Niobium-Titanium Alloys Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440933 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Niobium-Titanium Alloys Market Size

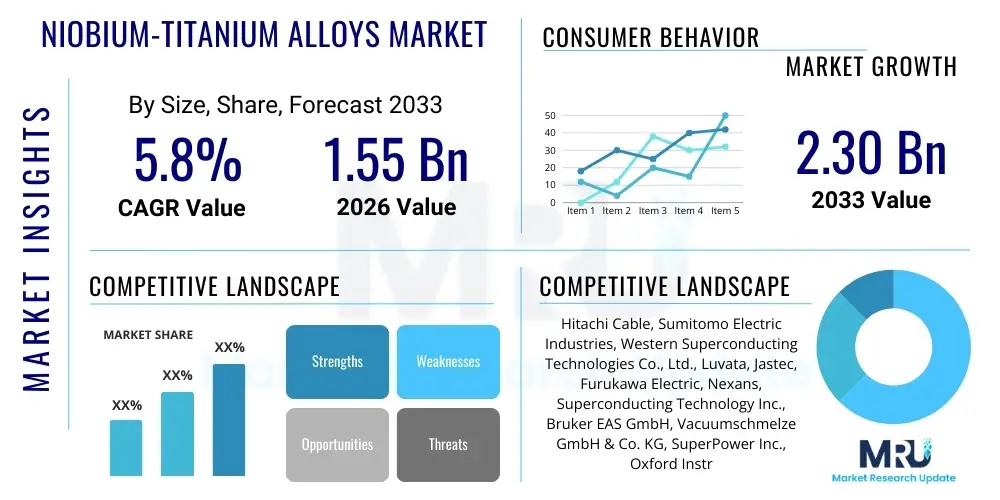

The Niobium-Titanium Alloys Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 1,000 Million by the end of the forecast period in 2033.

Niobium-Titanium Alloys Market introduction

The Niobium-Titanium (NbTi) Alloys Market revolves around specialized metallic compounds primarily valued for their superior superconducting properties, particularly at cryogenic temperatures. These alloys, typically containing 40% to 50% Niobium by weight, exhibit a critical transition temperature (Tc) high enough to operate efficiently when cooled by liquid helium. NbTi is the most mature and widely utilized Type II superconductor in commercial applications due to its excellent ductility, ease of fabrication into fine wires, and cost-effectiveness compared to higher-performance superconductors like Niobium-Tin (Nb3Sn). The primary market driver is the escalating demand from high-energy physics research, advanced medical imaging, and emerging fusion energy projects, necessitating robust, high-current-carrying magnet systems.

Niobium-Titanium alloys are meticulously processed to achieve optimal microstructures that enhance flux pinning—a mechanism crucial for sustaining high current density in a magnetic field. Fabrication typically involves complex metallurgical routes, including ingot melting, hot extrusion, and extensive cold drawing steps, often incorporating copper jacketing to provide thermal stabilization and protection against quenching events. The final product is usually in the form of multifilamentary wires or cables embedded in a copper matrix, designed for large-scale superconducting magnet construction. The reliability and established production infrastructure for NbTi have cemented its position as the foundational material for large-scale superconducting applications globally, supporting both commercial viability and scientific advancement.

Major applications of NbTi alloys span critical sectors where powerful magnetic fields are indispensable. Medical Resonance Imaging (MRI) machines constitute a significant segment of demand, utilizing NbTi wires to generate uniform, persistent magnetic fields essential for high-resolution diagnostic imaging. Beyond healthcare, high-energy particle accelerators, such as the Large Hadron Collider (LHC), rely extensively on NbTi for their enormous bending and focusing magnets. Furthermore, the burgeoning investment in magnetic confinement fusion research, exemplified by the ITER project, promises substantial, long-term demand for NbTi, positioning this specialized alloy at the intersection of fundamental science and next-generation energy technology. The inherent benefits, including high critical current density and exceptional mechanical workability, drive continuous market growth.

Niobium-Titanium Alloys Market Executive Summary

The Niobium-Titanium Alloys market is currently experiencing robust expansion, driven primarily by sustained global investments in advanced scientific infrastructure and the steady growth of the medical diagnostic equipment sector. A key business trend is the increasing vertical integration among specialized alloy manufacturers, aiming to control the highly complex supply chain from raw material refinement (Niobium and Titanium ores) through to the production of superconducting wire and cable. Furthermore, strategic partnerships between industrial suppliers and national research laboratories are essential for co-developing new composite designs that enhance current density and reduce AC loss, thereby improving the efficiency of next-generation magnets and supporting long-term commercial sustainability in energy and transport applications.

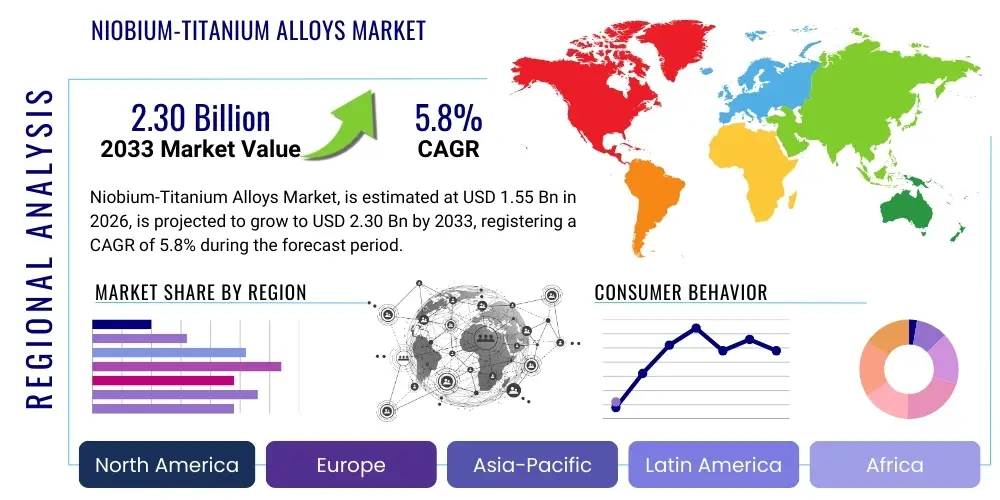

Regionally, the market exhibits a concentration of demand in areas with robust government funding for scientific research and advanced manufacturing capabilities. Asia Pacific, specifically China and Japan, is emerging as a dominant force, characterized by massive government investment in domestic particle accelerators, large-scale fusion research projects, and rapid expansion of medical infrastructure. North America and Europe remain foundational markets, driven by established MRI markets and ongoing upgrade cycles for legacy high-energy physics facilities. The competitive regional landscape necessitates localized production and distribution networks that adhere to stringent quality standards mandated by sensitive scientific and medical end-users, affecting pricing and market entry strategies across continents.

Segmentation trends highlight the dominance of the Wire and Cable segment, reflecting the alloy's primary usage form in magnet construction, followed by the Bar and Rod segment for structural supports in magnet systems. Application-wise, the Healthcare sector (MRI systems) currently holds the largest market share due to its consistent commercial deployment, but the Energy & Research sector, encompassing fusion and particle physics, is projected to register the highest Compound Annual Growth Rate (CAGR). This shift is underpinned by major global initiatives, such as the construction of next-generation fusion reactors and the planning phases for new, more powerful particle accelerators, requiring vast quantities of superconducting materials over the next decade.

AI Impact Analysis on Niobium-Titanium Alloys Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Niobium-Titanium Alloys market frequently center on how AI can optimize the highly complex manufacturing processes and accelerate materials discovery. Key concerns revolve around leveraging AI for predictive maintenance in cryogenic systems, optimizing alloy composition for enhanced superconducting properties, and automating quality control during the intricate wire drawing and heat treatment stages. Users are particularly keen on understanding AI's role in reducing production costs and lead times, as the bespoke nature and high precision required for superconducting wires make traditional manufacturing cycles slow and expensive. There is significant expectation that AI-driven simulation tools will revolutionize the design of composite conductors, moving beyond traditional trial-and-error methodologies.

AI's primary influence is expected in enhancing the efficiency and consistency of NbTi production, which directly impacts market supply and cost structure. Machine learning algorithms are being deployed to analyze vast datasets generated during the thermomechanical processing of NbTi wires, identifying subtle correlations between processing parameters (e.g., temperature profiles, strain rates) and final material performance (critical current density, flux pinning strength). This level of predictive analytics minimizes material wastage and maximizes yield of high-specification superconducting cable. Furthermore, AI contributes significantly to the operational efficiency of the end-use systems, such as optimizing scheduling and diagnostic performance in MRI machines, potentially broadening the commercial viability of these high-field technologies and subsequently boosting demand for NbTi components.

- AI-driven optimization of multi-stage heat treatment processes to improve flux pinning characteristics.

- Predictive modeling for material defect identification during extrusion and wire drawing, ensuring higher quality control.

- Enhanced simulation and rapid prototyping of novel NbTi composite designs using generative AI models.

- AI implementation in cryogenic system management for predictive maintenance and energy consumption optimization in high-field magnets.

- Accelerated analysis of experimental data in high-energy physics and fusion facilities, driving faster iteration cycles for NbTi magnet prototypes.

DRO & Impact Forces Of Niobium-Titanium Alloys Market

The market for Niobium-Titanium alloys is governed by a dynamic interplay of factors: strong drivers rooted in global scientific ambition and medical necessity, tempered by significant restraints concerning supply chain complexities and technological competition, balanced by crucial opportunities in next-generation energy and infrastructure projects. The primary driving force is the global commitment to advancing large-scale research projects, particularly fusion energy, which requires enormous, consistent supply of NbTi for magnetic confinement. Restraints largely center on the high capital expenditure required for production facilities and the volatility in Niobium raw material sourcing, demanding resilient supply chain strategies. Opportunities are vast, extending into superconducting power transmission and advanced industrial machinery, positioning the alloy at the forefront of the technological evolution toward highly efficient, high-density magnetic systems.

Drivers: The most prominent driver is the indispensable role of NbTi in Magnetic Resonance Imaging (MRI), a consistently expanding segment of the global healthcare industry, driven by aging populations and increasing diagnostic capabilities. Concurrently, large-scale, international science projects, notably the ITER fusion reactor and subsequent demonstration plants, are creating long-term, high-volume demand that anchors the market growth trajectory. Furthermore, NbTi’s established manufacturing base and comparatively lower cost relative to high-temperature or alternative low-temperature superconductors like Nb3Sn make it the preferred choice for applications that do not require ultra-high magnetic fields (e.g., fields below 10 Tesla). These factors provide a stable foundation for investment and continuous demand from major governmental and institutional buyers.

Restraints: The market faces considerable restraints concerning the complexity and cost of the manufacturing process, which involves high-temperature melting, intricate extrusion, and specialized cryogenic testing, leading to high barriers to entry for new competitors. Supply chain stability, specifically the sourcing and refinement of Niobium, a critical and sometimes geopolitically sensitive raw material, presents a persistent challenge. A secondary restraint is the technological encroachment by Niobium-Tin (Nb3Sn) alloys, which offer superior performance in fields above 10 Tesla; although more difficult to manufacture, Nb3Sn is increasingly being adopted in cutting-edge applications, potentially limiting the growth potential of NbTi in the highest-field magnet systems. Addressing these restraints requires significant R&D investment in materials processing and robust, diversified procurement strategies.

Opportunities and Impact Forces: Significant opportunities exist in the commercialization of technologies currently under research, particularly in Superconducting Magnetic Energy Storage (SMES) systems and superconducting fault current limiters (SFCLs), which promise revolutionary improvements in grid stability and energy efficiency. The long-term impact of fusion energy success would transform the NbTi market, moving it from a specialized research commodity to a foundational industrial material. Impact forces are also shaped by regulatory standards in the medical device sector (mandating material reliability) and by advancements in cryogenic cooling technology, which, by making lower temperatures more accessible and cheaper, enhances the operational envelope and commercial attractiveness of NbTi-based products across various industries, reinforcing its essential role in magnetic confinement and energy systems.

Segmentation Analysis

The Niobium-Titanium Alloys market is primarily segmented based on the Alloy Form, which dictates the application within magnet systems, and by End-Use Application, reflecting the major consuming industries globally. Analyzing these segments provides deep insights into the market structure, indicating that while bulk scientific research drives innovation, sustained commercial demand from the healthcare sector ensures financial stability. The highly technical nature of the material necessitates stringent quality controls and specialization within each segment, meaning manufacturers often focus expertise on specific alloy forms or target applications, such as fine multifilamentary wires for MRI versus larger, high-current cables for fusion energy research.

Further granularity in segmentation reveals distinct market dynamics. The Alloy Form segmentation, encompassing wires, cables, rods, and others, is crucial as the performance characteristics—such as critical current density and mechanical strength—are highly dependent on the final form factor. Superconducting cables, which combine multiple wires and copper stabilizers, represent the highest value segment due to the complexity of manufacturing and the critical role they play in carrying massive currents in large-scale accelerators and reactors. Conversely, the End-Use segmentation shows a clear dichotomy between stable, commercial markets (Healthcare) and highly funded, long-cycle development markets (Energy & Research), necessitating different sales strategies and supply chain commitments from key market players.

Understanding these segments is essential for strategic planning. For instance, expansion in the Healthcare segment requires compliance with stringent regulatory requirements (e.g., FDA, CE marking) and integration into existing medical device supply chains. In contrast, securing contracts in the Energy & Research sector often involves navigating international consortia (like ITER) or long-term government tenders, demanding substantial commitments to quality assurance and sustained production capacity. The continuous evolution of superconducting technology means that market participants must maintain flexible manufacturing capabilities to adapt to emerging specifications, ensuring that the NbTi alloys meet the increasingly demanding performance metrics of future high-field applications.

- By Alloy Form:

- Wire and Cable (Multifilamentary composites)

- Rod and Bar

- Sheet and Plate

- Others (Powders, Targets)

- By End-Use Application:

- Healthcare (MRI, NMR)

- Energy and Research (Fusion Reactors, Particle Accelerators, SMES)

- Industrial (Separators, Superconducting Magnets for Industry)

- Aerospace and Defense

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LAMEA)

- Middle East and Africa (MEA)

Value Chain Analysis For Niobium-Titanium Alloys Market

The value chain for Niobium-Titanium alloys is intrinsically complex, characterized by several highly specialized stages, beginning with the highly regulated upstream procurement of raw materials. Niobium is primarily sourced from specific geographic regions (notably Brazil and Canada), demanding robust logistics and supply security. Upstream processes involve the reduction and purification of Niobium and Titanium ores to produce high-purity ingots suitable for alloy manufacturing. Due to the requirement for exceptional material purity and consistency to ensure superconducting performance, only a limited number of specialized metallurgical firms operate at this initial stage, creating potential supply bottlenecks that significantly influence final product pricing and availability across the entire value chain.

The core manufacturing phase involves alloy melting, billet fabrication, and the extensive thermomechanical processing necessary to produce multifilamentary wire. This midstream stage is the most proprietary and capital-intensive, requiring specialized facilities for processes like hot extrusion, cold drawing, and precise heat treatment cycles designed to generate nanoscale NbTi filaments embedded in a copper matrix. Distribution channels are primarily direct or highly specialized indirect routes. Direct sales are common for large, governmental scientific contracts (e.g., ITER, CERN), where manufacturers interact closely with the end-user R&D teams for customized specifications. Indirect channels, often involving specialized distributors, cater primarily to the standardized MRI coil manufacturers and smaller industrial clients.

Downstream analysis focuses on the integration of the NbTi wire into final products. This stage involves the winding of the superconducting wire into complex magnet coils, insulation, integration into cryogenic systems, and final system testing. Key downstream actors include major medical device manufacturers (e.g., Siemens, GE Healthcare) and consortiums responsible for constructing large-scale research facilities. The high value-add at this stage is derived from precision engineering and system integration expertise. The critical reliance on direct communication between midstream manufacturers and downstream integrators underscores the highly technical nature of the market, where performance guarantees and reliability are paramount, establishing long-term, specialized supplier-customer relationships as the norm.

Niobium-Titanium Alloys Market Potential Customers

Potential customers for Niobium-Titanium alloys are concentrated within sectors requiring extremely high-field magnetic capabilities, primarily centered around large institutional and governmental buyers, as well as major commercial entities in advanced diagnostics. The core customer base comprises research institutions operating particle accelerators and experimental physicists conducting fusion energy research, whose need for reliable, large-volume superconducting wire drives significant procurement contracts. These buyers are highly sophisticated, prioritizing material performance metrics such as critical current density (Jc) and homogeneity across production batches, often requiring custom specifications that push the limits of current manufacturing capabilities.

The most stable and high-volume commercial customer segment is the global healthcare industry, specifically manufacturers of Magnetic Resonance Imaging (MRI) and Nuclear Magnetic Resonance (NMR) systems. These companies require consistent, reliable supplies of NbTi wire for building the superconducting magnets that are essential components of their products. Demand in this sector is driven by replacement cycles, expansion into emerging markets, and continuous technological advancements aimed at producing higher-field, more compact, and increasingly mobile diagnostic systems. The buyer profile here emphasizes cost-effectiveness, long-term supply agreements, and adherence to rigorous medical device quality standards and certifications.

Emerging potential customers include players in the industrial and transportation sectors. This encompasses companies developing Superconducting Magnetic Energy Storage (SMES) units for utility grids, firms innovating high-speed rail utilizing magnetic levitation (Maglev) technology, and specialized industrial firms utilizing high-gradient magnetic separators for purification processes. While currently smaller in volume than the research or healthcare segments, these industrial applications represent significant growth potential, contingent upon the successful commercialization and mass adoption of superconducting technologies outside traditional R&D settings. These customers are primarily focused on system longevity, low operational costs, and integration feasibility into existing infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 1,000 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hitachi Cable Ltd., Western Superconducting Technologies Co., Ltd. (WST), Luvata Oy, SuperPower Inc., Jastec Co., Ltd., Sumitomo Electric Industries, Furukawa Electric Co., Ltd., ATI Specialty Materials, Oxford Instruments, Alstom, General Electric (GE), Vacuumschmelze GmbH & Co. KG, AMSC (American Superconductor Corporation), Japan Superconductor Technology (JASTEC), Tokin Corporation, Ningxia Orient Tantalum Industry Co., Ltd. (NOTIC). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Niobium-Titanium Alloys Market Key Technology Landscape

The technological landscape of the Niobium-Titanium alloys market is dominated by advancements in materials processing aimed at maximizing critical current density (Jc) and enhancing mechanical robustness under extreme magnetic and thermal stresses. The core technology remains the "internal tin process" or related methodologies designed to create highly dense, uniform, and fine NbTi filaments within a stabilizing copper matrix. Current R&D efforts focus heavily on optimizing the final heat treatment stage—known as the "alpha precipitation" process—which is crucial for generating the flux pinning centers (precipitated alpha-Ti particles) that trap magnetic flux lines and allow the superconductor to carry high current loads without resistance. Innovations in this area, including multi-stage heat treatments and controlled deformation techniques, are vital for meeting the stringent performance requirements of next-generation fusion magnets and accelerator components, ensuring long-term technological competitiveness.

A crucial technological innovation impacting the market is the development of advanced cabling techniques for large-scale applications. Rutherford cables, widely used in accelerators and fusion devices, must be manufactured with extreme precision to ensure uniform current distribution and minimize energy losses due to mechanical motion or inter-strand coupling. The application of sophisticated non-destructive testing (NDT) methodologies, including eddy current testing and advanced microstructural analysis using electron microscopy, has become essential for maintaining the high-reliability standards required by institutional buyers. Furthermore, the integration of computational modeling, often incorporating Finite Element Analysis (FEA), allows researchers and manufacturers to predict the electromechanical performance of complex magnet structures, drastically reducing the physical prototyping costs and accelerating the pace of new conductor design.

The secondary, but equally vital, technology trend involves cryogenic engineering advancements. Since NbTi only operates effectively below its critical temperature (typically requiring liquid helium at 4.2 K), innovations in closed-cycle refrigeration systems and high-efficiency cryocoolers are enhancing the practicality and operational longevity of NbTi magnets. The transition towards high-power density cryocoolers that reduce dependence on large quantities of liquid helium is a major factor driving the commercial feasibility of smaller, more localized applications, such as specialized industrial magnets or compact MRI systems. This synergy between advanced materials science (NbTi) and sophisticated cooling technology is essential for expanding the market reach and reducing the operational complexities associated with using low-temperature superconducting technology in conventional settings, thereby strengthening the alloy's long-term market position.

Regional Highlights

The regional market landscape for Niobium-Titanium alloys is highly influenced by national priorities in science, healthcare infrastructure development, and governmental spending on energy research. Each region possesses unique demand drivers and regulatory environments that shape market strategies for key players.

North America maintains a highly developed market, characterized by mature healthcare spending and consistent investment in fundamental physics research. The United States, home to major universities, national laboratories, and leading MRI manufacturers, drives significant demand. The market here is defined by high quality expectations and regulatory compliance, focusing both on replacement and upgrade cycles for existing medical magnets and ongoing projects related to fusion energy (e.g., PPPL) and particle physics, ensuring stable, high-value demand.

Europe represents another key region, anchored by collaborative international projects like the European Organization for Nuclear Research (CERN) and the massive commitment to the ITER fusion project situated in France. This institutional demand creates a sustained need for high-specification NbTi cable. Furthermore, leading European companies in cryogenic equipment and medical devices contribute significantly to the commercial segment, maintaining a technological leadership position, particularly in specialized superconducting applications and the development of high-performance magnet systems.

Asia Pacific (APAC) is currently the fastest-growing market, driven primarily by government-led initiatives in China, Japan, and South Korea. China’s extensive infrastructure development in high-energy physics (e.g., proposed future colliders) and rapid expansion of its healthcare system necessitate substantial imports and domestic production of NbTi alloys. Japan and South Korea, with established excellence in superconductivity research and electronics manufacturing, contribute significantly through advanced industrial applications and participation in international research collaborations, positioning APAC as the critical growth engine for the next decade.

The Middle East and Africa (MEA) and Latin America (LAMEA) markets are currently nascent but show promise, primarily driven by investments in national medical infrastructure and nascent energy research programs. While volumes remain lower, increasing access to advanced diagnostic technologies (MRI machines) and strategic regional investments in science and technology hubs are creating localized demand pockets. Market growth in these regions is sensitive to government funding and access to necessary foreign exchange for technology procurement, yet they represent future diversification opportunities.

- Asia Pacific (APAC): Highest projected CAGR due to massive investments in fusion energy projects (e.g., China’s HT-7 and KSTAR) and rapid expansion of medical diagnostic capacity.

- North America: Market stability derived from strong R&D funding (DoE labs) and mature, high-value MRI manufacturing base.

- Europe: Central hub for major international science collaborations (CERN, ITER), securing long-term institutional demand for specialized conductors.

- Rest of the World (LAMEA/MEA): Emerging markets driven by healthcare modernization and initial foray into advanced energy research programs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Niobium-Titanium Alloys Market.- Hitachi Cable Ltd.

- Western Superconducting Technologies Co., Ltd. (WST)

- Luvata Oy

- SuperPower Inc.

- Jastec Co., Ltd. (Japan Superconductor Technology)

- Sumitomo Electric Industries

- Furukawa Electric Co., Ltd.

- ATI Specialty Materials

- Oxford Instruments

- General Electric (GE)

- Vacuumschmelze GmbH & Co. KG (VAC)

- AMSC (American Superconductor Corporation)

- Tokin Corporation

- Ningxia Orient Tantalum Industry Co., Ltd. (NOTIC)

- Iwatani Corporation

- Advanced Magnet Lab, Inc. (AML)

- E. I. du Pont de Nemours and Company

- Nippon Steel Corporation

- Sichuan EM Technology Co., Ltd.

- Treibacher Industrie AG

Frequently Asked Questions

Analyze common user questions about the Niobium-Titanium Alloys market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the demand for Niobium-Titanium alloys?

The primary applications driving demand are Magnetic Resonance Imaging (MRI) systems in the healthcare sector and large-scale scientific research projects, including high-energy particle accelerators and experimental magnetic confinement fusion reactors (like ITER). NbTi's high critical current density and fabrication ease make it the preferred low-temperature superconductor for magnets below 10 Tesla.

How does Niobium-Titanium compare to Niobium-Tin (Nb3Sn) in the superconductor market?

NbTi is highly ductile, easier to manufacture into complex wires, and significantly more cost-effective, making it dominant for applications requiring magnetic fields up to 10 Tesla. Nb3Sn, while more brittle and harder to process, offers superior performance in ultra-high magnetic fields (above 10 Tesla) and is increasingly used in cutting-edge research magnets, posing a technological competitive restraint to NbTi in the highest field niche.

Which geographical region is expected to show the fastest growth in the NbTi market?

Asia Pacific (APAC), particularly China, is projected to exhibit the fastest market growth. This acceleration is supported by massive government funding for developing domestic large-scale research infrastructure, including advanced particle physics facilities and ambitious fusion energy demonstration programs, alongside widespread investment in modernizing healthcare infrastructure.

What key metallurgical process is critical for Niobium-Titanium alloy performance?

The key process is the extensive thermomechanical processing, culminating in a precise, low-temperature heat treatment known as alpha precipitation. This heat treatment is critical because it creates nanoscale titanium precipitates (flux pinning centers) within the NbTi matrix, which are essential for trapping magnetic flux lines and maximizing the alloy's ability to sustain high current density without resistive loss.

How does the volatility of Niobium sourcing impact the market for these alloys?

Niobium is a strategically important element often sourced from geopolitically concentrated regions, leading to potential supply chain volatility. Fluctuations in Niobium price and availability directly influence the raw material cost for NbTi manufacturers. Consequently, market players must mitigate this risk through long-term sourcing contracts and robust inventory management to ensure stable supply for large, fixed-term scientific and medical contracts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager