Ethyl Methyl Carbonate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440842 | Date : Feb, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Ethyl Methyl Carbonate Market Size

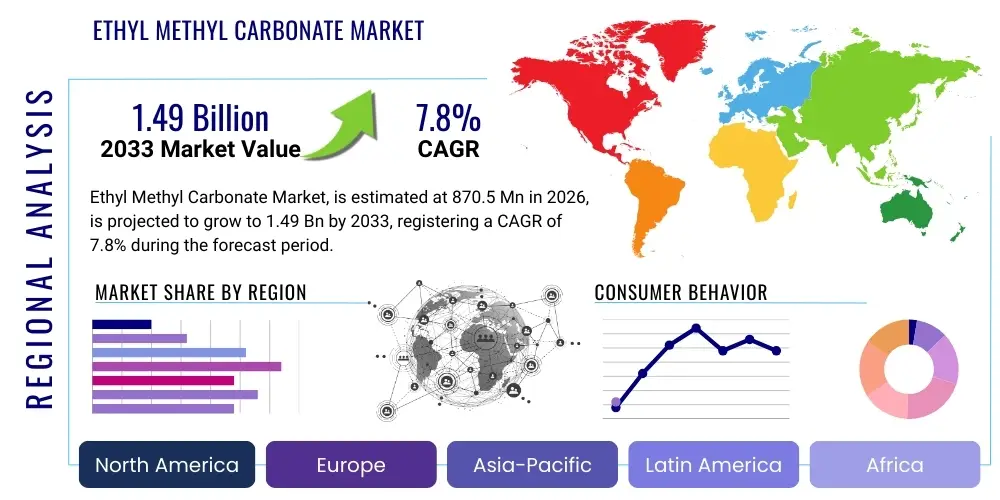

The Ethyl Methyl Carbonate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 870.5 Million in 2026 and is projected to reach USD 1.49 Billion by the end of the forecast period in 2033.

Ethyl Methyl Carbonate Market introduction

Ethyl Methyl Carbonate (EMC) is a colorless, odorless, flammable liquid with a high boiling point and low viscosity, belonging to the class of organic carbonates. Its unique chemical properties make it an indispensable compound across various industrial applications. Predominantly, EMC serves as a crucial component in electrolyte formulations for lithium-ion batteries, powering everything from electric vehicles (EVs) and portable electronics to large-scale energy storage systems. Beyond its pivotal role in the energy sector, EMC is highly valued as a high-performance solvent in the chemical and pharmaceutical industries, offering an environmentally friendlier alternative to traditional solvents due to its low toxicity and biodegradability. Major applications include its use as a solvent for resins, paints, and coatings, as well as a chemical intermediate in the synthesis of pharmaceuticals, agrochemicals, and other specialty chemicals. The primary benefits of EMC include its excellent solvency power, high dielectric constant, low viscosity, and high flash point, which collectively enhance the performance and safety of its end-products. The market's growth is primarily driven by the escalating global demand for electric vehicles, advancements in battery technology requiring superior electrolyte components, and the increasing adoption of sustainable and green chemical processes across various industrial sectors.

Ethyl Methyl Carbonate Market Executive Summary

The Ethyl Methyl Carbonate (EMC) market is experiencing robust growth, primarily fueled by the accelerating shift towards electric vehicles and the expanding consumer electronics sector, which heavily rely on advanced lithium-ion battery technology. Key business trends indicate a strong focus on capacity expansion, strategic partnerships, and mergers and acquisitions among manufacturers to meet the surging demand and enhance supply chain resilience. Innovation in production methods, particularly towards more sustainable and cost-effective synthesis routes, is also a prominent trend, aiming to improve product purity and reduce environmental impact. Regionally, Asia-Pacific dominates the market, driven by its extensive battery manufacturing ecosystem and rapid industrialization, while North America and Europe are showing significant growth due to increasing EV adoption and investments in renewable energy infrastructure. Segment-wise, battery-grade EMC holds the largest share, anticipated to maintain its lead owing to continuous advancements in battery chemistry, but the solvent and chemical intermediate segments are also projected for steady expansion, propelled by the demand for greener solvents and complex chemical synthesis in pharmaceuticals and agrochemicals. Overall, the market is characterized by intense competition, technological advancements, and a strong push towards sustainability and high-performance solutions.

AI Impact Analysis on Ethyl Methyl Carbonate Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the Ethyl Methyl Carbonate market, focusing on aspects like optimizing production efficiency, enhancing material properties, predicting market demand, and accelerating research and development. Common concerns revolve around the practical implementation challenges, data privacy, and the scale of investment required for AI integration. The overarching expectation is that AI will introduce significant efficiencies and innovation, from automating complex chemical synthesis processes to forecasting raw material prices and refining purification techniques. Users are keenly interested in how AI can contribute to more sustainable production methods, improve product consistency, and identify novel applications for EMC, ultimately impacting its cost-effectiveness and market competitiveness. There is also a strong curiosity about AI's role in discovering new, high-performance electrolyte formulations that could further boost battery efficiency and longevity, thereby extending EMC's utility in next-generation energy storage solutions.

- Optimized Production Processes: AI algorithms can analyze vast datasets from manufacturing plants to optimize reaction conditions, predict equipment failures, and fine-tune purification stages, leading to higher yields, reduced energy consumption, and lower operational costs in EMC synthesis.

- Enhanced Material Discovery and Design: Machine learning models can simulate molecular interactions and predict the performance of new electrolyte formulations or EMC derivatives, accelerating the discovery of novel materials with superior electrochemical properties for battery applications.

- Supply Chain and Demand Forecasting: AI-driven analytics provide more accurate predictions of raw material availability, price fluctuations, and market demand for EMC, enabling manufacturers to optimize inventory, improve logistics, and make informed procurement decisions, reducing waste and improving responsiveness.

- Quality Control and Purity Assurance: AI-powered vision systems and sensor networks can monitor EMC quality in real-time, detecting impurities or deviations from specifications with high precision, ensuring the consistent production of ultra-high purity grades required for sensitive applications like lithium-ion batteries.

- Predictive Maintenance: AI can predict potential malfunctions in production equipment by analyzing sensor data, enabling proactive maintenance that minimizes downtime, extends equipment lifespan, and maintains continuous production flow for EMC manufacturing facilities.

- Sustainable Process Development: AI can aid in designing more environmentally friendly synthesis routes for EMC, optimizing catalyst selection, and identifying pathways for carbon capture and utilization in its production, aligning with green chemistry principles.

- Market Intelligence and Competitive Analysis: AI tools can process and analyze market trends, competitor activities, and customer feedback to provide strategic insights, helping EMC producers identify new opportunities, adapt pricing strategies, and maintain a competitive edge.

DRO & Impact Forces Of Ethyl Methyl Carbonate Market

The Ethyl Methyl Carbonate (EMC) market is shaped by a dynamic interplay of driving forces, significant restraints, and emerging opportunities, all operating under various impact forces that influence its overall trajectory. The primary drivers include the escalating global demand for lithium-ion batteries, propelled by the rapid adoption of electric vehicles and the expansion of consumer electronics, which positions EMC as a critical electrolyte component. Furthermore, its increasing recognition as a green solvent and a versatile chemical intermediate in pharmaceuticals and agrochemicals also contributes significantly to market growth. However, the market faces notable restraints such as the volatile pricing of key raw materials like ethylene, methanol, and carbon monoxide, which can impact production costs and profit margins. Stringent environmental regulations concerning chemical manufacturing and waste disposal, alongside the high capital investment required for establishing new production facilities, also pose challenges. Opportunities lie in the continuous innovation in battery technology demanding even higher purity and specialized EMC grades, the development of bio-based or CO2-derived synthesis routes, and its expanding applications in nascent sectors like energy storage systems and advanced materials. These market dynamics are further influenced by factors such as the bargaining power of raw material suppliers and EMC buyers, the potential threat of new entrants due to high barriers to entry, the competitive intensity among existing players, and the availability of substitute chemicals, all of which dictate pricing strategies, innovation cycles, and market share.

- Drivers:

- Rapid Growth of Electric Vehicle (EV) Industry: The accelerating global transition to EVs is the foremost driver, as EMC is a critical component in the electrolyte of lithium-ion batteries that power these vehicles, ensuring optimal performance and safety.

- Expanding Consumer Electronics Market: Persistent demand for smartphones, laptops, and other portable electronic devices, all powered by lithium-ion batteries, continues to fuel the need for high-quality EMC.

- Increasing Demand for Energy Storage Systems (ESS): The integration of renewable energy sources like solar and wind requires robust battery storage solutions, where EMC-based electrolytes play a vital role, driving market expansion.

- Adoption of Green Solvents: EMC's properties as a low-toxicity, biodegradable, and efficient solvent are leading to its increased adoption as an environmentally friendly alternative in various chemical processes, replacing traditional volatile organic compounds (VOCs).

- Growth in Pharmaceutical and Agrochemical Industries: EMC serves as a crucial chemical intermediate and solvent in the synthesis of various pharmaceutical compounds and agricultural chemicals, driven by innovation and demand in these sectors.

- Restraints:

- Volatility of Raw Material Prices: Fluctuations in the prices of key feedstocks such as ethylene oxide, methanol, and carbon dioxide directly impact the production cost of EMC, affecting manufacturers' profitability and market stability.

- Stringent Environmental Regulations: Strict regulations regarding chemical manufacturing processes, waste management, and emissions can increase compliance costs and limit production capacities, especially for non-sustainable synthesis routes.

- High Capital Investment and Production Complexity: Establishing new EMC manufacturing facilities requires substantial capital investment and complex technological know-how, creating high barriers to entry for new players.

- Competition from Alternative Carbonates: While EMC offers distinct advantages, competition from other organic carbonates like Dimethyl Carbonate (DMC), Diethyl Carbonate (DEC), and Ethylene Carbonate (EC) can pose a restraint, especially in cost-sensitive applications.

- Opportunities:

- Advancements in Battery Technology: The ongoing research and development into next-generation lithium-ion batteries (e.g., solid-state batteries, high-energy density cells) create opportunities for specialized EMC formulations or blends with enhanced performance characteristics.

- Development of Sustainable Production Routes: Investment in bio-based feedstocks or direct synthesis from CO2 for EMC production presents significant opportunities for companies to gain a competitive edge and meet sustainability goals.

- Emerging Applications in Coatings and Adhesives: The unique solvent properties of EMC are being explored for advanced formulations in paints, coatings, and adhesives, offering new avenues for market growth beyond traditional uses.

- Geographic Expansion in Emerging Markets: Rapid industrialization and increasing EV adoption rates in developing economies offer untapped potential for market expansion and new facility investments.

- Impact Forces (Porter's Five Forces Analysis):

- Bargaining Power of Buyers: Moderate to high, especially for large battery manufacturers or chemical conglomerates, who can demand competitive pricing and specific quality standards due to their volume purchases.

- Bargaining Power of Suppliers: Moderate, as raw materials for EMC are commodity chemicals with several suppliers, but specialized catalysts or high-purity feedstocks might give some suppliers more leverage.

- Threat of New Entrants: Low to moderate, primarily due to the high capital investment, complex technology, intellectual property barriers, and stringent regulatory requirements involved in EMC production.

- Threat of Substitutes: Moderate, as other organic carbonates and alternative solvents exist, but EMC's unique blend of properties (high dielectric constant, low viscosity) makes it challenging to directly substitute in high-performance battery electrolytes without compromising performance.

- Competitive Rivalry: High, with several established global and regional players vying for market share, leading to continuous innovation, price competition, and focus on product quality and customer service.

Segmentation Analysis

The Ethyl Methyl Carbonate market is comprehensively segmented to provide a granular understanding of its diverse applications, grades, and end-use industries, reflecting the varied demands across its value chain. This segmentation helps in identifying key growth drivers within specific niches and assessing the competitive landscape more accurately. The market can be broadly categorized by product grade, which differentiates between the stringent purity requirements of battery applications and the broader specifications for industrial uses. Further segmentation by application highlights its crucial role in electrolyte solutions, its utility as a solvent across multiple industries, and its importance as a chemical intermediate. Additionally, analysis by end-use industry sheds light on the primary sectors consuming EMC, such as automotive, electronics, pharmaceuticals, and coatings, each with distinct growth patterns and specific demands for EMC's unique properties.

- By Grade:

- Battery Grade

- Industrial Grade

- By Application:

- Electrolyte Solvent for Lithium-ion Batteries

- General Solvents

- Chemical Intermediates

- Others (e.g., cleaning agents, degreasers)

- By End-Use Industry:

- Automotive (Electric Vehicles)

- Electronics (Consumer Electronics, Portable Devices)

- Energy Storage Systems

- Pharmaceuticals

- Coatings & Adhesives

- Agrochemicals

- Plastics & Polymers

- Others

Value Chain Analysis For Ethyl Methyl Carbonate Market

The value chain for the Ethyl Methyl Carbonate (EMC) market is a complex network spanning from upstream raw material sourcing to downstream end-use applications, involving various intermediaries and distribution channels. Upstream activities are centered on the procurement and processing of key feedstocks, which are primarily commodity chemicals with global suppliers. These raw materials undergo intricate synthesis processes, often requiring specialized technology and catalysts, to produce high-purity EMC. The midstream involves the manufacturing and purification of EMC, where quality control and consistency are paramount, especially for battery-grade applications. Downstream activities focus on the distribution and sale of EMC to various end-user industries, which then integrate it into their final products or processes, ranging from lithium-ion battery production to pharmaceutical synthesis and solvent applications. Effective management across this entire chain is crucial for maintaining competitive pricing, ensuring product quality, and responding efficiently to market demands.

Upstream analysis reveals that the primary raw materials for EMC production include ethylene oxide, carbon monoxide, and methanol. These chemicals are typically sourced from large petrochemical companies, and their availability and price volatility significantly influence the cost structure of EMC. The manufacturing process often involves complex chemical reactions, such as the transesterification of Dimethyl Carbonate (DMC) with ethanol or the direct synthesis from carbon monoxide and ethanol, followed by rigorous purification steps to achieve the high purity required for battery-grade EMC. Suppliers of these raw materials play a critical role, and their bargaining power can fluctuate based on global commodity prices, supply-demand dynamics, and regional geopolitical factors. Manufacturers often establish long-term contracts with multiple suppliers to mitigate risks associated with price volatility and ensure a stable supply chain.

Downstream analysis highlights the diverse applications of EMC across multiple industries. Lithium-ion battery manufacturers represent the largest segment, using EMC as a key component in their electrolyte solutions. Other significant downstream users include chemical companies for various synthesis processes, pharmaceutical manufacturers for drug intermediates, and coatings and adhesives producers utilizing EMC as a solvent. The distribution channel for EMC is multifaceted, encompassing both direct sales from manufacturers to large-volume industrial customers and indirect sales through a network of specialized chemical distributors. Direct sales channels are often employed for strategic partnerships with major end-users, ensuring tailored solutions and technical support. Indirect channels, through distributors, provide broader market reach, particularly to smaller- and medium-sized enterprises, leveraging their logistical expertise and local market knowledge. This dual approach ensures efficient market penetration and customer service across various scales of demand.

Ethyl Methyl Carbonate Market Potential Customers

The Ethyl Methyl Carbonate (EMC) market caters to a broad spectrum of end-users and buyers, driven by its unique chemical properties that make it indispensable in high-performance applications. The primary customer base is concentrated within industries that rely heavily on advanced chemical solutions for energy storage, material processing, and synthesis. These customers range from multinational corporations to specialized manufacturers, each seeking specific grades and quantities of EMC to meet their production requirements. Identifying and understanding these potential customers involves analyzing their technological needs, regulatory environments, and specific application demands, which vary significantly across different industrial sectors. The growth in demand from these diverse customer segments is a key indicator of the overall market health and future expansion opportunities for EMC manufacturers.

The most significant segment of potential customers for EMC comprises manufacturers of lithium-ion batteries. This includes companies producing batteries for electric vehicles, consumer electronics such as smartphones and laptops, and large-scale energy storage systems for grid applications. These customers demand ultra-high purity battery-grade EMC, which is critical for ensuring battery performance, longevity, and safety. Their purchasing decisions are heavily influenced by factors such as product specifications, supply reliability, technical support, and competitive pricing, as EMC forms a substantial part of their raw material costs. As battery technology continues to evolve, these customers will increasingly seek specialized EMC formulations that can enhance energy density, improve cycle life, and withstand extreme operating conditions.

Beyond the battery industry, other substantial potential customers include companies in the chemical, pharmaceutical, coatings, and agrochemical sectors. Pharmaceutical companies utilize EMC as a solvent and intermediate in the synthesis of various active pharmaceutical ingredients (APIs), valuing its low toxicity and efficiency in complex reactions. The coatings and adhesives industry increasingly adopts EMC as a green solvent, appreciating its effectiveness in dissolving resins while complying with stricter environmental regulations concerning volatile organic compounds (VOCs). Similarly, agrochemical producers use EMC in the synthesis of pesticides and herbicides. These customers prioritize product quality, consistent supply, regulatory compliance, and the environmental profile of the chemical. Manufacturers often engage directly with these large industrial customers, providing technical consultation and customized solutions to meet their specific formulation and processing needs, thereby fostering long-term relationships and securing stable demand.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 870.5 Million |

| Market Forecast in 2033 | USD 1.49 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, Mitsubishi Chemical Corporation, Empower Materials, Ltd., Huntsman Corporation, Kishida Chemical Co. Ltd., Shandong Shida Shenghua Chemical Group Co., Ltd., UBE Corporation, BASF SE, Central Glass Co., Ltd., FUJIFILM Wako Pure Chemical Corporation, Panax Etec Co. Ltd., Lishui Fuhua Chemical Co., Ltd., Dongying City Longxing Chemical Co., Ltd., Shandong JECO Chemical Co., Ltd., Thermo Fisher Scientific, Avantor Performance Materials, Ltd., Honeywell International Inc., Tokyo Chemical Industry Co., Ltd. (TCI), Sumitomo Chemical Co., Ltd., Tofco. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ethyl Methyl Carbonate Market Key Technology Landscape

The Ethyl Methyl Carbonate (EMC) market is significantly influenced by the continuous evolution of its production technologies and purification methods, aimed at enhancing efficiency, reducing costs, and improving product purity to meet stringent industry demands, especially from the lithium-ion battery sector. The key technological advancements revolve around developing more sustainable synthesis routes, optimizing catalytic processes, and implementing advanced separation techniques. These innovations are crucial for manufacturers to achieve competitive advantages, comply with evolving environmental regulations, and cater to the increasing requirements for high-performance and ultra-high purity EMC, which directly impacts the safety and efficiency of end-use products.

One of the most critical technological areas involves the synthesis of EMC. Traditionally, EMC has been produced via the transesterification of Dimethyl Carbonate (DMC) with ethanol or through processes involving phosgene, which is highly toxic. Modern technological efforts are focused on developing phosgene-free routes, such as the direct synthesis from carbon monoxide (CO), ethanol, and an oxidant, or the direct synthesis from carbon dioxide (CO2) and ethanol. These greener technologies not only mitigate environmental risks but also offer potential for cost reduction through the utilization of readily available and less hazardous feedstocks. Catalytic processes, involving both homogeneous and heterogeneous catalysts, are continually being refined to improve reaction selectivity, yield, and energy efficiency, pushing towards more sustainable and economically viable production methods. Researchers are also exploring novel catalyst materials, including ionic liquids and metal-organic frameworks (MOFs), to achieve superior performance under milder reaction conditions.

Beyond synthesis, the purification technology landscape is equally vital for EMC, particularly for battery-grade applications where even trace impurities can significantly degrade performance. Advanced purification techniques, such as multi-stage distillation, solvent extraction, membrane separation, and adsorption processes, are routinely employed and continuously optimized. These technologies aim to remove water, alcohols, and other organic impurities to achieve purities exceeding 99.99%. Innovations in online analytical techniques, including advanced chromatography and spectroscopic methods, enable real-time monitoring of purity during production, ensuring consistent quality and compliance with stringent specifications. Furthermore, process integration and automation, often leveraging AI and machine learning, are becoming increasingly prevalent to optimize the entire manufacturing workflow, from raw material intake to final product packaging, enhancing operational efficiency and reducing human error in the highly demanding production environment of high-purity Ethyl Methyl Carbonate.

Regional Highlights

The Ethyl Methyl Carbonate market exhibits significant regional disparities in terms of production capacity, consumption patterns, and growth drivers. Asia Pacific, particularly countries like China, Japan, and South Korea, stands as the dominant region due to its robust manufacturing base for lithium-ion batteries and a thriving electronics industry. This region also benefits from a well-established chemical production infrastructure and significant investments in renewable energy and electric vehicles. North America and Europe, while having lower production capacities compared to Asia Pacific, are experiencing substantial growth driven by strong government initiatives promoting EV adoption, increasing investments in gigafactories, and a growing emphasis on green chemistry solutions. These regions are also hubs for advanced research and development in battery technology and sustainable chemical processes. Latin America, the Middle East, and Africa represent emerging markets with nascent but growing demand, primarily influenced by industrialization, infrastructure development, and increasing regional investments in automotive and electronics manufacturing, albeit starting from a smaller base.

In Asia Pacific, the market growth is overwhelmingly propelled by China’s undisputed leadership in lithium-ion battery production and electric vehicle manufacturing. The country's extensive supply chain, competitive labor costs, and supportive government policies have fostered an environment conducive to large-scale EMC production and consumption. Japan and South Korea also play crucial roles, hosting major battery manufacturers and chemical companies that are key innovators in EMC synthesis and application. The region's expanding consumer electronics market, coupled with significant investments in renewable energy infrastructure, further cements its position as the largest and fastest-growing market for Ethyl Methyl Carbonate. This dominance is expected to continue throughout the forecast period, as these nations remain at the forefront of technological advancements in energy storage and EV technologies.

Conversely, North America and Europe are characterized by strong regulatory frameworks pushing for decarbonization and sustainable manufacturing, which indirectly boosts the demand for cleaner chemicals like EMC. The United States and Germany, for instance, are witnessing a surge in investments in battery manufacturing plants (gigafactories) to localize the EV supply chain, thereby increasing the domestic demand for battery-grade EMC. While these regions strive to reduce their reliance on Asian imports, challenges remain in establishing equivalent raw material supply chains and competitive production costs. However, their robust R&D ecosystems are actively exploring new, sustainable production methods for EMC, including CO2 utilization technologies, which could potentially reshape the global production landscape and strengthen their positions in the long run. The Latin American, Middle Eastern, and African markets, while currently smaller, are poised for future growth as industrialization accelerates and demand for EVs and consumer electronics gradually increases within these regions, necessitating local or regional supply chain development for critical chemicals like EMC.

- Asia Pacific: The largest market, driven by dominant lithium-ion battery production in China, South Korea, and Japan, extensive EV manufacturing, vast electronics industry, and robust chemical infrastructure. Significant government support and continuous investments in renewable energy bolster regional growth.

- North America: Experiencing substantial growth due to increasing EV adoption, government incentives for battery manufacturing, and expanding energy storage projects. Focus on domestic supply chain development and advanced R&D for sustainable EMC production.

- Europe: High growth driven by stringent emission regulations, rapid EV market expansion, significant investments in gigafactories, and a strong emphasis on green chemistry and circular economy principles, fostering demand for eco-friendly solvents and battery components.

- Latin America: Emerging market with growing industrialization and increasing automotive production. Demand is driven by local manufacturing expansion and gradual adoption of consumer electronics and electric mobility solutions.

- Middle East and Africa (MEA): A developing market with potential growth stemming from diversification strategies away from oil, investments in industrial infrastructure, and nascent but increasing interest in EVs and renewable energy projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ethyl Methyl Carbonate Market.- Merck KGaA

- Mitsubishi Chemical Corporation

- Empower Materials, Ltd.

- Huntsman Corporation

- Kishida Chemical Co. Ltd.

- Shandong Shida Shenghua Chemical Group Co., Ltd.

- UBE Corporation

- BASF SE

- Central Glass Co., Ltd.

- FUJIFILM Wako Pure Chemical Corporation

- Panax Etec Co. Ltd.

- Lishui Fuhua Chemical Co., Ltd.

- Dongying City Longxing Chemical Co., Ltd.

- Shandong JECO Chemical Co., Ltd.

- Thermo Fisher Scientific

- Avantor Performance Materials, Ltd.

- Honeywell International Inc.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Sumitomo Chemical Co., Ltd.

- Tofco

Frequently Asked Questions

Analyze common user questions about the Ethyl Methyl Carbonate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Ethyl Methyl Carbonate (EMC) primarily used for?

Ethyl Methyl Carbonate (EMC) is primarily used as a key component in electrolyte solutions for lithium-ion batteries, which power electric vehicles, consumer electronics, and energy storage systems. It also serves as an effective, environmentally friendly solvent and a versatile chemical intermediate in the pharmaceutical, agrochemical, and coatings industries.

Why is EMC important for lithium-ion battery performance?

EMC is crucial for lithium-ion batteries due to its excellent dielectric constant, low viscosity, and high flash point, which contribute to the electrolyte's stability, ionic conductivity, and safety. These properties ensure efficient ion transport, enhance battery cycle life, and improve overall performance in various temperature conditions.

What are the key drivers for the growth of the EMC market?

The main drivers for EMC market growth include the surging global demand for electric vehicles, the continuous expansion of the consumer electronics market, the increasing adoption of grid-scale energy storage systems, and the growing preference for green and sustainable solvents in various industrial applications.

Which region dominates the Ethyl Methyl Carbonate market?

Asia Pacific currently dominates the Ethyl Methyl Carbonate market. This is primarily attributed to the region's strong manufacturing base for lithium-ion batteries, particularly in China, South Korea, and Japan, alongside a rapidly expanding electric vehicle industry and significant investments in chemical production capabilities.

What are the environmental aspects associated with EMC production?

Historically, EMC production could involve toxic phosgene. However, current technological advancements focus on sustainable, phosgene-free synthesis routes, often utilizing carbon dioxide (CO2) or carbon monoxide (CO) as feedstocks. These greener methods aim to reduce the environmental footprint, minimize hazardous byproducts, and align with global sustainability goals for chemical manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager