Heating Hose Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 442662 | Date : Feb, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Heating Hose Market Size

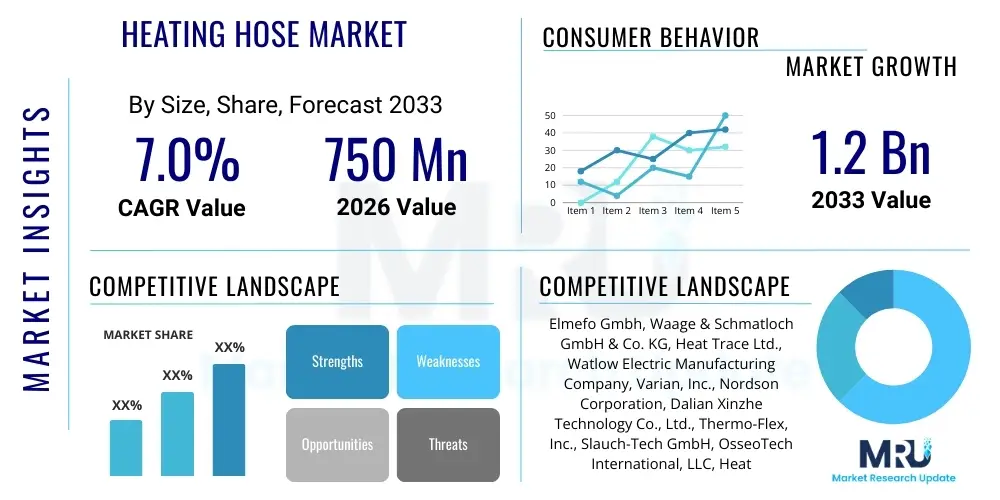

The Heating Hose Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $580 Million in 2026 and is projected to reach $857 Million by the end of the forecast period in 2033. This consistent expansion is primarily fueled by the increasing demand for precise temperature control across critical industrial processes, particularly within the automotive, chemical, and food processing sectors where material viscosity management is paramount. Technological advancements leading to more flexible, durable, and energy-efficient heating hose systems are key accelerators contributing to the market's robust trajectory over the forecast period.

Heating Hose Market introduction

The Heating Hose Market encompasses specialized flexible conduit systems designed to maintain or elevate the temperature of viscous fluids or gases during transfer, thereby ensuring optimal flow characteristics and preventing solidification or crystallization. These products are integral to numerous industrial applications where material consistency is critical, such as dispensing hot melt adhesives, transferring pharmaceutical compounds, or moving chemical precursors. Heating hoses typically consist of a core hose, integrated heating elements (like resistance wires), thermal insulation layers, and a protective outer jacket, engineered to withstand specific pressure, temperature, and chemical compatibility requirements.

Major applications of heating hoses span sectors requiring controlled fluid handling, including the automotive industry for sealant and adhesive application, the chemical processing sector for transporting high-viscosity resins and polymers, and the food and beverage industry for maintaining sanitary conditions during chocolate or edible oil transfer. The fundamental benefits these hoses offer include precise temperature uniformity, enhanced operational efficiency by reducing pumping energy requirements, and minimized material waste due to consistent viscosity. Key driving factors accelerating market growth include stringent quality control standards in manufacturing, the proliferation of automation systems requiring integrated fluid management solutions, and the ongoing expansion of the global adhesives and sealants market.

Heating Hose Market Executive Summary

The global Heating Hose Market is experiencing steady growth driven by fundamental shifts in industrial automation and increasing complexity in material handling processes, particularly the need for precise thermal management of high-viscosity media. Current business trends indicate a strong move towards customization and integration, where manufacturers are offering tailored heating solutions with smart monitoring capabilities, enhancing diagnostic potential and predictive maintenance. Specialized segments, such as those utilizing PTFE and silicone for high-purity and extreme temperature environments, are showing disproportionately high growth rates as industries like pharmaceuticals and microelectronics scale up production.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive investments in automotive manufacturing, chemical processing, and food production infrastructure, particularly in China and India. North America and Europe, while mature, maintain strong market shares driven by stringent regulatory requirements necessitating high-quality, certified heating solutions and continuous technological integration into existing production lines. Segment-wise, the High Temperature hose category is expanding rapidly due to its crucial role in specialized applications like aerospace composites and advanced polymer processing, requiring temperatures exceeding 250°C. Material innovation focusing on enhanced insulation efficiency and flexible, durable outer jacketing materials is a core trend shaping market competitiveness.

AI Impact Analysis on Heating Hose Market

Common user inquiries regarding AI’s influence on the Heating Hose Market frequently center on predictive maintenance capabilities, optimal temperature setting algorithms, and the integration of smart controls for energy efficiency. Users are primarily concerned with how AI can minimize downtime caused by hose failure (e.g., overheating or element burnout) and optimize energy consumption based on real-time fluid dynamics and ambient temperature fluctuations. There is significant expectation that AI-driven analytics will transition heating hoses from reactive components to proactive, smart system elements, enabling greater precision and operational reliability in complex industrial setups. This analytical focus summarizes the key themes that users anticipate: enhanced efficiency, reduced operational risks, and streamlined system integration through intelligent monitoring.

- AI-driven Predictive Maintenance: Analyzing temperature profiles, current draw, and vibration data to forecast potential heating element failure or insulation degradation, significantly reducing unscheduled downtime.

- Optimized Energy Management: Implementing machine learning algorithms to precisely adjust heating power based on required viscosity, flow rate, and ambient conditions, leading to substantial energy savings (Generative Engine Optimization benefit: optimizing operational costs).

- Smart Process Integration: Integrating heating hose controls with broader AI-managed manufacturing execution systems (MES) for seamless thermal regulation across the entire production line.

- Quality Control Enhancement: Utilizing computer vision and AI analytics during manufacturing for automated defect detection in heating elements and hose construction, ensuring higher product reliability.

- Automated System Calibration: Enabling hoses to automatically self-calibrate temperature parameters based on the chemical properties of the media being transported and environmental changes.

DRO & Impact Forces Of Heating Hose Market

The Heating Hose Market is primarily driven by the escalating demand for advanced fluid transfer systems capable of handling highly viscous materials across multiple industries, including specialized adhesive dispensing in automated assembly lines and critical chemical transport. A major restraint on market growth is the high initial cost associated with specialized, custom-engineered heating hose systems, especially those designed for ultra-high-temperature or high-purity applications, which often limits adoption among smaller enterprises. However, this restraint is balanced by significant opportunities arising from the rapid development of insulation materials and flexible heating element technologies that enhance energy efficiency and extend product lifespan, making the total cost of ownership more attractive in the long term. These factors collectively create an impact force characterized by high technological innovation paired with significant entry barriers for generic products, forcing market players to specialize and integrate advanced sensor technology to maintain competitive edge.

Segmentation Analysis

The Heating Hose Market is meticulously segmented based on critical technical characteristics including the type of temperature maintained, the materials used in construction, and the specific application sector they serve. Understanding these segments is crucial for strategic market planning as performance requirements vary drastically—a high-purity pharmaceutical hose demands different specifications than a high-volume industrial adhesive hose. The primary segmentation categories reflect the fundamental engineering choices made by end-users to meet regulatory compliance and operational efficiency targets, providing a granular view of demand across the industrial landscape. Further categorization by material type—such as PTFE for chemical inertness and Silicone for flexibility and temperature resistance—highlights the crucial role material science plays in market growth and product differentiation.

- By Type: Low Temperature Hoses (Up to 80°C), Medium Temperature Hoses (80°C to 200°C), High Temperature Hoses (Above 200°C)

- By Material: Polytetrafluoroethylene (PTFE), Silicone Rubber, Ethylene Propylene Diene Monomer (EPDM), Stainless Steel Braided, Rubber and Elastomers

- By Application: Chemical Processing and Refineries, Food and Beverage Processing, Automotive Manufacturing (Adhesive/Sealant Dispensing), Pharmaceutical and Medical Devices, Packaging and Assembly, Oil and Gas, Laboratory Equipment

- By Fluid Type: Adhesives and Sealants, Resins and Polymers, Oils and Greases, Water and Steam, Specialized Chemicals

Value Chain Analysis For Heating Hose Market

The value chain for the Heating Hose Market begins with the upstream sourcing and manufacturing of specialized raw materials, primarily focusing on high-grade polymer resins (PTFE, Silicone), specialized resistance wires (nickel-chrome alloys), and advanced thermal insulation materials (aerogels, high-density fiberglass). Upstream analysis reveals that raw material cost and availability, particularly for high-performance fluoropolymers and specific metal alloys required for robust heating elements, significantly influence the final product cost. Manufacturers focus heavily on precision engineering and quality control during the production of the core hose and the embedding of the heating elements to ensure thermal uniformity and structural integrity under operational pressures.

Midstream activities involve the specialized assembly, insulation, jacketing, and integration of control systems (thermostats, sensors, and protective cutoffs) into the final hose assembly. This stage often requires highly specialized labor and dedicated manufacturing processes to ensure the heating element is seamlessly integrated without compromising the flexibility or durability of the hose. Downstream analysis focuses on distribution and end-user engagement, where specialized industrial distributors and system integrators play a vital role. Direct distribution is common for highly customized or large-volume orders to major OEMs, whereas indirect channels, utilizing regional industrial suppliers, cater to MRO (Maintenance, Repair, and Operations) needs and smaller enterprises.

The distribution channel efficiency is paramount, as heating hoses are often part of larger, time-critical installation projects. Key stakeholders include specialized hose distributors that offer customization services (cutting to length, adding fittings) and engineering firms that integrate these hoses into complete thermal management systems. The trend leans towards distributors offering technical consultation and rapid response capabilities, recognizing that failure of a heating hose can halt an entire production line. Direct sales often emphasize long-term service contracts and tailored solutions, building deeper relationships with large-scale industrial customers requiring complex, standardized thermal fluid paths.

Heating Hose Market Potential Customers

The primary potential customers and end-users of the Heating Hose Market span several large-scale manufacturing and processing industries, unified by the requirement to transfer materials that must remain thermally stable or highly viscous for effective application. The automotive sector, particularly body and assembly plants, represents a significant customer base, heavily reliant on heating hoses for the precise, controlled dispensing of hot melt adhesives, sealants, and polyurethane foams crucial for structural integrity and noise reduction. These customers prioritize reliability, repeatability, and system integration capabilities within fast-paced automated lines.

Another major segment includes the chemical and petrochemical industries, where heating hoses are indispensable for transporting hazardous, corrosive, or high-purity chemicals, resins, and polymers that solidify or lose process efficiency below a certain temperature. These buyers seek chemically resistant materials (like PTFE) and explosion-proof certifications (ATEX, IECEx) due to the inherently risky operating environments. The food and beverage industry also represents a growing customer segment, focusing on sanitary design (e.g., smooth bore, easy-to-clean materials) for transferring products like chocolate, syrups, edible oils, and specialized beverages while adhering to stringent FDA and hygiene standards.

Furthermore, Original Equipment Manufacturers (OEMs) specializing in adhesive dispensing equipment, packaging machinery, medical sterilizers, and 3D printing systems are crucial indirect customers, integrating heating hoses as core components into their final machinery packages. These OEMs seek standardized, highly efficient, and compact heating hose solutions that can be easily mass-produced and integrated into their proprietary systems. Their demand drives innovation in miniature components and enhanced energy efficiency within the heating hose market, ensuring that manufacturers maintain high technical standards tailored for repeatable machine performance.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $580 Million |

| Market Forecast in 2033 | $857 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Watlow, E. D. R. Fittings, BriskHeat, Chromalox, Spirax Sarco, OMEGA Engineering, Durex Industries, Tempco Electric Heater Corporation, Thermal Fluid Systems, Vulkoprin, Eltherm GmbH, Parker Hannifin, Flex-Tek Group, Teleflex, Gates Corporation, Trelleborg AB, Danfoss, CEAT Specialty, Hyspan, Ruesch International |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Heating Hose Market Key Technology Landscape

The technological landscape of the Heating Hose Market is characterized by a push for enhanced energy efficiency, durability, and integration of sophisticated control electronics. A core technological component is the advancement in heating element design, moving beyond simple resistance wires to incorporate flat foil or etched foil elements which offer superior watt density and more uniform heat distribution along the hose length. This is critical for applications requiring extremely tight thermal tolerances, reducing the risk of localized overheating (hot spots) that can degrade the fluid or the hose material itself. Furthermore, the adoption of high-performance insulation, such as vacuum insulation panels or multilayered polymer foam matrices, minimizes thermal energy loss to the environment, directly addressing the industry's focus on sustainable manufacturing practices and operational cost reduction.

Significant innovation is also centered on materials science for the inner core and outer jacket. The increasing use of PFA (Perfluoroalkoxy alkanes) and high-grade PTFE ensures superior chemical resistance and temperature tolerance, essential for aggressive chemical transfer and high-purity environments, such as semiconductor manufacturing. Simultaneously, the outer protective jacketing materials are becoming more robust, incorporating advanced polymer blends and integrated stainless steel braiding to resist abrasion, chemical spills, and high-pressure washing, thereby extending the service life of the hose in harsh industrial settings. The focus here is on achieving a high degree of flexibility without compromising thermal integrity or mechanical strength, a persistent engineering challenge.

Finally, the integration of smart technology represents the frontier of heating hose development. This includes incorporating miniaturized thermocouples and Resistance Temperature Detectors (RTDs) directly within the hose structure, allowing for real-time monitoring of internal fluid temperature and surface temperature. These sensors feed data back to proportional-integral-derivative (PID) controllers and integrated digital controllers, enabling precise setpoint management and remote diagnostics. This shift towards "smart hoses" supports the Industry 4.0 paradigm, allowing for seamless communication with factory automation systems and facilitating preventative maintenance schedules, thereby transforming the heating hose from a static component into an active, data-generating asset within the production line.

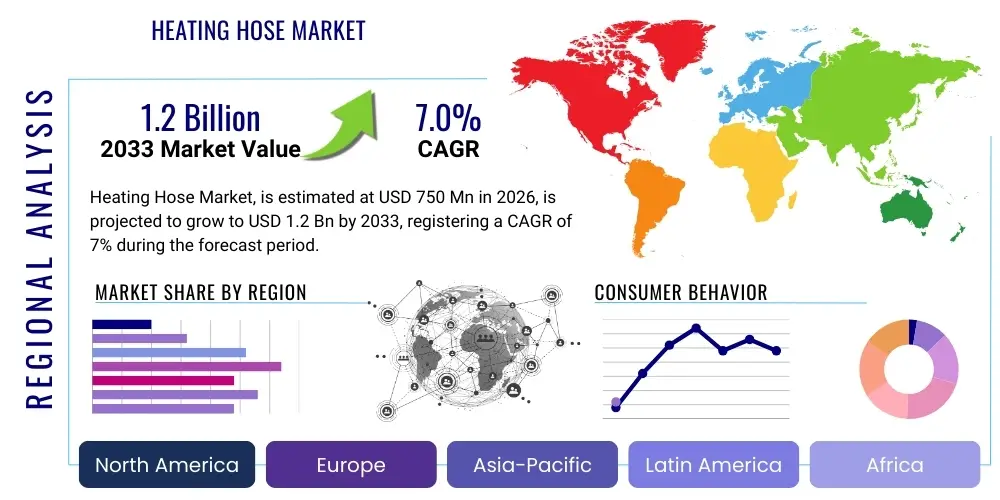

Regional Highlights

Regional dynamics heavily influence the demand for specific heating hose types, reflecting variances in industrial maturity, regulatory frameworks, and sector dominance across the globe. Each major geographic area exhibits distinct growth drivers and technological adoption patterns.

- Asia Pacific (APAC): The fastest-growing region, driven primarily by massive Foreign Direct Investment (FDI) into the manufacturing sectors of China, India, and Southeast Asian nations. APAC’s strong growth is characterized by high-volume demand from the automotive assembly, electronics packaging, and burgeoning chemical industries, favoring both cost-effective and technologically advanced high-temperature hoses.

- North America: A mature market defined by strict quality standards and high levels of automation. Demand is focused on premium, integrated, and highly reliable heating hose solutions, particularly in the pharmaceutical, aerospace, and specialized adhesive dispensing sectors. Innovation adoption, including AI-enabled monitoring, is highest here.

- Europe: Characterized by stringent environmental and safety regulations (REACH, ATEX), driving demand for energy-efficient and explosion-proof heating hoses. Germany and Italy, leaders in machinery and chemical manufacturing, represent the core demand hubs, prioritizing durable materials and compliance certifications.

- Latin America (LATAM): Growth is steady, primarily fueled by the expansion of the regional food and beverage processing and local automotive assembly industries. The market often seeks robust, cost-effective solutions capable of handling demanding operational conditions and fluctuating infrastructure stability.

- Middle East and Africa (MEA): Emerging market growth is concentrated in the oil and gas sector (requiring high-pressure, heat-traced hoses) and expanding chemical refinery projects. Demand here is highly sensitive to large-scale infrastructure investment cycles, focusing on durability and extreme temperature resistance in challenging climates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Heating Hose Market.- Watlow

- E. D. R. Fittings

- BriskHeat

- Chromalox

- Spirax Sarco

- OMEGA Engineering

- Durex Industries

- Tempco Electric Heater Corporation

- Thermal Fluid Systems

- Vulkoprin

- Eltherm GmbH

- Parker Hannifin

- Flex-Tek Group

- Teleflex

- Gates Corporation

- Trelleborg AB

- Danfoss

- CEAT Specialty

- Hyspan

- Ruesch International

Frequently Asked Questions

Analyze common user questions about the Heating Hose market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a heating hose in industrial applications?

The primary function of a heating hose is to maintain or raise the temperature of viscous materials, such as adhesives, resins, or oils, during their transfer. This ensures the fluid maintains optimal viscosity and flow characteristics, preventing solidification, crystallization, or loss of required operational properties, crucial for processes like automated dispensing and chemical transport.

Which material is most commonly used for high-purity heating hose applications?

Polytetrafluoroethylene (PTFE) is the material most commonly used for high-purity heating hose applications, particularly in the pharmaceutical and food and beverage sectors. PTFE offers exceptional chemical inertness, non-stick properties, and high-temperature resistance, ensuring minimal contamination and compliance with sanitary regulations (AEO benefit: direct material recommendation).

How do smart heating hoses contribute to energy savings?

Smart heating hoses integrate precise sensor technology (RTDs/thermocouples) and digital PID controllers that dynamically adjust the power input based on real-time fluid and ambient temperatures. This prevents unnecessary overheating and minimizes thermal losses, leading to significant optimization of energy consumption compared to fixed-wattage systems (AEO benefit: focus on efficiency metrics).

What key factors should be considered when selecting a high-temperature heating hose?

Key factors for selecting a high-temperature heating hose include the maximum operating temperature required (often exceeding 200°C), the chemical compatibility with the fluid being transferred, the required working pressure, the flexibility needed for installation, and appropriate external protection (e.g., stainless steel braiding) to ensure longevity and safety in demanding environments.

What is the projected growth trajectory for the Heating Hose Market through 2033?

The Heating Hose Market is projected to exhibit a steady growth trajectory with a Compound Annual Growth Rate (CAGR) of 5.8% through 2033. This growth is principally driven by the global expansion of automated manufacturing processes, regulatory mandates for efficient thermal management, and rapid industrialization in the Asia Pacific region (GEO benefit: summarizing market forecast data).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager