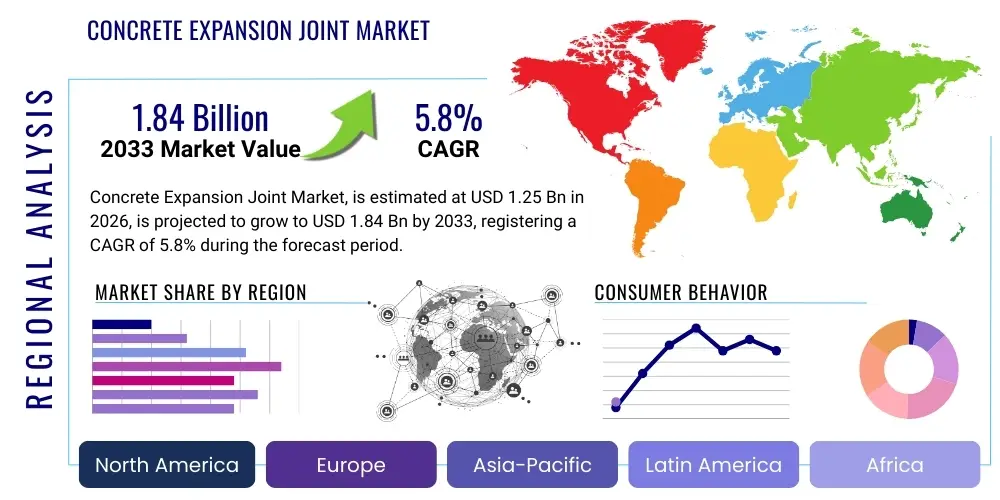

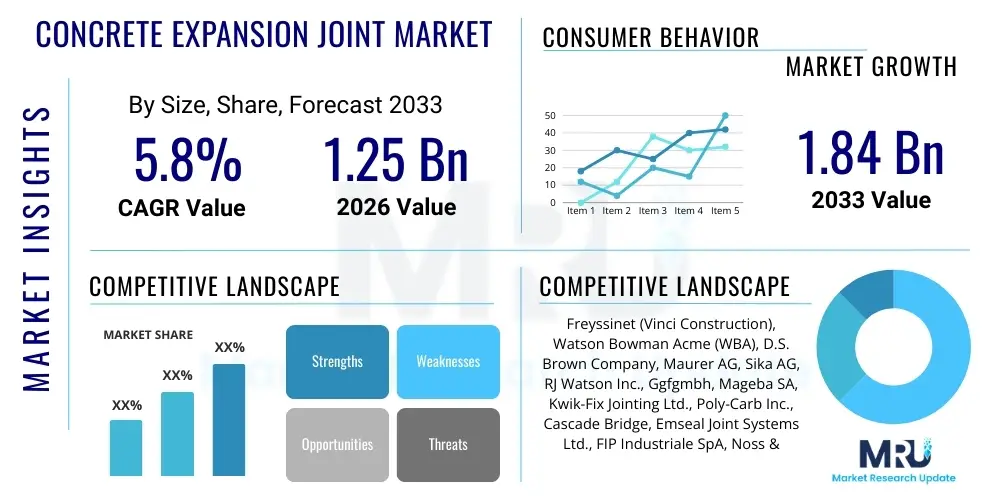

Concrete Expansion Joint Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434954 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Concrete Expansion Joint Market Size

The Concrete Expansion Joint Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.84 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally driven by accelerating global investments in critical civil infrastructure, including extensive bridge networks, high-speed rail corridors, and large-scale commercial developments, all of which necessitate robust solutions for managing structural movement caused by thermal variation, seismic activity, and concrete shrinkage. The indispensable role of expansion joints in ensuring the longevity and safety of these structures under varying environmental stresses solidifies the market's continuous expansion.

Concrete Expansion Joint Market introduction

The Concrete Expansion Joint Market encompasses the manufacturing, distribution, and installation of specialized structural components designed to absorb volumetric changes in concrete structures, preventing excessive stress accumulation that leads to cracking or structural failure. These joints are critical elements in bridges, parking garages, highways, dams, and large commercial slabs, functioning as a buffer against thermal expansion and contraction, differential settlement, and movement induced by live loads. The primary products include strip seal joints, compression seals, modular expansion joint systems, and various filler materials, all engineered to maintain a continuous, waterproof, and smooth transition surface while accommodating movement.

Major applications for concrete expansion joints span the entire construction ecosystem, with heavy civil infrastructure dominating demand. Specifically, Departments of Transportation (DOTs) globally rely on high-performance expansion joints for bridge decks and elevated roadways to ensure operational safety and minimize maintenance costs associated with water infiltration damage. Furthermore, the burgeoning demand for high-rise commercial buildings and mega-warehouses requires sophisticated joint systems to manage massive slab dimensions and control environmental forces. These joints not only facilitate necessary structural movement but also contribute significantly to the acoustic dampening and rider comfort in transportation infrastructure.

The market is primarily driven by escalating government expenditure on infrastructure modernization and rehabilitation projects, particularly in mature economies like North America and Europe, where aging assets require immediate overhaul. Concurrently, rapid urbanization and industrialization across the Asia Pacific region, specifically in China and India, are fueling new construction activities, creating substantial demand for structural components. Key benefits realized by adopting high-quality concrete expansion joints include enhanced structural durability, reduction in lifecycle maintenance expenses, improved water tightness to protect underlying components, and adherence to stringent modern engineering standards for resilience and safety.

Concrete Expansion Joint Market Executive Summary

The global Concrete Expansion Joint Market is characterized by robust business trends centered on material innovation and sustainability. A significant shift is observed toward high-performance, durable elastomeric and composite materials that offer superior resistance to corrosion, UV exposure, and traffic abrasion, thereby extending the service life of the joints and reducing environmental impact associated with frequent replacements. Furthermore, there is an increasing adoption of proprietary installation techniques and specialized equipment designed to accelerate project timelines and ensure precise fitting, which is crucial for achieving optimal long-term performance and meeting strict governmental timelines for infrastructure projects.

Regional trends indicate that the Asia Pacific (APAC) region remains the epicenter of market growth, driven by massive investments in new infrastructure, including high-speed rail networks and expansive public-private partnerships (PPPs) aimed at developing smart cities. North America and Europe, while growing at a slightly slower rate, maintain substantial market share due to critical infrastructure repair and maintenance backlogs, often focusing on advanced modular systems for quick bridge deck replacement. The Middle East and Africa (MEA) exhibit burgeoning potential, spurred by large-scale construction projects related to urbanization and preparation for global events, demanding joints capable of handling extreme temperature variations typical of desert environments.

Segment trends highlight the dominance of the bridge segment within applications, mandating highly resilient modular joints capable of accommodating substantial movement volumes. In terms of product type, the demand for strip seal joints remains strong due to their cost-effectiveness and proven performance, although the high-end market is increasingly favoring specialized seismic and finger joint systems for critical, high-movement structures. The long-term outlook emphasizes the integration of smart technologies, such as embedded sensors for monitoring joint condition and movement, transitioning the industry towards proactive maintenance and predictive analytics, which will shape future procurement specifications.

AI Impact Analysis on Concrete Expansion Joint Market

User inquiries regarding AI's influence in the concrete expansion joint sector frequently revolve around predictive maintenance schedules, optimizing material usage in complex joint designs, and automating quality control during installation and manufacturing. Users are keen to understand if AI-driven simulations can accurately model the long-term performance of different joint types under highly variable climatic and load conditions, thereby informing material selection and structural specifications. Concerns often focus on the required investment in sensor technology (IoT integration into joints) and the specialized expertise needed to interpret complex data streams generated by monitoring systems. The overarching expectation is that AI will significantly reduce unexpected joint failures, extend asset lifecycles, and streamline inventory management for maintenance agencies.

The direct application of Artificial Intelligence (AI) in the Concrete Expansion Joint Market is primarily focused on enhancing the life-cycle management of infrastructure assets. AI algorithms can analyze vast datasets collected from structural health monitoring (SHM) systems, including temperature, humidity, traffic load, and joint movement data, allowing maintenance teams to shift from calendar-based maintenance to condition-based and predictive maintenance. This proactive approach ensures that joints are repaired or replaced precisely when performance degradation is detected, minimizing costly failures, traffic disruptions, and extending the overall structural lifespan of bridges and highways. Furthermore, AI assists in optimizing logistics and inventory for replacement parts, predicting demand based on real-time weather patterns and structural usage.

In the manufacturing phase, Generative Design powered by AI is enabling engineers to optimize the geometric configuration of modular and finger joints, resulting in structures that are lighter, stronger, and more efficient in accommodating movement. AI models can simulate thousands of load cases and environmental scenarios far quicker than traditional finite element analysis (FEA), identifying potential stress concentration points and allowing for corrective design modifications before prototyping begins. This technological integration not only enhances product reliability but also drives down material waste, aligning with broader industry goals for sustainable and efficient construction practices.

- AI-powered Predictive Maintenance: Utilizes sensor data (IoT) embedded in joints to forecast failure points and schedule repairs proactively.

- Optimized Material Composition: Machine learning models analyze material performance data to suggest optimal polymer and metal alloy blends for extreme conditions.

- Generative Joint Design: AI algorithms assist in creating complex, movement-accommodating geometries for modular systems, maximizing efficiency and minimizing weight.

- Automated Quality Control (Manufacturing): Computer vision systems inspect seals and joint profiles during production, ensuring adherence to tight tolerance specifications.

- Resource Allocation Optimization: AI predicts maintenance needs across extensive road networks, optimizing crew deployment and spare parts inventory.

DRO & Impact Forces Of Concrete Expansion Joint Market

The dynamics of the Concrete Expansion Joint Market are dictated by strong drivers rooted in global infrastructure necessity, tempered by specific restraints related to installation complexity and material costs, while abundant opportunities exist in innovation and retrofitting. The primary driving force is the global commitment to massive civil infrastructure programs, particularly concerning bridge repair and highway expansion, which mandate the use of high-quality expansion joints for safety and compliance. Restraints, conversely, include the high capital cost associated with complex modular systems and the need for specialized labor and precise installation, where errors can lead to premature joint failure. Opportunities arise from developing smart, sensor-integrated joints and leveraging the vast retrofitting requirements of aging structures in developed regions. These forces collectively propel market expansion while emphasizing quality and technological advancement.

Drivers: Significant growth is propelled by escalating governmental spending on road and bridge infrastructure maintenance and new construction, particularly post-COVID-19 stimulus packages focusing on modernizing outdated transportation networks. Furthermore, the increasing global awareness of seismic activity and its impact on large structures necessitates the adoption of specialized, high-performance expansion joints capable of accommodating substantial multi-directional movement without compromising structural integrity. Strict regulatory frameworks, setting high standards for durability, watertightness, and load capacity in critical public infrastructure, also mandate the use of certified expansion joint solutions, fueling demand for premium products.

Restraints: The market faces restraints primarily due to high installation costs and complexity, particularly for large, bespoke modular systems which require extensive planning, traffic management, and specialized contracting expertise. Material price volatility, especially for steel and high-grade elastomers, presents a challenge for manufacturers in maintaining competitive pricing and stable supply chains. Additionally, the long replacement cycle of concrete structures means that demand is often concentrated in maintenance waves rather than continuous, rapid new construction, leading to cyclical fluctuations in segment-specific demand.

Opportunities: Key opportunities lie in the growing market for smart expansion joints integrated with IoT sensors that provide real-time performance data for proactive maintenance, offering significant cost savings over the structure's lifetime. The demand for retrofitting and rehabilitation of existing, aging infrastructure—especially bridges built decades ago that now require modern, heavy-duty joint replacements—presents a stable and long-term revenue stream. Innovation in self-healing materials and noise-reducing joints also opens new high-value market niches focused on enhancing urban living quality and structural resilience.

Impact Forces: The market's stability is significantly impacted by macro-economic factors, primarily interest rates and government budget allocations for infrastructure, which directly correlate with project commencement speed. Technological advancements, particularly in composite materials, disrupt traditional steel-based joint manufacturing, offering lighter and corrosion-resistant alternatives. Environmental regulations, emphasizing sustainable construction and reducing material waste, influence manufacturers to adopt eco-friendly production processes and recyclable joint components, reshaping the competitive landscape and product offering.

Segmentation Analysis

The Concrete Expansion Joint Market is systematically segmented based on Product Type, Material Type, Application, and End-Use, providing a comprehensive view of market dynamics and targeted opportunities. Product segmentation includes traditional categories such as strip seals and compression seals, alongside more complex high-performance systems like modular and finger joints, each catering to different levels of movement accommodation and traffic volume. The selection of the appropriate product type is fundamentally driven by the structural requirements of the project, specifically the anticipated movement range and the required level of watertightness and durability under heavy traffic loads.

Material segmentation is crucial, distinguishing between metal-based systems (primarily steel for modular joints), elastomeric materials (rubber and specialized polymers for seals and glands), and composite materials (used increasingly for lightweight and corrosion-resistant applications). The trend favors advanced elastomers due to their superior elasticity and longevity, especially in bridge applications where exposure to de-icing chemicals is severe. Application-wise, the market is heavily skewed towards transportation infrastructure, encompassing bridges, highways, and tunnels, which require the most durable and large-scale joint solutions, followed by commercial and industrial flooring where smaller, aesthetic joints are prioritized.

Further granularity is achieved through end-use segmentation, separating demand drivers between governmental bodies (Department of Transportation, Public Works) responsible for public infrastructure, and private entities (Commercial Developers, Industrial Facility Owners) focused on buildings and private campuses. This segmentation allows manufacturers to tailor their marketing and product development efforts, offering specialized, highly regulated products to government clients and more cost-effective, easily installed systems for commercial applications. The interplay between these segments determines the overall market growth profile and influences R&D investment towards next-generation joint systems.

- By Product Type:

- Strip Seal Joints

- Compression Seal Joints

- Modular Expansion Joint Systems (MEJS)

- Finger Joints

- Gland/Seal Systems

- Asphaltic Plug Joints

- By Material Type:

- Steel/Metal

- Elastomeric/Rubber

- Composite Materials

- Polyurethane/Epoxy Fillers

- By Application:

- Bridges and Viaducts (Dominant Segment)

- Highways and Roads

- Parking Structures

- Commercial Buildings and Industrial Flooring

- Tunnels and Underground Structures

- Dams and Water Retaining Structures

- By End-Use Sector:

- Government (Public Infrastructure)

- Commercial and Residential

- Industrial

- By Movement Capacity:

- Low Movement Joints (<50mm)

- Medium Movement Joints (50mm - 150mm)

- High Movement Joints (>150mm)

Value Chain Analysis For Concrete Expansion Joint Market

The value chain for the Concrete Expansion Joint Market begins with the upstream procurement of raw materials, primarily high-grade structural steel, specialized elastomeric polymers (rubber compounds), and chemical additives necessary for manufacturing sealing elements. Suppliers are typically global commodity producers, and the stability of this upstream segment is highly dependent on global mining and petrochemical market fluctuations. Manufacturers focus on precision engineering and complex fabrication, particularly for modular expansion joint systems (MEJS) which require high tolerances and rigorous quality testing. Key activities at this stage include welding, vulcanization of seals, and assembly, often demanding substantial capital investment in specialized machinery and certification.

The core manufacturing process is followed by a sophisticated distribution channel structure. Direct sales models are prevalent for large governmental infrastructure projects (bridges, highways), where manufacturers engage directly with Departments of Transportation (DOTs) or primary contractors to provide customized, highly engineered solutions and installation supervision. This direct channel ensures strict quality control and technical compliance. Conversely, for standardized products used in commercial building slabs or parking garages, the indirect channel utilizing specialized construction distributors and structural material suppliers is more common, ensuring broad market penetration and timely delivery to smaller construction sites.

The downstream segment involves specialized civil engineering contractors and installation teams who execute the physical integration of the joints into the concrete structure. This phase is crucial as the performance and longevity of the joint are highly sensitive to correct installation procedures, including proper anchoring, alignment, and seal placement. End-users, such as public works authorities and large commercial developers, ultimately drive the demand specifications, placing significant emphasis on durability, low noise emission, and guaranteed service life, thereby maintaining pressure on the entire value chain to adhere to high-performance standards and robust after-sales support.

Concrete Expansion Joint Market Potential Customers

The Concrete Expansion Joint Market serves a diverse yet highly specialized clientele, primarily comprising entities responsible for designing, building, and maintaining large-scale structures that are susceptible to movement. The most substantial segment of potential customers is governmental and quasi-governmental agencies, specifically national and regional Departments of Transportation (DOTs), Ministry of Public Works, and highway authorities. These bodies are the key buyers for high-specification, heavy-duty joint systems required for critical infrastructure such as major bridges, elevated roadways, and national highway systems. Their purchasing decisions are driven by strict regulatory compliance, long-term performance guarantees, and the need for seismic and water-tight capabilities.

Another major customer segment consists of large civil engineering and construction firms that operate as the primary contractors for large infrastructure projects (e.g., Bechtel, Vinci Construction). While not the ultimate end-users, these firms purchase the expansion joints on behalf of the asset owners and are crucial decision-makers regarding product selection, focusing on ease of installation, timely supply, and adherence to project budget constraints. Suppliers often engage with these firms early in the design phase to secure product specification and inclusion in the final Bills of Quantities (BoQs).

The commercial and industrial sector forms the third significant group, including commercial real estate developers, airport authorities, port operators, and owners of massive industrial flooring (e.g., logistics hubs and manufacturing plants). For these customers, the focus often shifts toward aesthetic considerations (flush mounting), fast installation, and joints designed to handle high point loads from forklifts or heavy machinery. Their needs typically involve lower-movement joints but demand high chemical resistance and durability against non-vehicular wear, representing a stable, albeit less volatile, segment of the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.84 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Freyssinet (Vinci Construction), Watson Bowman Acme (WBA), D.S. Brown Company, Maurer AG, Sika AG, RJ Watson Inc., Ggfgmbh, Mageba SA, Kwik-Fix Jointing Ltd., Poly-Carb Inc., Cascade Bridge, Emseal Joint Systems Ltd., FIP Industriale SpA, Noss & Sohn GmbH, Unison Joints Pty Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Concrete Expansion Joint Market Key Technology Landscape

The technology landscape within the Concrete Expansion Joint Market is rapidly evolving, driven by the need for enhanced durability, reduced maintenance, and improved structural resilience. A major focus area is the development and commercialization of high-performance elastomeric materials, such as advanced EPDM and specialized polymers, which offer superior resistance to harsh environmental elements like UV radiation, ozone, and chemical attacks from de-icing salts. These materials ensure that the primary sealing element retains its flexibility and water-tightness over extended periods, minimizing the risk of water infiltration that severely damages underlying bridge bearings and sub-structures. Manufacturers are investing heavily in compounding techniques to achieve materials that can withstand extremely low and high temperatures without cracking or softening.

Another transformative technology is the integration of Smart Expansion Joints, which incorporate embedded sensors, often based on fiber optics or piezoelectric materials, to create a Structural Health Monitoring (SHM) system. These sensors continuously track critical performance parameters, including joint movement (opening/closing), temperature, and vibration induced by traffic loads. The data collected is transmitted wirelessly to central management systems, allowing infrastructure owners to assess the joint's condition in real-time. This transition towards IoT-enabled infrastructure components facilitates condition-based maintenance, drastically lowering the overall lifecycle cost and increasing public safety by identifying potential issues before they escalate into structural failures.

Furthermore, innovations in installation methodology are improving product efficiency. Rapid-set polymer concrete and specialized anchor systems are being developed to significantly reduce the curing time required for joint installation and replacement. This acceleration is crucial for minimizing traffic disruption on high-volume highways and bridges, addressing a major operational challenge for transportation authorities globally. Modular Expansion Joint Systems (MEJS) are becoming lighter and more customizable through advanced manufacturing techniques like precision CNC machining, enabling quicker, more accurate, and less disruptive field installation while accommodating higher movement ranges necessary for seismic-prone regions and long-span bridges.

Regional Highlights

The Concrete Expansion Joint Market exhibits significant regional variation in demand drivers, product preferences, and growth rates, largely reflecting differences in infrastructure age, regulatory standards, and economic development cycles. These regional markets are critical to global performance, with specific countries driving substantial investment and technological adoption based on their unique needs. Understanding these regional dynamics is essential for strategic market planning.

Asia Pacific (APAC) is the undisputed leader in market growth, propelled by unprecedented levels of public and private investment in massive infrastructure development projects, especially in China, India, and Southeast Asian nations. The region’s rapid urbanization demands new expressways, high-speed rail lines, and expansive metropolitan transit systems, generating immense demand for all types of expansion joints, particularly cost-effective strip seals and increasing demand for specialized modular joints for signature bridges. The primary growth driver here is new construction rather than maintenance, although rehabilitation demand is rapidly emerging as initial projects mature.

North America (NA) represents a mature but stable market characterized by high demand for maintenance, repair, and rehabilitation (MR&R) projects. The United States and Canada face critical needs to upgrade aging bridge infrastructure, much of which exceeds its intended service life. Demand in NA is focused on high-performance, robust modular joints and specialized seismic solutions that comply with stringent state Department of Transportation (DOT) standards. The market here emphasizes quality, longevity, and ease of installation to minimize lane closure times, leading to a premium on technologically advanced and highly durable products.

Europe demonstrates steady growth, driven primarily by rehabilitation of existing road networks and regulatory harmonization across the European Union (EU) related to infrastructure safety and noise reduction. European standards often push for innovation in low-noise expansion joints (e.g., specialized asphaltic plug systems) suitable for dense urban areas. Germany, France, and the UK are key markets, emphasizing sustainability and demanding certified products that meet Eurocodes for structural stability and fire resistance, driving preference towards high-quality, engineered solutions from established local manufacturers.

The Middle East and Africa (MEA) region shows high, localized growth, especially within the Gulf Cooperation Council (GCC) countries (Saudi Arabia, UAE) due to ambitious mega-projects (e.g., NEOM, Dubai infrastructure upgrades). The demand here is for joints capable of handling extreme heat fluctuations and often specialized applications like large-scale airport infrastructure. Africa's market remains fragmented but holds long-term potential tied to future continental infrastructure development initiatives, focusing currently on basic, durable systems for road networks.

- Asia Pacific (APAC): Key drivers are large-scale new construction, high-speed rail development, and rapid urbanization; primary countries include China, India, and Japan.

- North America (NA): Driven by critical infrastructure repair and rehabilitation (MR&R); strong demand for seismic-grade and modular joints, concentrated in the US and Canada.

- Europe: Focus on sustainability, noise-reduction technology, and compliance with high EU structural standards; major markets are Germany, UK, and France.

- Latin America (LATAM): Growth tied to national road network upgrades and resource extraction infrastructure; market prone to economic volatility but showing potential in Brazil and Mexico.

- Middle East & Africa (MEA): High growth driven by specific regional mega-projects and demand for products resilient to extreme climate conditions (heat and sand).

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Concrete Expansion Joint Market.- Freyssinet (Vinci Construction)

- Watson Bowman Acme (WBA)

- D.S. Brown Company

- Maurer AG

- Sika AG

- RJ Watson Inc.

- Ggfgmbh

- Mageba SA

- Kwik-Fix Jointing Ltd.

- Poly-Carb Inc.

- Cascade Bridge

- Emseal Joint Systems Ltd.

- FIP Industriale SpA

- Noss & Sohn GmbH

- Unison Joints Pty Ltd.

- Pohlman Company

- WJ Worldwide

- Shandong Juhong Machinery Equipment Co., Ltd.

- KAP Concrete Repair & Restoration

- COSME International

Frequently Asked Questions

Analyze common user questions about the Concrete Expansion Joint market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a concrete expansion joint?

The primary function is to safely absorb thermal expansion and contraction, shrinkage, and structural movement (including seismic activity) within large concrete structures like bridges and highways. This prevents stress build-up, cracking, and eventual structural failure, ensuring long-term integrity and safety.

Which type of expansion joint is best suited for high-movement bridge applications?

Modular Expansion Joint Systems (MEJS) or Finger Joints are typically best for high-movement bridge applications (>150mm). MEJS offer robust, multi-cellular support and accommodate large, multi-directional displacements while maintaining traffic load capacity and excellent watertightness.

How does the integration of smart technology benefit expansion joint maintenance?

Smart technology, through embedded IoT sensors, allows for Structural Health Monitoring (SHM) by providing real-time data on joint movement, temperature, and wear. This enables predictive maintenance scheduling, reducing unexpected failures, minimizing traffic downtime, and optimizing maintenance budget allocation based on actual condition rather than fixed timelines.

What materials are commonly used in modern, high-performance expansion joints?

Modern, high-performance joints utilize structural steel for load-bearing elements, advanced elastomeric polymers (such as specialized EPDM or neoprene) for seals and glands to ensure durability and chemical resistance, and increasingly, composite materials for corrosion resistance and reduced weight.

Which region currently leads the global demand for concrete expansion joints?

The Asia Pacific (APAC) region currently leads global demand due to intense investment in new infrastructure projects, including high-speed rail, major highways, and rapid urbanization across economies like China and India. North America and Europe, however, maintain high demand driven by critical rehabilitation and repair projects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Concrete Expansion Joint Fillers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Concrete Expansion Joint Market Size Report By Type (Asphalt Expansion Joint, Foam Expansion Joint, Rubber Expansion Joint, Others), By Application (Buildings, Roads , Bridges , Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Concrete Expansion Joint Fillers Market Statistics 2025 Analysis By Application (Buildings, Roads, Bridges), By Type (Asphalt Expansion Joint, Foam Expansion Joint, Rubber Expansion Joint, Cork Expansion Joint), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager