Dextranase Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438167 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Dextranase Market Size

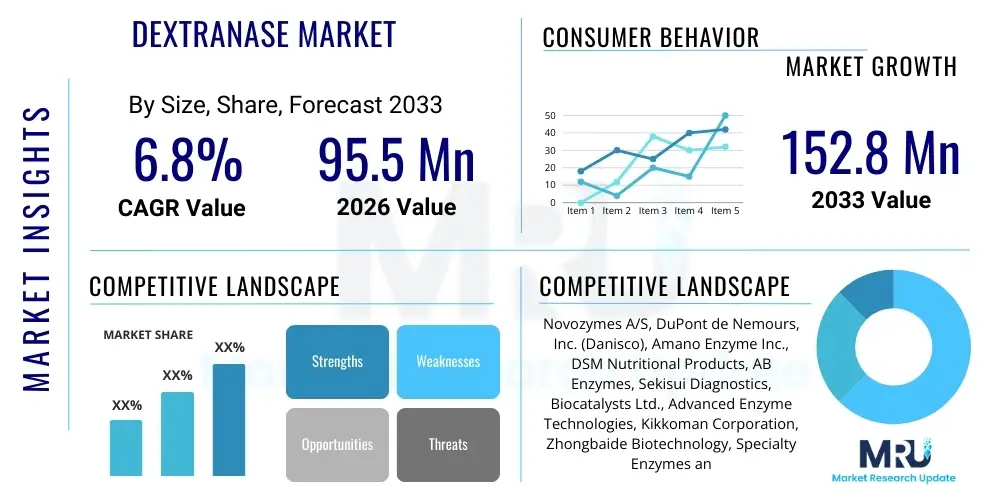

The Dextranase Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 95.5 Million in 2026 and is projected to reach USD 152.8 Million by the end of the forecast period in 2033.

Dextranase Market introduction

Dextranase, an enzyme classified as an endo-dextranase (EC 3.2.1.11), is fundamentally utilized for hydrolyzing the alpha-1,6-glucosidic linkages within the polymer dextran, yielding smaller oligosaccharides, primarily isomaltose. Dextran, a highly branched polysaccharide produced by microorganisms such as Leuconostoc mesenteroides during sugar processing, can cause significant viscosity issues and yield losses in the sugar industry. The primary commercial application of Dextranase is the remediation of processing impediments in the sugar industry, where it prevents fouling and crystallization defects, thereby enhancing sugar recovery efficiency and purity. Beyond sugar refining, Dextranase is critical in oral hygiene formulations for plaque control, breaking down glucans produced by cariogenic bacteria like Streptococcus mutans, and also finds niche applications in bioethanol production and medical research involving blood substitutes and antithrombotic agents.

Dextranase Market Executive Summary

The Dextranase market is experiencing robust growth driven predominantly by the escalating global demand for refined sugar and the continuous pressure on sugar producers to minimize losses and optimize operational throughput. Business trends indicate a strong shift towards the development of thermostable Dextranase variants, engineered through modern biotechnology, which are essential for surviving the high temperatures encountered in sugar cane processing. This focus on enzyme stability and improved specificity is attracting significant R&D investment. Regional trends highlight the Asia Pacific (APAC) region, particularly India and Brazil, as the principal growth engines due to their massive raw sugar production volumes and recent modernization efforts in their sugar mills. Conversely, North America and Europe show stable demand focused on high-value applications, such as pharmaceutical-grade Dextranase and specialty oral care products.

AI Impact Analysis on Dextranase Market

User inquiries regarding the role of Artificial Intelligence (AI) in the Dextranase sector frequently revolve around how AI can accelerate enzyme engineering, optimize fermentation yields, and predict the efficacy of novel enzyme formulations in diverse industrial matrices. Users are keenly interested in predictive modeling for enzyme stability under extreme conditions (high temperature, pH fluctuations) typical in the sugar refining process. There is also significant curiosity regarding AI’s capacity to identify and characterize new microbial sources for high-activity Dextranase enzymes, moving beyond traditional fungal strains. The key themes emerging from user concerns center on the reliability of AI-driven fermentation scaling and the cost-effectiveness of integrating sophisticated AI platforms into established, traditional industrial settings like sugar mills, which may require substantial upfront technological investment.

AI significantly influences the Dextranase market through advanced bioinformatics and structural biology. Machine learning algorithms are now routinely employed to analyze vast protein sequence databases, predicting optimal mutations that confer enhanced stability, specificity, or catalytic efficiency to Dextranase enzymes. This accelerated enzyme redesign process bypasses lengthy traditional laboratory screening methods, drastically reducing the time required to commercialize high-performance biocatalysts. Furthermore, AI-driven tools are being used to predict how different raw material compositions in the sugar industry—variations in sugarcane quality or beet purity—will impact dextran formation, allowing for proactive, precision dosing of Dextranase, thus minimizing chemical waste and maximizing enzymatic effectiveness.

In the manufacturing domain, AI optimizes industrial fermentation processes crucial for Dextranase production. Predictive maintenance algorithms monitor bioreactor parameters in real-time, analyzing variables like temperature, pH, dissolved oxygen, and nutrient feed rates to prevent suboptimal production conditions and maximize microbial yield. Deep learning models can forecast potential contamination issues or metabolic bottlenecks weeks in advance, enabling preemptive adjustments that ensure consistently high-titer production batches. This integration of AI not only reduces manufacturing costs and variability but also ensures a stable, high-quality supply of Dextranase necessary for global industrial consumers, addressing concerns about supply chain resilience and quality control.

- AI accelerates the rational design of thermostable and pH-optimized Dextranase variants.

- Machine learning models optimize large-scale fermentation processes, increasing yield and reducing batch variability.

- Predictive analytics aid sugar refineries in precision dosing of Dextranase based on real-time raw material quality assessment.

- Genomic analysis powered by AI rapidly identifies novel, high-performance microbial sources for enzyme extraction.

- AI assists in quality control and purity assessment for pharmaceutical-grade Dextranase applications.

DRO & Impact Forces Of Dextranase Market

The Dextranase market is shaped by a confluence of influential factors. Primary drivers include the necessity for enhanced sugar recovery rates globally, particularly in major producing nations, and growing consumer preference for natural, enzymatic solutions over harsh chemical treatments in processing. However, market growth is significantly restrained by the high production costs associated with industrial-scale enzyme fermentation and purification, alongside the specialized storage requirements needed to maintain enzyme activity. Opportunities lie in expanding Dextranase utilization into emerging applications like bioethanol production from dextran-rich molasses and the development of encapsulated or immobilized enzyme systems offering superior operational longevity. The key impact forces are regulatory shifts favoring sustainable bioprocesses and the continuous technological advancements in genetic engineering that reduce enzyme production costs and enhance functional stability.

Segmentation Analysis

The Dextranase market is intricately segmented based on its grade requirements, application area, biological source, and formulation type. This detailed segmentation reflects the diverse industry requirements, ranging from the high-volume, cost-sensitive demands of the sugar industry to the rigorous purity standards required for pharmaceutical and diagnostic applications. The application segment dominates the market landscape, with sugar processing maintaining the largest share due to the ubiquitous challenge of dextran contamination in raw sugar. The type segmentation emphasizes the qualitative differences in purity, which directly correlate with price points and end-user safety requirements, particularly for consumer-facing products like oral care.

- By Type

- Food Grade

- Industrial Grade

- Pharmaceutical Grade

- By Application

- Sugar Industry (Cane and Beet Refining)

- Oral Care Products (Toothpastes, Mouthwashes)

- Biofuel Production (Ethanol from Molasses)

- Research & Diagnostics

- Others (e.g., Textile, Laundry)

- By Source

- Microbial (e.g., Aspergillus spp., Penicillium spp.)

- Fungal

- By Formulation

- Liquid

- Powder (Lyophilized)

Value Chain Analysis For Dextranase Market

The Dextranase value chain begins with the upstream segment, primarily focused on sourcing raw materials such as microbial strains, fermentation nutrients (carbon and nitrogen sources), and necessary chemicals for media preparation. Key activities in the upstream include microbial strain selection, often involving proprietary or genetically modified organisms (GMOs) to enhance Dextranase yield and characteristics. R&D activities at this stage are crucial for developing strains that exhibit high catalytic activity and robustness, which are prerequisites for efficient industrial-scale production. The subsequent core stage involves fermentation, recovery, and extensive purification, where specialized equipment and stringent quality control protocols are applied, particularly for achieving pharmaceutical or food-grade purity levels, making this phase highly technology-intensive and cost-driving.

Moving into the downstream segment, the refined Dextranase product is formulated, often into stable liquid concentrates or lyophilized powders, tailored to the specific application needs of the end-user. Distribution channels are varied: direct sales are common for large industrial users like major sugar refining corporations, facilitating tailored logistics and technical support. Indirect channels, involving specialized chemical distributors or biotech intermediaries, serve smaller users and specialized sectors such as oral care and diagnostic laboratories. Effective inventory management and cold chain logistics are critical concerns in the distribution phase due to the enzyme’s inherent temperature sensitivity, especially in global transit across diverse climatic zones.

The efficiency of the value chain is largely dependent on vertical integration strategies adopted by leading enzyme manufacturers, allowing them to control quality from strain development to final formulation. Direct engagement with end-users, particularly in the sugar industry, enables rapid feedback on enzyme performance under real-world conditions, leading to quicker product iteration and improvement. The complexity of regulatory compliance, particularly for pharmaceutical and food-grade Dextranase, adds substantial overhead costs but reinforces market barriers to entry, ultimately favoring established players with sophisticated quality assurance systems and comprehensive intellectual property portfolios protecting their production methodologies and engineered strains.

Dextranase Market Potential Customers

The primary and most significant potential customers for Dextranase are large-scale sugar manufacturers, encompassing both cane and beet refineries globally. These industrial entities rely heavily on Dextranase as a critical process aid to mitigate the severe production inefficiencies caused by microbial dextran contamination, which can impede crystallization, increase molasses formation, and lead to substantial economic losses. The buying behavior of this segment is driven by enzyme efficacy (measured by activity units per dollar), thermostability, and the ability of the enzyme supplier to provide large, consistent volumes, coupled with robust technical support for integration into existing continuous processing lines. Geographical clusters of customers are concentrated in major sugar-producing regions, including Brazil, India, Thailand, and the United States.

A secondary, yet rapidly expanding customer base resides within the oral care and consumer goods industry. Companies specializing in dental hygiene products such as premium toothpastes, specialized mouthwashes, and professional dental cleaning formulations utilize Dextranase for its ability to hydrolyze glucans that form dental plaque matrices. This segment demands extremely high-purity, pharmaceutical-grade enzymes, where stringent quality assurance and regulatory approval (e.g., FDA or EMA clearance) are paramount purchasing criteria. Their consumption volumes are typically smaller than the sugar industry but offer higher profit margins due to the premium nature of the product, with purchasing decisions heavily influenced by clinical trial validation and consumer safety certifications.

Additionally, emerging customer segments include biofuel producers utilizing molasses (a dextran-rich byproduct) as a fermentation feedstock for bioethanol, and various academic and commercial research laboratories requiring Dextranase for carbohydrate modification studies and diagnostic assays. The biofuel sector seeks cost-effective, bulk-supply industrial-grade enzymes capable of functioning efficiently within complex fermentation broths. Research laboratories, conversely, require highly specialized, small-volume batches with maximum purity and specific activity specifications. These diverse customer needs underscore the necessity for suppliers to maintain a broad product portfolio covering varying purity levels and formulation types to maximize market penetration across all viable end-use sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 95.5 Million |

| Market Forecast in 2033 | USD 152.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Novozymes A/S, DuPont de Nemours, Inc. (Danisco), Amano Enzyme Inc., DSM Nutritional Products, AB Enzymes, Sekisui Diagnostics, Biocatalysts Ltd., Advanced Enzyme Technologies, Kikkoman Corporation, Zhongbaide Biotechnology, Specialty Enzymes and Biotechnologies, Antozyme Biotech Private Limited, Suntaq International, Creative Enzymes, Bioseutica, Megazyme Ltd., Sinozyme, Enzyme Development Corporation, Vland Biotech, Genencor (a part of IFF). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dextranase Market Key Technology Landscape

The technological evolution within the Dextranase market is primarily focused on enhancing the enzyme's operational characteristics to meet stringent industrial requirements, especially high temperature and pH tolerance within sugar refining. Key technological advancements involve directed evolution and site-directed mutagenesis, which are techniques used to genetically modify native Dextranase strains (often derived from Penicillium or Aspergillus) to improve their stability and reduce their susceptibility to thermal denaturation. These biotechnological efforts are aimed at creating 'super enzymes' that retain significant activity at processing temperatures exceeding 60°C, thereby maximizing enzyme utility and minimizing the need for cooling the process stream before enzyme addition.

Another crucial technology driving efficiency is enzyme immobilization. This process involves attaching Dextranase to an inert, insoluble support material, such as porous silica, polymeric resins, or magnetic nanoparticles. Immobilization significantly enhances the operational half-life of the enzyme, allows for continuous use in packed bed reactors, and facilitates easy separation and recycling from the reaction mixture. For the sugar industry, this technology minimizes the need for frequent enzyme replenishment and eliminates residual enzyme proteins in the final product, which is particularly beneficial for high-purity sugar production. Research is ongoing to develop cost-effective, high-binding capacity carriers that are resilient to shear stress and chemical cleaning protocols.

Furthermore, advancements in large-scale submerged fermentation technology, coupled with sophisticated downstream processing methods, are essential for reducing the manufacturing cost of high-quality Dextranase. High-density fermentation techniques are utilized to increase the concentration of the expressed enzyme, improving volumetric productivity. Purification methods, including advanced ultrafiltration and chromatography, are continually refined to achieve the exacting purity standards required for pharmaceutical and food-grade applications, ensuring the removal of residual microbial contaminants, medium components, and unwanted proteases which might degrade the Dextranase or pose regulatory challenges. The overall technological landscape is characterized by a persistent drive towards biomanufacturing efficiency and tailored enzyme function.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market for Dextranase, primarily driven by massive sugar production volumes in countries like India, China, Thailand, and Australia. The heavy reliance on sugarcane processing in the region means refineries frequently face severe dextran contamination challenges, creating substantial, consistent demand for industrial-grade Dextranase. Economic growth, increasing urbanization, and modernizing sugar processing infrastructure further catalyze market expansion.

- Latin America (LATAM): LATAM, particularly Brazil, holds a commanding position in the global sugar trade and bioethanol production, making it a critical market for Dextranase. Brazil's dual focus on sugar and fuel production, often utilizing dextran-rich molasses, fuels demand. The region’s focus is strongly skewed towards cost-effective, high-performance industrial enzyme formulations to ensure competitive pricing of its exported commodities.

- North America: North America is characterized by mature sugar processing industries (both cane and beet) and strong demand from the premium oral care and research sectors. While overall sugar production volume is lower compared to APAC, the region demonstrates higher consumption of pharmaceutical and high-purity Dextranase due to rigorous regulatory standards and robust investment in biotech research and specialized consumer health products.

- Europe: The European Dextranase market is centered predominantly around beet sugar processing, which also faces dextran issues, albeit different in scope than cane sugar. Demand is highly sophisticated, driven by stringent food safety regulations requiring high-purity enzymes. Europe also serves as a major hub for key global enzyme manufacturers, contributing significantly to R&D and the export of advanced Dextranase products globally.

- Middle East and Africa (MEA): The MEA region exhibits moderate but growing demand, concentrated primarily in sugar-producing nations like Egypt, Sudan, and South Africa. Market growth is projected to accelerate as regional sugar industries upgrade their processing technologies to meet domestic consumption needs and enhance export competitiveness, thereby increasing the necessity for efficient dextran control measures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dextranase Market.- Novozymes A/S

- DuPont de Nemours, Inc. (Danisco)

- Amano Enzyme Inc.

- DSM Nutritional Products

- AB Enzymes

- Sekisui Diagnostics

- Biocatalysts Ltd.

- Advanced Enzyme Technologies

- Kikkoman Corporation

- Zhongbaide Biotechnology

- Specialty Enzymes and Biotechnologies

- Antozyme Biotech Private Limited

- Suntaq International

- Creative Enzymes

- Bioseutica

- Megazyme Ltd.

- Sinozyme

- Enzyme Development Corporation

- Vland Biotech

- International Flavors & Fragrances (IFF) (Genencor)

Frequently Asked Questions

Analyze common user questions about the Dextranase market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Dextranase and why is it essential in the sugar industry?

Dextranase is an enzyme that specifically breaks down dextran, a viscous polysaccharide byproduct formed during sugar processing, particularly when raw cane or beet is delayed or contaminated by microbes like Leuconostoc mesenteroides. Dextranase addition is essential because high dextran levels severely impede the crystallization process, cause equipment fouling, and significantly reduce the quality and yield of final refined sugar, leading to substantial economic losses for manufacturers.

How does the source of Dextranase (Microbial vs. Fungal) impact its application?

Dextranase is commonly sourced from microorganisms, predominantly fungi such as Aspergillus and Penicillium species. Fungal-derived Dextranase is often preferred for large-scale industrial applications, like sugar processing, due to its high yield and relatively lower production cost. Microbial sources are increasingly being genetically engineered to produce variants with improved characteristics, such as enhanced thermostability and specific activity profiles, making them suitable for high-temperature industrial environments and specialized oral care applications requiring consistent purity.

What regulatory constraints affect the commercialization of Dextranase?

Regulatory constraints depend entirely on the intended application. For food-grade Dextranase used in sugar processing, manufacturers must comply with standards set by agencies like the FDA (Generally Recognized As Safe - GRAS status) and EFSA, focusing on non-toxicity and enzyme purity. Pharmaceutical-grade Dextranase, used in diagnostics or medical research, faces the most stringent controls, requiring compliance with Good Manufacturing Practices (GMP) and extensive clinical documentation related to safety, identity, strength, and purity, creating significant barriers to entry.

Beyond sugar refining, what are the emerging applications for Dextranase?

Emerging applications for Dextranase include its use in the advanced oral care industry for effective dental plaque control, where it hydrolyzes glucan films contributing to biofilm formation. Furthermore, Dextranase is increasingly being researched for optimizing the fermentation process in the biofuel industry, specifically for treating molasses derived from sugarcane, improving its suitability as a feedstock for ethanol production by reducing problematic viscosity caused by residual dextran.

What role does enzyme engineering play in future market growth for Dextranase?

Enzyme engineering, particularly utilizing AI-driven directed evolution, is critical for future market growth. This technology allows researchers to rapidly design and produce Dextranase variants optimized for extreme industrial conditions (e.g., pH 4.0 and 70°C). By enhancing thermal stability and substrate specificity, engineered enzymes can reduce processing time, minimize waste, lower operational costs for end-users, and expand the viability of Dextranase into novel, harsh industrial environments, thereby directly fueling commercial expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager