Baghouse Filters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430848 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Baghouse Filters Market Size

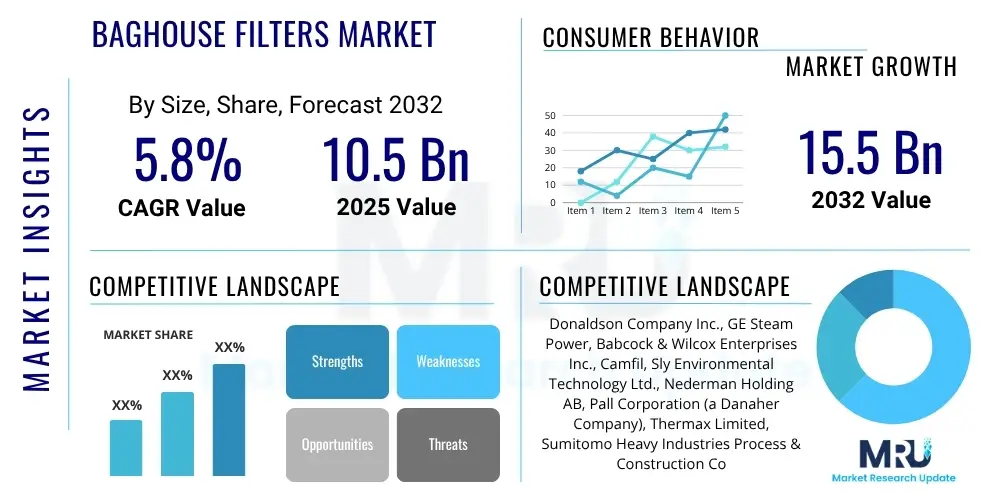

The Baghouse Filters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 10.5 Billion in 2025 and is projected to reach USD 15.5 Billion by the end of the forecast period in 2032.

Baghouse Filters Market introduction

Baghouse filters, also known as fabric filters, are highly efficient air pollution control devices designed to remove particulate matter from industrial gas streams. These systems operate by passing dust-laden air through fabric filter bags, which physically trap and collect dust particles. The collected dust is then periodically dislodged from the bags and collected in a hopper for disposal or recycling. This robust technology is critical for ensuring compliance with stringent air quality regulations and protecting both environmental health and industrial equipment.

The product encompasses a wide range of designs, including pulse jet, reverse air, and shaker baghouses, each suited for different dust loads, temperatures, and particulate characteristics. Major applications span across diverse heavy industries such as power generation, cement manufacturing, metallurgy, chemicals, and pharmaceuticals, where precise particulate control is paramount. Key benefits include high filtration efficiency, typically exceeding 99% for fine particulates, operational versatility, and the ability to handle large volumes of gas, contributing significantly to improved air quality and reduced operational downtime for industrial facilities.

Driving factors for the market include escalating global concerns over industrial air pollution, the implementation of stricter environmental protection laws worldwide, and increasing awareness regarding worker health and safety. Furthermore, continuous industrialization in emerging economies, coupled with technological advancements leading to more durable and efficient filter media and intelligent control systems, are propelling market expansion. The necessity for industries to comply with emissions standards, alongside the economic advantages of dust recovery, reinforces the sustained demand for baghouse filter solutions.

Baghouse Filters Market Executive Summary

The Baghouse Filters Market is poised for significant growth, driven by escalating environmental regulations and rapid industrialization globally. Business trends indicate a strong focus on developing advanced filter media and integrated smart control systems to enhance efficiency and reduce operational costs. Manufacturers are increasingly investing in research and development to offer specialized solutions tailored for specific industrial applications, responding to the demand for higher performance and extended service life. The market is also witnessing consolidation as companies seek to expand their technological capabilities and geographical reach.

Regional trends highlight Asia Pacific as the dominant and fastest-growing market, primarily due to the extensive industrial expansion, particularly in countries like China and India, coupled with rising environmental concerns and the enforcement of stricter pollution control policies. North America and Europe continue to be mature markets, characterized by stringent existing regulations and a strong emphasis on upgrading aging infrastructure and adopting advanced, energy-efficient filtration technologies. Latin America, the Middle East, and Africa are emerging as promising markets, fueled by infrastructure development, growth in mining and manufacturing, and increasing governmental focus on industrial emissions control.

Segment trends reveal a robust demand for pulse jet baghouses due to their superior cleaning efficiency and adaptability to various dust types, making them a preferred choice across numerous industries. The power generation and cement industries remain major application segments, alongside significant growth in chemical, metals, and food and beverage sectors. In terms of filter media, advanced synthetic materials offering higher temperature resistance and better chemical inertness are gaining traction over traditional woven fabrics, reflecting an industry-wide shift towards more durable and effective filtration solutions that contribute to overall system longevity and performance.

AI Impact Analysis on Baghouse Filters Market

Users frequently inquire about how Artificial Intelligence (AI) can enhance the efficiency, maintenance, and overall operational intelligence of baghouse filters, a traditionally mechanical system. Common questions revolve around predictive maintenance capabilities, energy optimization, fault detection, and the potential for autonomous operation. There is a strong expectation that AI will transform baghouse management from reactive to proactive, improving uptime and reducing operational expenditures. Key themes include leveraging data from sensors for real-time insights, integrating with existing SCADA or DCS systems, and developing smarter, self-optimizing filtration processes.

- AI-powered predictive maintenance identifies potential failures in fans, motors, and filter bags before they occur, reducing unplanned downtime.

- Optimized cleaning cycles through AI algorithms minimize compressed air usage and extend filter bag life, leading to energy savings.

- Real-time performance monitoring and anomaly detection using AI ensure optimal filtration efficiency and rapid identification of operational deviations.

- Integration with plant-wide control systems allows for holistic process optimization and automated adjustments based on production demands.

- AI facilitates better dust loading management by adjusting airflow and cleaning frequency, enhancing the overall capture rate.

- Advanced data analytics provide insights into operational patterns, enabling informed decision-making for system upgrades and process improvements.

- Improved regulatory compliance tracking and reporting through AI-driven data aggregation and analysis, simplifying environmental audits.

DRO & Impact Forces Of Baghouse Filters Market

The Baghouse Filters Market is significantly influenced by a confluence of drivers, restraints, and opportunities, all shaped by various impact forces. The primary drivers include the global push for stricter environmental regulations and air quality standards, which compel industries to invest in effective particulate emission control technologies. Rapid industrialization and urbanization, particularly in developing economies, further fuel demand as new manufacturing facilities and power plants are established. Growing awareness of occupational health and safety also drives adoption, as baghouse filters protect workers from harmful airborne particulates. Moreover, the increasing focus on energy efficiency and resource recovery, where captured dust can be recycled, adds economic incentive for investment.

However, the market faces several restraints that could impede its growth. The high initial capital investment required for baghouse filter systems, including design, installation, and associated infrastructure, can be a barrier for small and medium-sized enterprises. Operational costs, primarily related to energy consumption for fans and compressed air for bag cleaning, along with the regular replacement of filter bags, also contribute to the total cost of ownership. The availability of alternative dust collection technologies, such as electrostatic precipitators (ESPs) and scrubbers, while often less efficient for fine particulates, provides competitive alternatives in certain applications, further impacting market dynamics.

Despite these challenges, significant opportunities exist for market expansion. The retrofit market, involving the upgrade of older or less efficient pollution control systems, presents a substantial growth avenue. Emerging economies, undergoing rapid industrial expansion, represent untapped potential for new installations. Furthermore, technological advancements in filter media, such as high-performance fabrics and membrane technologies, promise improved efficiency and durability. The development of smart baghouse systems integrating IoT and AI for predictive maintenance and optimized operation also opens new revenue streams and enhances product value, driving future market growth and competitive advantage.

Segmentation Analysis

The Baghouse Filters Market is broadly segmented based on several key characteristics, including type, filter media, application, and end-user. This granular segmentation helps in understanding the diverse needs of various industries and the specific technological preferences adopted to address their unique dust collection challenges. The market's structure reflects the specialized requirements of different industrial processes, from high-temperature environments to specific particulate sizes, dictating the design and material choices for effective filtration solutions. This analysis allows for a comprehensive understanding of market dynamics and growth patterns across different product categories and consumer bases.

- By Type

- Pulse Jet Baghouse Filters

- Reverse Air Baghouse Filters

- Shaker Baghouse Filters

- Other Types (e.g., Cartridge Collectors)

- By Filter Media

- Woven (e.g., Polyester, Polypropylene)

- Non-Woven (e.g., Felt, Spunbond)

- Fiberglass

- PTFE (Polytetrafluoroethylene)

- Nomex

- Other Specialty Media (e.g., P84, PPS)

- By Application

- Power Generation (e.g., Coal-fired Power Plants)

- Cement Manufacturing

- Metal Processing (e.g., Steel, Aluminum, Foundries)

- Chemical Processing

- Food and Beverage

- Pharmaceuticals

- Mining

- Pulp and Paper

- Waste Incineration

- Other Industrial Applications

- By End-User

- Heavy Industries

- Manufacturing Sector

- Energy Sector

- Construction

- Other Industrial End-Users

Value Chain Analysis For Baghouse Filters Market

The value chain for the Baghouse Filters Market begins with the upstream activities involving the sourcing of raw materials and components critical for manufacturing. This segment includes suppliers of various filter media fabrics such as polyester, polypropylene, fiberglass, and specialty materials like PTFE and Nomex. It also encompasses suppliers of metal components for the baghouse housing, fan systems, control panels, and various other mechanical and electrical parts. The quality and availability of these raw materials directly impact the manufacturing process and the final product's performance and cost-effectiveness. Strong relationships with reliable suppliers are crucial for ensuring a consistent supply chain and maintaining product standards.

Further along the chain, the manufacturing and assembly phase involves the conversion of raw materials into finished baghouse filter systems. This stage includes the fabrication of baghouse casings, the sewing and finishing of filter bags, and the assembly of entire systems, including fans, hoppers, and control mechanisms. Manufacturers often specialize in different types of baghouses or filter media, leveraging proprietary technologies for improved efficiency and durability. After manufacturing, the products enter the distribution channel, which can be direct or indirect. Direct sales involve manufacturers selling directly to large industrial end-users, often accompanied by comprehensive engineering, installation, and commissioning services. Indirect distribution typically involves a network of distributors, agents, and engineering, procurement, and construction (EPC) firms that facilitate sales and provide localized support to a broader range of customers.

The downstream activities in the value chain are focused on installation, maintenance, and aftermarket services. Installation typically requires specialized engineering expertise to integrate the baghouse system into existing industrial processes. Post-installation, maintenance services, including filter bag replacement, system inspections, and repairs, are essential for ensuring the continued efficient operation of the units. The aftermarket segment, comprising replacement filter bags, spare parts, and upgrade components, represents a significant and recurring revenue stream for manufacturers and service providers. This part of the value chain is critical for long-term customer satisfaction and brand loyalty, as it ensures operational reliability and extends the lifespan of the filtration systems in the field.

Baghouse Filters Market Potential Customers

Potential customers for baghouse filters span a broad spectrum of industries that generate significant particulate matter as part of their operational processes and are subject to stringent air quality regulations. These industrial end-users prioritize efficient dust collection to comply with environmental standards, protect employee health, maintain equipment longevity, and, in some cases, recover valuable materials. The demand for baghouse filters is directly tied to the level of industrial activity and the regulatory landscape within a given region, making these sectors prime targets for market players.

Key sectors include heavy industries such as power generation, where coal-fired power plants rely heavily on baghouses to control fly ash emissions, and cement manufacturing, which requires robust systems for kiln dust and clinker dust. The metal processing industry, encompassing steel mills, foundries, and aluminum smelters, utilizes baghouses to capture particulate emissions from furnaces and casting operations. Chemical processing plants and pharmaceutical manufacturers need high-efficiency filtration to manage process dust and ensure product purity, often adhering to very strict cleanroom and emission standards. Additionally, mining operations, pulp and paper mills, and waste incineration facilities are significant buyers due to the large volumes of dust and particulate matter generated in their respective processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 10.5 Billion |

| Market Forecast in 2032 | USD 15.5 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Donaldson Company Inc., GE Steam Power, Babcock & Wilcox Enterprises Inc., Camfil, Sly Environmental Technology Ltd., Nederman Holding AB, Pall Corporation (a Danaher Company), Thermax Limited, Sumitomo Heavy Industries Process & Construction Co. Ltd., Mitsubishi Heavy Industries, Ltd., AAF International (Daikin Industries, Ltd.), BWF Envirotec, Fuji Filter Mfg. Co., Ltd., W. L. Gore & Associates, Inc., Gencor Industries Inc., Hamon Group, Qingdao Huada Environmental Protection Equipment Co. Ltd., Met-Pro Corporation, CECO Environmental, Micronics Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Baghouse Filters Market Key Technology Landscape

The Baghouse Filters Market is continuously evolving with significant technological advancements aimed at improving efficiency, durability, and operational intelligence. A central focus is on advanced filter media, which includes the development of high-performance fabrics like those incorporating PTFE membranes, aramid fibers, and various synthetic blends designed to withstand extreme temperatures, corrosive chemicals, and abrasive dusts. Innovations in nanofiber technology are also emerging, offering enhanced filtration efficiency for ultra-fine particulates while maintaining low pressure drops, which translates to reduced energy consumption for fan systems. These new media extend filter bag life and improve overall system performance, reducing the frequency of costly replacements and maintenance.

Another crucial area of technological development lies in intelligent control systems and automation. Modern baghouse filters are increasingly integrated with sensors, IoT devices, and advanced programmable logic controllers (PLCs) that enable real-time monitoring of differential pressure, temperature, and emissions. This data is leveraged for optimizing cleaning cycles, predicting maintenance needs, and diagnosing potential issues before they lead to downtime. The integration of artificial intelligence (AI) and machine learning (ML) algorithms allows for predictive maintenance, energy optimization, and even autonomous adjustments to operating parameters based on real-time process conditions, moving away from traditional reactive maintenance schedules. These smart systems contribute to higher uptime, lower operational costs, and improved regulatory compliance.

Furthermore, improvements in baghouse design and fan technology are contributing to the market's technological landscape. Modular designs are gaining traction, allowing for easier scalability, installation, and maintenance. Enhanced inlet designs and internal baffles are engineered to improve dust distribution and reduce abrasive wear on filter bags, thereby extending their operational life. Energy-efficient fan systems, often equipped with variable frequency drives (VFDs), are becoming standard, significantly reducing power consumption—a major operational cost. The focus is also on advanced dust discharge systems and explosion protection measures, particularly for handling combustible dusts, ensuring safer and more reliable operations across hazardous industrial environments.

Regional Highlights

- North America: This region is characterized by mature industrial sectors and stringent environmental regulations, particularly from the Environmental Protection Agency (EPA). Demand is driven by the need for compliance, upgrades of aging infrastructure, and a focus on advanced, energy-efficient filtration solutions in power generation, cement, and metal industries. The presence of key market players and a strong emphasis on worker safety also contributes to market stability and growth.

- Europe: Similar to North America, Europe boasts well-established industries and strict environmental policies, notably the EU Industrial Emissions Directive. The market here is focused on sustainable solutions, retrofit opportunities, and technological advancements in filter media and intelligent systems to meet evolving emission standards. Germany, the UK, and France are significant contributors, with a strong emphasis on clean industrial processes.

- Asia Pacific (APAC): APAC is the largest and fastest-growing market for baghouse filters, propelled by rapid industrialization, urbanization, and increasing manufacturing activities in countries like China, India, and Southeast Asia. The region faces significant air pollution challenges, leading governments to implement stricter emission control regulations, thereby driving substantial demand for new installations and upgrades across diverse heavy industries.

- Latin America: This region presents emerging opportunities due to ongoing industrial development, particularly in mining, cement, and power generation sectors. Growing environmental awareness and the adoption of international pollution control standards are gradually boosting the demand for baghouse filters. Brazil and Mexico are key markets, investing in industrial infrastructure and requiring robust particulate control solutions.

- Middle East and Africa (MEA): The MEA region is experiencing growth driven by investments in infrastructure, oil and gas, petrochemicals, and mining industries. While environmental regulations are still developing in some areas, increasing foreign investments and a greater focus on industrial sustainability are expected to fuel market expansion. Saudi Arabia, UAE, and South Africa are key countries in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Baghouse Filters Market.- Donaldson Company Inc.

- GE Steam Power

- Babcock & Wilcox Enterprises Inc.

- Camfil

- Sly Environmental Technology Ltd.

- Nederman Holding AB

- Pall Corporation (a Danaher Company)

- Thermax Limited

- Sumitomo Heavy Industries Process & Construction Co. Ltd.

- Mitsubishi Heavy Industries, Ltd.

- AAF International (Daikin Industries, Ltd.)

- BWF Envirotec

- Fuji Filter Mfg. Co., Ltd.

- W. L. Gore & Associates, Inc.

- Gencor Industries Inc.

- Hamon Group

- Qingdao Huada Environmental Protection Equipment Co. Ltd.

- Met-Pro Corporation

- CECO Environmental

- Micronics Inc.

Frequently Asked Questions

What are the primary benefits of using baghouse filters in industrial settings?

Baghouse filters offer high filtration efficiency, typically exceeding 99% for particulate matter, ensuring compliance with strict air quality regulations. They protect workers from harmful airborne dust, extend the lifespan of industrial machinery by preventing abrasive wear, and can facilitate the recovery of valuable process materials.

How often should baghouse filter bags be replaced?

The replacement frequency for baghouse filter bags varies significantly based on factors such as the type of dust, operating temperature, gas velocity, filter media, and cleaning cycle intensity. Typically, filter bags can last from 1 to 5 years, but real-time monitoring and predictive maintenance can optimize replacement schedules.

What is the difference between pulse jet and reverse air baghouse filters?

Pulse jet baghouses clean bags by short, high-pressure bursts of air from inside the bags, dislodging dust. Reverse air baghouses clean by introducing low-pressure air in the opposite direction of filtration, causing bags to collapse slightly and release dust. Pulse jets are generally more efficient for fine dust and continuous operation.

What factors should be considered when selecting a baghouse filter system?

Key factors include the characteristics of the dust (size, abrasiveness, combustibility), gas volume and temperature, desired filtration efficiency, available space, capital and operational costs, and local environmental regulations. Expert consultation is often recommended for optimal system design and selection.

How do smart baghouse systems improve operational efficiency?

Smart baghouse systems utilize sensors, IoT, and AI for real-time monitoring, predictive maintenance, and optimized cleaning cycles. This leads to reduced energy consumption, extended filter bag life, minimized downtime, and enhanced compliance tracking, resulting in significant operational cost savings and improved performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Baghouse Filters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Baghouse Filters For Woodworking Market Statistics 2025 Analysis By Application (Architectural Woodworking, Industrial Woodworking), By Type (Pulse Jet, Reverse Air, Shaker), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager