Cyclohexyl Vinyl Ether Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438018 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Cyclohexyl Vinyl Ether Market Size

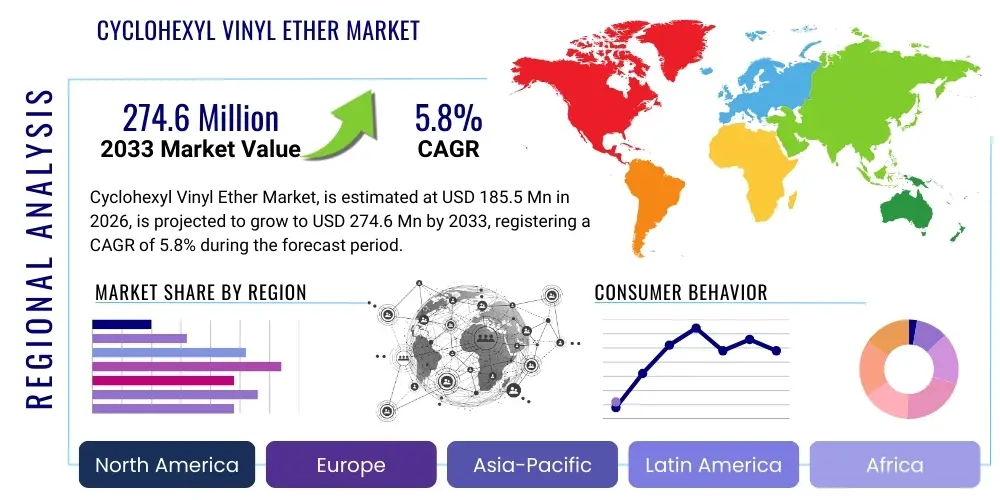

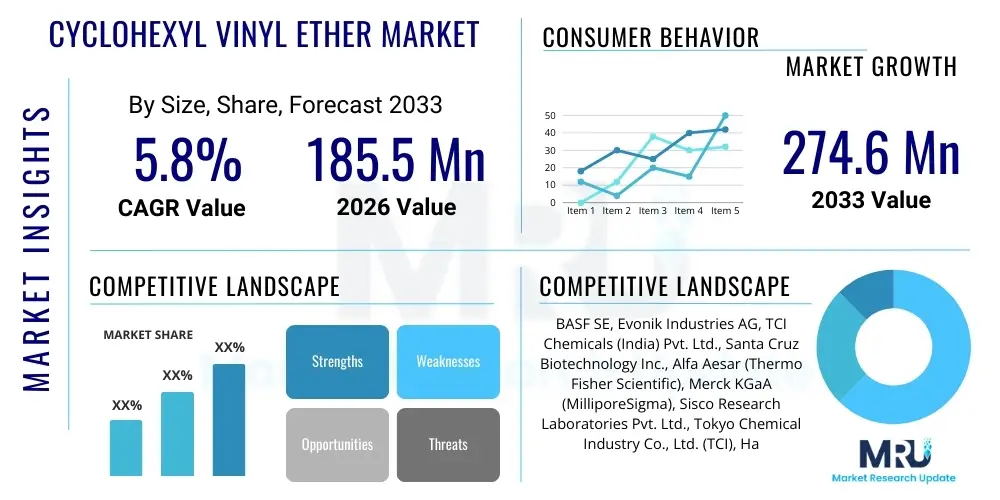

The Cyclohexyl Vinyl Ether Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $185.5 Million in 2026 and is projected to reach $274.6 Million by the end of the forecast period in 2033. This consistent expansion is primarily fueled by the increasing demand for high-performance, solvent-free coatings and adhesives, particularly within the automotive and electronics sectors where rapid curing technologies are mandatory for efficient manufacturing processes.

Cyclohexyl Vinyl Ether Market introduction

Cyclohexyl Vinyl Ether (CHVE) is a colorless, highly reactive chemical intermediate characterized by its vinyl ether functional group attached to a cyclohexyl moiety. This unique chemical structure enables CHVE to participate readily in cationic polymerization reactions, making it an indispensable component in specialty chemical synthesis. Its primary role in the industry is as a reactive diluent or intermediate monomer, substantially contributing to the performance characteristics of final polymer products, particularly those requiring fast curing speeds and excellent adhesion properties. Due to its volatility and reactivity, strict handling and synthesis protocols are necessary, positioning it as a specialized chemical product utilized almost exclusively in industrial settings.

The primary applications of CHVE center around its utility in UV-curable systems, specifically for coatings, inks, and adhesives. When incorporated into formulations, CHVE reduces viscosity, allowing for high-solids or 100% solids (solvent-free) formulations, which align with increasingly stringent environmental regulations targeting volatile organic compounds (VOCs). The benefits derived from using CHVE include enhanced adhesion to difficult substrates, improved hardness and scratch resistance of the cured film, and extremely rapid curing times under UV light, which drastically improves production throughput in continuous manufacturing lines, particularly in digital printing and sophisticated electronics assembly.

Key driving factors for the Cyclohexyl Vinyl Ether Market include the exponential growth of the global packaging and consumer electronics industries, both of which rely heavily on UV-cured materials for protective layers and functional adhesives. Furthermore, the increasing adoption of 3D printing and additive manufacturing techniques, where reactive vinyl ether monomers are often preferred for formulating specialty resins, further solidifies the demand trajectory. The shift towards sustainable and energy-efficient processing methods, like UV curing which consumes less energy than thermal curing, also acts as a significant long-term market propellant, positioning CHVE as a vital component in modern industrial chemistry.

Cyclohexyl Vinyl Ether Market Executive Summary

The Cyclohexyl Vinyl Ether market is experiencing robust growth driven by converging business trends, including the proliferation of solvent-free and high-solids formulations across various industries. A significant business trend involves the increased integration of CHVE into high-purity applications, specifically in the semiconductor and advanced display manufacturing sectors, where contaminants are severely restricted. This requires manufacturers to invest heavily in advanced purification technologies and stringent quality control protocols, leading to consolidation among top-tier suppliers capable of meeting these precise specifications. Furthermore, strategic partnerships between chemical suppliers and major coatings formulators are becoming essential to ensure a reliable supply chain for specialized products and co-develop next-generation UV-curable chemistries.

From a regional perspective, the Asia Pacific (APAC) region dominates the Cyclohexyl Vinyl Ether market, primarily due to the massive concentration of electronics manufacturing, automotive production, and general industrial coatings facilities in countries like China, South Korea, and Japan. This region exhibits both the highest volume consumption and the fastest growth rate, fueled by rapid industrialization and escalating consumer demand for durable goods requiring high-performance protective coatings. While North America and Europe remain key markets characterized by high-value, research-intensive applications and strict regulatory compliance standards, their growth is steadier, focusing more on substitution of traditional solvent-based systems rather than pure volume expansion.

Segment-wise, the high-purity grade segment is projected to exhibit the highest CAGR, reflective of its critical use in highly sensitive applications suchating as optical fibers, specialized medical devices, and semiconductor encapsulants, where chemical integrity is paramount. Application trends show the UV-curable coatings segment retaining the largest market share, but the use of CHVE as a polymer intermediate for synthesizing highly specialized resins, including those used in ion-exchange membranes or dental materials, is gaining traction. The market segments are generally resilient to economic fluctuations due to the essential nature of their end-use products, necessitating continuous innovation in polymerization techniques and formulation efficiency to maintain competitive advantage.

AI Impact Analysis on Cyclohexyl Vinyl Ether Market

Common user questions regarding AI's impact on the Cyclohexyl Vinyl Ether market typically revolve around optimizing synthesis efficiency, predicting product performance under varying environmental conditions, and automating complex supply chain logistics for highly reactive chemicals. Users are particularly interested in how Artificial Intelligence can minimize batch-to-batch variability and reduce the need for extensive physical experimentation in R&D labs when developing new UV-curable formulations incorporating CHVE. Key concerns include the high initial investment required for AI infrastructure and the necessity of high-quality, vast chemical reaction datasets needed to train effective predictive models relevant to specialty vinyl ether chemistry. Overall, the market expects AI to usher in an era of hyper-efficient production and accelerated material discovery, mitigating risks associated with handling highly reactive monomers.

The application of AI and machine learning (ML) is fundamentally transforming the R&D and manufacturing phases of specialty chemical production, including Cyclohexyl Vinyl Ether. In R&D, AI algorithms can rapidly screen millions of potential molecular structures and predict reaction pathways, thereby optimizing the yield and purity of CHVE synthesis, which is traditionally a complex and energy-intensive process. Furthermore, predictive maintenance models powered by ML are being deployed in synthesis reactors to anticipate equipment failures, ensuring continuous, safe operation and minimizing expensive downtime associated with processing hazardous, flammable intermediates. This enhanced operational efficiency is critical for maintaining competitiveness in a niche market where profit margins are dependent on production scale and consistency.

In the supply chain and quality control domains, AI significantly enhances responsiveness and reliability. Machine vision systems coupled with AI analyze spectroscopic data instantaneously during manufacturing to monitor purity levels, ensuring the product meets the stringent specifications required by electronics and medical end-users. Logistics optimization uses AI to forecast demand fluctuations more accurately, managing the inventory of CHVE—a substance requiring specific storage conditions—and minimizing transport risks. This analytical capability allows suppliers to implement just-in-time delivery systems for major industrial clients, substantially reducing the customer's holding costs and ensuring fresh, high-quality material is available precisely when needed for time-sensitive polymerization processes.

- Accelerated R&D through predictive modeling of CHVE reactivity and formulation stability.

- Optimization of complex chemical synthesis parameters to increase yield and reduce energy consumption.

- Enhanced quality control using machine learning for real-time spectroscopic purity verification.

- Improved supply chain logistics and demand forecasting for reactive chemical intermediates.

- Implementation of AI-driven predictive maintenance systems for synthesis equipment, boosting operational safety.

- Customized formulation development based on AI analysis of application-specific performance requirements.

DRO & Impact Forces Of Cyclohexyl Vinyl Ether Market

The Cyclohexyl Vinyl Ether market is subject to significant dynamics defined by strong environmental drivers coupled with technological constraints. The primary driver is the global mandate for sustainable chemistry, specifically the transition from solvent-based coatings to 100% solid, UV-curable systems, which significantly reduces VOC emissions. This push is strongly supported by technological advancements in UV lamp efficiency and polymerization photoinitiators, making CHVE-based systems increasingly viable for high-volume applications. However, restraints include the specialized and often proprietary synthesis process of high-purity CHVE, leading to high production costs and limited supplier diversity. The highly reactive nature of the monomer also presents considerable challenges in safe handling, storage, and transportation, necessitating expensive infrastructure and specialized training for market participants.

Opportunities for market expansion are centered on emerging high-growth technological sectors. The proliferation of advanced 3D printing technologies, particularly stereolithography and digital light processing, creates a significant demand for highly reactive monomers like CHVE that offer fast cure speeds and customizable mechanical properties. Furthermore, the burgeoning electric vehicle (EV) market requires new types of protective coatings and specialized encapsulants for battery components and sensitive electronic parts, which often utilize vinyl ether chemistry for enhanced thermal stability and moisture resistance. These high-value applications allow suppliers to command premium pricing, driving investment into further research and product line expansion within this niche chemical segment.

The impact forces shaping the market are heavily weighted by regulatory compliance and competitive intensity. Regulatory pressure, particularly from REACH in Europe and similar bodies globally, mandates stringent safety data and restricts certain potentially hazardous raw materials, indirectly favoring the use of cleaner, higher-performance alternatives like CHVE in approved formulations. Competitively, the market sees impact from alternatives such as acrylate and epoxy systems; while CHVE offers superior benefits in specific areas like cationic curing speed, competitive pricing and versatility of alternatives always exert pressure. Therefore, continuous innovation in catalyst technology and monomer purity are critical impact forces determining long-term success and market share retention.

Segmentation Analysis

The Cyclohexyl Vinyl Ether market is primarily segmented based on Purity Grade, Application, and End-Use Industry, reflecting the diverse and highly specialized requirements of its consumers. Purity grade segmentation distinguishes between High Purity (electronic and medical grade) and Industrial Grade, where the tolerance for residual impurities dictates suitability for sensitive electronic encapsulation versus general industrial coatings. Application segmentation focuses on the functional role of CHVE, predominantly covering its use in UV-Curable Coatings, Specialty Adhesives, and as a Polymer Intermediate. This structured segmentation allows manufacturers to align their production capabilities and quality assurance protocols with the exacting demands of their target customer base, ensuring that the right grade of material is matched to the specific polymerization or formulation requirement.

- By Purity Grade

- High Purity Grade (99.9%+)

- Industrial Grade (99.5% to 99.9%)

- By Application

- UV-Curable Coatings

- Specialty Adhesives & Sealants

- Polymer Intermediates (e.g., in synthesis of polyacetals or specialized resins)

- Reactive Diluents

- By End-Use Industry

- Coatings & Paints (Automotive, Wood, Metal)

- Electronics & Electrical (Encapsulants, Photoresists)

- Printing & Packaging (Inks, Overprint Varnishes)

- Medical & Dental

- Automotive

- By Region

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East & Africa (MEA)

Value Chain Analysis For Cyclohexyl Vinyl Ether Market

The value chain for Cyclohexyl Vinyl Ether begins with the upstream analysis involving the sourcing and production of key raw materials, primarily cyclohexanol and acetylene or ethylene, depending on the synthesis route (e.g., transvinylation or direct vinylation). These foundational chemicals are typically commodity items, yet their purity is paramount as residual impurities can significantly complicate the downstream synthesis of CHVE and negatively impact the final polymer performance. The primary challenge upstream lies in securing a stable, high-quality supply of these precursors, especially acetylene, which requires specialized handling. Manufacturers of CHVE must maintain rigorous control over their synthesis processes, often employing proprietary catalytic systems and multi-stage purification steps, making the manufacturing phase a high-value-add activity.

Midstream activities involve the synthesis, purification, and formulation of CHVE. Given the complexity and hazards associated with vinyl ether production, vertical integration or long-term supply contracts are common strategies used by large players to mitigate supply risk. After high-purity CHVE is produced, it moves through distribution channels which are highly specialized due to the chemical’s flammability and sensitivity to moisture and temperature. Direct distribution is often favored for high-volume customers in the coatings and electronics sectors, allowing for specialized handling and technical support. Indirect distribution, leveraging specialized chemical distributors, services smaller buyers and localized R&D facilities, ensuring broader market access while maintaining strict adherence to dangerous goods regulations.

The downstream segment encompasses the utilization of CHVE by end-users, mainly coatings formulators and specialty polymer manufacturers. These customers integrate CHVE into complex formulations to achieve specific performance characteristics, such as rapid curing or enhanced flexibility. The final value captured is significantly influenced by the technical support provided by CHVE suppliers, particularly in optimizing formulation parameters for specific application equipment (e.g., high-speed lithography or inkjet printing). The competitive advantage downstream is achieved not just through pricing, but primarily through consistent product quality and reliable technical partnership, ensuring the end product meets the required specifications for durability and regulatory compliance in high-stakes industries like aerospace or medical devices.

Cyclohexyl Vinyl Ether Market Potential Customers

The primary potential customers for Cyclohexyl Vinyl Ether are sophisticated industrial entities operating within sectors that necessitate rapid, efficient, and environmentally compliant coating and bonding solutions. These include major coatings formulators who specialize in high-performance surface treatments for the automotive and architectural sectors, where solvent emissions are increasingly regulated, driving the demand for 100% solid, UV-curable systems enabled by monomers like CHVE. Furthermore, large multinational manufacturers of consumer electronics and components represent a crucial buyer segment, using CHVE-based resins for encapsulation, dielectric layers, and protective varnishes on printed circuit boards (PCBs) and advanced display panels, demanding ultra-high purity grades.

Another significant cohort of buyers comprises specialty adhesive and sealant manufacturers. These companies require CHVE for formulating high-strength structural adhesives, pressure-sensitive tapes, and specialized sealants utilized in medical devices, dental materials, and critical assembly processes in the transportation industry. The unique cationic polymerization characteristics of CHVE allow these customers to achieve superior bond strengths and quick processing times that other monomer systems cannot easily replicate, justifying the higher material cost associated with this specialty chemical. These buyers often purchase in moderate bulk quantities and rely heavily on the supplier’s technical data and material safety handling expertise.

The final crucial potential customer group includes specialized polymer producers and chemical research & development institutions. Polymer producers leverage CHVE as a unique chemical intermediate for creating specialized block copolymers, high-refractive-index polymers, and novel resin systems used in advanced optics, ion-exchange applications, and additive manufacturing feedstock. Academic and corporate R&D laboratories purchase smaller quantities for experimental purposes, exploring new polymerization routes, catalyst systems, and emerging applications in areas such as renewable energy storage or advanced composite materials. These buyers prioritize product purity, detailed chemical analysis documentation, and reliable, small-batch supply capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $185.5 Million |

| Market Forecast in 2033 | $274.6 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Evonik Industries AG, TCI Chemicals (India) Pvt. Ltd., Santa Cruz Biotechnology Inc., Alfa Aesar (Thermo Fisher Scientific), Merck KGaA (MilliporeSigma), Sisco Research Laboratories Pvt. Ltd., Tokyo Chemical Industry Co., Ltd. (TCI), Hangzhou Dayang Chemical Co., Ltd., Wuxi Bikang Chemical Co., Ltd., Monomer-Polymer and Dajac Labs, P&G Chem India, Spectrum Chemical Manufacturing Corp., AK Scientific Inc., Parchem fine & specialty chemicals, Chemwill Asia Co., Ltd., Changzhou Tronly New Electronic Materials Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cyclohexyl Vinyl Ether Market Key Technology Landscape

The production and application of Cyclohexyl Vinyl Ether rely on several sophisticated technologies aimed at improving purity, safety, and efficiency. The core technological landscape is dominated by proprietary synthesis methods, frequently involving advanced catalysis. Newer technological developments focus on implementing highly selective catalysts, such as certain transition metal complexes (e.g., Ruthenium or Palladium), to enhance the yield of the vinylation reaction while simultaneously minimizing the formation of unwanted byproducts. This emphasis on catalytic selectivity is crucial for meeting the stringent purity requirements of the electronics and medical segments, where even trace contaminants can severely compromise product performance. Continuous flow chemistry is an emerging technology in this space, offering advantages over traditional batch processing by enhancing safety, improving thermal management for highly exothermic reactions, and ensuring consistent product quality across large volumes, thereby lowering operational costs.

In terms of application technology, the advancement of UV light sources and photoinitiators directly impacts the efficiency of CHVE usage. High-intensity LED UV curing systems are rapidly replacing traditional mercury vapor lamps, offering focused energy delivery, reduced heat generation, and lower energy consumption. This shift favors CHVE-based formulations as their cationic polymerization mechanism is highly responsive to specific UV wavelengths emitted by LEDs. Formulators are also integrating advanced analytical technologies, such as high-performance liquid chromatography (HPLC) and gas chromatography-mass spectrometry (GC-MS), to precisely monitor the degradation products and purity profiles of CHVE both before and after its incorporation into end products. This level of analytical rigor is necessary to validate regulatory compliance and guarantee performance consistency in highly technical applications.

Furthermore, technology related to material handling and safety is integral to the CHVE market landscape. Specialized inert atmosphere packaging and transport systems are employed to prevent premature polymerization during storage and shipping, given the monomer's high reactivity to moisture and oxygen. Manufacturers are increasingly utilizing digital twinning and simulation software to model reactor conditions and predict safe operating envelopes, reducing the reliance on purely empirical methods. The combination of highly optimized synthesis technology, advanced analytical validation, and superior handling protocols collectively ensures that the high-quality standards expected by major industrial buyers, particularly those in the semiconductor industry, are consistently met throughout the entire product lifecycle.

Regional Highlights

The Asia Pacific (APAC) region stands as the dominant force in the Cyclohexyl Vinyl Ether market, characterized by both high consumption volume and rapid growth. This regional supremacy is directly attributable to its position as the global hub for manufacturing in electronics, automotive components, and general industrial coatings. Countries like China, South Korea, and Japan drive massive demand for CHVE, primarily utilized in UV-curable inks for printing, protective coatings for electronic devices, and specialty resins for semiconductor packaging. Regulatory environments in APAC are progressively adopting stricter VOC emission standards, which inadvertently accelerate the adoption of solvent-free UV-curing technology, further stimulating CHVE usage. Localized manufacturing capabilities and aggressive capacity expansion by regional chemical producers contribute significantly to the competitive dynamics and supply stability within this highly active market.

North America and Europe represent mature markets for Cyclohexyl Vinyl Ether, characterized by established regulatory frameworks and a focus on high-value, niche applications rather than sheer volume. In Europe, stringent regulations such as REACH necessitate the use of advanced, low-toxicity chemical intermediates, favoring high-purity CHVE in applications like aerospace composites and high-specification medical devices. Germany and the UK are primary consumers, driven by robust automotive and medical technology sectors. North America, particularly the United States, focuses on innovation in additive manufacturing and advanced materials science; here, CHVE is valued for its unique properties in custom resin development and specialized photopolymer formulations used in defense and medical R&D, maintaining a steady, high-margin market demand.

Emerging economies in Latin America (LATAM) and the Middle East and Africa (MEA) currently hold smaller market shares but offer substantial growth potential. In LATAM, particularly Brazil and Mexico, industrialization across the automotive assembly and packaging sectors is increasing the requirement for high-speed, quality coatings and adhesives, gradually boosting CHVE imports and domestic consumption. The MEA region is experiencing growth driven by infrastructure development and increasing investment in localized manufacturing facilities, particularly in the UAE and Saudi Arabia. While consumption in these regions is currently lower, favorable government policies promoting industrial self-sufficiency and diversification are expected to catalyze future demand for specialty chemical intermediates like Cyclohexyl Vinyl Ether throughout the forecast period.

- Asia Pacific (APAC): Dominant market share fueled by mass electronics manufacturing, high growth in automotive coatings, and rapid adoption of packaging inks.

- North America: Focus on high-value, R&D-intensive applications, strong regulatory push for solvent-free technology, significant utilization in advanced 3D printing resins.

- Europe: Mature market driven by stringent environmental standards (REACH), concentration of high-specification automotive and aerospace components manufacturing.

- Latin America: Emerging demand growth linked to increasing domestic packaging and automotive assembly capacity expansion.

- Middle East & Africa (MEA): Growth potential driven by ongoing infrastructure projects and diversification efforts promoting local industrial base development.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cyclohexyl Vinyl Ether Market.- BASF SE

- Evonik Industries AG

- TCI Chemicals (India) Pvt. Ltd.

- Santa Cruz Biotechnology Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Merck KGaA (MilliporeSigma)

- Sisco Research Laboratories Pvt. Ltd.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Hangzhou Dayang Chemical Co., Ltd.

- Wuxi Bikang Chemical Co., Ltd.

- Monomer-Polymer and Dajac Labs

- P&G Chem India

- Spectrum Chemical Manufacturing Corp.

- AK Scientific Inc.

- Parchem fine & specialty chemicals

- Chemwill Asia Co., Ltd.

- Changzhou Tronly New Electronic Materials Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cyclohexyl Vinyl Ether market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using Cyclohexyl Vinyl Ether in UV curing applications?

The primary advantages are its ability to enable rapid cationic polymerization, resulting in exceptionally fast cure speeds, superior adhesion to diverse substrates (including plastics and metals), and formulation of 100% solid, solvent-free coatings that comply with low-VOC environmental regulations.

Which end-use industries drive the majority of the demand for High Purity Grade CHVE?

High Purity Grade CHVE demand is predominantly driven by the electronics and electrical industries, where it is used in semiconductor encapsulants, photoresists, and high-performance circuit board coatings that require minimal contamination risk.

How does the Cyclohexyl Vinyl Ether market address environmental sustainability challenges?

The market contributes to sustainability by facilitating the shift toward energy-efficient UV-curing processes and eliminating volatile organic compounds (VOCs) through the use of CHVE in high-solids and 100% solids formulations, reducing the chemical industry's environmental footprint.

What is the main competitive threat to Cyclohexyl Vinyl Ether in the specialty chemicals sector?

The main competitive threat comes from highly versatile and cost-effective acrylate monomers and specialized epoxy resins. While acrylates generally offer broader compatibility, CHVE maintains a competitive edge in applications requiring rapid cationic polymerization speeds and specific substrate adhesion.

Why is the Asia Pacific region expected to maintain market dominance through 2033?

APAC's dominance is sustained by its massive scale in consumer electronics and automotive manufacturing, coupled with ongoing rapid industrialization and the continuous adoption of advanced manufacturing techniques that rely heavily on high-performance UV-curable materials containing vinyl ethers.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager