Dextranase Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443477 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Dextranase Market Size

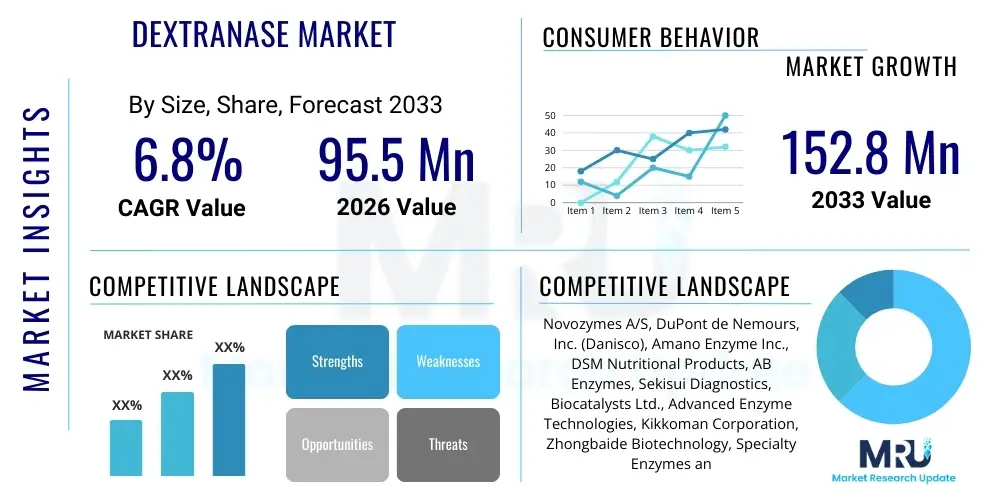

The Dextranase Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 155.8 Million in 2026 and is projected to reach USD 257.4 Million by the end of the forecast period in 2033.

Dextranase Market introduction

The Dextranase market encompasses the production, distribution, and application of the enzyme Dextranase, scientifically classified as an endo-alpha-1,6-D-glucanase. This enzyme hydrolyzes the alpha-1,6 glucosidic linkages in dextran, breaking down complex polysaccharide structures into smaller, manageable oligosaccharides, primarily isomaltose. Originally discovered for its role in mitigating dental plaque formation by degrading dextran produced by Streptococcus mutans, its primary industrial utility today lies in the sugar processing industry, where it is crucial for minimizing losses caused by microbial contamination.

Product description highlights high-purity, stable enzymatic preparations available in both liquid and powdered forms, catering to different industrial processing requirements, such as juice clarification, sucrose crystallization, and biotechnological applications. Major applications span the large-scale industrial use in sugarcane and sugar beet processing to enhance filtration efficiency and crystallization yield, as well as specialized uses in oral care products, diagnostics, and novel biocatalytic processes. The versatility of Dextranase allows its integration into sophisticated biorefinery models, positioning it as a key auxiliary enzyme in modern bioprocessing.

The primary benefits driving market expansion include significant improvement in sugar recovery yields, enhanced process efficiency in sugar mills, and a reduced requirement for harsh chemical treatments. Key factors propelling market growth involve the increasing global demand for refined sugar, stringent regulatory focus on food quality and safety, and the continuous advancement in enzyme engineering techniques which yield more thermostable and pH-tolerant variants of Dextranase, enabling its use across diverse operational conditions.

Dextranase Market Executive Summary

The Dextranase Market is characterized by robust growth, primarily fueled by the indispensable role of the enzyme in optimizing industrial sucrose extraction processes across major sugar-producing nations. Business trends indicate a strategic shift towards high-stability, recombinant Dextranase production, enabling manufacturers to offer tailored solutions that maximize performance under challenging industrial parameters, such as elevated temperatures and fluctuating pH levels. Furthermore, leading market participants are heavily investing in vertical integration and long-term supply agreements with large sugar cooperatives to secure market share and mitigate supply chain vulnerabilities, creating high entry barriers for new entrants.

Regional trends reveal that Asia Pacific (APAC), particularly India, China, and Southeast Asian nations, dominates market consumption due to the massive scale of their domestic sugar industries and ongoing modernization efforts aimed at improving yield efficiency. North America and Europe represent mature markets, where growth is driven by innovative applications in dental health, functional ingredients, and advanced biocatalysis, focusing on premium, high-value enzyme formulations. Latin America, particularly Brazil, is witnessing accelerated adoption, motivated by the necessity to enhance sugar production alongside biofuel co-products, requiring highly efficient enzymatic aids.

Segment trends highlight the dominance of the Sugar Industry application segment, commanding the largest revenue share, though the Biocatalysis and Dental Health segments are projected to record the highest compound growth rates, driven by novel biotechnological research and heightened consumer awareness regarding preventative oral hygiene. By product type, powdered Dextranase formulations are gaining traction owing to their superior shelf life and ease of transportation and dosing, although liquid formulations remain preferred in integrated, high-throughput sugar processing facilities that prioritize continuous workflow and operational simplicity.

AI Impact Analysis on Dextranase Market

User inquiries regarding AI's influence on the Dextranase market primarily center on how machine learning can optimize enzyme discovery, enhance production yield, and streamline application processes in industrial settings. Common questions explore AI's role in predicting Dextranase stability under extreme operational conditions, designing novel mutant enzymes with enhanced catalytic efficiency, and automating quality control during fermentation. Users are keenly interested in predictive analytics for managing microbial contamination in sugar mills, a direct application where timely Dextranase intervention is critical, suggesting an expectation that AI will transition Dextranase use from reactive treatment to proactive prevention.

The core themes identified in user concerns revolve around the integration cost of AI-driven optimization platforms and the intellectual property implications of using AI for novel enzyme design. Expectations are high regarding significant cost reductions through optimized fermentation protocols, enabling continuous process improvement and minimizing batch variations. Furthermore, users anticipate that AI algorithms will facilitate rapid screening of microbial strains for superior Dextranase producers, drastically reducing the traditional R&D cycle time required for commercial deployment. This shift is expected to democratize access to high-performance enzymes and potentially intensify competition among producers.

The tangible impact of AI is emerging in two distinct areas: metabolic pathway engineering and smart manufacturing. AI algorithms analyze vast genomic and proteomic datasets to identify optimal genetic modifications for increasing Dextranase expression levels in host organisms (e.g., yeasts or bacteria). In manufacturing, AI-powered sensors and real-time data analysis systems are deployed in fermentation tanks and sugar refineries to automatically adjust temperature, pH, and substrate concentrations, ensuring peak enzyme activity and usage efficiency. This intelligent application optimizes the total cost of ownership for end-users and promotes sustainability by minimizing enzyme wastage.

- AI accelerates the discovery and engineering of high-stability, high-activity Dextranase variants.

- Machine learning models optimize fermentation processes, significantly increasing industrial enzyme yield and reducing production costs.

- Predictive analytics aids sugar mills in early detection of dextran contamination, allowing proactive, dosage-optimized Dextranase treatment.

- AI facilitates automated quality control and standardization of enzyme preparations, ensuring product consistency.

- Data analytics platforms optimize supply chain logistics and inventory management for enzyme distribution globally.

DRO & Impact Forces Of Dextranase Market

The Dextranase market dynamic is shaped by a favorable balance of robust drivers rooted in industrial efficiency and significant opportunities in emerging biological applications, tempered by persistent challenges related to cost and specific application constraints. The overarching driver remains the economic imperative for maximizing sugar recovery in the global cane and beet processing industries, where dextran-induced viscosity remains a major obstacle to filtration and crystallization. Furthermore, increasing urbanization and subsequent rise in dental health consciousness fuel demand for enzyme-based oral care products, offering a sustainable alternative to chemical treatments.

Key restraints include the high initial capital investment required for dedicated enzyme manufacturing facilities employing recombinant technologies and the complex regulatory approval processes, particularly in highly regulated food and pharmaceutical markets, which can slow product commercialization. Furthermore, the specialized nature of Dextranase use means its adoption is heavily concentrated within niche industrial sectors, limiting immediate market diversification. Impact forces, such as fluctuating global sugar prices and shifts in agricultural policies favoring specific crops (e.g., sugar beets versus sugarcane), directly influence the profitability and investment capabilities of key end-user industries.

Significant opportunities are present in leveraging Dextranase for novel biocatalysis applications, specifically in the production of specialty chemicals and complex carbohydrates used in functional foods and pharmaceuticals. Advances in immobilization technology, encapsulating the Dextranase enzyme onto inert carriers, allow for continuous processing and enzyme recycling, dramatically improving cost-effectiveness and opening doors for its use in advanced biorefinery operations. The market is also benefiting from a general trend favoring the replacement of traditional chemical methods with environmentally friendly, highly specific enzymatic solutions.

Segmentation Analysis

The Dextranase market segmentation provides a granular view of market dynamics based on the enzyme’s form, its source, and its ultimate application across diverse end-user industries. Analyzing these segments is critical for manufacturers to tailor production strategies and for stakeholders to understand specific areas of growth and investment potential. The dominance of industrial applications necessitates a focus on segment performance driven by economic efficiency metrics, while the emerging segments require strategic investment in R&D to capitalize on future biological advancements and consumer trends, particularly those emphasizing health and advanced material production.

The primary segment drivers often interact; for example, the demand for high-purity, powdered Dextranase (Product Type) is intrinsically linked to its application in specialized dental formulations (Application), requiring different production standards compared to bulk enzymes used in the sugar industry. Geographic segmentation further overlays these trends, highlighting regional variations in regulatory requirements and industrial infrastructure, significantly influencing the preferred type and volume of Dextranase consumed in a given area. Detailed analysis across these categories reveals significant strategic pathways for market penetration and differentiation, focusing on optimizing enzyme stability and specific activity levels required for target applications.

- By Product Type:

- Liquid Form

- Powdered Form

- By Source:

- Bacterial Source (e.g., Penicillium species)

- Fungal Source (e.g., Aspergillus species)

- Recombinant Source

- By Application:

- Sugar Industry (Cane and Beet Processing)

- Dental Health and Oral Care Products

- Biocatalysis and Research

- Food Processing (Juice Clarification, etc.)

- By End-Use Industry:

- Food and Beverage

- Pharmaceutical and Biotechnology

- Cosmetics and Personal Care

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Dextranase Market

The Dextranase market value chain commences with upstream analysis, focusing on the procurement of raw materials, primarily microbial strains (often genetically modified or selected high-yield producers) and fermentation media components (carbon sources, nitrogen sources, and trace minerals). This stage is characterized by intense R&D efforts focused on strain optimization, fermentation technology refinement, and process scale-up. Key players often maintain proprietary strains and rely on specialized biotechnology suppliers for media ingredients, ensuring quality control and consistency in the enzyme production yield and specific activity.

The midstream involves the core manufacturing process: large-scale submerged fermentation, purification, concentration, and formulation (drying for powder or stabilization for liquid). Purification, which is crucial for applications like dental care and pharmaceuticals, constitutes a significant cost component, demanding advanced chromatography and filtration techniques. Distribution channels are bifurcated into direct and indirect routes. Direct distribution is common for large-volume industrial end-users, such as major international sugar conglomerates, often involving specialized logistics for handling temperature-sensitive biological products. This ensures technical support and streamlined supply.

Downstream analysis focuses on market application and end-users. Indirect distribution utilizes regional distributors and specialized chemical/enzyme supply houses, particularly targeting smaller sugar mills, niche food processors, or academic and research institutions. The effectiveness of the overall value chain relies heavily on maintaining a cold chain and ensuring rapid delivery to minimize enzyme degradation. Value addition occurs through technical services, including application consulting and dosing optimization provided by enzyme manufacturers, directly influencing customer loyalty and usage efficiency.

Dextranase Market Potential Customers

The primary and largest volume end-users of Dextranase are large-scale sugar manufacturers, encompassing both sugarcane and sugar beet processing facilities globally. These customers utilize the enzyme as a critical processing aid to hydrolyze dextran buildup caused by microbial infection of the raw material, thereby reducing syrup viscosity, improving filtration rates, and preventing crystallization inhibition, ultimately maximizing sucrose yield and enhancing product purity necessary for refined sugar markets. Their purchasing decisions are primarily driven by cost-effectiveness, enzyme stability, and reliability of supply.

Secondary but rapidly growing customer segments include pharmaceutical and biotechnology companies focused on developing advanced oral hygiene products, such as enzyme-based toothpastes, mouthwashes, and specialized treatments for plaque management. These customers require high-purity, standardized Dextranase preparations suitable for human contact and compliant with strict regulatory standards (e.g., FDA, EMA). Furthermore, academic and commercial research laboratories, especially those specializing in complex carbohydrate research and glycobiology, are consistent buyers for diagnostic and experimental purposes.

Additional potential customers reside within the broader food processing industry, particularly juice and beverage manufacturers who utilize Dextranase for clarification purposes and to prevent haze formation in specific fruit concentrates that may contain dextran-like polysaccharides. Furthermore, firms engaged in advanced biocatalysis, seeking enzymatic tools for the modification or synthesis of specialty oligosaccharides for functional food ingredients (prebiotics), represent high-value potential customers demanding extremely specific enzyme characteristics and robust performance profiles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 155.8 Million |

| Market Forecast in 2033 | USD 257.4 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Novozymes, DuPont, DSM, AB Enzymes, Amano Enzyme Inc., Biocatalysts Ltd., Advanced Enzymes, Puratos, Kerry Group, Chr. Hansen, BASF, Thermo Fisher Scientific, Megazyme, Kikkoman Biochemifa Company, Enzyme Development Corporation, Sekisui Diagnostics, Codexis, Verenium Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dextranase Market Key Technology Landscape

The Dextranase market's technological landscape is dominated by advancements in microbial fermentation and enzyme engineering, focused on maximizing yield, purity, and operational stability. Traditional Dextranase production utilized selected natural fungal or bacterial strains, primarily belonging to Penicillium and Aspergillus genera, via submerged fermentation. However, modern technology is heavily shifting towards recombinant DNA technology, where the Dextranase gene is cloned into robust host organisms like E. coli or Pichia pastoris. This recombinant approach allows for precision control over enzyme characteristics, enabling the creation of custom variants optimized for specific industrial environments, such as high temperatures encountered during sugar processing.

A crucial technological development is directed evolution and site-directed mutagenesis, enabling researchers to systematically modify the enzyme’s structure to enhance thermal stability and pH tolerance. For instance, engineering Dextranase variants that retain full activity at higher processing temperatures significantly reduces dosage requirements and improves overall catalytic efficiency in sugar mills. Furthermore, purification technology, including ultrafiltration and proprietary chromatographic methods, is vital for achieving the high-grade enzyme necessary for sensitive applications like diagnostics and oral care, minimizing contaminants and ensuring regulatory compliance.

Immobilization technology represents another frontier, where Dextranase is covalently or physically bonded to inert supports like porous beads or membranes. This breakthrough allows the enzyme to be used continuously in flow-through reactors without being lost in the product stream, drastically lowering operational costs and facilitating green chemistry approaches. Sensor technology and process analytical technologies (PAT) are increasingly employed in conjunction with production, using real-time data monitoring to maintain optimal fermentation conditions and ensure batch-to-batch consistency, providing a competitive edge to technology-forward enzyme producers.

Regional Highlights

The Dextranase market exhibits significant regional diversity driven by varying levels of sugar production, industrialization, and regulatory environments concerning enzyme use in food and health sectors. Asia Pacific (APAC) stands out as the primary market driver globally, necessitated by its enormous volume of sugarcane cultivation and processing, particularly in India, Thailand, and China. Modernization of APAC sugar mills, often prompted by government mandates to improve efficiency and reduce environmental impact, ensures sustained high demand for industrial Dextranase formulations.

North America and Europe represent key high-value markets, characterized less by volume and more by sophistication in application. In these regions, demand is focused on high-purity recombinant Dextranase for specialized dental applications, diagnostics, and emerging biocatalysis research. European manufacturers often lead in enzyme engineering and sustainability practices, setting global standards for production quality and environmental stewardship. The regulatory environment is generally stringent, favoring suppliers who can demonstrate impeccable quality assurance and traceability.

Latin America (LATAM), particularly Brazil, is essential due to its dominant position in global sugar and ethanol production. The integration of enzyme technology, including Dextranase, is critical for optimizing both sugar and co-product yields (like bioethanol). The Middle East and Africa (MEA) region presents untapped potential, with growing domestic sugar industries and increasing foreign investment in advanced processing facilities, though adoption rates are sometimes constrained by logistical challenges and slower integration of sophisticated biotechnological solutions.

- Asia Pacific (APAC): Dominates consumption driven by industrial sugar processing volume; focus on improving operational efficiency in cane sugar mills.

- North America: High-value market focused on premium dental health applications and advanced biotechnological research using purified enzymes.

- Europe: Characterized by stringent quality standards; strong demand for novel, thermostable, and sustainable recombinant Dextranase variants for industrial and specialized uses.

- Latin America (LATAM): Crucial due to massive sugar and biofuel production, driving demand for enzymes that optimize dual-product recovery.

- Middle East and Africa (MEA): Emerging market with increasing industrialization of sugar production, poised for growth through foreign investment and technology transfer.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dextranase Market.- Novozymes

- DuPont (Danisco/Genencor)

- DSM

- AB Enzymes

- Amano Enzyme Inc.

- Biocatalysts Ltd.

- Advanced Enzymes

- Puratos

- Kerry Group

- Chr. Hansen

- BASF

- Thermo Fisher Scientific

- Megazyme

- Kikkoman Biochemifa Company

- Enzyme Development Corporation

- Sekisui Diagnostics

- Codexis

- Verenium Corporation

Frequently Asked Questions

Analyze common user questions about the Dextranase market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary industrial application of Dextranase?

The primary industrial application of Dextranase is within the sugar processing industry, where it is used to hydrolyze dextran polysaccharides. Dextran, a microbial byproduct, causes significant viscosity issues in cane and beet processing, impeding filtration and crystallization. Dextranase application efficiently resolves this issue, maximizing sugar recovery yields.

How does recombinant technology impact Dextranase production?

Recombinant technology significantly enhances Dextranase production by allowing for the genetic engineering of microbial strains to achieve higher enzyme yields, improved purity, and enhanced stability (thermal and pH tolerance). This leads to more cost-effective and functionally superior enzymes tailored for demanding industrial environments.

Which geographical region holds the largest market share for Dextranase?

Asia Pacific (APAC) currently holds the largest market share for Dextranase consumption. This dominance is driven by the extensive scale of the sugar industry, particularly in major producing countries like India and China, and the ongoing investment in modernizing sugar processing facilities to improve efficiency.

What restraints are affecting the growth of the Dextranase market?

Key restraints include the high initial capital expenditure required for developing and scaling up recombinant enzyme manufacturing technologies and the complex, time-intensive regulatory approval process for utilizing novel enzyme products in food and pharmaceutical applications across different jurisdictions.

Beyond the sugar industry, what are the emerging applications for Dextranase?

Emerging applications for Dextranase include its use in the development of advanced oral health products (e.g., anti-plaque formulations), specialized biocatalysis for synthesizing novel carbohydrates (oligosaccharides), and specific diagnostic assays used in research and clinical settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager