Dispensers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431344 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Dispensers Market Size

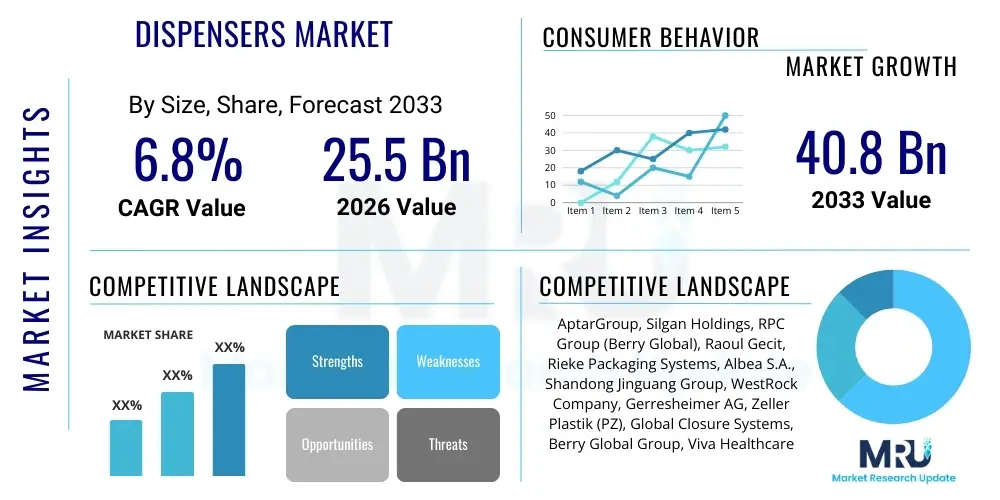

The Dispensers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 25.5 billion in 2026 and is projected to reach USD 40.8 billion by the end of the forecast period in 2033.

Dispensers Market introduction

The Dispensers Market encompasses a wide range of devices designed to control the flow and dosage of liquid, gel, or semi-solid products, ensuring precise delivery, hygiene, and convenience for end-users. These devices are critical components in packaging systems across diverse industries, including personal care, pharmaceuticals, food and beverage, and household cleaning. Product variations span from simple manual pump dispensers and trigger sprays to highly sophisticated electronic and sensor-based automatic dispensing systems, addressing the growing consumer demand for touchless operation, especially following global health crises that emphasized hygiene protocols. The evolution of the market is heavily influenced by material science advancements, aiming for more sustainable, recyclable, and bio-based plastic alternatives, aligning with global environmental directives.

Dispensers offer significant operational and consumer benefits, primarily centered on product preservation, waste reduction through controlled dosing, and enhanced user experience. Major applications involve the packaging of hand sanitizers, liquid soaps, lotions, creams, edible oils, pharmaceutical syrups, and industrial cleaning agents. The market growth is fundamentally driven by the expanding cosmetic and personal care industries, increasing urbanization leading to higher consumption of packaged goods, and stringent regulatory requirements mandating precise dosing in medical and pharmaceutical applications. Furthermore, the rise in disposable income in emerging economies and the expanding global tourism industry further fuel the demand for convenient, travel-friendly dispenser formats.

The increasing complexity of product formulations, particularly in the premium cosmetic and pharmaceutical sectors, necessitates high-performance dispensing mechanisms that maintain product integrity, prevent oxidation, and ensure accurate volumetric output. Driving factors also include technological integration, such as smart dispensers capable of monitoring usage and inventory, particularly in commercial and institutional settings like hospitals and hotels. The shift towards bulk packaging formats that utilize durable and refillable dispensing systems also represents a significant trend, promoting a circular economy approach while maintaining the functional efficiency required by modern consumers and businesses.

Dispensers Market Executive Summary

The Dispensers Market is experiencing robust growth fueled by converging trends in hygiene consciousness, automation, and sustainability. Business trends indicate a strong shift toward sensor-based and touchless dispensing systems, particularly in public and commercial domains, driven by post-pandemic public health concerns. Key market players are investing heavily in material innovation, focusing on single-polymer structures (monomaterials) to enhance recyclability and reduce the overall carbon footprint of dispensing solutions. Mergers, acquisitions, and strategic partnerships are common business strategies, aimed at consolidating supply chain control and expanding geographical reach, particularly in high-growth Asia Pacific regions where packaged consumer goods consumption is rapidly escalating.

Regionally, the Asia Pacific (APAC) region is poised to exhibit the fastest growth rate, driven by massive population density, rising disposable incomes, and the rapid expansion of domestic manufacturing capabilities across personal care and pharmaceutical industries. North America and Europe, while mature markets, maintain high market shares due to high consumer adoption rates of premium, technologically advanced, and sustainable dispensing solutions, coupled with strict regulatory frameworks that favor high-quality, leak-proof mechanisms. The Middle East and Africa (MEA) region shows accelerating demand, largely correlated with infrastructural development in the hospitality and healthcare sectors, which require large volumes of commercial-grade soap and sanitizer dispensers.

Segment trends highlight the dominance of the personal care application segment, which utilizes a vast array of pump and spray dispensers. However, the pharmaceutical segment is gaining traction, demanding highly specialized, airless, and preservative-free dispensing solutions to protect sensitive drug formulations. By mechanism, the automatic/sensor-based segment is expected to outpace the manual segment in terms of growth rate, reflecting the broader societal push towards automation and optimized hygiene practices in institutional environments. Material trends confirm a pivot away from multi-layered, hard-to-recycle plastics toward high-density polyethylene (HDPE) and polyethylene terephthalate (PET) that incorporate Post-Consumer Recycled (PCR) content, meeting corporate sustainability targets.

AI Impact Analysis on Dispensers Market

User queries regarding AI's influence in the Dispensers Market primarily revolve around how automation and machine learning can optimize inventory management, predict maintenance needs for complex electronic dispensers, and enhance the consumer personalization experience. Users are keen to understand the feasibility of predictive dosing algorithms, asking questions about AI-driven usage tracking in commercial settings (e.g., hospitals, offices) to prevent cross-contamination and ensure optimal stock levels. Concerns often focus on the cybersecurity of networked smart dispensers and the initial capital investment required for adopting AI-enabled hardware versus traditional mechanical systems. The prevailing expectation is that AI will transform dispensers from passive devices into active data-gathering endpoints, enhancing operational efficiency and driving down waste rates through intelligent, adaptive dosing protocols.

The integration of Artificial Intelligence and Machine Learning (ML) algorithms is set to revolutionize the backend operations and maintenance of advanced dispensing systems. For industrial applications, AI can analyze real-time flow data, pressure variations, and temperature inputs to predict potential mechanical failures in high-throughput dispensing lines, shifting maintenance from reactive to proactive. This dramatically reduces downtime in critical production environments such as food processing or pharmaceutical filling plants. Furthermore, in the consumer space, ML models can analyze usage patterns from smart home dispensers (e.g., detergent or supplement dispensers) to automatically reorder supplies, personalize dispensing volume based on learned behavior, and provide personalized consumption reports to the user, enhancing customer loyalty and convenience.

For large-scale institutional dispensing systems, such as those used for hand sanitizers in airports or corporate campuses, AI facilitates geo-spatial usage analysis. By aggregating data from numerous networked dispensers, facility managers can identify high-traffic zones, optimize cleaning schedules, and dynamically adjust refill frequency based on localized demand spikes. This capability significantly improves resource allocation and ensures compliance with institutional hygiene standards, representing a major advancement over traditional, manual monitoring processes. Consequently, while the initial cost might be higher, the long-term operational savings and improved public health outcomes justify the investment in AI-driven dispensing technology.

- AI optimizes supply chain logistics by predicting demand fluctuations for specific dispenser types and components.

- Predictive maintenance algorithms reduce operational downtime for high-volume automated dispensing equipment.

- Smart dispensers utilize machine learning to personalize dosage based on user history and product formulation requirements.

- Integration of AI in inventory systems allows for automatic reordering and real-time tracking of usage rates in institutional environments.

- Data analytics derived from smart dispensers provide valuable consumer behavior insights for product development and marketing strategies.

- AI-enabled vision systems improve quality control during the manufacturing process of complex pump and spray assemblies.

- Networked smart dispensers enhance public health monitoring by tracking sanitizer usage frequency across various public locations.

DRO & Impact Forces Of Dispensers Market

The Dispensers Market is primarily driven by heightened global hygiene awareness, increasing demand for controlled dosing mechanisms in regulated industries, and the continuous innovation in packaging designs promoting user convenience and aesthetic appeal. However, the market faces significant restraints, chiefly concerning the volatility in raw material prices, particularly petrochemical-derived plastics, and the substantial environmental pressure demanding a rapid shift away from single-use plastics toward sustainable alternatives. Opportunities are abundant in emerging economies characterized by fast-growing middle classes and expanding healthcare infrastructure, alongside the technological prospect of integrating smart features, connectivity, and biodegradable materials. These forces collectively propel the market forward while necessitating adaptive strategies from manufacturers to navigate material constraints and escalating regulatory scrutiny regarding waste management.

One major driving force is the regulatory environment in sectors like pharmaceuticals and food, where precise volumetric dispensing is mandatory to ensure efficacy and safety. This drives demand for high-precision, tamper-evident dispensing systems, particularly for liquid medications and highly concentrated food ingredients. The restraint imposed by high initial capital investment for specialized manufacturing equipment, such as sophisticated injection molding machinery required for complex pump components, also affects market entry for smaller players. Furthermore, the complexity involved in recycling multi-material dispensers (e.g., plastic pump components combined with metal springs and glass bottles) poses a significant challenge, forcing companies to prioritize monomaterial designs or invest in advanced chemical recycling infrastructure.

The impact forces are profoundly shaped by consumer perception of sustainability and hygiene. The opportunity to develop airless dispensing technology is highly attractive, as it minimizes product contamination, extends shelf life without relying on chemical preservatives, and caters to premium beauty and medical product lines. Conversely, the market is continually impacted by the threat of counterfeiting, especially for high-value cosmetic and pharmaceutical dispensers, necessitating investment in anti-tampering and authentication technologies. Successful market navigation requires companies to balance the need for high-performance mechanisms with the imperative for cost-effectiveness and ecological responsibility, making sustainable material sourcing and efficient manufacturing processes critical competitive advantages.

Segmentation Analysis

The Dispensers Market is broadly segmented based on the mechanism type, application area, material composition, and geography. This segmentation provides a granular view of market dynamics, revealing specific growth pockets driven by distinct end-user needs and technological adoption rates. For instance, pharmaceutical applications demand stringent material compliance and high accuracy, often relying on airless or metered dose dispensers, while the home care segment prioritizes robustness, cost-efficiency, and high-volume delivery pumps. Analyzing these segments helps stakeholders tailor product development and marketing efforts to specific vertical markets, ensuring alignment with regulatory standards and consumer preferences regarding sustainability and functionality.

Segmentation by mechanism, encompassing manual (pumps, triggers) and automatic (sensor-based, electronic) systems, reflects the shift towards enhanced hygiene and convenience. The automatic segment is poised for accelerated growth, particularly in institutional, public, and healthcare settings where minimizing surface contact is paramount. Application segmentation emphasizes the dominance of the personal care and cosmetic sectors, which are constantly introducing new products requiring innovative packaging solutions like fine mist sprays or dual-chamber dispensing systems for mixed formulations. Material segmentation highlights the ongoing transition from traditional plastics to sustainable options, including bio-plastics, PCR materials, and light weighting designs, directly responding to environmental pressures and governmental mandates aimed at reducing plastic waste.

Geographical segmentation reveals that market maturity levels vary significantly, influencing the predominant dispenser types demanded in each region. Developed economies focus on premiumization, technological sophistication (smart dispensers), and advanced sustainability features, whereas emerging markets prioritize basic functionality, volume, and cost-efficiency. Understanding the interplay between these segmentation variables is essential for strategic market penetration, enabling companies to optimize their product portfolio to meet the diverse and evolving needs across different socio-economic landscapes globally, from low-cost bulk dispensers to specialized, high-accuracy pharmaceutical injectors.

- By Type:

- Pump Dispensers (Lotion Pumps, Treatment Pumps)

- Spray Dispensers (Fine Mist Sprayers, Trigger Sprayers)

- Dropper Dispensers

- Metering Valves

- Airless Dispensers

- By Material:

- Plastic (PP, PE, PET)

- Glass

- Metal

- Bioplastics/PCR Content

- By Application:

- Personal Care & Cosmetics

- Pharmaceuticals & Healthcare (Drug Delivery Systems)

- Food & Beverage

- Home Care (Cleaning Agents, Detergents)

- Industrial & Institutional (I&I)

- By Mechanism:

- Manual/Mechanical

- Automatic/Sensor-based/Electronic

Value Chain Analysis For Dispensers Market

The Value Chain for the Dispensers Market is complex and involves multiple stages, beginning with raw material procurement and extending through specialized manufacturing, distribution, and final integration by end-user industries. Upstream analysis focuses heavily on securing a stable and cost-effective supply of virgin resins (PP, PE, PET), metals (springs), and increasingly, Post-Consumer Recycled (PCR) plastics or bio-based feedstocks. Raw material suppliers wield considerable influence due to price volatility, necessitating long-term contracts and strategic partnerships between compounders and dispenser manufacturers to mitigate risk. Furthermore, the quality of raw materials directly impacts the functionality and durability of critical components like pump pistons and dip tubes, making quality assurance at this stage paramount.

The midstream segment involves specialized manufacturing processes, primarily injection molding and assembly. Dispenser manufacturers require significant technological expertise and heavy investment in precision tooling to produce components with tight tolerances, ensuring leak-proof seals and accurate dosing volumes. The assembly process is often highly automated, particularly for high-volume, standard products, but can involve complex manual stages for specialized or premium airless systems. Downstream analysis focuses on effective distribution channels, which include both direct sales to major multinational cosmetic or pharmaceutical companies and indirect sales through packaging distributors and wholesalers who cater to smaller brands and regional players. The choice of channel depends on the volume, customization requirements, and geographical dispersion of the final customer.

Direct distribution channels are typically employed for highly customized or proprietary dispensing systems used by major CPG or pharmaceutical clients, facilitating closer collaboration on design, testing, and quality control. Conversely, indirect channels leverage the distributor's existing network and logistical infrastructure, offering a faster route to market for standardized products across diverse small and medium-sized enterprises (SMEs). The effectiveness of the value chain relies heavily on efficiency in logistics and inventory management, given the high volume and relatively low unit value of many mass-market dispensers. Increasing focus on sustainable packaging mandates continuous collaboration throughout the chain—from material suppliers providing certified PCR content to distributors promoting refillable and reusable dispensing solutions to the end-users.

Dispensers Market Potential Customers

The primary customers for the Dispensers Market span across highly diversified sectors, characterized by a fundamental need for precise, hygienic, and convenient product delivery mechanisms. End-users are predominantly categorized into fast-moving consumer goods (FMCG) companies, which include major global brands in personal care (shampoo, lotions, skincare) and home care (cleaning liquids, detergents). These customers demand high-speed, cost-efficient, and aesthetically appealing dispensers that align with their brand identity and target consumer demographics. The sheer volume required by these multinational corporations makes them the largest purchasers in terms of unit count, driving economies of scale in dispenser manufacturing.

A second major customer group comprises pharmaceutical and medical device companies. These customers require dispensers for sensitive applications, such as liquid medicines, topical treatments, and controlled-dose nasal or ocular sprays. Their purchasing criteria are strictly governed by regulatory bodies (like the FDA or EMA), emphasizing safety, material compatibility, anti-contamination features (e.g., airless technology), and highly accurate metering capability. For this segment, cost often takes a secondary role to performance, compliance, and product integrity, driving demand for specialized, high-value dispensing components and drug delivery systems.

Institutional and industrial buyers, including hospitality chains, healthcare facilities, government bodies, and industrial cleaning chemical manufacturers, form the third significant customer base. These entities primarily purchase high-capacity, durable, and often automated dispensers for bulk usage (e.g., hand sanitizers, industrial degreasers, and commercial soaps). The purchasing decision here is heavily influenced by factors such as durability, ease of maintenance, bulk pricing, and increasingly, connectivity for usage monitoring. Retail food service and specialty beverage producers also represent growing niche customers, requiring specialized pump dispensers for syrups, sauces, and condiments that ensure consistent quality and portion control.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 25.5 Billion |

| Market Forecast in 2033 | USD 40.8 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AptarGroup, Silgan Holdings, RPC Group (Berry Global), Raoul Gecit, Rieke Packaging Systems, Albea S.A., Shandong Jinguang Group, WestRock Company, Gerresheimer AG, Zeller Plastik (PZ), Global Closure Systems, Berry Global Group, Viva Healthcare Packaging, Coster Aerosols, Guala Closures S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dispensers Market Key Technology Landscape

The technological landscape of the Dispensers Market is rapidly evolving, driven primarily by the need for superior performance, sustainability, and connectivity. Advanced injection molding and assembly techniques are central to manufacturing precision components that ensure zero leakage and consistent dosage, often involving multi-cavity tooling and automated vision systems for defect detection. A critical area of innovation is Airless Dispensing Technology, which utilizes vacuum pressure and internal pistons rather than dip tubes, preventing product exposure to air and minimizing contamination, thereby eliminating the need for excessive preservatives, particularly vital for sensitive cosmetic and pharmaceutical formulations. This technology is gaining traction as it maximizes product evacuation, reducing waste and enhancing user satisfaction.

Another significant technological advancement is the widespread adoption of Sensor-Based and Electronic Dispensing Systems. These systems leverage infrared sensors, ultrasonic detectors, and often flow meters to enable touchless operation, a major priority in hygiene-sensitive environments. Furthermore, modern electronic dispensers frequently incorporate Internet of Things (IoT) capabilities, allowing them to connect to central networks for real-time monitoring of usage data, battery life, and inventory levels. This integration facilitates smarter maintenance planning, efficient resource management, and robust data collection for optimizing facility operations, moving the market toward "smart packaging" solutions that provide value beyond mere product containment and delivery.

Sustainability-focused technology is reshaping material composition and design. Manufacturers are increasingly utilizing Post-Consumer Recycled (PCR) content in plastics and focusing on creating monomaterial dispensers, where all components (housing, pump, and spring substitute) are made from the same polymer (e.g., HDPE or PP). This simplification drastically improves end-of-life recycling efficiency compared to traditional designs that mix materials like metal springs, glass bottles, and various plastics. Furthermore, light weighting technology—reducing the total mass of the dispenser while maintaining functionality and durability—is a continuous focus, achieving both cost savings and a lower carbon footprint during transportation and disposal, reflecting a proactive response to escalating environmental regulatory and consumer demands worldwide.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing market, primarily fueled by high population density, rapid industrialization, and significant expansion in the middle-class consumer base. Countries like China, India, and Southeast Asian nations are witnessing explosive growth in the personal care, cosmetic, and pharmaceutical manufacturing sectors, driving massive demand for high-volume standard dispensers. Increased focus on public health and sanitation, coupled with rising disposable incomes, encourages greater consumption of packaged goods and sophisticated dispensing solutions, including those with sustainability certifications.

- North America: North America holds a substantial market share, characterized by high adoption rates of advanced and premium dispensing technologies. The region drives innovation in smart, connected, and airless dispensing systems, particularly within the prestige beauty and specialty pharmaceutical markets. Stringent FDA regulations governing drug delivery systems ensure consistent demand for high-precision, compliant components. The region is also at the forefront of the movement toward sustainability, with strong corporate commitments to utilizing PCR content and ensuring dispenser recyclability.

- Europe: Europe is a mature but highly influential market, distinguished by strict environmental regulations, notably the EU’s packaging and packaging waste directives, which heavily favor refillable, reusable, and mono-material dispenser designs. The region demonstrates strong demand for aesthetically pleasing and highly functional dispensers for luxury cosmetics and organic personal care products. Germany, France, and the UK are key contributors, driven by a robust healthcare sector and high consumer expectations regarding product quality and ecological integrity.

- Latin America (LATAM): The LATAM market is exhibiting steady growth, largely driven by expanding local production of consumer packaged goods and improving economic conditions, particularly in Brazil and Mexico. Demand is generally focused on cost-effective, high-volume plastic pump and spray dispensers for household and mass-market personal care products. Infrastructure improvements in healthcare and tourism also necessitate the increased use of institutional dispensing systems.

- Middle East and Africa (MEA): Growth in the MEA region is accelerating, primarily linked to massive investments in commercial infrastructure (hotels, malls, offices) and healthcare expansion. The demand centers around high-capacity, robust dispensers for soap and sanitizer, reflecting a strong emphasis on hygiene standards. Oil-rich nations drive demand for premium packaging components for imported or domestically manufactured high-end cosmetic lines, although overall market volume remains lower compared to APAC or North America.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dispensers Market.- AptarGroup

- Silgan Holdings

- RPC Group (Berry Global)

- Raoul Gecit

- Rieke Packaging Systems

- Albea S.A.

- Shandong Jinguang Group

- WestRock Company

- Gerresheimer AG

- Zeller Plastik (PZ)

- Global Closure Systems

- Berry Global Group

- Viva Healthcare Packaging

- Coster Aerosols

- Guala Closures S.p.A.

- Zhejiang B&C Packaging Co., Ltd.

- O.Berk Company

- Yoshino Kogyosho Co., Ltd.

- Hana Global Co., Ltd.

- Pum-Tech Korea Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dispensers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the automatic dispenser market segment?

The automatic dispenser segment is primarily driven by heightened global awareness regarding hygiene and sanitation, accelerated by recent public health concerns. The demand for touchless operation in public facilities, healthcare settings, and commercial spaces to minimize cross-contamination is the major catalyst, supported by technological advancements like reliable sensor technology and IoT integration for monitoring.

How is sustainability impacting material choices within the dispenser industry?

Sustainability is profoundly shifting material choices toward Post-Consumer Recycled (PCR) plastics, bio-based polymers, and monomaterial designs (such as all-PP or all-PET pumps). Manufacturers are prioritizing materials that simplify the recycling process, aiming to meet corporate targets and regulatory mandates concerning plastic waste reduction and increased packaging circularity.

What distinguishes airless dispensing technology from standard pump mechanisms?

Airless dispensing technology utilizes a piston or diaphragm mechanism within the container to create a vacuum, dispensing the product without introducing air. Unlike standard pump mechanisms that use a dip tube and allow air entry, airless systems protect sensitive, preservative-free formulations from oxidation and contamination, maximizing product lifespan and ensuring near-total evacuation of the contents.

Which geographical region is expected to demonstrate the highest growth rate for dispensers, and why?

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR). This exponential growth is attributed to rapid urbanization, expanding manufacturing capacity in the personal care and pharmaceutical industries, rising disposable incomes, and increasing access to packaged consumer goods across populous countries like China and India.

What key challenges related to material costs and design complexity affect dispenser manufacturers?

Dispenser manufacturers face challenges primarily related to the volatility and upward trend in pricing for petrochemical-derived plastic resins (feedstocks). Furthermore, the intricate design of pump and spray systems, which often require precise tooling and assembly of multiple complex components (springs, closures, pistons), demands significant capital investment and rigorous quality control to ensure flawless, leak-proof functionality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Facial Tissue Dispensers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Tilting Dispensers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Ink Dispensers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Commercial Paper Towel Dispensers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Beverage Refrigerators and Dispensers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager