Niobium-Titanium Alloys Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437497 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Niobium-Titanium Alloys Market Size

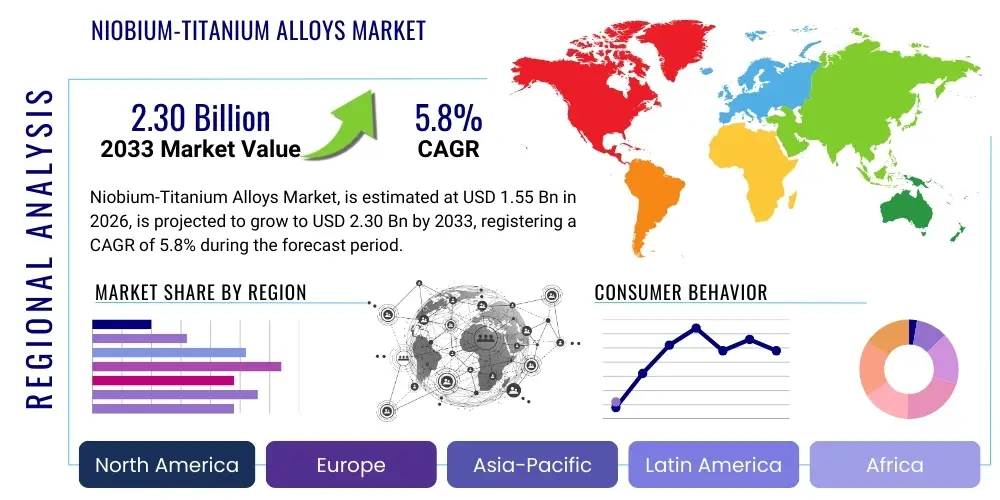

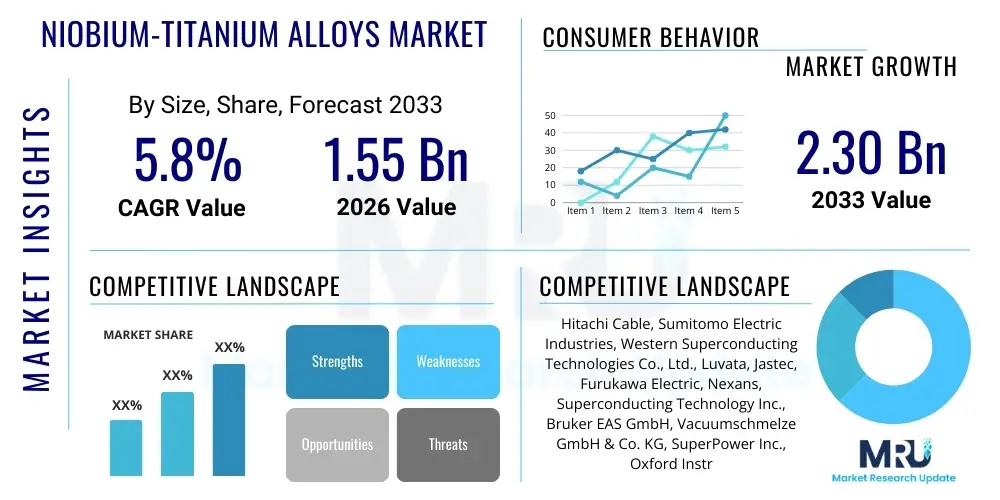

The Niobium-Titanium Alloys Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.55 Billion in 2026 and is projected to reach USD 2.30 Billion by the end of the forecast period in 2033.

Niobium-Titanium Alloys Market introduction

Niobium-Titanium (Nb-Ti) alloys constitute a critical class of materials primarily recognized for their exceptional Type II superconductivity properties, especially when cooled to cryogenic temperatures, typically below 10 Kelvin. The defining characteristic of Nb-Ti alloys is their high critical current density and relatively low cost compared to other high-field superconductors like Niobium-Tin (Nb3Sn), making them the material of choice for large-scale superconducting applications. These alloys are typically utilized in the form of multifilamentary wires embedded in a copper matrix, which provides mechanical support and thermal stabilization. The structure of these composites is engineered to maximize magnetic field generation efficiency and minimize energy losses during operation.

The principal application driving the demand for Nb-Ti alloys is Magnetic Resonance Imaging (MRI) systems in the healthcare sector, which rely heavily on stable, powerful superconducting magnets. Beyond medical diagnostics, these alloys are indispensable in advanced scientific research, particularly in high-energy physics where they form the core components of electromagnets used in particle accelerators, such as the Large Hadron Collider (LHC). Furthermore, Nb-Ti finds use in industrial applications requiring high magnetic fields, including magnetic separation technology and superconducting magnetic energy storage (SMES) systems, demonstrating its versatile utility across high-technology domains. The operational reliability and established manufacturing processes for Nb-Ti alloys solidify its foundational role in the global superconductor market.

The market growth is fundamentally propelled by escalating global investment in medical infrastructure, particularly in emerging economies expanding access to advanced diagnostic tools like MRI. Simultaneously, sustained government and private sector funding for fundamental physics research and large-scale accelerator projects contribute significantly to demand. The continuous development of superconducting transmission lines, though still nascent, presents a substantial future opportunity, leveraging the alloy's efficiency in power transmission. Key driving factors include superior superconducting performance at liquid helium temperatures, high durability under cyclical mechanical and thermal stresses, and mature supply chains ensuring competitive pricing and reliable production capacities for high-volume applications.

Niobium-Titanium Alloys Market Executive Summary

The Niobium-Titanium Alloys Market exhibits strong stability, underpinned by non-discretionary demand from the healthcare and scientific research sectors. Current business trends indicate a shift towards optimizing alloy performance through advanced wire manufacturing techniques, such as powder-in-tube processing and specialized extrusion methods, aiming for higher critical current densities and reduced AC losses, which are vital for specialized pulsed magnet systems. There is also a notable consolidation among major producers focusing on vertical integration to control the supply chain from raw niobium ore processing to final wire composite fabrication. This focus on efficiency and quality control is necessary to meet the stringent specifications required by major research facilities and medical device manufacturers, maintaining high barriers to entry for new competitors.

Regionally, Asia Pacific (APAC) is projected to experience the fastest growth, primarily fueled by massive infrastructure investment in China and India, focusing on expanding MRI adoption and establishing new national research facilities, particularly fusion energy projects. North America and Europe, while representing mature markets, maintain dominance in terms of value contribution due to the presence of key original equipment manufacturers (OEMs) for MRI machines and established large-scale particle physics laboratories. The regional competitive dynamics are characterized by intense R&D efforts in established Western markets focusing on optimizing wire uniformity and reducing production costs, while APAC focuses on scaling up production capacity to meet rapidly increasing domestic and regional demand across various industrial applications.

Segment-wise, the MRI segment maintains the largest market share owing to its stable, recurring demand pattern and the necessity of Nb-Ti in virtually all commercial superconducting MRI magnets. However, the fusion and high-energy physics segment, encompassing large-scale accelerators and experimental reactors (like ITER), is poised for the most significant percentage growth, driven by substantial, multi-decade international projects requiring enormous volumes of highly specialized superconducting wire. Furthermore, within the alloy type segmentation, the standard Nb-47wt%Ti composition remains dominant, but specialized compositions optimized for higher magnetic fields or specific temperature profiles are seeing increased uptake in niche, high-performance applications, indicating a trend toward market diversification based on end-use requirements.

AI Impact Analysis on Niobium-Titanium Alloys Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Niobium-Titanium Alloys Market often center on how AI can optimize material design, streamline complex manufacturing processes, and accelerate the discovery of novel superconducting composites. Common questions include: Can AI predict the optimal heat treatment required for maximum critical current density in Nb-Ti wires? How can machine learning algorithms improve quality control during the drawing and extrusion phases? And will AI-driven design tools lead to the eventual replacement of Nb-Ti with superior, computationally discovered superconductors? Users are focused on leveraging AI for predictive maintenance in MRI and accelerator facilities, thereby extending magnet lifespan and maximizing operational uptime, which directly influences replacement cycles and overall demand stability for Nb-Ti components.

AI’s influence is primarily felt in the material science R&D pipeline and advanced manufacturing control systems. Machine learning models are increasingly deployed to analyze vast datasets relating to alloy composition variations, heat treatment protocols, and resulting superconducting properties. This predictive modeling allows manufacturers to significantly shorten the R&D cycle for customized wires and optimize existing production lines for greater consistency and efficiency. By simulating the internal stress and phase transformation kinetics during wire processing, AI minimizes costly physical experimentation, leading to faster throughput and potentially reduced material wastage, thereby lowering production costs for high-specification Nb-Ti composites.

Furthermore, AI algorithms are crucial in enhancing the operational performance of systems utilizing Nb-Ti magnets. In large particle accelerators and fusion reactors, AI is used for real-time monitoring of magnetic field stability, cryocooler efficiency, and anomaly detection, preventing catastrophic quench events. This increased reliability in end-user systems encourages further investment in large-scale projects, indirectly driving sustained demand for Nb-Ti. While AI is unlikely to replace Nb-Ti instantly, it accelerates the refinement of its manufacturing and operational management, making existing applications more efficient and paving the way for the exploration of next-generation applications requiring highly controlled and uniform superconducting performance.

- AI-driven optimization of heat treatment protocols for enhanced critical current density (Jc).

- Machine learning integration for real-time defect detection and quality control during wire drawing processes.

- Predictive maintenance analytics for superconducting magnets in MRI and high-energy physics facilities.

- Accelerated discovery and screening of novel high-performance superconducting alloy alternatives.

- Optimization of complex cryogenic cooling systems through smart control algorithms.

DRO & Impact Forces Of Niobium-Titanium Alloys Market

The market for Niobium-Titanium alloys is strongly influenced by a robust set of drivers and restraints, framed by significant long-term opportunities and powerful external forces. Primary drivers include the foundational role of Nb-Ti in standard medical MRI technology, which ensures continuous baseline demand, coupled with massive, multi-decade capital projects in high-energy physics and fusion energy (e.g., ITER, China Fusion Engineering Test Reactor). However, the market faces significant restraints, chiefly the extreme reliance on cryogenic cooling (liquid helium), which incurs high operational costs and presents logistical challenges, alongside increasing competition from high-temperature superconducting (HTS) materials in select power transmission and industrial applications. Opportunities primarily arise from the increasing adoption of lightweight and mobile MRI systems and the potential commercialization of superconducting power grids and magnetic levitation transport systems, which require reliable, scalable superconducting wires.

The impact forces shaping this market are dominated by regulatory environment and technological substitution. Regulatory forces, particularly those governing medical device approvals (FDA, CE Mark), mandate strict material quality and consistency, indirectly favoring established suppliers of high-purity Nb-Ti wires. Simultaneously, technological substitution represents the most potent external threat; while HTS materials (like YBCO and BSCCO) currently operate at lower current densities than Nb-Ti at low temperatures, their ability to function at less extreme cryogenic levels (liquid nitrogen or higher) threatens to displace Nb-Ti in future power applications. Conversely, the continuous miniaturization trend in electronics and medical technology mandates higher power density in magnets, pushing demand for further refinement of Nb-Ti composites to achieve superior performance characteristics within smaller volumes.

Overall market trajectory is dictated by the balance between established infrastructure demand and innovation pressure. The long lifecycle and high investment costs associated with MRI machines and particle accelerators lock in demand for Nb-Ti for decades, ensuring stability. However, investment into fusion energy and advanced power applications often involves calculated risks favoring cutting-edge materials. Therefore, manufacturers must continuously invest in process engineering to maintain cost-effectiveness and performance superiority over substitute materials in the 4 Kelvin operating range, especially focusing on reducing the cost and complexity associated with liquid helium infrastructure to mitigate the most significant operational restraint facing the entire cryogenic superconductor industry.

Segmentation Analysis

The Niobium-Titanium Alloys Market is comprehensively segmented based on its structural form, primary end-use application, and specific alloy composition. The segmentation by structural form, predominantly superconducting wires, dictates the material preparation and manufacturing complexity, influencing cost and performance metrics. Application segmentation provides a clear view of demand drivers, with Medical imaging (MRI) consistently dominating due to widespread hospital adoption and replacement cycles. Meanwhile, the alloy type segmentation, while seemingly narrow, differentiates between standard high-volume alloys and specialized compositions engineered for extreme environments or high magnetic field requirements in niche scientific instrumentation. Understanding these distinct segments is crucial for manufacturers to tailor production capabilities and for investors to gauge market risk and potential growth areas, especially considering the differing regulatory and technical requirements across end-user industries.

- By Form:

- Wires and Filaments

- Rods and Billets

- Sheets and Plates

- By Application:

- Medical Imaging (MRI/NMR)

- High-Energy Physics (Particle Accelerators)

- Fusion Energy Research (Tokamaks/Stellarators)

- Superconducting Magnetic Energy Storage (SMES)

- Magnetic Separation

- Others (e.g., Superconducting Generators, Maglev Trains)

- By Alloy Type:

- Nb-47wt%Ti (Standard Composition)

- Nb-50wt%Ti

- Other Niobium-Titanium Compositions

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Niobium-Titanium Alloys Market

The value chain for Niobium-Titanium alloys is complex and highly specialized, beginning with the extraction and refining of raw materials, Niobium and Titanium, which are sourced globally, primarily from Brazil, Canada, and Australia. The upstream stage involves highly capital-intensive processes to produce high-purity ferro-niobium and titanium sponge, which are then alloyed through vacuum arc melting or electron beam melting into large-scale ingots or billets. Purity levels at this stage are paramount, as trace impurities significantly degrade superconducting properties. Manufacturers focusing on cost efficiency often seek long-term supply agreements with key mining and refining companies to mitigate volatility in raw material prices and ensure consistent input quality for subsequent processing.

The core manufacturing stage, or midstream, involves transforming these ingots into superconducting wires, a process that includes numerous cycles of extrusion, cold drawing, and intermediate heat treatments to create the necessary microstructure for optimal superconductivity. This stage requires specialized machinery and proprietary expertise to produce multifilamentary composite wires (typically Nb-Ti embedded in a copper or sometimes aluminum matrix). Distribution channels are predominantly direct, particularly for large-volume, high-specification orders destined for major scientific research centers (CERN, Fermilab) or large medical OEMs (Siemens Healthineers, GE Healthcare). Direct distribution ensures technical specifications are accurately met and allows for robust after-sales support and technical consultation essential for complex magnet assembly.

The downstream segment involves the incorporation of these wires into finished products, such as magnet coils for MRI systems, detector magnets for particle accelerators, or conductors for large-scale energy projects. End-users are highly concentrated, meaning a small number of global medical OEMs and national scientific laboratories account for the bulk of demand. Indirect distribution may occur through specialized magnet fabricators or system integrators who purchase the wire and then supply the finished magnet to the final end-user. The success in the downstream market hinges on reliability and certification, often requiring years of rigorous testing and regulatory compliance, reinforcing the market position of established suppliers who can guarantee product longevity and performance stability.

Niobium-Titanium Alloys Market Potential Customers

The primary end-users and potential customers for Niobium-Titanium alloys are heavily concentrated in sectors requiring intense, stable magnetic fields for advanced diagnostic, research, or power management purposes. Healthcare institutions, including hospitals, diagnostic imaging centers, and specialized clinics, represent the largest and most stable customer base globally, driven by the indispensable role of Nb-Ti in virtually all superconducting MRI systems. These buyers prioritize long-term reliability, low maintenance requirements, and stringent quality control, often relying on global medical device manufacturers as their direct suppliers, who in turn place high-volume, recurring orders for Nb-Ti wire.

A second major customer category is large governmental and multinational research organizations and universities dedicated to fundamental physics and energy research. This includes laboratories running high-energy particle accelerators (like the U.S. Department of Energy labs, European labs, and Asian research institutes) and international consortia focused on fusion energy, notably ITER. These customers demand highly specialized, customized Nb-Ti wires capable of operating under extreme mechanical and thermal stresses and require bulk quantities over long development timelines, making them critical, albeit cyclical, buyers whose demand is tied directly to public funding cycles and large project milestones. Their purchasing decisions are driven by performance specifications, tolerance limits, and successful adherence to rigorous international standards.

Emerging potential customer segments include developers of superconducting power transmission infrastructure and advanced transportation systems. Utility companies, while currently a small segment, represent a massive future opportunity if High-Temperature Superconducting (HTS) substitutes fail to achieve the required current density or if Nb-Ti manufacturing costs drop significantly. Furthermore, advanced defense and aerospace sectors are potential customers for specialized applications such as high-power microwave devices and lightweight superconducting motors, where the high power-to-weight ratio of Nb-Ti magnets offers a distinct advantage over conventional technologies, pushing demand for sophisticated, lightweight alloy composites and highly controlled manufacturing runs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.55 Billion |

| Market Forecast in 2033 | USD 2.30 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hitachi Cable, Sumitomo Electric Industries, Western Superconducting Technologies Co., Ltd., Luvata, Jastec, Furukawa Electric, Nexans, Superconducting Technology Inc., Bruker EAS GmbH, Vacuumschmelze GmbH & Co. KG, SuperPower Inc., Oxford Instruments, ATI, K-TIG Limited, Superconductor Technologies Inc., Alstrom, Supercon, Inc., General Cable, Japan Superconductor Technology, Inc., NIMS. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Niobium-Titanium Alloys Market Key Technology Landscape

The technological landscape of the Niobium-Titanium Alloys Market is defined by continuous advancements in wire fabrication techniques aimed at maximizing flux pinning, which is essential for high critical current density (Jc). The primary technology involves the production of multifilamentary composite wires using the 'Jelly Roll' or 'Rod-in-Tube' methods, followed by extensive cold working and precise, multi-stage heat treatments. Current technological innovation is focused on enhancing the homogeneity of the alpha-Ti precipitates within the Niobium matrix, as these precipitates act as effective flux pinning centers. Technologies like hydrostatic extrusion and specialized drawing dies are employed to achieve high filament packing fractions and extreme reduction ratios, pushing the boundaries of mechanical and superconducting performance for use in high-field magnets.

A crucial aspect of the technology landscape is the material processing infrastructure, particularly large-scale vacuum melting furnaces necessary for producing high-purity Nb-Ti billets, which must meet stringent chemical and physical specifications. Furthermore, advanced non-destructive testing and quality assurance technologies are paramount. Eddy current testing, critical current testing (Ic), and microstructural analysis using scanning electron microscopy (SEM) are standard practices. The drive toward higher performance, particularly for next-generation particle accelerators requiring fields above 9 Tesla, necessitates continuous refinement in both the composition and the processing parameters to ensure wire stability and prevent magnet quenching under maximum operational stress.

In addition to fabrication improvements, integration technology plays a significant role. This involves the use of specialized insulation materials and cabling technologies, such as Rutherford cables, which bundle hundreds of individual multifilamentary strands into high-current conductors for use in large accelerator magnets. Furthermore, the technology for managing the interface between the superconducting wire and the copper stabilizer—ensuring low electrical resistance and efficient heat transfer—is vital for the stable operation of superconducting systems. Ongoing research is also exploring alternative matrices and barrier layers to further enhance the mechanical properties and reduce AC losses in applications requiring rapid magnetic field cycling, like certain specialized fusion experiments.

Regional Highlights

Geographically, the Niobium-Titanium Alloys Market demonstrates distinct consumption patterns across key regions, highly correlated with investment in advanced medical infrastructure and government funding for fundamental science projects. North America, driven primarily by the United States, holds a significant market share due to its established healthcare system and the presence of world-leading particle physics laboratories and magnet manufacturers. The region maintains high, stable demand for Nb-Ti wires for new MRI installations and routine maintenance, alongside specialized, high-specification orders for ongoing large-scale scientific programs.

Europe represents another mature and high-value market, anchored by significant scientific investment in countries like Switzerland (CERN), Germany, and France. The demand here is dual-focused: a steady requirement for medical applications and large, periodic spikes in demand related to upgrades and expansions of major European research facilities. European manufacturers often lead in specialized wire composite technology and high-pprecision manufacturing, catering to the most demanding scientific applications.

Asia Pacific (APAC) is emerging as the fastest-growing regional market, propelled by rapid urbanization, expanding healthcare access, and unprecedented investments by governments in China, South Korea, and Japan into fusion energy research (e.g., China's CFETR project) and advanced medical technology manufacturing. The demand in APAC is characterized by high-volume, cost-competitive manufacturing focused on supplying the domestic medical device market, while specialized, high-purity Nb-Ti is imported or produced by joint ventures to meet the exacting standards of large physics projects.

- North America: Stable demand driven by advanced MRI technology adoption and long-term funding for high-energy physics research (e.g., Fermilab). Key manufacturing and R&D hub.

- Europe: High-value market focused on precision manufacturing and scientific research centers (CERN, fusion projects). Strong regulatory framework governing medical device materials.

- Asia Pacific (APAC): Highest growth rate fueled by expanding healthcare infrastructure in China and India, coupled with massive government investment in fusion and accelerator technology. Dominant consumer for medical imaging applications.

- Latin America (LATAM) & Middle East and Africa (MEA): Nascent markets primarily dependent on imported medical systems. Growth trajectory is closely tied to external investment in healthcare and infrastructure modernization projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Niobium-Titanium Alloys Market.- Hitachi Cable, Ltd.

- Sumitomo Electric Industries, Ltd.

- Western Superconducting Technologies Co., Ltd. (WST)

- Luvata (part of Mitsubishi Materials Corporation)

- Furukawa Electric Co., Ltd.

- Nexans S.A.

- Superconducting Technology Inc.

- Bruker EAS GmbH (Bruker Energy & Analytics Systems)

- Vacuumschmelze GmbH & Co. KG (VAC)

- SuperPower Inc.

- Oxford Instruments plc

- Supercon, Inc.

- Japan Superconductor Technology, Inc. (JASTEC)

- ATI (Allegheny Technologies Incorporated)

- K-TIG Limited

- Linde plc (through supply of cryogenic gases)

- General Cable (part of Prysmian Group)

- NioCorp Developments Ltd. (raw material focus)

- Tokin Corporation

- Vesuvius plc

Frequently Asked Questions

Analyze common user questions about the Niobium-Titanium Alloys market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the long-term demand for Niobium-Titanium alloys?

The primary driver is the pervasive adoption and essential nature of superconducting Niobium-Titanium (Nb-Ti) in Magnetic Resonance Imaging (MRI) systems globally. The stable replacement cycle of MRI equipment and the expansion of healthcare services ensure continuous, non-cyclical demand for Nb-Ti wires, providing market stability.

How do Niobium-Titanium alloys compare technologically to High-Temperature Superconductors (HTS)?

Nb-Ti alloys offer higher critical current density (Jc) and are more cost-effective and easier to manufacture for large-scale magnets requiring magnetic fields up to approximately 9 Tesla. HTS materials, conversely, operate at warmer temperatures (liquid nitrogen), reducing cooling costs, but often have higher initial material costs and are currently less mature for extremely high-field, bulk applications than established Nb-Ti.

Which region holds the highest growth potential for Niobium-Titanium alloy consumption?

Asia Pacific (APAC), particularly China and India, holds the highest growth potential. This growth is fueled by massive state-backed investments in fusion energy projects, major particle accelerator construction, and rapid expansion of advanced medical infrastructure, increasing the installation base for MRI systems.

What are the main restraints impacting the growth of the Nb-Ti market?

The principal restraint is the absolute requirement for extreme cryogenic cooling, specifically liquid helium (4 Kelvin), which is expensive, logistically complex, and subject to periodic supply shortages. This high operational cost associated with cooling limits the application scope outside of established medical and scientific centers.

What role does the Nb-47wt%Ti composition play in the market?

The Nb-47wt%Ti composition is the standard, most widely manufactured, and most commercially dominant alloy type. It is optimized for use in the temperature range of 4.2 K and provides the best balance of superconducting performance, manufacturability, and cost-effectiveness for mass-produced items like medical MRI magnets and standard scientific dipoles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager