Baghouse Filters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441574 | Date : Feb, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Baghouse Filters Market Size

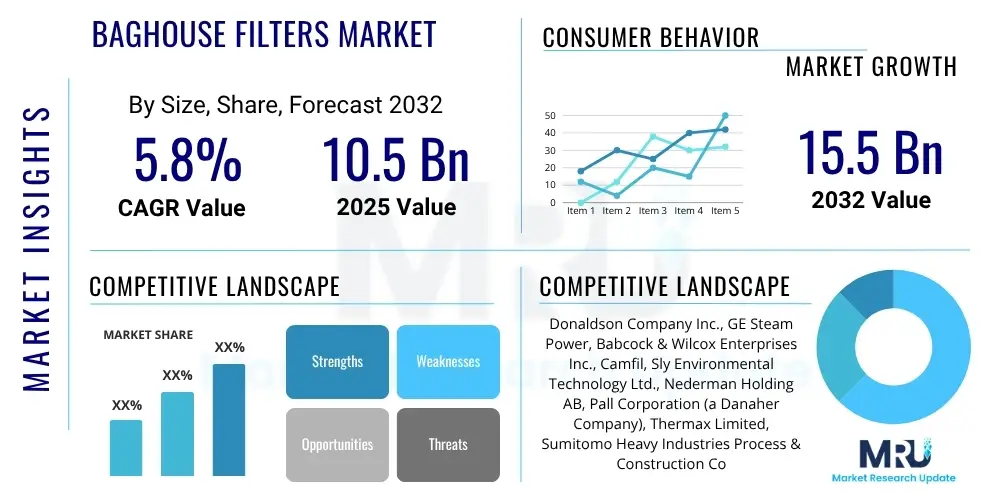

The Baghouse Filters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.6 Billion by the end of the forecast period in 2033. This consistent expansion is primarily driven by stringent global environmental regulations aimed at reducing industrial particulate matter emissions, coupled with sustained industrialization, particularly in emerging economies across Asia Pacific.

Baghouse Filters Market introduction

Baghouse filters, also known as fabric filters or fabric collectors, are highly efficient air pollution control devices designed to capture particulate matter (PM) from industrial gas streams. These systems operate by passing dust-laden air through large fabric bags, effectively filtering out solids before the clean air is released into the atmosphere. The principle application lies in industries generating high volumes of dust, ensuring compliance with both local and international air quality standards such as those enforced by the EPA and regional bodies.

Major applications of baghouse filter systems include power generation facilities (coal-fired plants), cement manufacturing, metallurgical processes (steel and non-ferrous metals), chemical processing, and pharmaceutical production. The key benefit these systems offer is their superior dust collection efficiency, often exceeding 99.9%, especially for fine particulates. Furthermore, they can handle large gas volumes and high temperatures, making them versatile across diverse industrial environments. Their effectiveness in capturing ultra-fine dust (PM2.5) is a critical factor driving adoption in regions facing severe air pollution challenges.

The market growth is strongly influenced by mandatory emission control policies and the continuous modernization of industrial infrastructure globally. Driving factors include the increasing focus on sustainable manufacturing practices, the phasing out of older, less efficient electrostatic precipitators (ESPs) in favor of modern fabric filtration technology, and technological advancements improving cleaning mechanisms (such as Pulse Jet technology), which enhance system longevity and operational efficiency.

Baghouse Filters Market Executive Summary

The Baghouse Filters Market displays robust growth, underpinned by critical business trends focusing on operational efficiency and regulatory compliance. Technologically, the shift towards Pulse Jet cleaning mechanisms dominates, offering lower maintenance costs and continuous operation capability compared to traditional shaker or reverse-air systems. Key vendors are prioritizing the integration of advanced materials, such as PTFE and composite fibers, to handle harsh operating conditions, including high temperatures and corrosive chemical exposure, thereby extending the filter bag lifespan and system reliability.

Regionally, Asia Pacific maintains its position as the largest and fastest-growing market due to rapid industrial expansion, significant investment in infrastructure projects, and increasingly strict government mandates on air quality in countries like China and India. North America and Europe, while mature, are characterized by high demand for retrofit installations, specialized high-efficiency particulate air (HEPA) systems, and stringent monitoring requirements, driving the adoption of smart filtration solutions and integrated sensor technologies. The chemical, cement, and power generation sectors remain the primary end-users globally, with high capital expenditure directed toward pollution control technologies.

Segment-wise, the market sees dynamic growth in the non-woven media segment, preferred for its high filtration efficiency and versatility across various applications, especially in power plants utilizing biomass or specific coal types. The trend leans towards modular and scalable baghouse designs that allow industries to expand capacity or adapt to changing production levels efficiently, minimizing downtime and installation complexity. Sustainability initiatives are also influencing procurement decisions, favoring systems that offer lower energy consumption for cleaning cycles and longer intervals between filter replacements.

AI Impact Analysis on Baghouse Filters Market

Common user questions regarding AI's impact on the Baghouse Filters Market center around themes of predictive maintenance, optimization of cleaning cycles, fault detection, and energy efficiency. Users are primarily concerned with how AI can extend the life of expensive filter bags, minimize unscheduled downtime, and reduce the overall operational expenditure (OPEX) associated with dust collection systems. There is significant interest in using machine learning algorithms to analyze pressure drop data, temperature fluctuations, and particulate concentration in real-time to forecast performance degradation, moving operations from reactive maintenance schedules to proactive, condition-based servicing. This shift is anticipated to revolutionize how industrial facilities manage air quality control assets.

The integration of AI leverages high-frequency sensor data generated by smart baghouses to establish operational baselines and identify anomalies far earlier than traditional monitoring methods. For instance, AI models can learn the optimal cleaning cycle frequency for specific dust loads and environmental conditions, preventing premature bag wear caused by excessive pulsing or insufficient cleaning leading to high differential pressure. This intelligent optimization ensures peak operational performance while significantly conserving compressed air usage—a major energy expense in Pulse Jet systems. Furthermore, AI facilitates complex root cause analysis when performance drops, rapidly diagnosing issues related to faulty valves, broken bags, or inadequate dust disposal mechanisms.

Ultimately, the impact of AI is transforming baghouse filters from passive air scrubbers into highly sophisticated, interconnected assets within the industrial internet of things (IIoT). This integration allows for remote diagnostics, centralized performance management across multiple plant locations, and improved reporting for regulatory compliance. The long-term expectation is that AI-driven predictive capabilities will become a standard offering, differentiating vendors based on the intelligence and accuracy of their integrated software solutions rather than solely on hardware specifications.

- AI-driven Predictive Maintenance (PdM) reduces unscheduled downtime and maximizes bag lifespan.

- Machine Learning (ML) algorithms optimize Pulse Jet cleaning cycles for reduced compressed air consumption (energy saving).

- Real-time data analysis identifies early signs of bag failure or system degradation through pressure drop monitoring.

- Enhanced fault detection and diagnosis speed up repair processes and improve regulatory compliance documentation.

- AI integration enables remote monitoring and centralized management of distributed baghouse systems (IIoT adoption).

DRO & Impact Forces Of Baghouse Filters Market

The dynamics of the Baghouse Filters Market are governed by a complex interplay of stringent environmental regulations (Driver), substantial capital investment requirements (Restraint), and the expanding scope of industrial applications (Opportunity). The primary driver is the global mandate for cleaner air, enforced through increasingly tight emission limits for particulate matter (PM), sulfur dioxide (SO2), and nitrogen oxides (NOx) across sectors such as power generation and cement manufacturing. This regulatory push forces industries to adopt highly efficient dust collection systems, directly translating into market demand for advanced baghouse technologies. Furthermore, technological improvements, particularly in high-temperature and chemical-resistant filter media, expand the applicability of baghouses into specialized industrial processes.

Key restraints tempering market growth include the high initial capital expenditure (CAPEX) associated with installing large-scale baghouse systems, particularly complex reverse-air units or specialized Pulse Jet systems in existing infrastructure. Operational restraints also include the recurring cost of replacement filter bags, which are consumables sensitive to temperature spikes and abrasive dust loads. In certain high-dust load environments, competition from alternative pollution control technologies, such as enhanced electrostatic precipitators (ESPs) or hybrid systems, can pose a minor challenge, although baghouses generally hold an advantage in efficiency for fine particulate capture.

Opportunities for market players are significant, centered on the burgeoning retrofit market in developed economies where aging pollution control infrastructure needs upgrading to meet new standards. In developing regions, opportunities are driven by greenfield industrial projects that require state-of-the-art emission control from the outset. Strategic growth avenues include developing smart filtration systems integrated with IIoT technology, focusing on energy-efficient designs (e.g., lower pressure drop systems), and offering specialized filter media tailored for emerging industrial processes like waste-to-energy and biomass co-firing. Impact forces, such as global efforts toward decarbonization and circular economy practices, necessitate continuous innovation in dust management to handle diverse fuel sources and industrial byproducts.

Segmentation Analysis

The Baghouse Filters Market is segmented across several critical parameters, including type of cleaning mechanism, material of filter media, and end-use application, providing a granular view of market dynamics and adoption patterns. The selection of a specific baghouse type is often dictated by the dust characteristics, gas flow rate, temperature, and specific regulatory requirements of the industrial process. Understanding these segmentation nuances is essential for stakeholders to tailor product offerings and competitive strategies, particularly focusing on high-growth segments such as Pulse Jet systems and specialized non-woven media for heavy industry applications.

The dominance of the Pulse Jet segment stems from its superior cleaning efficiency, shorter cleaning cycle duration, and capacity for continuous operation without needing to shut down or isolate individual compartments for maintenance. Meanwhile, the non-woven media segment is favored for its high dust loading capacity and excellent filtration performance, especially for ultra-fine particles, driving its adoption in modern power plants and sophisticated manufacturing facilities. Application-wise, the cement and power generation sectors collectively account for the largest share due to the massive volume of flue gas and particulate matter generated by these industries globally, necessitating robust and highly durable filtration solutions.

- By Type:

- Pulse Jet Baghouses

- Reverse Air Baghouses

- Shaker Baghouses

- Cartridge Collectors

- By Filter Media:

- Woven (Fiberglass, Aramid)

- Non-Woven (Polyester, Polypropylene, PTFE, P84)

- By Application/End-Use Industry:

- Cement Industry

- Power Generation (Coal, Biomass)

- Chemical Processing

- Metallurgy (Steel, Non-Ferrous Metals)

- Pharmaceuticals

- Food & Beverage

- Mining

- Others (Incineration, Pulp & Paper)

- By Operation:

- Continuous Operation

- Intermittent Operation

Value Chain Analysis For Baghouse Filters Market

The value chain for the Baghouse Filters Market begins with raw material suppliers, including manufacturers of high-performance technical textiles, specialized metals (for housing and internal components), and control instrumentation. The upstream phase is crucial, as the quality and resistance of the filter media (e.g., fiberglass, PTFE, specialized polymers) directly determine the operating temperature range, chemical compatibility, and overall filtration efficiency of the final product. Innovation in upstream material science, particularly coatings and composite media, significantly enhances product competitiveness downstream, impacting system lifespan and required maintenance frequency.

Midstream activities involve core manufacturing, encompassing the fabrication of the filter housing, design engineering (including computational fluid dynamics for optimized gas flow), and the assembly of critical components such as solenoid valves, dust hoppers, and cleaning mechanisms. System integrators and original equipment manufacturers (OEMs) play a pivotal role here, offering standardized or highly customized baghouse solutions based on specific client needs regarding gas volume, temperature profile, and dust characteristics. Certification and adherence to stringent quality controls (e.g., ASME standards) are essential at this stage to ensure system reliability and safety.

The downstream sector focuses on distribution, installation, maintenance, and aftermarket services. Distribution channels involve both direct sales to large industrial clients (e.g., major power companies) and indirect sales through specialized engineering, procurement, and construction (EPC) firms and regional distributors. Aftermarket services, particularly the continuous supply of replacement filter bags and complex system monitoring/optimization, represent a significant revenue stream. The trend is moving towards digital servicing, where vendors offer predictive maintenance contracts supported by IoT-enabled sensors and software analytics to ensure optimal performance over the asset's lifecycle, strengthening the direct customer relationship.

Baghouse Filters Market Potential Customers

Potential customers for baghouse filters are fundamentally any industrial facility involved in processes that generate significant airborne particulate matter requiring environmental control and regulatory compliance. The primary market consists of heavy process industries characterized by high gas volumes and demanding operating conditions. These end-users are driven by regulatory pressure to minimize emissions and the economic need to capture valuable dust or minimize equipment wear from abrasive particulates. Therefore, procurement decisions are heavily influenced by system reliability, filtration efficiency, and total cost of ownership (TCO).

The most lucrative segments are those undergoing expansion or modernization, necessitating new air pollution control equipment. For instance, utilities shifting from pure coal to co-firing biomass or utilizing specialized fuels require updated filtration systems capable of handling varying particulate compositions and temperatures. Similarly, cement manufacturers, continually investing in capacity expansion and energy efficiency, are persistent high-volume buyers. In developed economies, the focus is on smaller, specialized dust collectors (cartridge collectors) for niche applications in pharmaceutical manufacturing, food processing (where hygiene standards are paramount), and specialized chemical synthesis where cross-contamination must be prevented.

Procurement within large corporations often involves complex bidding processes managed by engineering departments or specialized environmental compliance teams. Decisions involve trade-offs between initial capital outlay and long-term operational costs, including energy consumption for compressed air and replacement media costs. Consequently, vendors who can demonstrate superior energy efficiency, extended bag life, and integrated digital performance monitoring solutions possess a distinct advantage when targeting these sophisticated end-users.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Donaldson Company, Inc., AAF International (Daikin), GEA Group, FLSmidth, Mitsubishi Hitachi Power Systems (MHPS), Babcock & Wilcox (B&W), Clarcor (Parker Hannifin), Nederman Holding AB, Camfil, Thermax Limited, Scientific Dust Collectors, Parker Hannifin Corporation, Intensiv-Filter GmbH, EnviroCare International, BWF Tec, Sino-Filter, C&G Environmental Protection. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Baghouse Filters Market Key Technology Landscape

The technology landscape of the Baghouse Filters Market is characterized by continuous innovation focused on three primary areas: maximizing filtration efficiency, extending component lifespan under extreme conditions, and reducing energy consumption associated with the cleaning process. Modern baghouse systems increasingly rely on advanced materials science, moving beyond conventional fabrics to utilize sophisticated non-woven media like expanded polytetrafluoroethylene (ePTFE) membranes, polyimide (P84), and specialized aramid fibers. These materials offer superior resistance to high temperatures (up to 500°F), chemical attack, and moisture, thereby broadening the application range, especially in flue gas desulfurization (FGD) bypass applications and severe chemical manufacturing environments.

A significant technological advancement is the widespread adoption and refinement of Pulse Jet cleaning mechanisms. Recent innovations focus on optimizing the geometry of venturis and nozzles to ensure uniform pressure distribution across the length of the bag, maximizing dust cake removal while minimizing the required compressed air volume. This optimization, often informed by computational fluid dynamics (CFD) modeling, directly translates to reduced energy consumption and less mechanical stress on the filter bags, resulting in longer operational periods between replacements. Furthermore, the integration of differential pressure (DP) monitoring sensors and control logic has become standard, allowing for cleaning cycles to be activated only when necessary, contributing to energy savings and overall system health.

Beyond core hardware, the integration of IIoT and digitalization represents the most transformative current technological trend. Smart baghouses incorporate a network of sensors monitoring critical parameters—temperature, humidity, dust loading, and differential pressure—feeding data into centralized cloud-based analytics platforms. This technological capability facilitates predictive analytics for potential bag failures, provides real-time reporting for regulatory audits, and enables sophisticated remote troubleshooting. The move towards modular design also represents a key technological shift, allowing for easier, faster installation and scalability, particularly attractive for mid-sized industrial users looking for flexible air pollution control solutions that can adapt to changing production capacities.

Regional Highlights

The Baghouse Filters Market exhibits distinct regional dynamics driven by differing industrialization rates, regulatory stringency, and maturity of existing infrastructure.

- Asia Pacific (APAC): APAC is the dominant and fastest-growing region, fueled by rapid industrialization, urbanization, and large-scale investment in power generation, cement, and steel production, particularly in China and India. The regional market growth is heavily mandated by governments implementing increasingly strict air pollution control policies (e.g., China's Blue Sky Protection Campaign). Demand focuses on large-capacity Pulse Jet baghouses utilizing high-efficiency non-woven media to cope with extensive dust loads and complex flue gas compositions. This region represents the largest opportunities for greenfield projects and substantial new installations.

- North America: This region is characterized by a mature market focused primarily on system upgrades, modernization (retrofitting older ESPs with baghouses), and stringent compliance with federal and state environmental laws (EPA). Key demand drivers include minimizing greenhouse gas emissions and achieving compliance for smaller, specialized sources. The market emphasizes specialized filter media for high-value manufacturing (e.g., aerospace, pharmaceuticals) and the adoption of IIoT-enabled smart filtration solutions for maximizing uptime and operational efficiency.

- Europe: The European market is highly regulated (driven by the Industrial Emissions Directive - IED) and emphasizes environmental sustainability and energy efficiency. Demand is strong for highly efficient fabric filters, particularly in power and waste-to-energy sectors. There is a notable preference for systems offering the lowest possible total cost of ownership, favoring advanced filtration materials and digital controls that minimize energy consumption during cleaning cycles. Germany, the UK, and Italy are key contributors due to robust manufacturing and energy sectors.

- Latin America (LATAM): Growth in LATAM is steady, driven by infrastructure development and expansion in mining and cement industries in Brazil, Mexico, and Chile. Market adoption is slower than in APAC but is accelerating due to international pressure and harmonization of environmental standards. Price sensitivity remains a factor, often influencing procurement towards systems offering a favorable balance between initial cost and long-term performance.

- Middle East and Africa (MEA): Market growth is linked to large oil and gas sector projects, petrochemical refining, and ambitious infrastructure plans (e.g., Saudi Vision 2030). Demand is rising for specialized baghouses capable of handling harsh desert conditions, high temperatures, and specific dust characteristics related to local mineral processing. Regulatory enforcement is increasing, driving demand for compliant filtration solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Baghouse Filters Market.- Donaldson Company, Inc.

- AAF International (Daikin Industries, Ltd.)

- GEA Group Aktiengesellschaft

- FLSmidth & Co. A/S

- Mitsubishi Hitachi Power Systems, Ltd. (MHPS)

- Babcock & Wilcox Enterprises, Inc. (B&W)

- Clarcor (A Parker Hannifin Company)

- Nederman Holding AB

- Camfil AB

- Thermax Limited

- Scientific Dust Collectors

- Gencor Industries Inc.

- Sino-Filter Co., Ltd.

- Intensiv-Filter GmbH & Co. KG

- BWF Tec GmbH & Co. KG

- EnviroCare International

- C&G Environmental Protection Holdings Ltd.

- Alstom Power (GE)

Frequently Asked Questions

Analyze common user questions about the Baghouse Filters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Baghouse Filters Market?

The primary driver is the increasing stringency of global environmental regulations, particularly regarding the control of industrial particulate matter (PM) emissions (including PM2.5 and PM10), forcing industries like power generation and cement manufacturing to adopt highly efficient filtration systems.

Which cleaning technology dominates the market and why is it preferred?

The Pulse Jet cleaning technology dominates the market due to its ability to operate continuously without requiring system shutdown, superior cleaning effectiveness using compressed air pulses, and lower maintenance requirements compared to traditional reverse air or shaker methods.

How does AI impact the operational efficiency of baghouse filtration systems?

AI significantly enhances operational efficiency through predictive maintenance (PdM), using sensor data to forecast potential bag failures and optimize the cleaning cycle frequency, thereby reducing energy consumption, minimizing unscheduled downtime, and extending the lifespan of expensive filter media.

Which geographical region represents the largest market share for baghouse filters?

Asia Pacific (APAC) holds the largest market share and is the fastest-growing region, driven by extensive industrial expansion, massive infrastructure projects, and heightened regulatory enforcement regarding air quality control in countries such as China and India.

What are the typical operating temperature limitations for standard filter media?

Standard polyester filter media is limited to approximately 275°F (135°C). However, high-performance media such as fiberglass, P84 (polyimide), and PTFE composites are commonly used for applications exceeding 400°F (200°C), making baghouses viable for high-temperature industrial flue gases.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Baghouse Filters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032

- Baghouse Filters For Woodworking Market Statistics 2025 Analysis By Application (Architectural Woodworking, Industrial Woodworking), By Type (Pulse Jet, Reverse Air, Shaker), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager