Cyclohexyl Vinyl Ether Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440956 | Date : Feb, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Cyclohexyl Vinyl Ether Market Size

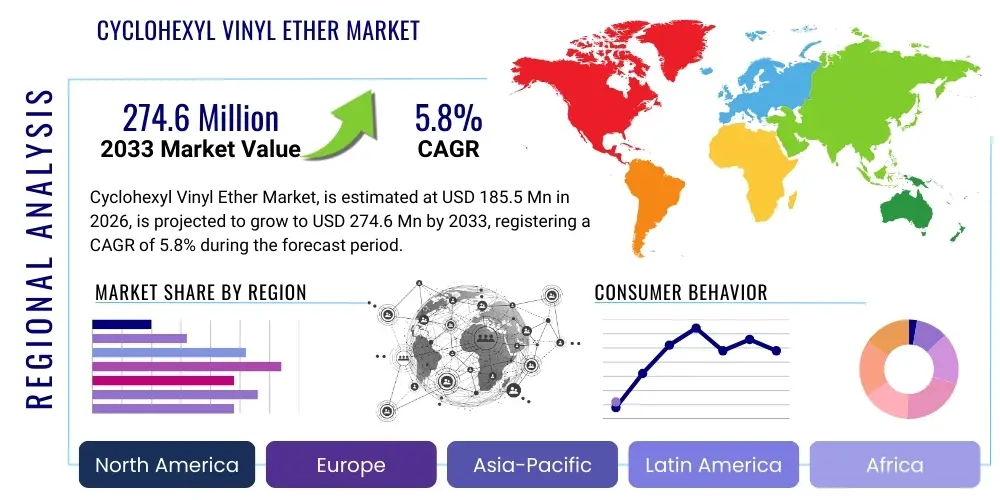

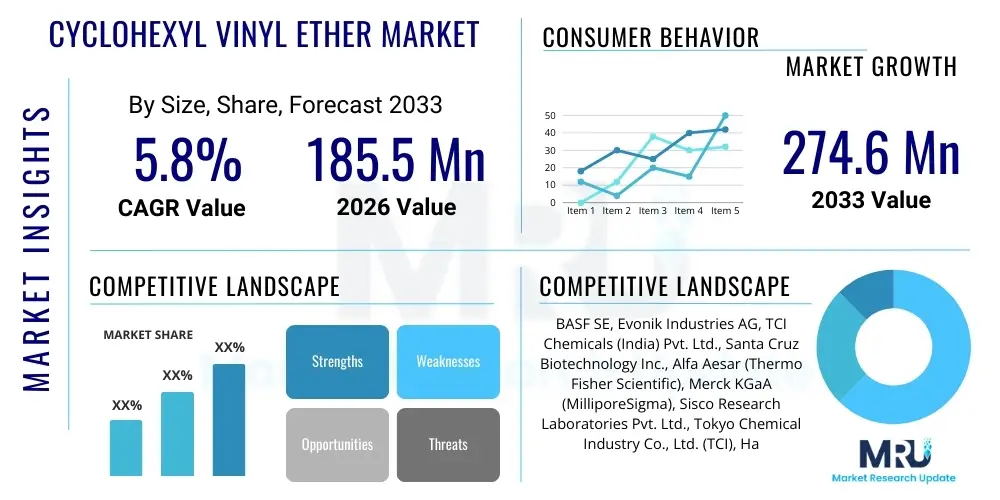

The Cyclohexyl Vinyl Ether Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 45.5 Million in 2026 and is projected to reach USD 67.4 Million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by increasing demand for high-performance specialty chemicals across various industrial applications, particularly in advanced coatings and adhesive formulations where its unique chemical reactivity provides significant performance benefits. The relatively niche nature of this chemical compound dictates a moderate, yet stable, growth rate focused primarily on value-added segments rather than volume expansion.

Cyclohexyl Vinyl Ether Market introduction

The Cyclohexyl Vinyl Ether (CHVE) Market encompasses the production, distribution, and utilization of this specific vinyl ether compound, which is chemically known for its high reactivity due to the presence of the vinyl group adjacent to the ether linkage, and the stability imparted by the cyclohexyl ring. CHVE serves primarily as a reactive diluent, an intermediate in the synthesis of specialized polymers, and a critical component in advanced UV-curable systems. Its distinctive properties, including low viscosity, excellent solvent capabilities, and rapid curing mechanisms, make it indispensable in applications demanding high chemical resistance, superior adhesion, and fast processing times. The compound is predominantly used in high-solid coatings, radiation-curable inks, specialty lubricants, and pharmaceutical intermediates, driving consistent demand from end-user industries focusing on next-generation materials and manufacturing efficiencies.

The primary driving factors for market expansion are the robust growth in the electronics and automotive sectors, both of which require specialized coatings and encapsulation materials offering extreme durability and performance under harsh environmental conditions. The shift towards sustainable and solvent-free coating technologies, particularly UV-curing and electron beam (EB) curing systems, strongly favors vinyl ethers like CHVE, as they contribute to lower Volatile Organic Compound (VOC) emissions compared to traditional solvent-based systems. Furthermore, increasing regulatory scrutiny on hazardous substances in major global economies is pushing manufacturers to adopt safer, high-solids or 100% reactive systems, positioning CHVE as a vital enabler for regulatory compliance and environmental responsibility.

Major applications of Cyclohexyl Vinyl Ether include its function as a monomer in cationic polymerization, yielding polymers with unique structural features, and its crucial role in adjusting the viscosity and enhancing the reactivity of formulations in radiation-curing applications. The benefits derived from its incorporation are multifaceted, ranging from accelerated curing speeds and enhanced cross-linking density in coatings to improved dielectric properties in electronic materials. Geographically, manufacturing hubs in Asia Pacific, particularly China and India, coupled with increasing R&D investments in North America and Europe aimed at developing advanced materials, dictate the global distribution of demand and production capacity for this specialized chemical intermediate.

Cyclohexyl Vinyl Ether Market Executive Summary

The Cyclohexyl Vinyl Ether (CHVE) market exhibits stable growth driven by key business trends focused on vertical integration among specialty chemical producers and increased collaboration between raw material suppliers and end-product formulators, particularly in the adhesives and sealants sector. Manufacturers are prioritizing product customization and high purity grades to meet stringent regulatory and performance requirements in sensitive applications such as medical devices and precision electronics. A prominent business trend involves strategic capacity expansion in regions witnessing high downstream manufacturing growth, coupled with continuous process optimization through catalyst innovation to reduce production costs and improve yield efficiencies. The focus on establishing secure, resilient supply chains is paramount, given the specialized nature of CHVE synthesis and the limited number of global suppliers, thereby influencing pricing stability and market accessibility.

Regionally, the Asia Pacific (APAC) stands as the dominant consumer and producer, fueled by rapid industrialization, burgeoning electronics manufacturing bases, and significant investment in infrastructure requiring durable coatings and construction chemicals. North America and Europe, while slower in volume growth, lead in technology adoption, particularly in developing high-value, niche applications like aerospace coatings and advanced composite matrices, often demanding ultra-high purity CHVE. These regions are also characterized by stringent environmental regulations, which further accelerate the demand for low-VOC, UV-curable solutions where CHVE plays a critical role. The Middle East and Africa (MEA) and Latin America are emerging markets showing potential, primarily driven by expanding construction and automotive maintenance industries seeking imported specialty chemical solutions.

Segment trends highlight the dominance of the high-purity grade segment due to its mandatory use in advanced electronic and pharmaceutical applications where even minor impurities can compromise product integrity. Application-wise, the coatings and inks sector holds the largest market share, consistently demanding CHVE for superior scratch resistance and faster line speeds in industrial finishing. However, the segment related to pharmaceutical and chemical synthesis intermediates is projected to show the highest CAGR, reflecting increasing R&D activities leveraging CHVE’s unique chemical structure for synthesizing complex organic molecules and advanced polymer architectures. Market growth remains highly sensitive to fluctuations in crude oil prices, which directly impact the cost of raw materials necessary for CHVE production, necessitating robust risk management strategies by market participants.

AI Impact Analysis on Cyclohexyl Vinyl Ether Market

User inquiries regarding AI's influence on the Cyclohexyl Vinyl Ether market frequently center on how artificial intelligence can accelerate chemical formulation development, optimize complex synthesis routes, and enhance supply chain predictability. Common concerns revolve around the capital investment required for AI integration, the necessity for specialized data sets pertaining to chemical reactivity and polymerization kinetics, and the potential for AI to displace human expertise in specialized chemical engineering. Users also express high expectations that AI could unlock novel applications for CHVE by predicting its behavior in multi-component systems, particularly within rapidly evolving fields like additive manufacturing and flexible electronics, thereby reducing the time-to-market for new, high-performance materials based on vinyl ether chemistries. Furthermore, there is significant interest in using machine learning algorithms to monitor and optimize large-scale polymerization reactors, ensuring consistent quality and minimizing batch variations for high-purity CHVE.

The integration of AI and machine learning (ML) platforms is poised to revolutionize several critical facets of the Cyclohexyl Vinyl Ether value chain, moving beyond traditional statistical process control to predictive analytics. In the research and development phase, AI algorithms can simulate millions of chemical reactions and potential polymer structures, drastically shortening the time required to identify optimal co-monomers or catalysts compatible with CHVE, leading to faster discovery of new high-value derivatives. This computational acceleration minimizes costly and time-consuming laboratory experiments, allowing manufacturers to respond more rapidly to shifting market demands for specialized performance characteristics, such as tailored glass transition temperatures or specific refractive indices required by optical applications. This predictive power is a key driver for enhanced innovation velocity within the specialty chemical segment.

Within manufacturing and supply chain operations, AI’s impact is felt through advanced demand forecasting and production scheduling. By analyzing complex variables including raw material price volatility, global logistics constraints, and real-time order flow, AI systems can optimize inventory levels of critical precursors like cyclohexanol and acetylene, minimizing holding costs while preventing stockouts. Moreover, the implementation of AI-driven quality control systems, utilizing sensor data and image recognition to monitor reactor conditions and product purity in real-time, ensures that the produced CHVE consistently meets the rigorous specifications required by the electronics and pharmaceutical industries. This optimization leads to reduced waste, enhanced operational efficiency, and overall higher reliability across the specialty chemical supply network, benefiting both producers and downstream users of CHVE.

- Accelerated discovery of novel CHVE derivatives and co-polymers using generative AI models.

- Optimization of complex catalytic synthesis routes for improved yield and reduced energy consumption.

- Enhanced supply chain risk management through predictive analytics of raw material price fluctuations and logistics bottlenecks.

- Real-time quality control and process monitoring in polymerization reactors using machine learning algorithms.

- Customized formulation design for UV-curable coatings by predicting performance characteristics based on component ratios.

- Improved predictive maintenance schedules for specialized production equipment, minimizing costly downtime.

DRO & Impact Forces Of Cyclohexyl Vinyl Ether Market

The Cyclohexyl Vinyl Ether market is influenced by a dynamic interplay of factors encapsulated by Drivers, Restraints, and Opportunities (DRO). Primary drivers include the escalating demand for environmentally friendly, low-VOC coatings and adhesives, particularly in advanced manufacturing sectors like automotive finishing and electronic component encapsulation, where CHVE enables rapid, solvent-free UV-curing technology. However, the market faces significant restraints, chiefly stemming from the high volatility and relatively elevated cost of specialized raw materials and the complexity inherent in synthesizing and purifying high-grade vinyl ethers, which limits widespread adoption compared to commodity chemicals. Opportunities arise predominantly in niche, high-growth areas such as specialized polymer synthesis for 3D printing resins, advanced optical materials, and highly customized pharmaceutical intermediates, requiring the unique reactivity profile of CHVE. These forces collectively shape the market structure, compelling manufacturers to invest heavily in process efficiency and novel application development to mitigate cost pressures and capitalize on specialized demand pockets.

Key impact forces shaping the market trajectory include technological shifts, regulatory mandates, and competitive intensity. Technological advancements in UV LED curing equipment are expanding the addressable market for CHVE-based formulations, making radiation curing more accessible and efficient for small and medium-sized enterprises. Simultaneously, evolving regulatory landscapes, particularly those restricting the use of certain hazardous solvents or monomers in consumer products in regions like the European Union (REACH), amplify the attractiveness of CHVE as a compliant, high-performance alternative. The competitive landscape is characterized by intense focus on intellectual property surrounding synthesis patents and application-specific formulations, necessitating continuous investment in proprietary research and development to maintain market differentiation and price premium for specialized grades. Global macroeconomic stability also exerts a powerful influence, as industrial output directly correlates with the demand for specialty coatings and adhesives, making the market vulnerable to downturns in key manufacturing economies.

The balance between these forces determines the overall profitability and strategic direction of market participants. While the high-performance requirements in industries like microelectronics ensure consistent demand and allow for premium pricing (a key opportunity), the dependency on petrochemical derivatives exposes the market to significant commodity price risk (a major restraint). Successfully navigating this complex environment requires specialty chemical companies to focus on vertical integration, secure long-term raw material contracts, and aggressively pursue innovation in specialized, high-margin applications where the performance benefits of Cyclohexyl Vinyl Ether are irreplaceable. Furthermore, geographic expansion into rapidly industrializing regions where environmental regulations are still developing offers pathways for volume growth, balancing the high-value, low-volume nature of established markets.

Segmentation Analysis

The Cyclohexyl Vinyl Ether market is comprehensively segmented based on Purity, Application, and Geographic Region, reflecting the diverse end-user requirements and the necessity for differentiated product offerings. Segmentation by purity grade is crucial because standard technical grade CHVE is suitable for general-purpose coatings, whereas ultra-high purity grades are mandated for sensitive applications such as semiconductor manufacturing, optical elements, and high-end medical devices, where contaminants can significantly impair performance or cause product failure. Application segmentation provides insights into major consumption trends, with the largest segments being industrial coatings and high-performance adhesives, followed by specialty synthesis and research uses. Regional analysis highlights consumption and production dynamics, showing concentrated demand in established industrial centers and burgeoning growth in manufacturing hubs across Asia.

This structured segmentation allows market participants to tailor their manufacturing processes, distribution strategies, and pricing models to specific market needs. For instance, manufacturers targeting the electronics industry must invest heavily in advanced purification technology to meet the stringent ultra-high purity specifications, justifying a higher price point. Conversely, those focusing on the large-volume industrial coatings sector prioritize cost-efficiency and supply reliability for technical-grade material. The segmentation analysis thus serves as a critical strategic tool for identifying underserved niches, assessing competitive strengths within specific product categories, and accurately forecasting regional demand shifts driven by regulatory changes or sectoral growth rates, ensuring optimized resource allocation across the entire value chain.

Understanding the interaction between these segments is vital; for example, the growth in UV LED curing technology (a technological driver) directly impacts the demand within the Coatings application segment, favoring high-purity material, thereby reinforcing the dominance of the Ultra-High Purity grade segment in terms of value. This interdependence underscores the specialized nature of the CHVE market, where differentiation is achieved through precise chemical specifications and demonstrated performance in demanding end-use environments rather than generalized volume sales. The detailed segmentation informs product development pipelines, focusing R&D efforts on meeting the most challenging specifications in the fastest-growing application areas, thereby maximizing return on investment.

- By Purity Grade:

- Technical Grade (98-99%)

- High Purity Grade (99.5%+)

- Ultra-High Purity Grade (99.9%+ for electronic/optical applications)

- By Application:

- Coatings and Inks (UV/EB Curable Systems)

- Adhesives and Sealants

- Chemical Intermediates and Synthesis

- Specialty Polymers and Resins

- Electronic Materials and Encapsulants

- Pharmaceutical and Research Applications

- By Region:

- North America (NA)

- Europe (EU)

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Cyclohexyl Vinyl Ether Market

The value chain for Cyclohexyl Vinyl Ether begins with the upstream sourcing of key raw materials, primarily cyclohexanol and acetylene, which are derived from petrochemical feedstocks, linking the market directly to the global oil and gas industry’s volatility. Cyclohexanol is typically produced via the catalytic oxidation of cyclohexane, while acetylene is often generated through the cracking of hydrocarbons or the reaction of calcium carbide with water. The stability and purity of these upstream components are paramount, as they directly influence the yield and quality of the final CHVE product. Key challenges in the upstream segment include ensuring consistent supply amidst fluctuating commodity prices and managing the energy-intensive nature of both raw material production and the subsequent vinyl ether synthesis process, necessitating strong contractual relationships with primary chemical producers.

The midstream stage involves the highly specialized manufacturing of CHVE, typically achieved through the catalytic addition of acetylene to cyclohexanol (Reppe synthesis or variations thereof) or through transvinylation reactions. This stage is characterized by high technical barriers to entry, requiring specialized high-pressure reactor systems and sophisticated purification technologies, such as advanced distillation columns and proprietary adsorption systems, to achieve the ultra-high purity grades required by niche industries. Operational excellence in this segment is defined by catalyst efficiency, waste minimization, and adherence to rigorous quality control standards, especially for materials destined for microelectronics. Integration strategies often involve backward integration into cyclohexanol production or forward integration into precursor blending and customized formulation services to capture greater margin.

The downstream distribution channel involves moving the finished CHVE product to diverse end-users. Distribution is managed through two primary channels: direct sales to large-volume industrial consumers (e.g., major coating producers or polymer manufacturers) and indirect sales via specialized chemical distributors and agents, particularly for smaller orders and reach into fragmented regional markets. Direct sales facilitate deep technical collaboration and customized supply agreements, while indirect channels provide market penetration and logistical efficiency. Effective supply chain management is crucial, often involving specialized packaging and handling due to the chemical reactivity and flammability of vinyl ethers. Potential customers include formulators of UV-curable inks, specialty adhesive manufacturers, and producers of advanced engineering plastics who value the chemical’s fast reaction kinetics and structural integrity contributions.

Cyclohexyl Vinyl Ether Market Potential Customers

Potential customers for Cyclohexyl Vinyl Ether span a variety of high-performance industries that utilize its unique attributes in specialized formulations and synthetic processes. The most significant customer base resides in the coatings and graphic arts sectors, where companies specializing in UV and Electron Beam (EB) curable coatings and inks utilize CHVE as a low-viscosity, highly reactive monomer and reactive diluent. These customers seek improved throughput, enhanced chemical resistance, and the ability to meet strict VOC reduction targets, making CHVE an essential component in industrial wood coatings, automotive clear coats, and high-speed digital printing inks. The demand from these formulators is volume-driven but highly sensitive to product performance specifications and regulatory compliance.

A second crucial segment includes manufacturers of high-performance adhesives and sealants, particularly those servicing the aerospace, medical device, and electronics assembly markets. These end-users leverage CHVE’s capacity to achieve rapid cure speeds and superior adhesion to challenging substrates, often required for structural bonding applications demanding high mechanical strength and thermal stability. Companies in the specialty polymer synthesis field also represent important customers, employing CHVE as a key monomer to create novel polymer architectures with tailored properties, such as high refractive index materials for optical applications or specialized elastomers for demanding engineering uses. These customers prioritize the ultra-high purity grades and technical support for complex polymerization processes.

Furthermore, niche markets such as high-end laboratory research facilities, pharmaceutical intermediate synthesis companies, and producers of specialized electronic encapsulants and dielectric materials constitute critical, high-value customer segments. In these applications, CHVE is valued not just for its physical properties, but for its role as a key chemical intermediate in creating proprietary, often patented, downstream products. Purchasing decisions across all potential customer segments are heavily weighted by product purity, consistency of supply, detailed technical documentation, and compliance certifications (e.g., ISO, REACH registration), reflecting the high-stakes nature of the products they ultimately manufacture using Cyclohexyl Vinyl Ether.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.5 Million |

| Market Forecast in 2033 | USD 67.4 Million |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Sigma-Aldrich (Merck KGaA), TCI Chemicals (Tokyo Chemical Industry Co., Ltd.), Dairen Chemical Corporation, Mitsubishi Chemical Corporation, Wacker Chemie AG, Arkema S.A., Kuraray Co., Ltd., Reaxis Inc., Kowa Group, Monomer-Polymer and Dajac Laboratories, Inc., Cangzhou Runtian Chemical Co., Ltd., Fuxin Chemical Group, J&K Scientific, Hefei TNJ Chemical Industry Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cyclohexyl Vinyl Ether Market Key Technology Landscape

The technology landscape for the Cyclohexyl Vinyl Ether market is primarily centered around optimizing the chemical synthesis process and advancing purification techniques to meet the escalating demand for high-purity grades. Traditionally, CHVE production relies on variations of the Reppe synthesis, involving the reaction of cyclohexanol and acetylene under specific pressure and catalytic conditions, often utilizing potassium hydroxide or other strong bases. Contemporary technological advancements are focused on developing highly selective, heterogeneous catalysts that operate at milder conditions, thereby enhancing reaction yield, reducing energy input, and improving safety profiles, which are crucial for large-scale, cost-effective manufacturing. Furthermore, continuous flow chemistry techniques are being explored as a modern alternative to traditional batch processing, offering tighter control over reaction kinetics and enabling more consistent quality output, particularly for specialized chemical intermediates.

A second critical area of technological innovation involves purification and quality control, essential for servicing the electronics and optical materials segments. Achieving ultra-high purity (99.9%+) requires sophisticated separation technologies beyond standard fractional distillation. This includes the utilization of advanced solvent extraction, complex molecular sieves, and customized adsorption media designed to selectively remove trace impurities, such as aldehydes or unreacted precursors, that could compromise the downstream performance of CHVE in sensitive applications. The implementation of advanced analytical technologies, such as high-resolution gas chromatography and mass spectrometry, is integral to real-time process monitoring and ensuring compliance with stringent customer specifications, forming a high technological barrier to entry for new market players.

The downstream technology landscape is equally vital, focusing on the utilization technologies that drive demand. Key among these are improvements in UV LED curing systems, which require photoinitiator packages and reactive diluents, including CHVE, that are highly efficient under specific UV wavelengths (e.g., 365 nm to 405 nm). Formulation science technology is also paramount, where formulators leverage CHVE’s low viscosity and high cationically reactive double bond to create complex, multi-functional coating systems. Technological competence in this area involves precisely balancing cure speed, film properties (hardness, flexibility, chemical resistance), and adhesion characteristics across a wide range of industrial substrates, thereby maximizing the performance utility of the Cyclohexyl Vinyl Ether monomer in end-use applications and sustaining market relevance.

Regional Highlights

Regional dynamics play a crucial role in shaping the Cyclohexyl Vinyl Ether market, driven by varying industrialization rates, regulatory environments, and the concentration of key end-use manufacturers.

- Asia Pacific (APAC): This region dominates the global market in terms of both consumption and production capacity. The robust growth is fueled by the massive presence of manufacturing hubs for electronics (particularly in China, South Korea, and Taiwan), automotive components, and industrial goods. Rapid infrastructure development in India and Southeast Asian nations further bolsters demand for high-performance coatings and adhesives. APAC benefits from relatively lower operational costs and less stringent environmental regulations (though these are rapidly evolving), making it the central global supply region.

- North America: Characterized by a focus on high-value, niche applications and advanced R&D. Demand is strong from the aerospace, medical device, and specialty electronics sectors, which require ultra-high purity grades of CHVE. While production capacity growth is moderate, the region is a leader in technological innovation, driving the development of next-generation UV-curable resins and 3D printing materials based on vinyl ether chemistry. Regulatory compliance (e.g., emphasis on low-VOC formulations) strongly influences material selection.

- Europe: The European market is highly regulated (driven by REACH) and exhibits steady, mature demand, emphasizing sustainability and performance. Key consumption sectors include high-end automotive refinishing, specialized industrial coatings, and luxury packaging inks. European manufacturers focus on maintaining premium quality and often integrate CHVE into proprietary formulations designed for superior environmental and performance standards, leading to consistent demand for high-purity material, often sourced through long-term contracts.

- Latin America (LATAM) and Middle East & Africa (MEA): These are emerging markets, currently smaller in volume but offering high growth potential. Demand in LATAM is primarily driven by expanding construction, packaging, and automotive assembly industries in countries like Brazil and Mexico. MEA market growth is linked to oil and gas infrastructure maintenance (requiring specialized protective coatings) and rapid urbanization, with most high-performance CHVE being imported. Growth depends heavily on local industrial investment and global economic stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cyclohexyl Vinyl Ether Market.- BASF SE

- Sigma-Aldrich (Merck KGaA)

- TCI Chemicals (Tokyo Chemical Industry Co., Ltd.)

- Dairen Chemical Corporation

- Mitsubishi Chemical Corporation

- Wacker Chemie AG

- Arkema S.A.

- Kuraray Co., Ltd.

- Reaxis Inc.

- Kowa Group

- Monomer-Polymer and Dajac Laboratories, Inc.

- Cangzhou Runtian Chemical Co., Ltd.

- Fuxin Chemical Group

- J&K Scientific

- Hefei TNJ Chemical Industry Co., Ltd.

- Evonik Industries AG

- Huntsman Corporation

- Covestro AG

- The Dow Chemical Company

Frequently Asked Questions

Analyze common user questions about the Cyclohexyl Vinyl Ether market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Cyclohexyl Vinyl Ether in industrial coatings?

Cyclohexyl Vinyl Ether (CHVE) functions primarily as a highly reactive monomer and reactive diluent in UV/EB curable coating and ink formulations. It significantly reduces the viscosity of the formulation while rapidly participating in the cationic polymerization process upon radiation exposure, leading to faster curing times, reduced Volatile Organic Compound (VOC) content, and enhanced final film properties such as hardness and chemical resistance.

How does the purity of Cyclohexyl Vinyl Ether affect its end-use applications?

Purity is a critical differentiator for CHVE. Technical grades (98-99%) are used in general industrial coatings. However, ultra-high purity grades (99.9%+) are mandatory for high-stakes applications such as electronic encapsulants, optical materials, and precision medical devices, where even trace impurities can negatively impact performance, reliability, and lifetime or interfere with sensitive processes like semiconductor lithography.

Which geographical region exhibits the highest demand for Cyclohexyl Vinyl Ether?

The Asia Pacific (APAC) region currently holds the highest demand for Cyclohexyl Vinyl Ether. This dominance is driven by the region's vast and rapidly expanding electronics, automotive, and general manufacturing sectors, which rely extensively on UV-curable systems and specialty adhesives, particularly in countries like China, Japan, and South Korea.

What are the main synthetic routes used to produce Cyclohexyl Vinyl Ether commercially?

The predominant commercial production method for Cyclohexyl Vinyl Ether involves variations of the Reppe synthesis, where cyclohexanol reacts with acetylene under high pressure and temperature conditions, typically employing a basic catalyst (such as potassium hydroxide). Alternative, milder methods include transvinylation reactions using vinyl acetate, though the Reppe process remains the most scalable for bulk production.

What are the primary restraints challenging the growth of the CHVE market?

The primary restraints include the high production cost, largely due to the expensive and volatile nature of petrochemical-derived raw materials (like cyclohexanol and acetylene), and the complexity and high energy requirements of the specialized synthesis and purification processes needed to consistently achieve high-purity grades required by premium end-users.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Cyclohexyl Vinyl Ether Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Cyclohexyl Vinyl Ether Market Statistics 2025 Analysis By Application (Fluroresin, Modifiers), By Type (Normal Product (CHVE 99-99.5 Percent), Customized Product (CHVE >99.5 Percent)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager