Copper Tungsten Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441063 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Copper Tungsten Market Size

The Copper Tungsten Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $550 Million USD in 2026 and is projected to reach $860 Million USD by the end of the forecast period in 2033. This robust expansion is primarily driven by the escalating demand for high-performance materials in critical applications, particularly within the electronics, aerospace, and defense sectors. The unique combination of tungsten's high melting point and copper's excellent electrical and thermal conductivity positions Copper Tungsten (CuW) alloys as indispensable components for thermal management and electrical contact applications where high wear resistance and arc erosion stability are mandatory. The market trajectory reflects substantial investment in advanced manufacturing techniques, allowing for the production of complex shapes and higher purity alloys necessary for miniaturized electronic devices.

Copper Tungsten Market introduction

The Copper Tungsten Market encompasses the production and distribution of composite materials synthesized from tungsten and copper powders, characterized by their superior physical and mechanical properties. These pseudo-alloys are not true alloys in the traditional sense, as copper and tungsten are mutually insoluble, but are engineered via powder metallurgy techniques such as pressing, sintering, and infiltration to leverage the best attributes of both constituent metals. The resulting material boasts high thermal stability, exceptional electrical conductivity, low coefficient of thermal expansion (CTE) matching critical semiconductor substrates, and outstanding resistance to arc erosion. These attributes make CuW materials ideal for demanding environments where conventional materials fail to maintain integrity or performance.

Major applications for Copper Tungsten materials span critical industrial and high-technology domains. In electrical discharge machining (EDM), CuW is utilized extensively as electrodes due to its superior wear resistance and ability to hold fine detail. Furthermore, its excellent thermal management properties make it essential for manufacturing heat sinks and thermal planes in high-power electronic devices, particularly those utilized in military radar systems, telecommunications, and advanced computing. CuW is also foundational in resistance welding electrodes, vacuum contacts, and high-voltage circuit breakers where it mitigates damage from electrical arcing. The ongoing global technological shift towards higher power densities and smaller form factors inherently drives the demand for these sophisticated composite materials.

The core driving factors propelling market growth include the exponential growth in the semiconductor industry, which requires reliable thermal management solutions for ever-more powerful chips. Secondly, the modernization and expansion of defense and aerospace systems necessitate robust, reliable components for demanding operational conditions. Lastly, the increasing global investment in renewable energy and smart grid infrastructure utilizes CuW in critical switchgear and circuit protection devices. The material's inherent benefits—such as its density, hardness, and thermal efficiency—outweigh the relatively high production costs for specialized applications, ensuring sustained market expansion throughout the forecast period.

Copper Tungsten Market Executive Summary

The Copper Tungsten Market is currently undergoing significant transformation driven by rapid technological advancements and evolving end-user requirements, particularly in Asia Pacific (APAC). Business trends indicate a strong move toward tailored alloy compositions and the adoption of additive manufacturing techniques (AM) to reduce waste and produce geometries previously unattainable through conventional pressing and sintering. Key players are increasingly investing in proprietary powder processing technologies to enhance material uniformity and consistency, addressing the strict quality requirements of the semiconductor and medical device industries. Furthermore, sustainability concerns are influencing supply chain optimization, focusing on efficient raw material sourcing and minimization of energy consumption during production, positioning companies with robust recycling programs favorably.

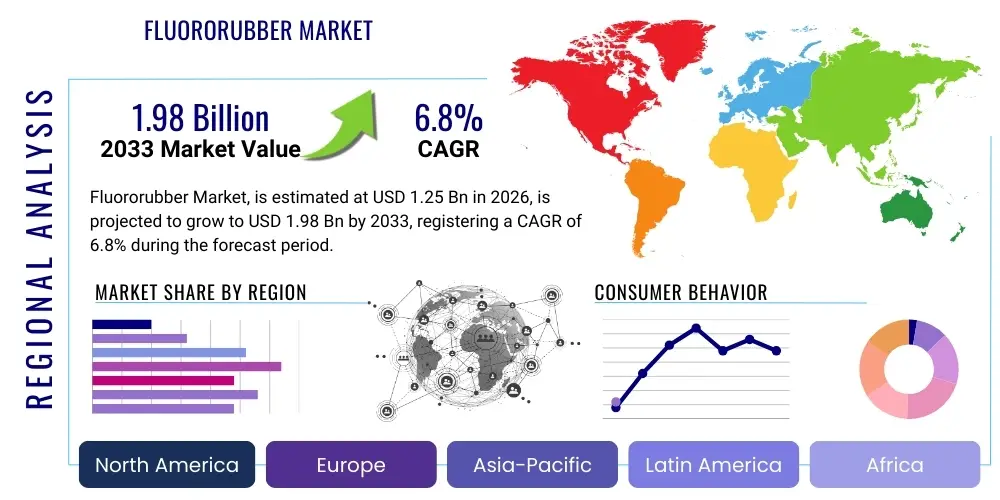

Regionally, APAC stands as the undisputed leader, largely due to the concentration of electronics manufacturing hubs in countries like China, South Korea, and Taiwan. These nations serve as the primary consumers of CuW for high-performance heat sinks, integrated circuits (ICs), and electrical contacts, fueled by massive government and private sector investments in 5G infrastructure and advanced chip fabrication. North America and Europe, while possessing mature markets, demonstrate growth primarily through high-value defense, aerospace, and specialized industrial equipment segments, emphasizing high-purity, application-specific grades. The Middle East and Africa (MEA) and Latin America remain nascent but show promising potential, especially in the oil & gas and power generation sectors where CuW’s electrical properties are crucial for reliability and safety.

Segmentation trends reveal that the Infiltration Method segment dominates production, owing to its capability to yield materials with high density and excellent microstructure control, essential for precision components. However, the Pressing & Sintering segment is showing accelerated adoption for simpler geometries and lower cost applications. In terms of end-use, the Electronics segment, specifically driven by the thermal management component market (heat sinks and thermal spreaders), is the most prominent revenue generator. Concurrently, the increasing complexity of Electrical Discharge Machining (EDM) operations across various manufacturing sectors ensures sustained, stable demand for high-quality CuW electrodes, confirming the material's critical role across multiple industrial processes.

AI Impact Analysis on Copper Tungsten Market

Common user questions regarding AI's influence on the Copper Tungsten market frequently revolve around process optimization, predictive material science, and enhancing manufacturing efficiency. Users often ask: How can AI algorithms optimize the pressing and sintering parameters to achieve desired density and microstructure? Can machine learning predict the long-term performance and failure points of CuW electrical contacts under high-stress conditions? What is the role of AI in analyzing raw powder purity and ensuring consistency in large-scale production? The analysis indicates key themes center on the ability of AI to mitigate traditional production variability, reduce costly material waste, and accelerate the discovery of novel CuW compositions tailored for extreme operational environments, fundamentally shifting quality control from reactive inspection to proactive prediction. This technological integration promises to lower the barrier to entry for complex material processing, optimizing both cost and performance across the entire value chain.

- AI-driven optimization of powder metallurgy parameters (e.g., compaction pressure, sintering temperature, infiltration time) to maximize density and minimize porosity.

- Predictive maintenance analytics applied to EDM electrodes and electrical contacts, forecasting wear rates and operational lifespan based on real-time usage data.

- Machine learning algorithms utilized for quality control, analyzing microscopic images and sensor data to ensure precise copper-tungsten distribution and phase uniformity.

- Acceleration of R&D through computational materials science, rapidly screening new CuW compositions and processing routes for specific thermal or electrical requirements.

- Supply chain risk management enhanced by AI, predicting raw material cost volatility and optimizing inventory levels for tungsten and copper powders.

DRO & Impact Forces Of Copper Tungsten Market

The Copper Tungsten Market is fundamentally shaped by a delicate balance of inherent material advantages, economic constraints, and burgeoning technological requirements. Drivers such as the persistent demand for miniaturization in electronic devices, necessitating highly efficient thermal management solutions, and the critical need for arc-resistant materials in advanced circuit protection systems, provide significant impetus. However, these drivers are counterbalanced by substantial restraints, predominantly the high and volatile cost of tungsten raw materials, coupled with the inherent difficulty and expense associated with machining these hard, dense composites. Opportunities emerge through innovation, particularly the refinement of additive manufacturing techniques, which promises greater geometric flexibility and reduced material waste, along with strategic expansion into high-growth sectors like 5G/6G communication infrastructure and high-power laser applications. These forces create a dynamic market environment where technological differentiation and cost optimization are essential for sustained competitiveness.

The primary Drivers of the market center around the superior physical characteristics of CuW composites. Their high thermal conductivity ensures efficient heat dissipation, essential for the reliability of semiconductor devices operating at increased power levels, thus mitigating the risk of thermal runaway. Furthermore, the exceptional erosion resistance and high melting point of CuW make it the material of choice for demanding electrical contacts, especially in vacuum interrupters and high-current relays, ensuring operational longevity and safety in critical power infrastructure. The expansion of defense spending globally, specifically for advanced radar and missile guidance systems that require lightweight yet robust thermal management components, further solidifies the foundation for market expansion. This persistent demand from high-reliability applications guarantees stable, long-term growth.

Conversely, significant Restraints pose challenges to widespread adoption. The scarcity and geopolitical complexity associated with tungsten sourcing contribute directly to high raw material costs, forcing manufacturers to meticulously manage their supply chains and pricing strategies. Moreover, the hardness and brittleness inherent in high tungsten content composites make traditional machining and finishing operations exceptionally difficult and time-consuming, necessitating specialized tooling and expertise, thereby increasing production lead times and overall component costs. Market opportunities, however, present pathways to overcome these barriers. The development of advanced net-shape fabrication techniques, including binder jetting and laser powder bed fusion optimized for CuW powders, promises to circumvent costly post-processing. Additionally, the emergence of niche applications in high-frequency communications and specialized medical imaging equipment represents new, high-margin revenue streams that leverage the material's unique blend of electrical and thermal properties.

- Drivers:

- Escalating demand from the semiconductor and high-power electronics industries for advanced thermal management components.

- Critical reliance on CuW for arc-resistant electrical contacts in high-voltage and vacuum switchgear.

- Increased global investment in defense and aerospace sectors requiring high-density, thermally stable materials.

- Restraints:

- High volatility and cost associated with raw tungsten powder procurement.

- Difficulty and expense of machining and fabricating complex CuW component geometries.

- Environmental and regulatory pressures related to handling and disposal of certain manufacturing byproducts.

- Opportunities:

- Advancements in Additive Manufacturing (AM) techniques to produce complex, net-shape CuW parts efficiently.

- Expansion into emerging applications such as 5G/6G infrastructure components and specialized medical technology.

- Development of customized composite grades optimizing cost-performance ratios for specific end-uses.

- Impact Forces:

- Technological innovation in powder metallurgy driving material property improvements and consistency.

- Geopolitical stability influencing the price and availability of key raw materials (tungsten).

- Shifting regulatory landscape concerning electrical and thermal performance standards in high-reliability systems.

Segmentation Analysis

The Copper Tungsten Market is strategically segmented based on critical technical variables, including the manufacturing method utilized, the percentage composition of copper, and the application in various end-use industries. This segmentation provides a granular view of market dynamics, revealing that performance requirements often dictate the preferred manufacturing route and material specification. The method of production, typically categorized into the infiltration method and the pressing & sintering method, significantly affects the final density, microstructure, and cost of the resulting component, driving differential adoption across applications like thermal management and electrical contacts. Furthermore, the copper concentration dictates the material's thermal and electrical conductivity, with higher copper content alloys favoring electrical contact applications and lower copper content alloys preferred where hardness and arc resistance are paramount. Understanding these segments is crucial for stakeholders to tailor their product offerings and maximize market penetration.

The manufacturing method segmentation reflects fundamental differences in processing capabilities and resulting material integrity. The infiltration technique, where a porous sintered tungsten preform is impregnated with molten copper, typically yields high-density materials with superior thermal uniformity and reduced porosity, making them highly desirable for precision components like semiconductor heat sinks. Conversely, the pressing and sintering method is more cost-effective for simpler shapes and large volumes, primarily utilized for resistance welding electrodes and standard electrical contacts. The application-based segmentation highlights the primary demand sectors, with Electrical Discharge Machining (EDM) consistently representing a significant consumer base due to the non-ferrous materials requiring precision machining, while the thermal management sector sees rapid expansion fueled by the consumer electronics and data center markets. This structural diversification underscores the versatility of CuW composites.

Analyzing the end-user segmentation reveals where the highest value transactions occur. The Electronics industry, encompassing everything from integrated circuit packaging to high-frequency communication modules, is the largest consumer, valuing CuW for its exceptional thermal dissipation capabilities. The Automotive sector is increasingly adopting CuW in electric vehicle (EV) charging infrastructure and high-reliability sensors, driven by electrification trends. The Defense and Aerospace segments, although smaller in volume, represent high-margin markets requiring materials certified to rigorous performance standards for use in avionics, radar components, and missile control surfaces. The Energy sector utilizes CuW in high-power switching and circuit protection devices, underscoring its essential role in maintaining the reliability and safety of modern power grids and renewable energy systems globally.

- By Manufacturing Method:

- Infiltration Method

- Pressing and Sintering Method

- By Copper Content (Composition):

- Low Copper Content (e.g., CuW 70/30, CuW 80/20)

- High Copper Content (e.g., CuW 50/50, CuW 60/40)

- By Application:

- Electrical Discharge Machining (EDM) Electrodes

- Resistance Welding Electrodes

- Heat Sinks and Thermal Management Components

- Electrical Contacts and Circuit Breakers

- Aerospace and Defense Components

- By End-User Industry:

- Electronics and Semiconductor

- Automotive (EVs and traditional vehicles)

- Defense and Aerospace

- Energy and Power Generation

- Industrial Machinery and Tooling

Value Chain Analysis For Copper Tungsten Market

The Copper Tungsten market value chain is intricate, commencing with the highly specialized procurement and processing of raw materials and culminating in the delivery of highly engineered components to sophisticated end-users. The upstream segment is dominated by the sourcing and refining of high-purity tungsten and copper powders, a critical and often cost-intensive step. Tungsten is typically mined and then processed into fine, consistent powders via chemical reduction, demanding stringent quality control to ensure optimal densification during sintering. Copper, being more readily available, is also processed into fine powders or utilized as billets for the infiltration process. Key suppliers in the upstream market exert significant influence over commodity pricing and availability, directly impacting manufacturers' production costs and overall market competitiveness. Vertical integration, where companies manage both powder production and component manufacturing, is a strategy often employed to mitigate supply chain volatility and ensure quality consistency from the outset.

The midstream segment involves the core manufacturing processes: pressing, sintering, and copper infiltration. Component manufacturers use specialized equipment for compaction and high-temperature vacuum sintering to create tungsten skeletons, which are then infiltrated with molten copper to achieve near-theoretical density. This manufacturing phase is highly technical and requires deep metallurgical expertise to control the microstructure, ensuring the final composite meets the exact thermal, electrical, and mechanical specifications demanded by applications like heat sinks or vacuum contacts. Distribution channels are highly specialized, often relying on a combination of direct sales and technical distributors. For high-volume, standardized products (like EDM electrodes), indirect distribution through industrial supply houses is common. However, for highly customized components intended for defense or advanced semiconductor applications, direct engagement between the manufacturer's engineering team and the end-user is typical to manage complex technical requirements and quality assurance protocols.

The downstream segment consists of end-users who integrate CuW components into their final products. The largest consumers are Original Equipment Manufacturers (OEMs) in the electronics, defense, and power industries. Their decision-making process is heavily influenced by material reliability, lifespan, and adherence to specific industry standards (e.g., MIL-SPECs in defense or SEMI standards in semiconductor fabrication). Direct sales channels are frequently employed to serve these customers, providing technical support and quality traceability. The performance of CuW components directly impacts the operational reliability of high-value systems, establishing a strong incentive for end-users to prefer established, quality-focused manufacturers. This demand for reliability reinforces the importance of maintaining a high-integrity, quality-assured supply chain from raw powder to final component installation.

Copper Tungsten Market Potential Customers

Potential customers for Copper Tungsten composites are concentrated within industries that require materials capable of surviving high-power, high-temperature, and high-wear environments while maintaining optimal electrical and thermal performance. The largest consumer base resides in the semiconductor and advanced electronics manufacturing sectors. These end-users, including global fabrication plants and IC packaging houses, are the primary purchasers of CuW heat sinks and thermal spreaders. They seek materials with a Coefficient of Thermal Expansion (CTE) closely matched to silicon and gallium arsenide substrates to prevent mechanical stress failures, making CuW an ideal solution for mitigating heat buildup in high-density integrated circuits and power modules vital for data centers and 5G infrastructure. Their procurement decisions prioritize performance, thermal efficiency, and long-term reliability over initial component cost.

Another significant customer segment is the industrial tooling and machinery sector, particularly those involved in precision fabrication and metalworking. Electrical Discharge Machining (EDM) operators purchase CuW electrodes for complex die sinking and precision hole drilling, especially when working with difficult materials like cemented carbides or hardened steel. The exceptional wear resistance of CuW ensures the electrodes maintain their shape and integrity throughout the machining process, delivering high precision and reducing tooling replacement frequency. Similarly, companies specializing in resistance welding equipment rely on CuW welding tips and inserts due to their ability to withstand intense heat and pressure cycles without sticking or deteriorating, ensuring consistent weld quality in high-volume production lines, such as those found in the automotive manufacturing sector.

Finally, the defense, aerospace, and energy infrastructure sectors represent high-value, critical customer segments. Defense contractors require CuW for specialized components in missile systems, satellite thermal controls, and heavy-duty electrical contacts in military avionics and radar systems where failure is not an option. Utilities and power distribution companies use CuW in high-voltage circuit breakers, switchgear, and vacuum interrupters. In these applications, the material's ability to resist the corrosive effects of electrical arcing is paramount for ensuring the safety and continuity of power supply. These customers typically operate under strict regulatory and performance standards, leading them to engage in long-term contracts with suppliers who can guarantee material purity, stringent quality control, and complete traceability throughout the manufacturing cycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million USD |

| Market Forecast in 2033 | $860 Million USD |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SinterMet LLC, AT&M (Advanced Technology & Materials Co., Ltd.), Sandvik AB, Kennametal Inc., Sumitomo Electric Industries, Plansee Group, Midwest Tungsten Service, Mi-Tech Metals Inc., ADMATEL, Elmet Technologies, H.C. Starck Solutions, Ametek Inc., Changsha Huarui Advanced Materials Co., Ltd., China Tungsten and Molybdenum Co., Ltd., Global Tungsten & Powders. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Copper Tungsten Market Key Technology Landscape

The Copper Tungsten market is heavily reliant on sophisticated powder metallurgy techniques, which serve as the foundation for manufacturing high-quality composite materials with precise structural control. The predominant technology remains the combination of pressing, pre-sintering of the tungsten skeleton, followed by liquid phase copper infiltration. Recent technological advancements focus on optimizing the powder preparation stage, specifically utilizing ultra-fine and nano-sized tungsten powders. These finer powders allow for lower sintering temperatures, improved material homogeneity, and the achievement of higher relative densities, which are crucial for minimizing porosity that can negatively affect thermal conductivity and arc erosion resistance in the final component. Manufacturers are continually investing in advanced vacuum sintering furnaces and controlled atmosphere processing to ensure maximum purity and consistent performance across production batches, particularly for demanding semiconductor applications.

A rapidly evolving technological frontier is the adoption of Additive Manufacturing (AM) for CuW components. Traditional powder metallurgy limits the geometric complexity achievable without extensive post-processing machining. However, techniques such as Binder Jetting (BJ) and Laser Powder Bed Fusion (LPBF), adapted for refractory metals, are beginning to demonstrate feasibility for CuW. While still facing challenges related to differential melting points and density control, AM promises unprecedented geometric freedom, enabling the fabrication of highly complex internal cooling channels within heat sinks or intricately shaped EDM electrodes, significantly reducing material waste and lead times. This shift toward net-shape or near-net-shape fabrication is expected to drastically alter the cost structure and design limitations traditionally associated with CuW composites, unlocking new potential applications in compact, high-power systems.

Furthermore, technology focused on surface treatment and post-processing is gaining importance. Specialized techniques such as Hot Isostatic Pressing (HIP) are used after infiltration to further minimize residual porosity, thereby enhancing the fatigue life and overall mechanical integrity of critical components used in aerospace and defense. Innovations in surface coating technologies, often involving thin layers of refractory metals or ceramics, are being researched to potentially extend the lifespan of CuW electrical contacts and welding electrodes, particularly in highly corrosive or high-temperature operational environments. The integration of advanced computational fluid dynamics (CFD) and thermal modeling software is also becoming standard practice, allowing engineers to design and validate component performance virtually before committing to costly physical prototyping, optimizing the blend of copper and tungsten for specific thermal load requirements.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market leader, accounting for the largest share of global CuW consumption, driven primarily by the massive, concentrated electronics and semiconductor manufacturing industry in countries like China, South Korea, Taiwan, and Japan. The region’s aggressive expansion in 5G telecommunications infrastructure and electric vehicle production necessitates vast quantities of high-performance thermal management and electrical contact materials. Rapid industrialization and robust government support for high-tech manufacturing solidify APAC's position as both the largest producer and consumer, emphasizing volume production and competitive pricing structures.

- North America: North America represents a mature, high-value market characterized by stringent performance requirements, primarily fueled by the aerospace, defense, and specialized medical device sectors. The demand here focuses heavily on high-specification, certified CuW alloys utilized in critical radar systems, missile guidance, and advanced medical accelerators. While overall volume is lower compared to APAC, the average selling price (ASP) is significantly higher due to the strict quality control, traceability requirements, and emphasis on domestic sourcing for national security applications.

- Europe: Europe is a significant market driven by high-end industrial machinery, automotive manufacturing (especially precision resistance welding), and advanced energy infrastructure. Countries like Germany and the United Kingdom utilize CuW extensively in high-quality EDM tooling and high-voltage circuit protection devices within their modernized power grids. European manufacturers emphasize sustainability and are increasingly integrating AI-driven optimization into their powder metallurgy processes to reduce waste and improve energy efficiency, aligning with regional regulatory trends.

- Latin America (LATAM): The CuW market in Latin America is developing, with demand primarily stemming from the regional oil & gas sector (requiring specialized electrical components for drilling equipment) and initial investments in high-voltage power transmission infrastructure modernization. Growth is steady but often subject to economic volatility and reliance on imported specialized components from North America and Europe.

- Middle East and Africa (MEA): MEA's growth is concentrated in large-scale energy projects and infrastructural development, particularly in the Gulf Cooperation Council (GCC) countries. The market for CuW is focused on reliable electrical contacts and switchgear essential for managing regional power distribution networks and supporting nascent aerospace and defense industries. Specialized thermal management components are also seeing increased adoption with the growth of regional data centers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Copper Tungsten Market.- SinterMet LLC

- AT&M (Advanced Technology & Materials Co., Ltd.)

- Sandvik AB

- Kennametal Inc.

- Sumitomo Electric Industries

- Plansee Group

- Midwest Tungsten Service

- Mi-Tech Metals Inc.

- ADMATEL

- Elmet Technologies

- H.C. Starck Solutions

- Ametek Inc.

- Changsha Huarui Advanced Materials Co., Ltd.

- China Tungsten and Molybdenum Co., Ltd.

- Global Tungsten & Powders

- Refractory Metals and Alloys Co. (RMA)

- Treibacher Industrie AG

- Duramet Corporation

- Tungsten Heavy Powder, Inc.

Frequently Asked Questions

Analyze common user questions about the Copper Tungsten market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Copper Tungsten over traditional heat sink materials?

Copper Tungsten (CuW) offers a superior combination of high thermal conductivity (due to copper) and low coefficient of thermal expansion (CTE, matching semiconductor materials like silicon due to tungsten). This crucial combination allows for efficient heat dissipation while minimizing thermal stress and mechanical failure in high-power electronic devices, a critical advantage over pure copper or aluminum alloys.

Which manufacturing method is dominant in the Copper Tungsten market?

The Infiltration Method is currently the dominant manufacturing technique. It involves pre-sintering a porous tungsten skeleton and then infiltrating it with molten copper. This process is preferred because it yields fully dense materials with minimal porosity and exceptional uniformity, which is vital for high-reliability applications like semiconductor thermal spreaders and vacuum interrupters.

How does the cost volatility of tungsten affect the Copper Tungsten market?

Tungsten, as a critical raw material, is subject to high price volatility and geopolitical supply risks. This directly influences the manufacturing cost of CuW composites. Manufacturers mitigate this risk through strategic sourcing, long-term contracts, and by focusing on high-margin, application-specific alloys where performance justifies the material premium.

What role does Copper Tungsten play in Electrical Discharge Machining (EDM)?

CuW is highly valued as an electrode material in EDM due to its exceptional wear resistance and high melting point. This ensures that the electrode retains its precise shape during the spark erosion process, enabling high-precision machining of hard materials such as tool steels and carbides with minimal electrode degradation.

Is Additive Manufacturing (AM) a viable technology for producing Copper Tungsten components?

Yes, AM technologies such as Binder Jetting and Laser Powder Bed Fusion are emerging as viable options. While still under development, AM allows for the production of complex, intricate geometries, such as optimized internal cooling structures, that are difficult or impossible to achieve with traditional powder metallurgy, offering future cost and design benefits, especially for aerospace parts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Copper Tungsten Alloys Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Copper Tungsten Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager