Glass Microfiber Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441096 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Glass Microfiber Market Size

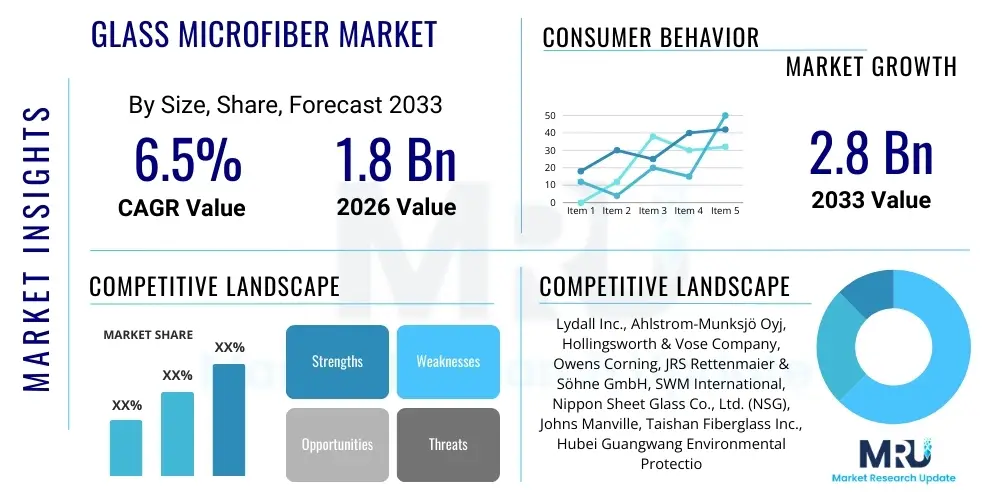

The Glass Microfiber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by increasing demand from high-efficiency filtration applications, particularly in the HVAC and automotive sectors, coupled with rising environmental regulations demanding superior air and liquid purification standards globally. The inherent properties of glass microfiber, such as high thermal resistance, chemical inertness, and fine fiber diameter, position it as a critical material across diversified industrial landscapes, sustaining this strong market growth trajectory over the decade.

Glass Microfiber Market introduction

Glass microfiber, often characterized by fiber diameters ranging from sub-micron to several microns, is a specialized material derived from processed glass compositions. This material exhibits exceptional filtration efficiency, high temperature tolerance, and chemical stability, making it indispensable in demanding technical applications. Major applications span high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filtration media, battery separators in lead-acid and specialized batteries, advanced thermal and acoustic insulation materials, and specialized laboratory filter papers. The primary benefits include superior dirt holding capacity, low-pressure drop, and high thermal performance. Driving factors propelling this market include increasingly stringent environmental protection laws worldwide, the escalating global demand for renewable energy storage solutions utilizing absorbent glass mat (AGM) technology, and continuous technological advancements improving fiber uniformity and reducing manufacturing costs, thereby expanding its accessibility across various industrial end-users.

Glass Microfiber Market Executive Summary

The Glass Microfiber Market is experiencing rapid structural evolution driven by shifting global business trends towards sustainability and superior product performance. A significant business trend involves the integration of high-purity glass microfiber media into advanced industrial filtration systems to meet increasingly rigorous emissions standards, particularly in energy and manufacturing sectors. Regional trends highlight Asia Pacific (APAC) as the fastest-growing region, fueled by massive infrastructure development and the rapid expansion of the automotive and electronics manufacturing industries, requiring specialized insulation and separation materials. Segment trends indicate that the filtration media segment continues to dominate the market share due to critical applications in air quality management and liquid purification, while the battery separator segment is exhibiting the highest growth trajectory, primarily supported by the booming production of AGM batteries essential for start-stop automotive systems and uninterruptible power supplies (UPS). These combined forces of regulatory compliance, technological innovation, and regional industrialization underscore the positive market outlook.

AI Impact Analysis on Glass Microfiber Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Glass Microfiber Market predominantly center on optimizing manufacturing processes, enhancing product quality control, and predicting demand fluctuations. Users frequently ask if AI can automate the complex processes of fiberizing and web formation, which are critical to maintaining the precise structure and filtration efficiency of the final product. Key concerns revolve around integrating AI-driven predictive maintenance systems to minimize downtime in high-capital production lines, and the use of machine learning algorithms to correlate raw material variations with final product performance characteristics, such as pressure drop and permeability. The expectation is that AI will significantly streamline quality assurance by identifying microscopic defects in real-time, thereby reducing material waste and production variance, leading to a more efficient and cost-effective supply chain for glass microfiber producers globally. This integration of smart manufacturing promises higher yields and tighter adherence to exacting customer specifications.

- AI-driven optimization of fiberization processes, improving uniformity and reducing manufacturing variance.

- Predictive maintenance schedules for high-temperature furnaces and attenuation equipment, minimizing unexpected downtime.

- Enhanced quality control using machine vision and learning algorithms to detect micro-defects in media sheets in real-time.

- Demand forecasting and supply chain optimization based on AI analysis of end-user industry trends (e.g., HVAC system upgrades, battery production volumes).

- Development of novel fiber formulations through AI simulation and material informatics, accelerating R&D cycles.

DRO & Impact Forces Of Glass Microfiber Market

The dynamics of the Glass Microfiber Market are governed by a complex interplay of Drivers, Restraints, and Opportunities, which collectively form the Impact Forces shaping the industry's future. Key drivers include stringent global environmental regulations mandating high-efficiency filtration solutions across industries, particularly in automotive and industrial exhaust purification, alongside the rapid adoption of AGM batteries in the automotive sector for advanced electrical systems. Restraints predominantly involve the high initial capital investment required for establishing advanced manufacturing facilities capable of producing ultra-fine, consistent fibers, coupled with volatile raw material prices, specifically boric acid and silica, which are fundamental components of specialized glass compositions. Opportunities are substantial, centered on the emerging demand for advanced insulation in aerospace and electric vehicle (EV) battery packs, and the development of next-generation filtration media optimized for pharmaceutical and semiconductor manufacturing cleanrooms. These forces ensure that while market entry remains challenging, the potential for high-value applications continues to draw strategic investments and innovation.

Segmentation Analysis

The Glass Microfiber Market is extensively segmented based on criteria such as product type, application, and end-user industry, enabling precise market sizing and strategic targeting. The product type segmentation distinguishes between various fiber compositions and processing methods, crucial for determining suitability for specialized applications. Application segmentation provides insights into where the material is predominantly consumed, such as in air filtration, liquid filtration, or insulation. End-user segmentation categorizes consumption across major industries like Automotive, Energy, Pharmaceutical, and HVAC, reflecting specific demand characteristics and regulatory environments unique to each sector. This detailed segmentation allows stakeholders to understand the underlying drivers and niche areas of high growth potential within the broader market landscape, facilitating focused investment in R&D and manufacturing capacity expansion to meet specific technological requirements of sophisticated end-users globally.

- By Product Type:

- Borosilicate Glass Microfiber

- Quartz Microfiber

- Standard Glass Microfiber

- By Application:

- Filtration Media (HEPA/ULPA, Liquid)

- Battery Separators (AGM)

- Insulation Products (Thermal and Acoustic)

- Specialty Papers (Laboratory and Medical)

- By End-User Industry:

- Automotive and Transportation

- HVAC (Heating, Ventilation, and Air Conditioning)

- Energy and Utilities

- Pharmaceutical and Biotechnology

- Electronics and Semiconductors

- Aerospace and Defense

- By Fiber Diameter:

- Sub-micron (Less than 1 micron)

- 1 to 5 microns

- Above 5 microns

Value Chain Analysis For Glass Microfiber Market

The value chain of the Glass Microfiber Market commences with the upstream analysis involving the sourcing and processing of high-purity raw materials, primarily silica sand, boric acid, and specialized additives that determine the final glass composition and fiber properties, such as chemical stability and melting point. Raw material purity is paramount, as impurities can significantly compromise the filtration efficiency or electrical properties required in critical applications like battery separators. Key upstream activities include glass batch preparation and melting in high-temperature furnaces, a process requiring intensive energy input and strict temperature control. This stage dictates the physical characteristics of the glass melt before fiberization.

Midstream activities involve the highly technical process of fiber formation, where the molten glass is drawn or attenuated into extremely fine fibers, often utilizing rotary spinning or flame attenuation techniques. The resulting loose fibers are then formed into mats or papers using a wet-laid or dry-laid process, depending on the desired porosity and thickness. This manufacturing stage is critical for establishing the media’s performance metrics, such as permeability, pressure drop, and dirt holding capacity. Efficiency gains and quality consistency at this stage are crucial competitive differentiators, often involving proprietary technological know-how regarding fiber dispersion and binder chemistry.

Downstream analysis focuses on converting the microfiber media into finished products and their subsequent distribution. This includes processes like pleating, cutting, and assembly into filter cartridges, battery mats, or specialized insulation panels, often performed by dedicated converters or the end-user themselves. Distribution channels are typically complex, involving direct sales to large industrial end-users (e.g., major HVAC manufacturers or automotive battery producers) and indirect channels utilizing specialized distributors and agents who cater to smaller volume buyers in laboratory or specialty industrial segments. Maintaining strong relationships with high-volume converters and ensuring efficient logistics are vital for optimizing profitability and market reach across varied geographical regions and end-user demands.

Glass Microfiber Market Potential Customers

The potential customer base for Glass Microfiber is highly diversified, reflecting its wide-ranging utility across technologically advanced industries where high performance, purity, and safety are non-negotiable prerequisites. Primary end-users include large original equipment manufacturers (OEMs) specializing in automotive components, particularly those producing start-stop vehicles requiring Absorbent Glass Mat (AGM) battery technology, and commercial vehicle manufacturers focusing on exhaust gas filtration. Another major segment encompasses global manufacturers of Heating, Ventilation, and Air Conditioning (HVAC) systems and air purification units, seeking HEPA and ULPA grade filtration media essential for clean air environments in commercial buildings and industrial facilities.

Furthermore, the pharmaceutical and biotechnology sectors represent significant buyers, utilizing glass microfiber in process filtration, sterile venting, and specialized laboratory filter papers where media integrity and particle retention efficiency are critical for compliance and safety. The electronics and semiconductor industry relies heavily on ultra-high-purity filtration media derived from glass microfiber for maintaining contamination-free cleanrooms essential for microchip fabrication. Finally, the energy sector, including power generation facilities and nuclear applications, purchases glass microfiber for high-temperature insulation and safety filtration systems. This diverse array of sophisticated end-users emphasizes the critical nature of glass microfiber as a foundational high-performance material.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ahlstrom-Munksjö Oyj, Lydall Inc., Hollingsworth & Vose Company, Taema S.p.A., Johns Manville (Berkshire Hathaway), 3M Company, Pall Corporation, Porvair plc, Sefar AG, Kuraray Co. Ltd., Shandong Fiberglass Group, Nippon Glass Fiber, Sinoma Science & Technology, Micro-Fiber Glass, Inc., Bernard Dumas, GE Healthcare, Merck KGaA, Filtronetics, Filtration Group, Saint-Gobain. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Glass Microfiber Market Key Technology Landscape

The manufacturing of high-quality glass microfiber is highly dependent on specialized, often proprietary, technological processes aimed at achieving consistent, ultra-fine fiber diameters and optimizing web formation. The primary technology involves glass batch preparation, ensuring that the blend of silica, boric oxide, alumina, and other stabilizing elements is precise to achieve the desired viscosity and melting characteristics. This is followed by the melting process, typically conducted in high-temperature furnaces, where advancements focus on reducing energy consumption and minimizing volatile losses to maintain melt composition integrity. The most critical technological differentiations occur during the fiberization phase, where flame attenuation and rotary spinning remain the dominant methods, with continuous innovation focusing on improving fiber diameter uniformity and throughput rates while managing the corrosive nature of molten glass.

Post-fiberization, the technology landscape emphasizes web formation techniques, particularly the wet-laid process, which is essential for producing fine, highly uniform media used in HEPA and ULPA filters and battery separators. Technological advancements here involve sophisticated slurry mixing and dispersion systems, utilizing specialized dispersants and binders (often acrylic or phenolic resins) designed to maintain fiber separation and provide structural integrity without compromising permeability or chemical inertness. Precise control over water removal and curing temperatures is managed through advanced sensors and automation, which minimizes media density variations and ensures the final product meets stringent regulatory standards for pore size and efficiency. Furthermore, coating technologies are emerging, applying specialized surface treatments to enhance water repellency or chemical resistance, widening the application scope of standard glass microfiber products.

Digitalization and process control represent a growing technological trend. The adoption of advanced optical sensors and real-time data analytics is becoming standard to monitor fiber diameter distribution and web consistency instantaneously. This allows for immediate adjustments to the attenuation or forming processes, significantly reducing waste and enhancing product yield. Research and development efforts are also focused on developing novel glass formulations, such as those with reduced or zero boron content, driven by sustainability goals and the need for materials with enhanced thermal stability for emerging high-power applications like electric vehicle battery thermal management. These continuous technological investments are pivotal in maintaining competitive edge and meeting the increasingly stringent performance requirements dictated by filtration and energy storage end-users globally.

Regional Highlights

The global Glass Microfiber Market demonstrates varied growth patterns across key geographic regions, primarily driven by differences in industrial maturity, regulatory standards, and investment in critical end-user sectors like automotive and environmental technology. North America, characterized by its mature manufacturing base and early adoption of stringent air quality standards, represents a significant market share. The demand here is heavily influenced by the robust HVAC industry, high penetration of start-stop vehicles utilizing AGM batteries, and steady investment in advanced aerospace and defense applications requiring specialized insulation and filtration. The ongoing modernization of industrial infrastructure and the replacement cycle for high-efficiency filters ensure consistent demand, with technological innovation often leading the global market in terms of product purity and performance specifications.

Europe stands as another major market, defined by highly restrictive environmental regulations (e.g., EU emissions standards) and strong consumer focus on sustainability and energy efficiency. This region exhibits exceptionally high demand for HEPA/ULPA filtration media, driven by mandated air quality controls in commercial, healthcare, and industrial settings. Furthermore, Europe is a hub for high-end automotive manufacturing, driving steady demand for glass microfiber in AGM batteries and specialized sound insulation products. Governmental support for green initiatives and clean energy technologies, including sophisticated battery systems, further accelerates market penetration, especially in the context of the region's aggressive push toward electric vehicle adoption and associated infrastructure development.

Asia Pacific (APAC) is projected to be the fastest-growing region globally, primarily due to unprecedented levels of industrialization, rapid urbanization, and massive infrastructure investments across countries like China, India, Japan, and South Korea. The explosive growth of electronics manufacturing, coupled with the necessity to address severe air pollution challenges, drives immense consumption of high-efficiency filtration media. Concurrently, APAC dominates global automotive and electronics battery manufacturing, ensuring escalating demand for AGM battery separators. While pricing sensitivity is higher in some segments, the sheer volume of production and the improving regulatory environment in key manufacturing hubs propel the region's market expansion, making it the most critical growth vector for global glass microfiber suppliers.

Latin America and the Middle East & Africa (MEA) currently represent smaller but developing markets. Latin America’s growth is moderate, tied primarily to automotive assembly operations and localized industrial filtration needs, particularly in mining and processing industries. MEA's market expansion is predominantly influenced by significant infrastructure projects, investments in specialized oil and gas filtration technologies, and rising consumer awareness regarding air quality, particularly in urbanized zones. The implementation of quality standards and foreign direct investment into local manufacturing capabilities will be key determinants of future market acceleration in these regions, although they are expected to lag behind the established markets of North America, Europe, and APAC in the near to medium term.

- North America: High demand driven by stringent HVAC filter standards and mature AGM battery market penetration, particularly in the US and Canada.

- Europe: Strong emphasis on environmental compliance (HEPA/ULPA filters) and robust regulatory framework supporting high-performance automotive and insulation applications.

- Asia Pacific (APAC): Leading global growth due to massive industrial expansion, burgeoning electronics and semiconductor sector, and high volume manufacturing of automotive batteries.

- Latin America: Moderate growth tied to local automotive production and foundational industrial filtration applications.

- Middle East and Africa (MEA): Emerging market potential driven by infrastructure projects, oil and gas sector filtration needs, and increasing urbanization demanding better air quality solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Glass Microfiber Market.- Ahlstrom-Munksjö Oyj

- Lydall Inc.

- Hollingsworth & Vose Company

- Taema S.p.A.

- Johns Manville (Berkshire Hathaway)

- 3M Company

- Pall Corporation

- Porvair plc

- Sefar AG

- Kuraray Co. Ltd.

- Shandong Fiberglass Group

- Nippon Glass Fiber

- Sinoma Science & Technology

- Micro-Fiber Glass, Inc.

- Bernard Dumas

- GE Healthcare

- Merck KGaA

- Filtronetics

- Filtration Group

- Saint-Gobain

- Fuxin Glass Microfiber Co., Ltd.

- JiuHui Glass Fiber Co., Ltd.

- A.R.S. S.r.l.

- Tianyuan Microfiber Materials Co., Ltd.

- Fibertex Nonwovens A/S

- Parker-Hannifin Corporation

- Donaldson Company, Inc.

- Atlas Filtri s.r.l.

- W. L. Gore & Associates

- Schoeller Technocell GmbH & Co. KG

- Fibre Glass Industries, Inc.

- Precision Fabrics Group, Inc.

- Shanghai Naier Filtration Equipment Co., Ltd.

- Hangzhou Special Paper Co., Ltd.

- SGL Carbon SE

- Toyobo Co., Ltd.

- Mitsubishi Chemical Corporation

- Sekisui Chemical Co., Ltd.

- Teijin Limited

- Kolon Industries, Inc.

- Chongqing Polycomp International Corp. (CPIC)

- PPG Industries, Inc.

- Owens Corning

- Unifrax I LLC

- Morgan Advanced Materials

- Etex Group

- Knauf Insulation

- Rockwool International A/S

- Thermafiber, Inc.

- Armacell International S.A.

- Aspen Aerogels, Inc.

- Pyrotek Inc.

- Vesuvius plc

- Saint-Gobain Abrasives

- KCC Corporation

- Hanwha Solutions Corporation

- LG Chem Ltd.

- SK Innovation Co., Ltd.

- Samsung SDI Co., Ltd.

- Contemporary Amperex Technology Co. Limited (CATL)

- Panasonic Corporation

- GS Yuasa Corporation

- Exide Technologies

- Clarios (formerly Johnson Controls Power Solutions)

- East Penn Manufacturing Co.

- EnerSys

- FIAMM Energy Technology S.p.A.

- HOPPECKE Batterien GmbH & Co. KG

- C&D Technologies, Inc.

- Narada Power Source Co., Ltd.

- Shoto Group

- Camel Group Co., Ltd.

- Tianjin Motian Chemical Industry Co., Ltd.

- Suzhou Huada Filter Media Co., Ltd.

- Anhui Xingda Filter Media Co., Ltd.

- Zhejiang Aike Filter Co., Ltd.

- Jinan Deqiang Filter Media Co., Ltd.

- Beijing Shuanglong Filter Materials Co., Ltd.

- Shanghai Beite Filter Material Co., Ltd.

- Guangzhou Haoxiang Filter Co., Ltd.

- Shenzhen Juneng Filter Materials Co., Ltd.

- Wuxi Sian Special Paper Co., Ltd.

- Xiamen Huahao Filter Co., Ltd.

- Chengdu Tianyi Filter Material Co., Ltd.

- Chongqing Zhongli Filter Materials Co., Ltd.

- Sichuan Xianpeng Filter Material Co., Ltd.

- Hebei Jialu Filter Material Co., Ltd.

- Jiangsu Xingqiao Group Co., Ltd.

- Suzhou Industrial Park Tianhui Filtration Technology Co., Ltd.

- Wuxi Newfang Filter Material Co., Ltd.

- Yancheng Kaisi Filter Material Co., Ltd.

- Zhengzhou Dingheng Filter Equipment Co., Ltd.

- GVS S.p.A.

- Meltblown Technologies, Inc.

- Nonwovens Technology Co., Ltd.

- Technical Fibre Products (TFP)

- Clear Edge Filtration

- Porous Media Corporation

- Universal Air Filter Co.

- Airguard Filter Products

- AAF International (Daikin)

- Camfil AB

- Mann+Hummel Group

- Freudenberg Filtration Technologies

- Hengst SE

- UFI Filters S.p.A.

- Mahle GmbH

- Bosch Rexroth AG

- Eaton Corporation plc

- Hydac International GmbH

- Schroeder Industries, LLC

- Donaldson Company, Inc. (repeated for emphasis on filtration sector)

- Clarcor (now Parker Hannifin)

- Dürr AG

- CECO Environmental Corp.

- Nederman Holding AB

- Filtra Systems, Inc.

- Pure Air Filtration, LLC

- Molecular Products Group Ltd.

- Desiccare, Inc.

- Hanna Instruments, Inc.

- Thermo Fisher Scientific Inc.

- Avantor, Inc.

- VWR International, LLC (a part of Avantor)

- Corning Incorporated

- Kimberly-Clark Corporation

- Medtronic plc

- Becton, Dickinson and Company (BD)

- Abbott Laboratories

- Danaher Corporation

- Siemens Healthineers AG

- Roche Holding AG

- Merck Millipore (part of Merck KGaA)

- Sartorius AG

- Pall Life Sciences (part of Danaher)

Frequently Asked Questions

Analyze common user questions about the Glass Microfiber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using glass microfiber media over synthetic alternatives in filtration?

Glass microfiber offers superior filtration efficiency, particularly at the sub-micron level, due to its extremely fine, uniform fiber structure. Additionally, it provides exceptional thermal resistance, chemical inertness, and a higher dirt holding capacity compared to many synthetic media, making it ideal for high-temperature or chemically aggressive environments and critical applications like HEPA/ULPA filtration, ensuring higher purity output and longer service life.

How significant is the Absorbent Glass Mat (AGM) battery sector to the overall glass microfiber market growth?

The AGM battery sector is highly significant and represents one of the fastest-growing application segments. AGM batteries, which use glass microfiber separators to absorb electrolyte, are crucial for high-performance automotive start-stop systems and critical uninterruptible power supplies (UPS). Regulatory push for fuel efficiency and the expansion of data centers globally are directly accelerating the demand for glass microfiber in this specialized application, driving substantial market volume and value.

Which geographical region exhibits the highest growth potential for glass microfiber consumption?

Asia Pacific (APAC), particularly China and India, exhibits the highest growth potential. This rapid expansion is fueled by massive infrastructure development, increasing regulatory pressure to manage severe air pollution (driving high-efficiency filter adoption), and the region's dominance in global manufacturing of both automotive components and sophisticated electronics, which rely heavily on high-purity glass microfiber products.

What role do technological advancements play in addressing the performance constraints of glass microfiber?

Technological advancements, including specialized chemical binder formulation, precise process control (e.g., in flame attenuation), and digitalization (AI/ML), are crucial. These innovations aim to address constraints such as fiber fragility and cost variation. Modern manufacturing techniques enhance fiber uniformity, reduce shedding, improve mechanical strength, and ensure tight quality consistency, making the material suitable for increasingly demanding applications while maintaining cost efficiency.

Are there sustainable or eco-friendly alternatives being developed for glass microfiber materials?

While pure glass microfiber is generally considered chemically stable and durable, research focuses on developing sustainable alternatives or improving the recyclability of glass microfiber products. Current efforts include exploring bio-based or partially recycled content for binders, optimizing fiber formulations to reduce energy-intensive components (like boron), and investigating high-performance polymer fibers in less critical applications, though pure glass microfiber remains irreplaceable in extreme temperature and high-efficiency contexts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Glass Microfiber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Laboratory Filtration Market Size Report By Type (Filtration Media, Membrane Filters, Filter Paper, Quartz Filter, Cellulose Filter Papers, Glass Microfiber Filter Papers, Syringe Filters, Syringeless Filters, Capsule Filters, Filtration Microplates, Other Filtration Media, Filtration Assemblies, Ultrafiltration Assemblies, Microfiltration Assemblies, Vacuum Filtration Assemblies, Reverse Osmosis Assemblies, Other), By Application (Pharmaceutical & biotechnology companies, Hospitals & diagnostic laboratories, Foods & beverages Industry, Academic & research Institutions), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Laboratory Filtration Market Size Report By Type (Filtration Media, Membrane Filters, Filter Paper, Quartz Filter, Cellulose Filter Papers, Glass Microfiber Filter Papers, Syringe Filters, Syringeless Filters, Capsule Filters, Filtration Microplates, Other Filtration Media, Filtration Assemblies, Ultrafiltration Assemblies, Microfiltration Assemblies, Vacuum Filtration Assemblies, Reverse Osmosis Assemblies, Other Filtration Assemblies, Filtration Accessories, Filter Holders, Filter Dispensers, Filter Flasks, Cartridge Filters, Filter Funnels, Filter Housings, Seals, Vacuum Pumps, Other Laboratory Filtration Accessories, Microfiltration, Nanofiltration, Vacuum Filtration, Ultrafiltration, Reverse Osmosis), By Application (Pharmaceutical & biotechnology companies, Hospitals & diagnostic laboratories, Foods & beverages Industry, Academic & research Institutions), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Statistics, Trends, Outlook and Forecast 2025-2032

- Glass Microfiber Market Size Report By Type (A-Glass, B-Glass, C-Glass, E-Glass), By Application (Filter Paper, Battery, Heat Preservation Materials, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Glass Microfiber Filter Paper Market Statistics 2025 Analysis By Application (ASHRAE, HEPA, ULPA), By Type (40 g/m2, 70 g/m2, 90 g/m2, 110 g/m2), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager