includes specialized uses in aggressive chemical environments, such as industrial processing plants where corrosion resistance is paramount, or in applications requiring electromagnetic transparency (e.g., certain defense or telecommunications infrastructure) where metal reinforcement would interfere.

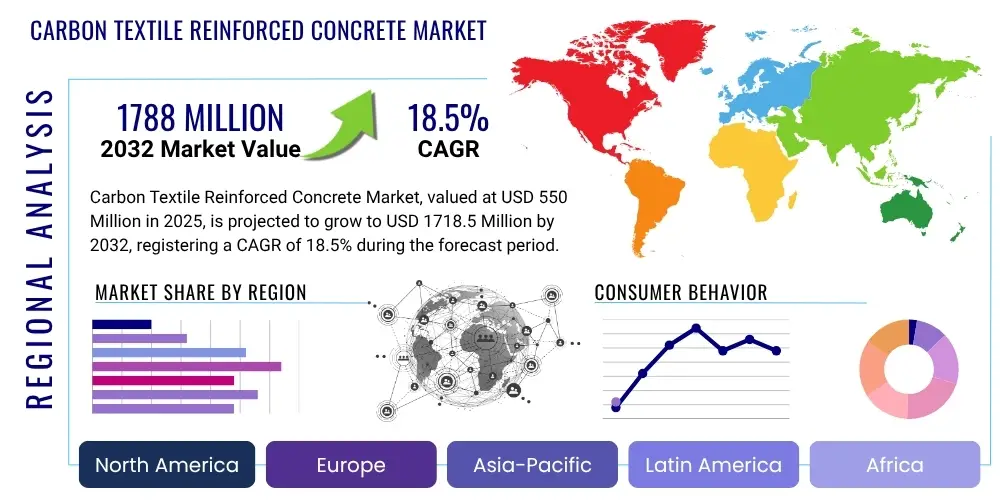

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Carbon Textile Reinforced Concrete Market

The value chain for the Carbon Textile Reinforced Concrete (CTRC) market is intricate and multifaceted, involving several distinct and interdependent stages, from the initial sourcing and production of raw materials to the final application and integration of the composite product into various construction projects. Each stage plays a critical role in contributing to the overall product cost, performance characteristics, and market competitiveness. The upstream segment of the value chain is predominantly defined by the highly specialized production of high-quality carbon fibers, which serve as the fundamental reinforcement material. This complex process involves advanced chemical engineering to transform precursor materials, primarily Polyacrylonitrile (PAN) or pitch, into robust carbon fibers through stages of stabilization, carbonization, and surface treatment. Key players in this initial stage are typically large chemical companies and highly specialized fiber manufacturers possessing advanced technological capabilities, significant capital investments in sophisticated equipment, and extensive research and development expertise. Following the production of the raw carbon fibers, these fibers are then meticulously processed into various textile forms, such as precise meshes, grids, or fabrics, utilizing advanced weaving, knitting, or braiding techniques. This initial stage is absolutely critical, as the inherent quality, consistency, and specific mechanical properties of the carbon textiles directly and profoundly influence the ultimate performance, durability, and cost-effectiveness of the final CTRC product. Ensuring a stable, high-volume supply of high-grade carbon fibers at competitive prices is a major challenge and a key differentiator for companies operating higher up in the CTRC value chain, requiring strong vertical integration or robust supplier relationships.

Carbon Textile Reinforced Concrete Market Potential Customers

The Carbon Textile Reinforced Concrete (CTRC) market targets an exceptionally diverse and growing range of end-users and buyers, spanning various segments of the global construction and infrastructure industries. These customers are primarily united by a common pursuit of superior performance, enhanced durability, and greater sustainability in their projects. Primary potential customers include large-scale construction companies and general contractors actively involved in both new build construction and extensive renovation projects for a wide array of commercial, residential, and industrial structures. These entities are increasingly seeking advanced and innovative materials that can significantly reduce project timelines, substantially lower long-term maintenance costs, and consistently meet stringent performance and safety requirements, particularly in regions characterized by harsh environmental conditions, high seismic activity, or aggressive chemical exposures. Architects and structural engineers also represent critical influencers and, in many cases, direct specifiers and buyers, as they meticulously select and specify materials based on complex design requirements, paramount structural integrity considerations, and aesthetic aspirations. They are increasingly recognizing and embracing CTRC's profound potential for creating lightweight, slender, and aesthetically pleasing structures without compromising essential strength, safety, or resilience. Their growing familiarity with and confidence in CTRC's capabilities is a significant driving force for its innovative incorporation into modern architectural designs and complex engineering solutions, pushing the boundaries of what is structurally and aesthetically possible.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155 Million |

| Market Forecast in 2033 | USD 475 Million |

| Growth Rate | 17.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SGL Carbon, Hexcel Corporation, Teijin Limited, Mitsubishi Chemical Corporation, Toray Industries Inc., BASF SE, Holcim Ltd., Cemex S.A.B. de C.V., HeidelbergCement AG, Imerys S.A., Saint-Gobain S.A., Owens Corning, Chomarat Group, Solvay S.A., Dow Chemical Company, Nippon Carbon Co. Ltd., Kureha Corporation, GrafTech International Ltd., Sumitomo Corporation, Daicel Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbon Textile Reinforced Concrete Market Key Technology Landscape

The Carbon Textile Reinforced Concrete (CTRC) market's remarkable growth and continuous innovation are intrinsically linked to a dynamic and rapidly evolving technological landscape, which encompasses significant advancements across material science, sophisticated manufacturing processes, and cutting-edge digital tools. At its foundational core, the underlying technology primarily revolves around the advanced production of high-performance carbon fibers, which are manufactured through highly complex pyrolysis processes from specialized precursor materials such as Polyacrylonitrile (PAN) or pitch. Innovations in carbon fiber technology are intensely focused on achieving significantly higher tensile strength, improved elastic modulus, and developing more cost-effective and energy-efficient production methods, frequently involving advanced plasma treatments, precise surface modification techniques, and breakthroughs in fiber spinning technologies. These critical developments are primarily aimed at profoundly enhancing the mechanical properties and durability of the carbon fibers while simultaneously reducing their manufacturing cost, thereby making CTRC a more economically viable and competitive alternative to traditional construction materials. Furthermore, substantial research and development efforts are dedicated to pioneering sustainable and recycled carbon fibers, which aligns perfectly with global initiatives to reduce the environmental footprint of construction materials, pushing the boundaries of both material performance and ecological responsibility, ensuring the long-term viability of the material.

Regional Highlights

- North America: This region represents a significant and rapidly expanding market for Carbon Textile Reinforced Concrete, primarily driven by substantial governmental and private sector investments in critical infrastructure rehabilitation, repair, and a growing, concerted focus on highly sustainable and resilient construction practices. Countries such as the United States and Canada are undertaking extensive and complex projects to repair, strengthen, and upgrade aging bridges, deteriorating highways, and vital public buildings, where CTRC's superior durability, lightweight properties, and unparalleled corrosion resistance offer distinct and compelling advantages over traditional materials. The strong presence of leading research institutions, a highly skilled engineering workforce, and a proactive emphasis on technological innovation and early adoption also significantly contribute to the rapid integration of advanced materials like CTRC. There is a growing awareness and recognition among engineers, architects, and urban planners regarding the long-term cost benefits, reduced lifecycle costs, and superior performance of CTRC, further supported by regional government initiatives and incentives promoting green building certifications, sustainable urban development, and materials with a significantly reduced environmental impact. The increasing demand for lightweight, high-performance precast elements in rapid urban development and modular construction projects also plays a crucial role in fueling market growth across the region.

- Europe: Europe stands as a pioneering and highly influential region in the comprehensive adoption, advanced research, and continuous development of Carbon Textile Reinforced Concrete. This leadership is robustly propelled by stringent environmental regulations, a strong and unwavering commitment to significantly reducing carbon emissions across the entire construction sector, and a rich heritage of meticulously preserving and rehabilitating historical and culturally significant structures. Countries such as Germany, Switzerland, Italy, and the Netherlands have consistently been at the forefront of both academic research and practical application of CTRC, particularly in the critical areas of repair, strengthening, and seismic upgrading of existing concrete and masonry structures, where its unique properties are invaluable. The overarching emphasis on resource efficiency, circular economy principles, and achieving an extended service life for both public and private infrastructure projects robustly drives significant and sustained demand. European Union directives and national initiatives promoting sustainable urban development, energy efficiency in buildings, and the use of innovative, long-lasting construction materials further bolster the market for high-performance solutions like CTRC, especially in comprehensive retrofit applications and new construction projects aiming for exemplary energy efficiency, exceptional durability, and aesthetic innovation.

- Asia Pacific (APAC): The Asia Pacific region is rapidly emerging as the fastest-growing and most dynamic market for Carbon Textile Reinforced Concrete globally, primarily fueled by unprecedented rates of urbanization, a multitude of massive infrastructure development projects, and accelerating industrialization across key economies like China, India, Japan, South Korea, and Southeast Asian nations. The urgent and pervasive need for robust, earthquake-resistant, and typhoon-resilient structures in seismically active and climate-vulnerable areas, combined with a strong demand for rapid, efficient, and cost-effective construction methods to keep pace with economic growth, is significantly accelerating the adoption of CTRC. While initial cost sensitivity remains an important factor in some segments, the undeniable long-term benefits of enhanced durability, reduced maintenance requirements, and superior structural performance are increasingly recognized and valued by regional stakeholders. Extensive investments in high-speed rail networks, smart cities initiatives, and large-scale sustainable building projects are providing substantial and sustained opportunities for market expansion, with regional governments, major construction conglomerates, and innovative developers actively exploring, piloting, and implementing advanced material solutions like CTRC to build future-ready infrastructure.

- Latin America: The CTRC market in Latin America is currently in its nascent stages of development but demonstrates promising and significant growth potential. This growth is largely driven by the pressing need for modern infrastructure development, the increasing awareness of sustainable building practices, and a growing imperative to enhance structural resilience against natural hazards prevalent in the region. Countries like Brazil, Mexico, Chile, and Colombia are actively investing in urban development, critical infrastructure upgrades, and housing projects, where CTRC can offer highly effective solutions for enhancing structural resilience, particularly against pervasive seismic activity, aggressive coastal environments, and high humidity levels. Market growth is presently being supported by successful pilot projects, collaborative research initiatives with international partners, and a gradual but steady increase in adoption as local construction companies, structural engineers, and governmental agencies gain comprehensive familiarity and confidence in the material's compelling benefits and application methodologies. Overcoming initial cost barriers through technological advancements and promoting widespread standardization of design and construction practices are key strategic imperatives for achieving wider and more rapid market penetration in this burgeoning region.

- Middle East and Africa (MEA): This expansive region presents a unique and compelling set of drivers and opportunities for the Carbon Textile Reinforced Concrete market. Significant and ambitious investments in mega-projects, futuristic smart cities, and diverse, large-scale infrastructure development, particularly within the affluent Gulf Cooperation Council (GCC) countries (e.g., UAE, Saudi Arabia, Qatar), are creating substantial demand for advanced, high-performance, and resilient building materials. The incredibly harsh desert climate, extreme temperatures, and corrosive saline coastal environments prevalent in parts of the MEA region necessitate construction solutions that offer unparalleled corrosion resistance, exceptional durability, and long-term structural integrity, where CTRC's superior performance characteristics are a decisive advantage. While the market is still developing and maturing, the strong governmental focus on innovation, sustainability, and maximizing long-term asset value in newly planned cities and large-scale ventures (such as NEOM in Saudi Arabia) is expected to accelerate CTRC adoption significantly. Africa's burgeoning infrastructure needs, driven by rapid population growth and economic development, also represent a substantial long-term growth opportunity, as governments seek durable, low-maintenance, and resilient solutions for rapidly expanding urban centers and critical national infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbon Textile Reinforced Concrete Market.- SGL Carbon

- Hexcel Corporation

- Teijin Limited

- Mitsubishi Chemical Corporation

- Toray Industries Inc.

- BASF SE

- Holcim Ltd.

- Cemex S.A.B. de C.V.

- HeidelbergCement AG

- Imerys S.A.

- Saint-Gobain S.A.

- Owens Corning

- Chomarat Group

- Solvay S.A.

- Dow Chemical Company

- Nippon Carbon Co. Ltd.

- Kureha Corporation

- GrafTech International Ltd.

- Sumitomo Corporation

- Daicel Corporation

Frequently Asked Questions

Analyze common user questions about the Carbon Textile Reinforced Concrete market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Carbon Textile Reinforced Concrete (CTRC)?

Carbon Textile Reinforced Concrete (CTRC) is an advanced composite material that ingeniously utilizes high-strength, non-corrosive carbon fiber textiles as a sophisticated reinforcement mechanism embedded within a specially formulated, fine-grained concrete matrix. Distinct from traditional steel-reinforced concrete, CTRC capitalizes on carbon's inherent superior tensile strength, remarkable stiffness, and fundamental chemical inertness, offering exceptional durability, significantly lighter weight, and unparalleled resistance to corrosion and aggressive chemical environments. This combination dramatically extends the service life of structures while reducing maintenance requirements. It represents a significant paradigm shift in construction materials, enabling the creation of thinner, more resilient, and inherently sustainable structural elements for a wide spectrum of applications, ranging from innovative new construction projects to the vital strengthening and rehabilitation of existing critical infrastructure, thereby addressing modern demands for performance and sustainability.

What are the main advantages of using CTRC over traditional concrete?

CTRC offers numerous and compelling advantages over conventional steel-reinforced concrete, including significantly higher tensile strength and stiffness, which allows for the design of more slender, elegant, and lightweight structural components without compromising safety or structural integrity. Its carbon fiber reinforcement is completely non-corrosive, fundamentally eliminating the primary cause of degradation and costly repairs in steel-reinforced structures, thus drastically increasing the service life of buildings and critical infrastructure and substantially reducing long-term maintenance expenses. CTRC also provides superior resistance to chemical attack, environmental factors, and fatigue, exhibits enhanced crack control, and can be applied in very thin layers. These attributes make it exceptionally ideal for comprehensive repair, strengthening, and architectural applications where stringent requirements for weight reduction, durability, aesthetic appeal, and extended lifespan are paramount considerations. Furthermore, its extended operational life inherently contributes to a reduced overall environmental footprint, aligning with global sustainability goals.

What are the primary applications of Carbon Textile Reinforced Concrete?

The primary applications of CTRC span a broad and critical array of construction and infrastructure sectors globally. It is extensively utilized for the comprehensive repair, strengthening, and seismic retrofitting of existing concrete structures such as aging bridges, historical buildings, and vital public monuments, where its lightweight nature and high-strength properties are invaluable for enhancing resilience without imposing excessive additional loads. In new construction, CTRC enables the creation of innovative, architecturally slender, and exceptionally durable designs for residential, commercial, and industrial buildings, as well as complex civil engineering projects like tunnels, marine structures, and specialized containment facilities. It is also increasingly employed in the prefabrication industry for efficiently producing high-performance, lightweight facade elements, wall panels, and other bespoke architectural components, offering immense design flexibility and significantly improved construction efficiency. Niche applications include structures exposed to highly aggressive chemical environments where corrosion is a major concern, or those requiring specific electromagnetic transparency, thereby showcasing its versatility across challenging engineering contexts.

What challenges does the CTRC market face?

Despite its myriad benefits, the CTRC market faces several significant challenges that impede its widespread adoption. Foremost among these is the relatively high initial cost of carbon fibers compared to traditional steel reinforcement, which can present a substantial financial barrier for certain projects, particularly in cost-sensitive markets, although long-term lifecycle cost savings often offset this. There is also a critical need for greater awareness, comprehensive education, and specific training among structural engineers, architects, and construction contractors regarding the material's unique properties, design considerations, and precise application techniques. The current absence of comprehensive, globally standardized building codes and universally accepted design guidelines specifically tailored for CTRC further hinders its broader market acceptance and integration into mainstream construction practices. Additionally, the nascent stage of the supply chain, though rapidly maturing, can occasionally lead to procurement complexities or limited availability in certain regions, and specialized installation expertise is frequently required, which can add to project complexity and labor costs. Overcoming these challenges through continuous cost reduction initiatives, robust standardization efforts, and extensive educational outreach is absolutely crucial for the sustained expansion and broader market penetration of CTRC.

How does CTRC contribute to sustainable construction?

CTRC significantly contributes to sustainable construction practices by offering an exceptionally durable, remarkably long-lasting, and resource-efficient material solution. Its fundamentally non-corrosive nature eliminates the pervasive need for frequent and costly repairs and premature replacements often associated with steel-reinforced concrete structures, thereby substantially reducing overall material consumption, minimizing waste generation, and lowering the environmental impact of maintenance activities throughout a structure's entire operational lifespan. The inherent lightweight nature of CTRC further reduces transportation-related emissions and often allows for smaller, less resource-intensive foundations, collectively lowering the embodied carbon footprint of construction projects. By enabling the creation of thinner, more structurally efficient, and longer-lasting structures, CTRC optimizes material resource utilization. Its extended service life, reduced lifecycle environmental impact, and contribution to resilient infrastructure align perfectly with leading green building principles, circular economy objectives, and the urgent global drive towards a more sustainable, durable, and eco-friendly built environment for future generations, making it a cornerstone of modern green construction.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Carbon Textile Reinforced Concrete Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Carbon Textile Reinforced Concrete Market Statistics 2025 Analysis By Application (Bridge, Road, Building), By Type (Regular-Tow carbon fiber Textile Reinforced Concrete, Large-Tow carbon fiber Textile Reinforced Concrete), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Carbon Textile Reinforced Concrete Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Regular-Tow carbon fiber Textile Reinforced Concrete, Large-Tow carbon fiber Textile Reinforced Concrete), By Application (Bridge, Road, Commercial & Residential Building, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager