Magnesium Bisglycinate API Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443474 | Date : Feb, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Magnesium Bisglycinate API Market Size

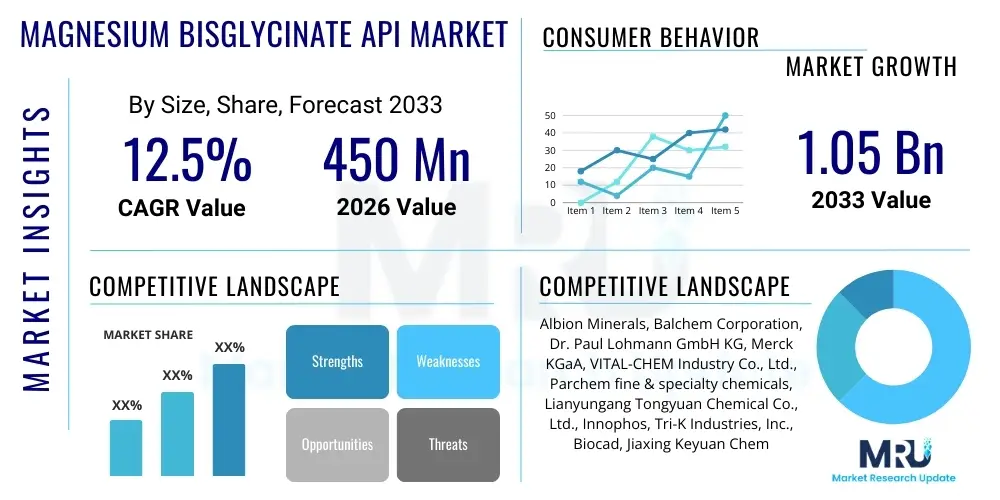

The Magnesium Bisglycinate API Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 525.4 million in 2026 and is projected to reach USD 1,003.8 million by the end of the forecast period in 2033.

Magnesium Bisglycinate API Market introduction

The Magnesium Bisglycinate API (Active Pharmaceutical Ingredient) Market encompasses the manufacturing and distribution of high-purity chelated magnesium compounds used primarily in pharmaceutical and nutraceutical formulations. Magnesium bisglycinate, often preferred over simpler magnesium salts due to its superior bioavailability and reduced gastrointestinal side effects, is synthesized by chelating magnesium ions with two molecules of the amino acid glycine. This enhanced absorption profile has positioned it as a critical ingredient for manufacturers focusing on high-efficacy dietary supplements aimed at addressing prevalent issues such as muscle function support, sleep quality improvement, stress reduction, and cardiovascular health maintenance. The market’s growth trajectory is intrinsically linked to the rising global awareness of micronutrient deficiencies and the aging population’s increasing reliance on proactive health management through supplements.

The core product in this market is the standardized, high-purity magnesium bisglycinate powder, manufactured under stringent Good Manufacturing Practice (GMP) standards to meet regulatory requirements across different geographical jurisdictions. Major applications span the therapeutic landscape, including prescription medications for certain magnesium deficiency disorders (though less common than supplement use), and, more significantly, over-the-counter dietary supplements. The API serves as a vital component in capsules, tablets, powdered drink mixes, and functional foods, catering to a diverse consumer base ranging from athletes seeking enhanced recovery to individuals managing chronic stress or sleep disturbances. The market structure involves specialized chemical manufacturers supplying bulk API to finished product formulators globally, creating complex supply chain dynamics centered around sourcing quality raw materials (magnesium oxide/carbonate and glycine).

Driving factors for sustained market expansion include the burgeoning demand for high-absorption minerals, significant investments in clinical trials validating the health benefits of magnesium bisglycinate, and continuous product innovation leading to enhanced delivery systems. Furthermore, regulatory support, particularly in developed economies, emphasizing the disclosure and quality assurance of dietary ingredients, favors certified API suppliers. Benefits derived from utilizing this API include enhanced formulation stability, greater consumer compliance due to reduced digestive distress compared to compounds like magnesium oxide or citrate, and stronger brand positioning for finished product manufacturers who can leverage the clinical evidence supporting chelated mineral efficacy. However, the market faces constraints related to the higher production costs associated with the chelation process compared to generic magnesium salts, necessitating efficient synthesis methods and robust quality control protocols.

Magnesium Bisglycinate API Market Executive Summary

The Magnesium Bisglycinate API Market is characterized by robust expansion driven primarily by shifting consumer preferences towards superior-quality, bioavailable nutraceutical ingredients and the increasing prevalence of lifestyle-related health concerns. Business trends indicate a strong focus on backward integration among key players, securing consistent glycine and magnesium sourcing to mitigate supply chain volatility and maintain competitive pricing. There is a discernible trend toward customized API formulations, including granulated or micronized variants, tailored for specific drug delivery systems or consumer preferences, particularly within the sports nutrition and specialized medical food segments. Strategic collaborations between API producers and large pharmaceutical/nutraceutical contract manufacturers are intensifying to streamline the development-to-market timeline for new finished products, emphasizing rigorous purity standards and third-party certifications (e.g., USP, EFSA compliance) to build market trust and regulatory acceptance.

Regionally, North America and Europe currently dominate the market share, attributed to high consumer health spending, mature regulatory environments supportive of dietary supplements, and established distribution networks for specialized health products. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth trajectory, fueled by rapid urbanization, increasing disposable incomes, and a growing middle class adopting Westernized supplement consumption habits. Key APAC countries like China and India are evolving from primarily raw material suppliers to significant consumption centers, prompting international API manufacturers to establish local manufacturing or distribution partnerships to navigate complex regional regulatory landscapes and capitalize on localized demand. The Middle East and Africa (MEA) and Latin America (LATAM) represent emerging opportunities, characterized by foundational growth in pharmaceutical manufacturing and rising health consciousness, though market penetration remains challenging due to varying quality standards and economic volatility.

Segment-wise, the Nutraceuticals segment, specifically the Dietary Supplements category, remains the largest application driver for Magnesium Bisglycinate API, leveraging its efficacy in sleep aids, anxiety reduction formulas, and muscle recovery products. Purity level segmentation sees high-purity (99% and above) APIs commanding a premium, driven by pharmaceutical applications and high-end nutraceutical brands prioritizing ingredient integrity and minimizing trace impurities. Future growth is anticipated in the functional food and beverage segments, requiring novel API formulations that offer enhanced solubility without compromising the chelate structure. Overall, the market outlook is overwhelmingly positive, contingent on managing input costs and navigating the intellectual property landscape surrounding patented chelation technologies, ensuring sustainable supply of this premium mineral source.

AI Impact Analysis on Magnesium Bisglycinate API Market

Common user questions regarding AI's influence in the Magnesium Bisglycinate API market typically revolve around optimizing complex synthesis processes, predicting raw material price fluctuations, ensuring enhanced supply chain transparency, and accelerating clinical validation of product efficacy. Users are concerned about how AI can handle the intricate parameters involved in the chelation reaction—such as pH control, temperature management, and stoichiometric ratios—to maximize yield and maintain consistent high purity, which are critical differentiators in the API space. There is significant interest in AI's role in predictive maintenance for specialized reaction vessels and crystallization equipment, minimizing costly downtime. Furthermore, questions frequently arise regarding AI-driven market analysis tools capable of forecasting demand shifts based on real-time health trends and social media sentiment related to magnesium supplementation, allowing manufacturers to optimize inventory levels and production schedules dynamically.

AI adoption is poised to revolutionize several functional areas within the Magnesium Bisglycinate API sector, moving beyond simple automation to sophisticated process control and decision support. In research and development, AI algorithms can rapidly screen potential precursor combinations and optimize reaction kinetics, significantly reducing the time and cost associated with developing scale-up protocols for GMP manufacturing. For quality assurance, machine learning models can analyze spectroscopic data (e.g., FTIR, HPLC) in real-time to detect minute impurities or deviations in product crystallinity and particle size distribution, far exceeding the capabilities of traditional statistical process control. This enhanced quality control system is crucial for maintaining the stringent API standards required for both pharmaceutical and high-end nutraceutical applications, thereby reinforcing consumer trust and regulatory compliance globally.

The immediate practical impact lies in optimizing the highly energy-intensive and time-consuming drying and crystallization phases of magnesium bisglycinate production. AI-powered smart sensors and IoT integration allow for the creation of digital twins of manufacturing facilities, enabling simulation of various production scenarios and proactive identification of energy inefficiencies. This leads to substantial cost savings and helps maintain competitive pricing despite the intrinsically higher cost of chelated minerals. Furthermore, AI platforms are increasingly employed in regulatory intelligence, systematically tracking global changes in permissible impurity limits, novel testing requirements, and regional labeling guidelines, ensuring that the exported API batches meet the diverse compliance mandates of end-user markets like the European Union (EU) and the United States (US) FDA without delays or costly recalls, thereby solidifying market leadership through proactive compliance management.

- AI-driven optimization of chelation reaction parameters for maximum yield and purity consistency.

- Predictive analytics for raw material (glycine, magnesium salts) price forecasting and procurement strategy optimization.

- Machine learning integration into spectroscopic quality control for real-time impurity detection and batch release efficiency.

- Automation of regulatory intelligence gathering to ensure proactive compliance with global API standards (e.g., USP, EP).

- Use of digital twins for simulating manufacturing scale-up, minimizing production risks, and optimizing energy consumption.

- AI-enhanced demand forecasting based on consumer sentiment and epidemiological data for just-in-time inventory management.

DRO & Impact Forces Of Magnesium Bisglycinate API Market

The Magnesium Bisglycinate API Market is propelled primarily by the rising global recognition of magnesium deficiency as a public health concern and the superior pharmacokinetic profile of the bisglycinate chelate. Drivers include increasing consumer disposable income dedicated to preventative healthcare, the proliferation of digital health platforms promoting personalized nutrition, and the escalating demand for high-bioavailability supplements among the elderly and athletic populations. However, the market faces significant restraints, most notably the higher complexity and cost associated with manufacturing true chelated forms compared to cheaper, less effective magnesium salts (e.g., oxide or sulfate), which creates price competition and risks market confusion regarding product efficacy. Furthermore, stringent regulatory requirements, particularly concerning solvent residues and heavy metal contaminants in API production, necessitate significant capital investment in advanced manufacturing technologies. Opportunities abound in expanding application scope into clinical nutrition, targeting conditions like pre-eclampsia and certain neurological disorders, and capitalizing on the untapped potential in emerging economies where health supplement consumption is rapidly increasing.

The impact forces within this market reflect the interplay between clinical validation, supply chain integrity, and consumer perception. The force of buyer power is moderate to high, as large nutraceutical companies exert considerable influence over pricing and quality specifications, often demanding multi-source assurance and extensive documentation regarding stability and toxicology. Supplier power is also significant, particularly for high-grade glycine and specialized chelation catalysts, leading to moderate vertical integration attempts by major API producers to secure critical inputs and stabilize production costs. Competitive rivalry is intensifying, with established chemical companies defending their market share against new entrants from Asian manufacturing hubs, focusing on differentiating through intellectual property surrounding novel chelation processes or superior particle size distribution technologies crucial for specific dosage forms.

Technological impact forces are substantial, driving constant pressure for process innovation aimed at improving yield, reducing energy consumption, and achieving higher purity levels more efficiently. Innovations in green chemistry and enzymatic synthesis methods present an opportunity to lower production barriers and enhance sustainability credentials, increasingly valued by end consumers. Regulatory impact remains a critical external force; evolving pharmacopeial standards and increased scrutiny of ‘bioavailability claims’ by agencies like the FDA and EMA compel API manufacturers to invest heavily in clinical and dissolution studies to substantiate product superiority. This environment favors established manufacturers with deep pockets and validated quality systems, thus potentially raising the barrier to entry for smaller or non-compliant suppliers, ultimately stabilizing the market by prioritizing quality over cost and ensuring consumer safety.

Segmentation Analysis

The Magnesium Bisglycinate API Market is extensively segmented based on key parameters including Purity Level, Application, and Region, reflecting the diverse requirements of pharmaceutical and nutraceutical industries globally. Segmentation by Purity Level is critical, as it directly correlates with the end-product application, regulatory pathway, and achievable market price. The Application segmentation clearly defines the primary demand drivers, distinguishing between the high volume, consumer-driven nutraceutical sector and the stringent quality demands of the smaller, but higher-value, pharmaceutical category. Geographic segmentation highlights the disparities in market maturity, regulatory adoption rates, and consumer health spending across major global regions, offering strategic insights for market penetration and resource allocation decisions for API suppliers.

The Purity Level segment is sharply divided into 99% Purity and Below 99% Purity, reflecting the requirement of specific regulatory bodies. High-purity APIs (99%+) are mandatory for most pharmaceutical applications and preferred by premium nutraceutical brands seeking to minimize residual solvent contamination and maximize therapeutic efficacy. Conversely, APIs categorized as Below 99% Purity often cater to cost-sensitive applications such as certain cosmetic formulations or bulk animal nutrition, where the tolerance for trace impurities is slightly higher, allowing for potentially lower manufacturing costs. However, even the "Below 99%" category within the bisglycinate segment must maintain robust quality standards significantly higher than those for generic mineral salts, focusing on low heavy metal and microbiological contamination.

Application analysis confirms that Nutraceuticals, encompassing a vast array of dietary supplements, remains the market's dominant segment, leveraging the API's strong consumer appeal for stress relief, improved sleep, and general muscle health. The Pharmaceuticals segment, though smaller, represents a high-growth opportunity due to specific clinical uses where high bioavailability is crucial, often demanding the most rigorous quality documentation. The emerging Cosmetics and Animal Nutrition segments are also gaining traction. Cosmetics utilize the API for skin barrier repair and soothing properties, while Animal Nutrition, particularly in high-value livestock or companion animal supplements, benefits from the high absorption rate to enhance health and performance metrics, creating varied demand structures that API manufacturers must strategically address.

- Purity Level

- 99% Purity

- Below 99% Purity

- Application

- Pharmaceuticals

- Nutraceuticals (Dietary Supplements)

- Cosmetics

- Animal Nutrition

- Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Magnesium Bisglycinate API Market

The Value Chain for the Magnesium Bisglycinate API Market begins with upstream activities involving the sourcing of primary raw materials: high-grade magnesium oxide or carbonate and pharmaceutical-grade glycine. Upstream analysis focuses heavily on securing reliable, cost-effective, and compliant suppliers for these precursors, as their quality directly impacts the final API’s purity and batch consistency. Manufacturers often engage in long-term supply agreements or vertical integration to stabilize input costs and manage geopolitical risks associated with global chemical sourcing. The core manufacturing stage involves the complex chelation process, purification, crystallization, and subsequent drying and milling of the API powder. This stage requires specialized chemical expertise, proprietary technology (often guarded IP related to efficient chelation methods), and significant capital expenditure for GMP-compliant facilities capable of high throughput and stringent quality control, representing the highest value addition point in the chain.

The downstream analysis primarily concerns the distribution and final formulation phases. Once manufactured, the bulk API is packaged according to regulatory requirements and distributed through both direct and indirect channels. Direct distribution involves large API manufacturers selling directly to major pharmaceutical or nutraceutical corporations that possess in-house formulation capabilities (e.g., tablet compression, encapsulation). This channel offers higher margins and tighter quality control collaboration. Indirect distribution utilizes specialized chemical distributors or brokers who handle logistics, customs clearance, and small-volume sales to smaller contract manufacturing organizations (CMOs) or regional supplement brands. The CMOs then formulate the API into finished products—capsules, powders, or liquids—before marketing them to consumers.

The distribution channel dynamics are complex, heavily relying on specialized logistics providers capable of handling pharmaceutical precursors under monitored conditions, especially across international borders. The direct sales channel emphasizes relationship management, technical support, and documentation rigor, catering primarily to the pharmaceutical and premium nutraceutical segments that demand comprehensive audit trails. Conversely, the indirect channel provides market reach and flexibility, particularly valuable in fragmented markets or regions with high regulatory variability. Effective management of this chain—from precursor quality assurance (reducing heavy metal risk) to final formulation support (ensuring API solubility and stability in the final dosage form)—is critical for maximizing profitability and maintaining brand reputation in a market increasingly sensitive to ingredient origin and integrity.

Magnesium Bisglycinate API Market Potential Customers

The primary potential customers for Magnesium Bisglycinate API are large-scale nutraceutical companies specializing in the development and marketing of dietary supplements focused on specific health outcomes such as sleep enhancement, stress management, muscle recovery, and bone health. These customers prioritize APIs with proven high bioavailability and excellent stability profiles, enabling them to differentiate their final products in a crowded supplement market. They require suppliers capable of providing extensive technical dossiers, regulatory support (e.g., GRAS status documentation in the US, Novel Food approval relevance in the EU), and consistent batch quality, often demanding annual volumes in the metric tons range. Their buying decisions are heavily influenced by the API supplier’s capacity for innovation in formulation support and the ability to guarantee supply chain integrity from source to finished product, minimizing the risk of adulteration or contamination.

A secondary, yet highly critical customer base, consists of Pharmaceutical Companies and Contract Manufacturing Organizations (CMOs) operating within the drug manufacturing space. While magnesium bisglycinate is less common in mainstream prescription drugs than traditional inorganic salts, its high-purity variants are increasingly sought for specialized medical foods, clinical nutrition formulations, and certain off-label uses where superior absorption is clinically advantageous. These customers operate under the strictest regulatory oversight (e.g., FDA, EMA compliance) and require API suppliers who can provide Drug Master Files (DMFs), rigorous validation studies, and adherence to ICH Q7 GMP guidelines, making them high-value, albeit volume-constrained, buyers. CMOs, acting as intermediaries, purchase API on behalf of smaller brands, demanding flexibility in packaging, batch size, and logistics, while still requiring robust quality documentation.

Emerging potential customer segments include premium Cosmetics and functional Food & Beverage manufacturers. Cosmetics companies utilize magnesium bisglycinate for topical applications focused on anti-inflammation and skin rejuvenation, requiring APIs that are easy to disperse and stable in aqueous solutions. Functional food producers integrate the API into health bars, fortified beverages, or specialized hydration mixes, demanding micronized or highly soluble forms that do not impact the taste or texture of the final product. These emerging segments seek innovative partnership models with API manufacturers to co-develop formulations that overcome solubility challenges and meet evolving consumer demands for convenient, multi-functional health products. Therefore, the supplier's technical service capacity is as important as the product quality itself for these specialized customer groups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 525.4 million |

| Market Forecast in 2033 | USD 1,003.8 million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Albion Minerals, Balchem Corporation, Dr. Paul Lohmann GmbH KG, Premier Magnesia LLC, Kyowa Hakko Bio Co., Ltd., Jungbunzlauer Suisse AG, The Chemical Company, Innophos Holdings Inc., Foodchem International Corporation, Spec-Chem Industry Inc., Shaanxi Hongkang Biological Technology Co., Ltd., Xi'an Green Spring Technology Co., Ltd., Hebei Pengkai Chemical Co., Ltd., Shandong Jinyuan Biochemical Co., Ltd., Changsha Natureway Biological Technology Co., Ltd., Nantong Chemicals Co., Ltd., Huachen Biological Technology Co., Ltd., Anhui Boke Biochemical Co., Ltd., Jiangsu Aoxin Chemical Co., Ltd., Zhejiang Huashen Pharmaceutical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Magnesium Bisglycinate API Market Key Technology Landscape

The manufacturing of Magnesium Bisglycinate API relies heavily on advanced chelation chemistry and sophisticated purification technologies to ensure the formation of a stable, bioavailable compound free from toxic contaminants. The core technology involves the synthesis reaction where magnesium salts react with glycine, requiring precise control over pH, temperature, and reaction time to maximize the chelation yield and minimize side product formation, such as unchelated salts or impurities. Key technological differentiators among leading producers include proprietary methods for continuous flow synthesis, which enhance efficiency and scalability compared to traditional batch processing, and patented crystallization techniques designed to produce specific particle sizes and morphologies crucial for enhanced API dissolution and subsequent formulation into high-density tablets or capsules. Furthermore, the selection of appropriate reaction solvents and minimization of solvent residues, often achieved through vacuum drying or thin-film evaporation, remains a critical technical challenge that defines the purity grade and market suitability of the final product.

Beyond the primary synthesis, the technology landscape is shaped by stringent analytical and quality assurance protocols. High-Performance Liquid Chromatography (HPLC), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), and Fourier-Transform Infrared Spectroscopy (FTIR) are standard technologies employed to rigorously verify the chelate structure, confirm the absence of heavy metals (e.g., lead, cadmium, arsenic), and quantify residual solvents. Advanced process analytical technology (PAT) tools, often incorporating real-time monitoring and AI-driven control systems, are increasingly deployed in GMP facilities to ensure batch-to-batch consistency and preemptively adjust reaction parameters, thereby optimizing resource utilization and minimizing deviation risks. This level of technological sophistication is mandatory for API manufacturers targeting the highly lucrative, but equally demanding, European and North American nutraceutical and pharmaceutical markets.

Innovation is also focusing on technologies related to improved ingredient solubility and stability within complex delivery systems. Techniques such as microencapsulation, spray drying, and specialized agglomeration are being explored to create enhanced forms of Magnesium Bisglycinate API that are suitable for use in liquid suspensions, functional beverages, or effervescent tablets without degradation or sedimentation. These particle engineering technologies address major formulation challenges faced by downstream customers, expanding the API's utility beyond traditional capsule and tablet formats. Furthermore, sustainable manufacturing practices, including the adoption of green solvents and waste minimization techniques, are emerging as critical technological competencies, driven by corporate social responsibility mandates and increasing regulatory pressure to reduce the environmental footprint of chemical production, providing a competitive edge to technologically forward-thinking API suppliers.

Regional Highlights

- North America: North America, led by the United States and Canada, represents the largest and most mature market for Magnesium Bisglycinate API, primarily due to high consumer spending on dietary supplements, strong health awareness regarding mineral deficiencies, and the robust presence of leading nutraceutical brands. The region’s demand is heavily concentrated in the high-purity segment, driven by marketing focused on superior bioavailability and clean-label standards. Stringent FDA and Health Canada regulations necessitate that API suppliers provide comprehensive documentation, including Non-GMO verification and detailed heavy metal testing, ensuring premium pricing for compliant products. The increasing popularity of personalized nutrition and athletic performance supplements further solidifies North America's dominance, making it a critical strategic region for key market players.

- Europe: Europe holds a substantial market share, characterized by high regulatory scrutiny, particularly through the European Food Safety Authority (EFSA), which carefully evaluates health claims and novel food ingredients. Countries like Germany, the UK, and France are significant consumers, driven by a culturally ingrained preference for health and wellness products, including specific mineral supplements for nervous system and muscle function support. The demand here favors suppliers capable of demonstrating compliance with the EU's strict Pharmacopoeia standards and rigorous trace impurity limits, often encouraging local production or specialized importation procedures. The European market exhibits strong growth in functional foods utilizing magnesium bisglycinate to cater to an aging population seeking proactive solutions for age-related health issues.

- Asia Pacific (APAC): The APAC region is anticipated to be the fastest-growing market over the forecast period, transitioning rapidly from primarily a manufacturing base to a major consumer market. Growth is fueled by rising disposable incomes in countries like China, India, and South Korea, coupled with increasing adoption of Western supplement trends. While pricing sensitivity remains a factor, there is a growing segment demanding high-quality, imported API, driven by local formulators seeking to upgrade their product lines. Regulatory fragmentation across APAC countries poses logistical challenges, but the immense size of the consumer base, particularly in urban areas, makes strategic investment in local distribution and regulatory navigation essential for capturing future market growth, especially in the rapidly expanding animal nutrition segment.

- Latin America (LATAM): The LATAM market, while smaller in absolute terms, offers emerging growth potential, particularly in Brazil and Mexico. Market expansion is closely tied to the modernization of pharmaceutical and nutraceutical manufacturing capabilities and growing governmental efforts to improve public health awareness regarding nutritional deficiencies. Price sensitivity is relatively high, often favoring regionally sourced or cost-competitive API, but the shift towards high-value supplements is accelerating among affluent consumers. Establishing strong local partnerships and understanding the unique import/export complexities are key success factors in this region.

- Middle East and Africa (MEA): The MEA region is characterized by nascent market development, with demand concentrated in affluent Gulf Cooperation Council (GCC) countries. Growth drivers include significant healthcare expenditure and a reliance on imported finished goods and high-quality APIs. Market penetration relies heavily on establishing robust supply chains that adhere to often complex customs and religious certification requirements, such as Halal compliance, which necessitates specialized production protocols. South Africa acts as a regional hub, driving localized manufacturing and distribution efforts for both human and animal health supplements containing magnesium bisglycinate.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Magnesium Bisglycinate API Market.- Albion Minerals

- Balchem Corporation

- Dr. Paul Lohmann GmbH KG

- Premier Magnesia LLC

- Kyowa Hakko Bio Co., Ltd.

- Jungbunzlauer Suisse AG

- The Chemical Company

- Innophos Holdings Inc.

- Foodchem International Corporation

- Spec-Chem Industry Inc.

- Shaanxi Hongkang Biological Technology Co., Ltd.

- Xi'an Green Spring Technology Co., Ltd.

- Hebei Pengkai Chemical Co., Ltd.

- Shandong Jinyuan Biochemical Co., Ltd.

- Changsha Natureway Biological Technology Co., Ltd.

- Nantong Chemicals Co., Ltd.

- Huachen Biological Technology Co., Ltd.

- Anhui Boke Biochemical Co., Ltd.

- Jiangsu Aoxin Chemical Co., Ltd.

- Zhejiang Huashen Pharmaceutical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Magnesium Bisglycinate API market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes Magnesium Bisglycinate API from other magnesium salts in terms of market value?

Magnesium Bisglycinate is a chelated mineral API, meaning the magnesium ion is bound to two glycine molecules. This chelation process significantly enhances its bioavailability and reduces gastrointestinal distress compared to standard salts like oxide or citrate. The superior efficacy and better patient tolerance command a higher market price and drive demand from premium nutraceutical brands, justifying the increased manufacturing cost and complexity involved in its production.

What are the primary purity requirements impacting Magnesium Bisglycinate API market segmentation?

The primary purity distinction is between 99% Purity and Below 99% Purity. APIs meeting or exceeding 99% purity are typically required for pharmaceutical applications and high-end dietary supplements demanding minimal residual solvent, heavy metal, and microbiological contamination, adhering strictly to global pharmacopeial standards (e.g., USP, EP). Below 99% purity serves the broader, more cost-sensitive nutraceutical and animal nutrition markets, though strict quality control remains essential for consumer safety and regulatory compliance.

How is the global supply chain for Magnesium Bisglycinate API managed given its specialized nature?

The supply chain is vertically integrated for core players, starting with sourcing specialized precursors (high-grade glycine and magnesium sources) and moving through proprietary chelation processes in GMP facilities. Distribution relies on specialized logistics networks, utilizing both direct sales to major formulators and indirect channels through chemical distributors. Supply chain integrity is ensured through rigorous quality checks at every stage, focusing particularly on preventing heavy metal contamination and verifying the authenticity of the chelate structure.

Which geographical region exhibits the most significant growth opportunity for this API market?

Asia Pacific (APAC) is projected to offer the most significant growth opportunity. This accelerated expansion is driven by rapidly increasing consumer awareness of preventative health, rising disposable incomes, and the modernization of the local nutraceutical industry in key markets such as China and India. While North America and Europe currently hold the largest market shares, APAC’s foundational shift in consumption habits guarantees a higher Compound Annual Growth Rate over the forecast period.

What specific impact does AI have on the quality control and efficiency of API production?

AI significantly enhances quality control by integrating machine learning models with Process Analytical Technology (PAT), allowing for real-time monitoring and analysis of spectroscopic data (HPLC, FTIR). This enables immediate detection of batch deviations or impurities, improving product consistency and reducing waste. Furthermore, AI optimizes complex reaction parameters (temperature, pH) in the chelation process, leading to higher yields, reduced energy consumption, and more efficient scale-up from lab to commercial production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager