Cubic Boron Nitride Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440007 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Cubic Boron Nitride Market Size

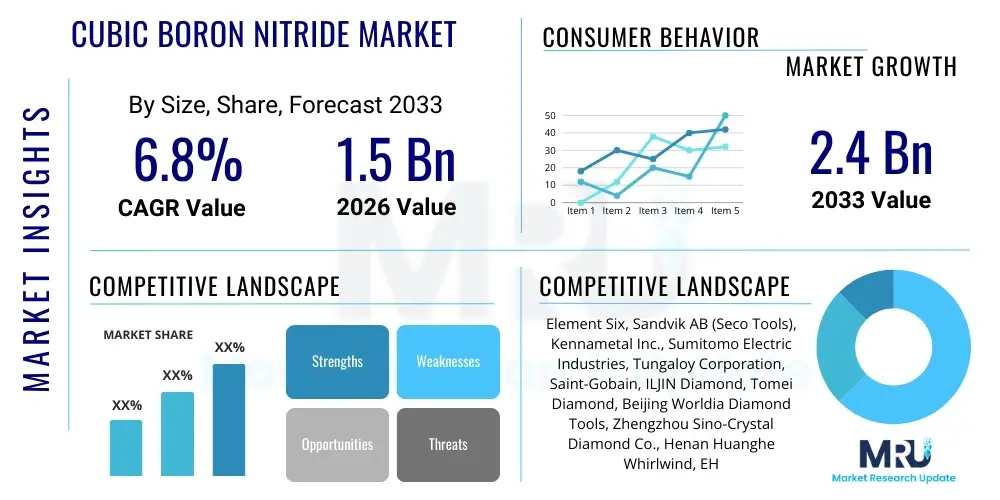

The Cubic Boron Nitride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 3.10 billion by the end of the forecast period in 2033.

Cubic Boron Nitride Market introduction

The Cubic Boron Nitride (cBN) market encompasses the production, distribution, and application of a synthetic superabrasive material renowned for its exceptional hardness, second only to diamond. Developed under high-pressure, high-temperature conditions, cBN possesses superior thermal stability and chemical inertness, making it indispensable for machining ferrous materials and nickel-based superalloys where diamond would chemically react. Its unique properties allow for efficient and precise machining of hardened steels, cast irons, and various aerospace alloys, materials that are notoriously difficult to process with conventional abrasives, thereby extending tool life and improving surface finish.

The product, cBN, is typically available in various forms, including micro-powder, polycrystalline compacts (PcBN), and as coatings on cutting tools. These forms cater to a wide array of industrial applications. Major applications include grinding wheels for precision shaping, cutting tools for high-speed material removal, honing stones for fine finishing, and polishing pastes. The primary benefits of utilizing cBN include significantly enhanced productivity, extended tool longevity, superior workpiece quality, and the ability to machine hard-to-cut materials that are critical in modern engineering. Its resistance to high temperatures and chemical stability with ferrous metals differentiates it from other abrasives, allowing for dry machining processes in many cases.

Driving factors for the growth of the cBN market are deeply rooted in the increasing global demand for high-performance components across various industries. The automotive sector, particularly with the advent of electric vehicles (EVs) and their stringent requirements for lightweight and durable components, relies heavily on cBN for machining. Similarly, the aerospace industry's continuous innovation in superalloys for jet engines and structural parts drives demand. Furthermore, the general machinery manufacturing sector, requiring precision tools for complex molds, dies, and gears, contributes significantly. The pursuit of enhanced manufacturing efficiency, reduced operational costs, and the development of advanced materials that necessitate sophisticated machining solutions continue to propel the cBN market forward.

Cubic Boron Nitride Market Executive Summary

The Cubic Boron Nitride (cBN) market is characterized by several dynamic business trends, including a growing emphasis on research and development to enhance cBN's properties and expand its applications. Manufacturers are increasingly investing in advanced synthesis technologies to produce larger, purer cBN crystals and more robust polycrystalline cBN (PcBN) compacts. There is also a notable trend towards consolidation within the industry, as larger players acquire specialized manufacturers to broaden their product portfolios and geographical reach. Furthermore, sustainability initiatives are influencing product development, with a focus on tools that offer longer lifespans and enable more efficient, resource-friendly machining processes, aligning with Industry 4.0 principles for optimized production environments.

Regionally, the market exhibits varied growth trajectories, with Asia-Pacific emerging as the dominant force, primarily driven by robust manufacturing growth in countries like China, India, Japan, and South Korea. These nations are experiencing significant expansion in their automotive, aerospace, and general industrial sectors, which are major consumers of cBN tools. North America and Europe maintain their positions as mature markets, characterized by high-value applications and a strong focus on advanced manufacturing techniques, particularly in precision engineering and high-performance sectors. Emerging markets in Latin America and the Middle East & Africa are also showing promising potential, fueled by ongoing industrialization and infrastructure development projects that necessitate sophisticated machining solutions.

Segment-wise, the grinding wheels category continues to hold the largest share within the cBN market, reflecting its critical role in precision finishing operations across numerous industries. However, the demand for cBN inserts and coatings is experiencing accelerated growth, driven by the increasing adoption of high-speed cutting applications for advanced alloys. The automotive industry remains the largest end-use segment, propelled by the complex machining requirements for engine components, braking systems, and particularly the intricate parts of electric vehicle powertrains. The aerospace and defense sector also represents a high-growth segment, with continuous innovation in superalloy materials necessitating the superior performance of cBN cutting and grinding tools for turbine blades and structural components.

AI Impact Analysis on Cubic Boron Nitride Market

Users are keenly interested in understanding how Artificial Intelligence (AI) will revolutionize various facets of the Cubic Boron Nitride market, from initial design and manufacturing to application and maintenance. Common questions revolve around AI's ability to optimize the design of cBN tools for specific performance metrics, predict tool wear and remaining useful life, and enhance the overall efficiency and precision of machining processes. There is also significant curiosity regarding AI's role in accelerating the discovery of novel cBN material compositions or bonding technologies, and how it might facilitate the development of customized cBN solutions tailored to unique industrial challenges. Ultimately, users anticipate that AI will lead to more intelligent, durable, and cost-effective cBN tools, contributing to reduced operational expenditures and superior machining outcomes across various high-value applications.

- Predictive analytics for optimizing cBN tool wear and extending service life.

- AI-driven simulation for enhanced cBN tool design and performance prediction.

- Real-time process control in cBN synthesis and manufacturing for quality improvement.

- Automated quality inspection and defect detection in cBN products.

- Optimized tool path generation and machining parameters for cBN tools in CNC applications.

- Accelerated material discovery for novel cBN compositions and bonding technologies.

- Customized cBN tool recommendations based on specific material and application requirements.

- Supply chain optimization for cBN raw materials and finished products, enhancing efficiency.

- Development of smart cBN tools with integrated sensors for performance monitoring.

DRO & Impact Forces Of Cubic Boron Nitride Market

The Cubic Boron Nitride (cBN) market is significantly influenced by a confluence of drivers, restraints, and opportunities, all contributing to its evolving impact forces. A primary driver is the escalating global demand for high-precision machining of increasingly hard-to-machine materials, such as hardened steels, nickel-based superalloys, and specific cast irons, which are integral to modern industrial applications. Industries like aerospace and defense, automotive (especially electric vehicle components), and medical devices are continuously pushing material boundaries, creating an imperative for superabrasives like cBN. Furthermore, continuous technological advancements in cBN tool manufacturing, including improved synthesis processes, advanced bonding technologies, and sophisticated tool geometries, enhance performance and broaden applicability, thereby propelling market growth.

Despite the strong growth drivers, the cBN market faces several restraints. The high initial cost of cBN tools compared to conventional abrasives or even some diamond tools can be a barrier for adoption, particularly for smaller enterprises or in regions with constrained budgets. Intense competition from alternative superabrasives, such as advanced diamond tools, and emerging ceramic materials also poses a challenge, as these alternatives sometimes offer competitive performance in specific applications or at lower price points. Additionally, the complexities inherent in cBN synthesis and processing, requiring high-pressure, high-temperature (HPHT) conditions, demand significant capital investment and specialized expertise, which can limit new market entrants. Global economic slowdowns or geopolitical uncertainties can also impact manufacturing output, consequently dampening demand for industrial tools.

Opportunities within the cBN market are substantial and diverse. There is significant potential for expansion into new, emerging applications within sectors such as renewable energy (e.g., wind turbine components), additive manufacturing post-processing, and advanced electronics, where ultra-precise and efficient material removal is critical. The ongoing development of more cost-effective cBN variants or hybrid abrasive tools that combine cBN with other materials could significantly lower entry barriers and expand market reach. Furthermore, increasing industrialization and manufacturing growth in emerging economies present untapped markets for cBN products. The drive towards greater automation and digitalization in manufacturing also favors cBN tools due to their consistency and ability to withstand demanding conditions, making them ideal for automated production lines.

Segmentation Analysis

The Cubic Boron Nitride (cBN) market is meticulously segmented to provide a comprehensive understanding of its varied applications, product forms, and end-user industries. This segmentation allows for targeted market analysis, revealing specific growth drivers and challenges within each category. The market is primarily bifurcated by the type of cBN product, distinguishing between micro-powders, solid compacts, and coatings, each serving distinct functional requirements. Furthermore, it is categorized by its diverse applications, which include precision grinding, high-efficiency cutting, fine honing, and meticulous polishing operations. Lastly, the market is differentiated by the predominant end-use industries that leverage cBN technology, reflecting the broad utility of this superabrasive material across critical manufacturing sectors.

- By Type:

- cBN Micro-powder

- cBN Compacts (Polycrystalline cBN - PcBN)

- cBN Coatings

- By Application:

- Grinding

- Cutting

- Honing

- Polishing

- Lapping

- By End-use Industry:

- Automotive (Engine components, transmission systems, braking components, EV parts)

- Aerospace & Defense (Turbine blades, landing gear components, structural elements)

- Industrial Manufacturing (Molds, dies, gears, bearings, machine tools)

- Energy (Oil & Gas drilling, wind turbine components, power generation)

- Medical & Dental (Surgical instruments, orthopedic implants, dental prosthetics)

- Others (Electronics, Gemstone processing, Tool & Die manufacturing)

Value Chain Analysis For Cubic Boron Nitride Market

The value chain for the Cubic Boron Nitride (cBN) market is intricate, beginning with upstream activities that encompass the sourcing and processing of raw materials. This segment involves suppliers of elemental boron, nitrogen, and various catalysts or binders essential for the synthesis process. Additionally, it includes manufacturers of the specialized high-pressure, high-temperature (HPHT) equipment required to transform hexagonal boron nitride (hBN) into its cubic superabrasive form. Extensive research and development efforts are concentrated upstream to innovate precursor materials and optimize the energy-intensive synthesis processes, aiming for higher purity, larger crystal sizes, and more cost-effective production, which are critical for the quality and performance of the final cBN products.

Midstream activities primarily involve the conversion of cBN raw materials into various forms suitable for industrial applications. This includes processes like crushing and sizing cBN crystals into micro-powders, sintering cBN grains with ceramic or metallic binders to produce polycrystalline cBN (PcBN) compacts, and applying cBN as thin-film coatings onto substrates through PVD or CVD techniques. These intermediate products are then supplied to tool manufacturers who integrate cBN into finished goods such as grinding wheels, cutting inserts, honing stones, and lapping compounds. This stage is crucial for ensuring the mechanical integrity, thermal stability, and abrasive performance of the cBN tools, requiring specialized engineering and bonding technologies to meet diverse application demands.

The downstream segment of the value chain focuses on the distribution and end-use of cBN products. Finished cBN tools are distributed through a combination of direct sales channels to large industrial clients and specialized distributors who cater to a broader market, including small and medium-sized enterprises. Technical sales teams play a vital role in providing application-specific expertise and support to end-users, ensuring optimal performance and troubleshooting. Direct sales are often preferred for highly customized or large-volume orders from key strategic customers in sectors like automotive and aerospace, where close collaboration is essential. Indirect channels, leveraging established networks of industrial suppliers and sometimes online platforms, facilitate wider market penetration, particularly for standard products or smaller-scale requirements, ensuring accessibility across diverse geographical regions and industrial applications.

Cubic Boron Nitride Market Potential Customers

The primary potential customers for Cubic Boron Nitride (cBN) products are diverse industrial entities that require advanced machining solutions for materials deemed challenging with conventional abrasives. These include manufacturers operating within the automotive sector, which utilizes cBN extensively for finishing hardened steel engine components, transmission parts, and brake systems, as well as for machining high-strength alloys used in electric vehicle drivetrains. The aerospace and defense industries represent another significant customer base, relying on cBN tools for precision grinding and cutting of nickel-based superalloys, titanium alloys, and other heat-resistant materials crucial for jet engine components, turbine blades, and landing gear, where material integrity and precision are paramount.

Beyond these major segments, the general industrial manufacturing sector forms a broad and vital customer segment. This includes companies involved in producing high-precision molds and dies, gears, bearings, and various machine tool components that demand superior surface finish and dimensional accuracy. Manufacturers of heavy machinery, agricultural equipment, and mining tools also utilize cBN for enhancing the durability and performance of their critical parts. Furthermore, the medical device industry is an emerging customer group, requiring cBN for the precise machining of stainless steel surgical instruments, orthopedic implants, and other biomedical components, where extreme precision and biocompatibility are essential. Research and development institutions also represent potential customers, using cBN for advanced material studies and prototype development.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.10 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Element Six, Sandvik Hyperion, Tomei Diamond, Sumitomo Electric, Momentive Technologies, Zhengzhou Xinxiang Superhard Material, Sino-Crystal Diamond, ILJIN Diamond, Ceratizit, Kennametal, Kyocera, Mitsubishi Materials, Mapal, LMT Tools, Reishauer, Tyrolit, Noritake, Saint-Gobain Abrasives, Dymet Alloys, Beijing Worldia |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cubic Boron Nitride Market Key Technology Landscape

The technological landscape of the Cubic Boron Nitride (cBN) market is continuously evolving, driven by the need for enhanced performance, cost-effectiveness, and broader application range. A critical area of advancement lies in the high-pressure, high-temperature (HPHT) synthesis process itself, where researchers are striving to achieve larger, purer cBN single crystals with fewer defects, as well as optimizing the process for increased yield and reduced energy consumption. Innovations also include the development of novel catalyst systems and binder materials that enable the production of cBN variants with tailored properties, such as improved fracture toughness or specific thermal conductivity, extending their utility in diverse and demanding environments.

Beyond the fundamental synthesis, significant technological progress is observed in the manufacturing and integration of cBN into finished tools. This includes the development of advanced bonding technologies for cBN grinding wheels, encompassing vitrified, resin, metal, and electroplated bonds, each optimized for different applications and workpiece materials. These bonding systems are crucial for securely holding the cBN abrasive particles and ensuring efficient material removal without premature degradation. Furthermore, advancements in physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques allow for the creation of high-performance cBN coatings on cutting tool inserts, significantly enhancing their wear resistance, hardness, and chemical stability, enabling higher cutting speeds and longer tool life in challenging machining operations.

The market also benefits from innovations in tool design and digital manufacturing. Micro-structuring techniques are being applied to cBN tools to create intricate geometries and optimize chip evacuation, reducing cutting forces and improving surface finish. The integration of additive manufacturing principles is exploring the potential for producing complex cBN tool forms or hybrid tools with multi-material compositions. Moreover, the adoption of Industry 4.0 technologies, such as digital twin simulation, predictive analytics, and real-time process monitoring, is revolutionizing cBN tool manufacturing. These digital tools allow for precise control over production parameters, enable proactive maintenance, and facilitate rapid prototyping and testing of new cBN tool designs, leading to greater efficiency, reduced waste, and accelerated innovation cycles across the entire value chain.

Regional Highlights

- North America: This region is a mature market characterized by advanced manufacturing capabilities, particularly in the aerospace and defense, automotive (including EV production), and precision machinery sectors. Strong R&D investments and a focus on high-performance materials drive demand for cBN in high-value applications, with the United States being a key contributor.

- Europe: A significant market with a robust industrial base, especially in Germany, Italy, and the UK, focusing on automotive, industrial machinery, and medical device manufacturing. The region emphasizes efficiency, automation, and sustainable production, fostering the adoption of advanced cBN tools for precision and longevity.

- Asia Pacific (APAC): The leading and fastest-growing region, driven by rapid industrialization, expanding manufacturing sectors, and increasing automotive production in countries like China, India, Japan, and South Korea. These nations are both major producers and consumers of cBN, fueled by large-scale infrastructure projects and a growing demand for consumer electronics and industrial equipment.

- Latin America: An emerging market for cBN, with growth primarily in the automotive and industrial sectors of Brazil and Mexico. Investments in manufacturing capabilities and infrastructure development are gradually increasing the demand for advanced abrasive solutions.

- Middle East and Africa (MEA): This region is witnessing a gradual increase in industrial activity, particularly in the construction, energy (oil and gas), and manufacturing sectors, especially in the GCC countries. While smaller, the market shows potential with ongoing diversification efforts and investments in local production capabilities that require sophisticated tooling.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cubic Boron Nitride Market.- Element Six

- Sandvik Hyperion

- Tomei Diamond

- Sumitomo Electric Industries Ltd.

- Momentive Technologies

- Zhengzhou Xinxiang Superhard Material Co. Ltd.

- Sino-Crystal Diamond Co. Ltd.

- ILJIN Diamond Co. Ltd.

- Ceratizit S.A.

- Kennametal Inc.

- Kyocera Corporation

- Mitsubishi Materials Corporation

- Mapal Dr. Kress KG

- LMT Tools

- Reishauer AG

- Tyrolit Schleifmittelwerke Swarovski K.G.

- Noritake Co. Ltd.

- Saint-Gobain Abrasives

- Dymet Alloys

- Beijing Worldia Diamond Tools Co. Ltd.

Frequently Asked Questions

What is Cubic Boron Nitride (cBN) and why is it important?

Cubic Boron Nitride (cBN) is a synthetic superabrasive material, second in hardness only to diamond. Its importance stems from its exceptional thermal stability and chemical inertness, making it ideal for machining hardened ferrous metals and superalloys that react chemically with diamond at high temperatures. It significantly improves precision, efficiency, and tool life in industrial applications.

What are the primary applications of cBN in industrial settings?

The primary applications of cBN include grinding (for precision shaping of hard materials), cutting (for high-speed material removal with inserts), honing (for fine finishing of bores), polishing, and lapping. These are crucial in industries such as automotive, aerospace, general manufacturing, and medical device production for processing hardened steels, cast irons, and nickel-based alloys.

How does cBN compare to industrial diamond as an abrasive material?

While both cBN and industrial diamond are superabrasives, cBN is preferred for machining ferrous metals (like steel and cast iron) and nickel or cobalt-based superalloys because diamond reacts chemically with these materials at high temperatures, leading to rapid wear. cBN exhibits superior chemical inertness and thermal stability in these applications, making it more effective and durable.

What key factors are driving the growth of the Cubic Boron Nitride market?

Key growth drivers include the increasing global demand for high-precision machining of difficult-to-cut materials across the automotive (especially EVs), aerospace, and defense industries. Continuous technological advancements in cBN synthesis and tool manufacturing, along with the pursuit of enhanced manufacturing efficiency and reduced operational costs, also propel market expansion.

What are the main challenges faced by the Cubic Boron Nitride market?

The primary challenges include the high initial cost of cBN tools compared to conventional abrasives, intense competition from alternative superabrasives like advanced diamond tools, and the inherent complexities and high capital investment required for cBN synthesis and processing. Economic fluctuations and supply chain vulnerabilities also pose significant market restraints.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Cubic Boron Nitride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Superabrasives Market Statistics 2025 Analysis By Application (Automotive, Aerospace and Defense, Building and Construction, Oil and Gas), By Type (Diamond Material, Cubic Boron Nitride Material, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Cubic Boron Nitride Abrasive Market Statistics 2025 Analysis By Application (Automotive, Machinery, Metal Fabrication, Electronics, Other), By Type (CBN Monocrystalline, CBN Micro Mist), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Superabrasive Market Statistics 2025 Analysis By Application (Automotive, Machinery, Metal Fabrication, Aerospace), By Type (Diamond, Cubic Boron Nitride (CBN), Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Hexagonal BN Market Statistics 2025 Analysis By Application (Hexagonal Boron Nitride Composite Ceramics, Preparation of Cubic Boron Nitride (CBN), Paint, Coatings and Lubricants Industry, Cosmetics Industry, Industrial Packaging), By Type (Premium Grade (PG), Customized Grade (CG), Standard Grade (SG)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager