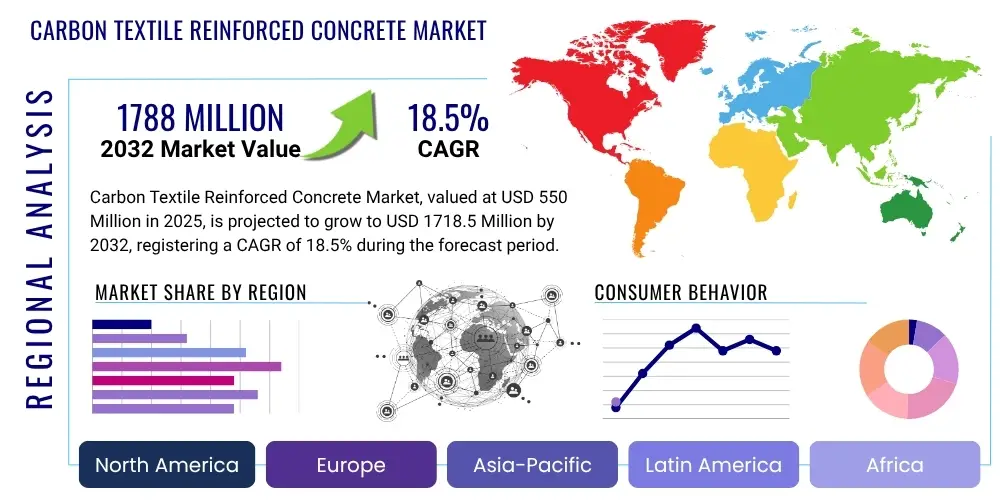

Carbon Textile Reinforced Concrete Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428764 | Date : Oct, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Carbon Textile Reinforced Concrete Market Size

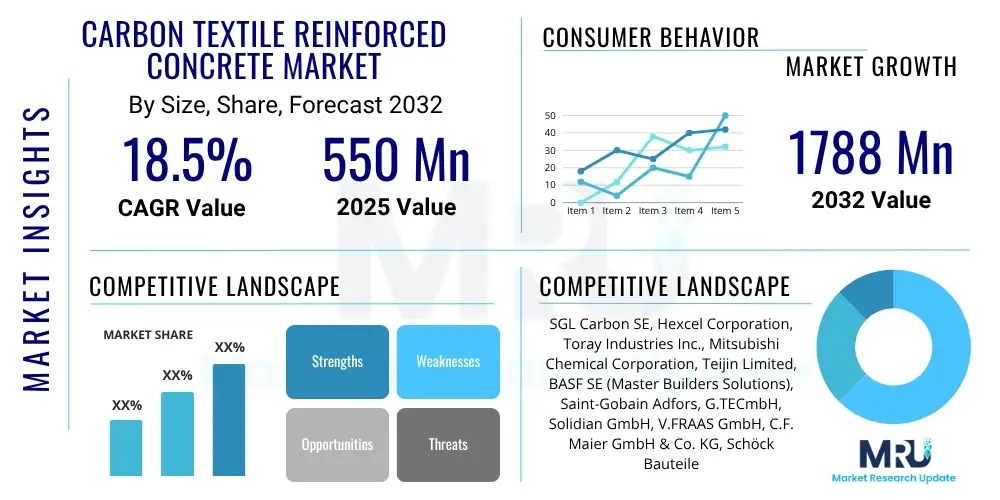

The Carbon Textile Reinforced Concrete Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at $550 million in 2025 and is projected to reach $1788 million by the end of the forecast period in 2032.

Carbon Textile Reinforced Concrete Market introduction

The Carbon Textile Reinforced Concrete (CTRC) market represents a rapidly evolving segment within the global construction industry, offering advanced material solutions for infrastructure and building applications. CTRC, also known as Carbon Fiber Reinforced Concrete (CFRC) or Textile Reinforced Concrete (TRC) specifically using carbon fibers, combines the compressive strength of concrete with the exceptional tensile strength and corrosion resistance of carbon fiber textiles. This composite material fundamentally addresses many limitations of traditional steel-reinforced concrete, primarily its susceptibility to corrosion, heavy weight, and susceptibility to cracking, paving the way for more durable, lightweight, and sustainable construction practices. The market encompasses a range of products including pre-fabricated elements, repair systems, and strengthening solutions, finding diverse applications across civil engineering, building construction, and architectural design.

The core product, Carbon Textile Reinforced Concrete, is characterized by its innovative reinforcement structure where fine carbon fiber meshes or fabrics replace conventional steel rebar. These textiles are impregnated with a fine-grained concrete matrix, often specialized for high performance. The exceptional strength-to-weight ratio of carbon fibers, coupled with their inertness to chemical degradation, renders CTRC an ideal material for structures exposed to harsh environments, such as coastal areas, bridges, and industrial facilities. Its lightweight nature significantly reduces structural dead load, offering cost savings in foundations and seismic design, while also enabling thinner and more aesthetically pleasing structural elements. The product lifecycle benefits from superior durability, leading to reduced maintenance costs and an extended service life for structures.

Major applications for Carbon Textile Reinforced Concrete span across critical infrastructure projects, including the repair, strengthening, and new construction of bridges, tunnels, and parking structures. In the building sector, CTRC is increasingly utilized for facades, slender architectural elements, and seismic retrofitting of existing buildings, providing enhanced safety and structural integrity. The numerous benefits of CTRC, such as its corrosion resistance, high tensile strength, lightweight properties, and reduced material consumption, are significant driving factors for market growth. These advantages align with the escalating global demand for sustainable construction materials, longer-lasting infrastructure, and innovative solutions to address aging infrastructure challenges, making CTRC a pivotal technology for the future of construction.

Carbon Textile Reinforced Concrete Market Executive Summary

The Carbon Textile Reinforced Concrete market is experiencing robust growth driven by a confluence of factors including increasing infrastructure investments, a heightened focus on sustainable construction, and the inherent superior performance characteristics of CTRC over traditional materials. Business trends indicate a significant push towards research and development, with manufacturers continuously innovating to improve material properties, reduce production costs, and expand application versatility. Strategic collaborations between material suppliers, construction companies, and academic institutions are becoming more prevalent, fostering market penetration and accelerating the adoption of CTRC in new and niche applications. Furthermore, the market is witnessing a trend towards modular and prefabricated CTRC components, streamlining construction processes and enhancing efficiency.

Regionally, Europe has been a pioneer in the adoption and development of Carbon Textile Reinforced Concrete, particularly in Germany and Switzerland, owing to strong regulatory support, significant investment in infrastructure repair, and a mature research ecosystem. Asia Pacific is emerging as a rapidly growing market, propelled by massive urbanization projects, increasing awareness of advanced construction materials, and a burgeoning demand for sustainable and resilient infrastructure in countries like China, Japan, and India. North America is also exhibiting substantial growth, driven by extensive infrastructure rehabilitation programs and a growing appreciation for the long-term cost benefits and environmental advantages offered by CTRC. Latin America and the Middle East and Africa regions are showing nascent growth, primarily due to rising construction activities and an increasing emphasis on modernizing urban and industrial infrastructure.

Segment trends reveal that repair and renovation applications currently dominate the market, as CTRC provides an effective and durable solution for rehabilitating aging concrete structures without adding excessive weight or compromising aesthetics. However, the new construction segment is projected to gain significant traction, particularly in the creation of slender, lightweight, and high-performance architectural and structural elements. By fiber type, carbon fiber textiles constitute the largest share due to their superior strength and durability, though research into hybrid textiles and alternative materials like basalt and glass is ongoing to diversify product offerings and address cost sensitivities. The infrastructure sector remains the primary end-user, but increasing applications in commercial and residential buildings, particularly for facades and seismic strengthening, are contributing to market diversification.

AI Impact Analysis on Carbon Textile Reinforced Concrete Market

Users often question how Artificial Intelligence (AI) can enhance various stages of the Carbon Textile Reinforced Concrete (CTRC) lifecycle, from material design and optimization to production, quality control, and predictive maintenance. Key themes revolve around leveraging AI to accelerate the discovery of optimal material compositions, improve manufacturing precision, reduce waste, and predict the long-term performance and durability of CTRC structures under various environmental loads. Concerns frequently arise regarding the substantial data requirements for effective AI implementation, the associated integration costs, and the need for a highly skilled workforce proficient in both construction engineering and AI technologies to fully harness its potential in this specialized domain. There is a strong expectation that AI will streamline complex design processes, minimize human error, and unlock new possibilities for customized and efficient CTRC solutions, thereby addressing current challenges related to standardization and cost.

- AI for Material Composition Optimization: AI algorithms can analyze vast datasets of material properties to predict optimal concrete mix designs and carbon textile configurations, enhancing strength, durability, and workability while minimizing material usage.

- AI-driven Predictive Maintenance: Utilizing sensor data and AI, the structural health of CTRC elements can be continuously monitored, enabling predictive maintenance schedules and early detection of potential issues, thereby extending service life and reducing repair costs.

- Automated Quality Control and Inspection: AI-powered computer vision systems can perform real-time quality checks during manufacturing and construction, identifying defects in carbon textile placement or concrete application with higher precision and speed than manual methods.

- Optimized Production Processes: AI can optimize manufacturing parameters for CTRC components, leading to reduced energy consumption, increased throughput, and lower production costs by fine-tuning curing times, mixing sequences, and textile impregnation processes.

- Structural Design and Simulation: AI-powered generative design tools can rapidly explore numerous CTRC structural configurations, optimizing for weight, strength, and material efficiency, significantly shortening design cycles and improving structural performance.

- Supply Chain Management: AI can enhance the efficiency of the CTRC supply chain by predicting demand, optimizing inventory levels for carbon fibers and specialty concrete components, and streamlining logistics, reducing lead times and material waste.

- Robotics and Automation in Construction: AI guides robotic systems for precise placement of carbon textiles and application of concrete, improving consistency, safety, and efficiency on construction sites, especially for complex geometries or large-scale projects.

- Environmental Impact Assessment: AI models can simulate and optimize the environmental footprint of CTRC projects, from raw material sourcing to end-of-life, supporting sustainable practices and compliance with green building standards.

- Customization and Personalization: AI enables the design and production of highly customized CTRC elements tailored to specific project requirements, offering architectural flexibility and performance advantages not achievable with conventional materials.

- Enhanced Data Analytics for Performance: AI can process data from field performance, laboratory tests, and environmental conditions to provide deeper insights into CTRC behavior over time, informing future material development and application guidelines.

DRO & Impact Forces Of Carbon Textile Reinforced Concrete Market

The Carbon Textile Reinforced Concrete (CTRC) market is propelled by a multitude of dynamic factors. Key drivers include the escalating global demand for sustainable and resilient infrastructure, particularly for repair and rehabilitation of aging structures where CTRC offers superior long-term performance compared to traditional materials. Its inherent corrosion resistance, high strength-to-weight ratio, and ability to form thinner, more durable elements align perfectly with the evolving requirements of modern construction, promoting efficiency and extended service life. Environmental mandates and increasing awareness regarding the lifecycle costs of construction materials further stimulate adoption, positioning CTRC as a preferred choice for green building initiatives and reducing the carbon footprint of construction.

However, the market also faces notable restraints. The initial higher material cost of carbon fibers compared to steel rebar remains a significant barrier, particularly for projects with budget constraints, despite the long-term savings in maintenance. A lack of standardized building codes and regulations specifically tailored for CTRC in many regions impedes its widespread adoption, as engineers and architects often prefer well-established methods. Limited awareness and technical expertise among the broader construction community regarding the design, handling, and application techniques of CTRC also contribute to slower market penetration. Furthermore, the specialized manufacturing processes for carbon textiles and fine-grained concrete require significant investment in technology and skilled labor, posing challenges for smaller players.

Significant opportunities exist for market expansion. Developing economies, undergoing rapid urbanization and infrastructure development, present vast untapped potential for CTRC, particularly in projects that prioritize durability and sustainability from the outset. Continued research and development in material science aim to reduce the cost of carbon fibers and enhance the performance of concrete matrices, fostering greater commercial viability. The increasing focus on seismic strengthening and climate change resilience, especially in vulnerable regions, opens new avenues for CTRC applications in retrofitting and designing robust structures. Strategic partnerships between material manufacturers, prefabricators, and construction firms are crucial for scaling production, standardizing practices, and educating the market, unlocking broader adoption and driving innovation.

The market is heavily influenced by several impact forces. Technological advancements in carbon fiber production, textile weaving, and concrete mix designs directly influence the cost-effectiveness and performance of CTRC, making it more competitive. Economic conditions, including construction spending and raw material prices, dictate investment levels and project feasibility. Environmental regulations, such as those promoting reduced carbon emissions and resource efficiency, favor the adoption of sustainable materials like CTRC. The competitive landscape, characterized by the presence of both established material giants and innovative startups, drives continuous improvement and market expansion through product differentiation and application development. These forces collectively shape the trajectory and growth potential of the Carbon Textile Reinforced Concrete market.

Segmentation Analysis

The Carbon Textile Reinforced Concrete market is comprehensively segmented to provide a detailed understanding of its diverse applications, material compositions, and end-user adoption patterns. This segmentation allows for precise market analysis, identifying key growth drivers and opportunities across different product categories, application areas, and geographical regions. Understanding these distinct segments is crucial for stakeholders to tailor their strategies, product development, and market penetration efforts effectively within the evolving landscape of advanced construction materials. The market is primarily categorized based on the type of carbon fiber textile used, the specific application of the CTRC, and the overarching end-use sector, alongside distinctions in manufacturing methods.

- By Fiber Type

- Carbon Fiber

- Glass Fiber (often in hybrid or comparison studies)

- Basalt Fiber (emerging alternatives, sometimes used in TRC, but market primarily focuses on carbon for CTRC)

- Aramid Fiber (less common in concrete reinforcement but part of broader textile reinforcement research)

- By Application

- Repair and Renovation

- Bridge Repair

- Building Restoration

- Facade Renovation

- Corrosion Damage Repair

- Strengthening

- Seismic Strengthening

- Load Capacity Enhancement

- Structural Reinforcement

- New Construction

- Facades and Architectural Elements

- Thin-walled Structures

- Pre-fabricated Elements

- Bridges and Tunnels (New Build)

- Repair and Renovation

- By End-Use Sector

- Infrastructure

- Bridges and Highways

- Tunnels

- Dams and Water Management Structures

- Ports and Marine Structures

- Building and Construction

- Commercial Buildings

- Residential Buildings

- Public Buildings (Hospitals, Schools)

- Architectural Projects

- Industrial

- Industrial Facilities

- Chemical Plants (corrosion resistance)

- Power Plants

- Others (e.g., historical preservation, specialized structures)

- Infrastructure

- By Manufacturing Method

- Pre-impregnated Textiles (P-TRC)

- Post-impregnated Textiles (I-TRC)

- Dry Textile Layup

Value Chain Analysis For Carbon Textile Reinforced Concrete Market

The value chain for the Carbon Textile Reinforced Concrete (CTRC) market begins with the upstream suppliers of raw materials, which are critical for the final product's performance. This stage primarily involves manufacturers of high-performance carbon fibers, which are then processed into textile meshes or fabrics. Key players in this segment are specialized chemical and advanced materials companies that produce the carbon precursors and undertake the energy-intensive carbonization process. Additionally, the supply of fine-grained, high-performance concrete components, including specialized cements, aggregates, and admixtures, forms another vital upstream link. Quality control and consistency at this foundational stage are paramount, as they directly impact the mechanical properties and durability of the finished CTRC product.

Moving downstream, the value chain encompasses the impregnation and manufacturing of CTRC elements, followed by distribution and application. This mid-stream segment includes companies specializing in developing and producing the textile reinforcement systems, often involving intricate weaving or knitting processes, and then impregnating them with suitable polymer or cementitious matrices. Some firms focus on creating pre-fabricated CTRC elements, such as panels, beams, or columns, which are then transported to construction sites. Other players specialize in providing on-site application solutions, where the carbon textiles are integrated into existing concrete structures or cast with fresh concrete. This stage requires specialized equipment, technical expertise, and adherence to precise engineering specifications to ensure optimal composite performance.

The distribution channel for Carbon Textile Reinforced Concrete varies, encompassing both direct and indirect approaches. Direct sales are common for large-scale infrastructure projects or highly customized architectural applications, where manufacturers directly engage with engineering firms, contractors, and public agencies to provide tailored solutions and technical support. Indirect distribution involves working through specialized construction material distributors, agents, and sometimes even through general contractors who have developed expertise in advanced composites. The choice of channel often depends on the project's scale, complexity, and geographical location. The ultimate end-users or buyers of CTRC products are primarily government infrastructure agencies, private construction companies, architectural firms, and industrial facility owners seeking durable, lightweight, and corrosion-resistant building solutions for new builds, repairs, or strengthening projects.

Carbon Textile Reinforced Concrete Market Potential Customers

The potential customers for Carbon Textile Reinforced Concrete (CTRC) are diverse and primarily fall within sectors demanding high-performance, durable, and sustainable construction solutions. End-users or buyers of CTRC products largely include governmental infrastructure departments responsible for maintaining and expanding public works such as bridges, tunnels, and highways. These agencies are increasingly recognizing the long-term economic and environmental benefits of CTRC, especially its resistance to corrosion and reduced maintenance requirements, which contribute to lower lifecycle costs for critical infrastructure assets. Private construction and engineering firms also represent a significant customer base, particularly those involved in large-scale commercial, industrial, and residential projects that require advanced materials for structural integrity, aesthetic appeal, or expedited construction timelines.

Beyond traditional construction, architectural firms and developers focused on innovative and sustainable building designs are increasingly adopting CTRC. Its ability to create slender, lightweight, and visually appealing elements makes it ideal for modern facades, unique structural components, and high-performance pre-fabricated modules. Moreover, companies specializing in the repair, renovation, and strengthening of existing structures, including heritage buildings and those requiring seismic upgrades, are key adopters. The ease of application and minimal increase in dead load offered by CTRC are particularly attractive in these retrofitting scenarios, providing a durable solution without extensive demolition or disruption, thereby preserving the original structure while enhancing its resilience.

The drivers for adoption among these customer segments are multifaceted. Infrastructure agencies prioritize longevity, resilience against environmental degradation, and reduced total cost of ownership. Private developers and architects seek material innovation that allows for greater design freedom, faster construction, and improved environmental performance. Industrial clients often require materials that can withstand aggressive chemical environments, where CTRC's corrosion resistance is a distinct advantage. As awareness grows regarding the lifecycle benefits, energy efficiency, and sustainability credentials of CTRC, its appeal broadens across an even wider spectrum of end-users who are committed to long-term value, structural performance, and environmentally responsible construction practices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $550 Million |

| Market Forecast in 2032 | $1788 Million |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SGL Carbon SE, Hexcel Corporation, Toray Industries Inc., Mitsubishi Chemical Corporation, Teijin Limited, BASF SE (Master Builders Solutions), Saint-Gobain Adfors, G.TECmbH, Solidian GmbH, V.FRAAS GmbH, C.F. Maier GmbH & Co. KG, Schöck Bauteile GmbH, Carbocon GmbH, Fibos GmbH, Carbon Contech GmbH, Chomarat Group, Dow Chemical Company, Owens Corning, Johns Manville, PPG Industries |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbon Textile Reinforced Concrete Market Key Technology Landscape

The key technology landscape of the Carbon Textile Reinforced Concrete (CTRC) market is characterized by innovations spanning material science, manufacturing processes, and digital integration. At its core, the production of high-performance carbon fibers remains a foundational technology, focusing on achieving optimal tensile strength, modulus, and ductility at competitive costs. Advancements in carbon fiber precursor materials, such as Pitch-based and PAN-based fibers, along with enhanced carbonization techniques, are continuously improving fiber properties and reducing production energy consumption. Concurrently, the development of sophisticated textile weaving and knitting technologies allows for the creation of precise, application-specific carbon fiber meshes and fabrics with controlled pore structures and fiber orientation, crucial for effective load transfer within the concrete matrix.

Another critical area of technological innovation lies in the concrete matrix itself and the impregnation methods. Fine-grained, high-performance concrete mixes are essential to ensure full penetration and bond with the carbon textile, often incorporating reactive powders, superplasticizers, and micro-fillers to achieve high strength, low permeability, and improved workability. New impregnation techniques, ranging from vacuum-assisted methods to optimized wet-layup processes, are being developed to ensure uniform saturation of the textile, minimizing voids and maximizing the composite's structural efficiency. Furthermore, research into self-healing concrete, smart concretes with integrated sensors, and the use of recycled aggregates or supplementary cementitious materials contributes to enhancing the sustainability and functionality of CTRC solutions.

Beyond material and process innovations, digital technologies are playing an increasingly significant role in shaping the CTRC market. Building Information Modeling (BIM) platforms are being adapted to incorporate CTRC components, enabling more accurate design, simulation, and project management. Computational design and simulation tools allow engineers to model the complex behavior of CTRC under various loading conditions, optimizing material usage and structural performance. Additionally, advancements in additive manufacturing (3D printing) are exploring the potential for creating intricate CTRC geometries and bespoke architectural elements, offering unprecedented design freedom. Robotic automation in the fabrication and installation of CTRC further enhances precision, accelerates construction, and ensures consistency, marking a transformative shift in the application of this advanced material.

Regional Highlights

- Europe: A leading region in CTRC research, development, and application, particularly Germany, Switzerland, and Italy. Driven by an extensive need for infrastructure repair, strong governmental support for sustainable construction, and well-established academic and industrial collaborations. High adoption in bridge strengthening, facade renovation, and historic preservation.

- North America: Experiencing robust growth due to significant investments in infrastructure revitalization and a growing awareness of long-term lifecycle benefits. The U.S. and Canada are focusing on enhancing the resilience of structures against natural disasters and corrosion, leading to increased adoption in seismic retrofitting and coastal infrastructure projects.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapid urbanization, massive new construction projects, and increasing adoption of advanced construction materials in countries like China, Japan, India, and South Korea. Emphasis on high-performance buildings, rapid infrastructure development, and sustainable solutions for urban expansion.

- Latin America: An emerging market with increasing interest in CTRC for new infrastructure development and addressing existing structural deficiencies. Countries like Brazil, Mexico, and Chile are exploring its potential for seismic reinforcement and durable construction solutions, though adoption rates are still nascent.

- Middle East and Africa (MEA): Growing demand for modern and sustainable infrastructure in line with economic diversification and Vision 2030 initiatives. Large-scale construction projects in the UAE, Saudi Arabia, and Qatar are evaluating CTRC for its aesthetic flexibility, lightweight properties, and resistance to harsh desert or marine environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbon Textile Reinforced Concrete Market.- SGL Carbon SE

- Hexcel Corporation

- Toray Industries Inc.

- Mitsubishi Chemical Corpora

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Carbon Textile Reinforced Concrete Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Carbon Textile Reinforced Concrete Market Statistics 2025 Analysis By Application (Bridge, Road, Building), By Type (Regular-Tow carbon fiber Textile Reinforced Concrete, Large-Tow carbon fiber Textile Reinforced Concrete), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Carbon Textile Reinforced Concrete Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Regular-Tow carbon fiber Textile Reinforced Concrete, Large-Tow carbon fiber Textile Reinforced Concrete), By Application (Bridge, Road, Commercial & Residential Building, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager