Precast Concrete Release Agents Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443259 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Precast Concrete Release Agents Market Size

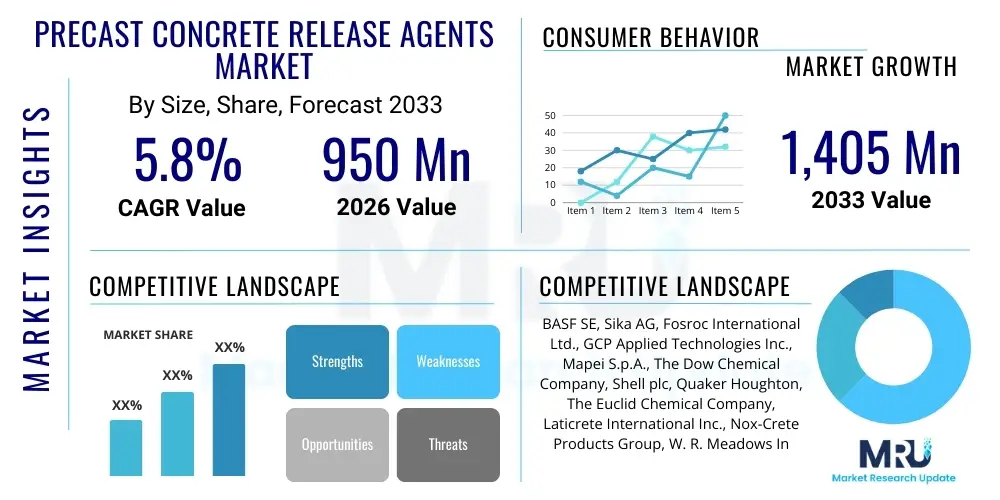

The Precast Concrete Release Agents Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $550 Million USD in 2026 and is projected to reach $810 Million USD by the end of the forecast period in 2033.

Precast Concrete Release Agents Market introduction

Precast concrete release agents, often referred to as mold release oils or demolding agents, are specialized chemical formulations applied to the surface of molds or forms before concrete pouring. Their primary function is to create a physical or chemical barrier between the concrete and the mold material, preventing adhesion and ensuring the easy, clean release of the cured precast element without causing surface defects or damaging the formwork. The resultant concrete products exhibit superior surface finishes, which is crucial for aesthetic and structural integrity in modern construction projects.

The product composition varies widely, encompassing mineral oil-based, vegetable oil-based (biodegradable), and synthetic solvent-based formulations, each tailored to specific concrete mix designs, curing methods (e.g., steam curing), and mold materials (steel, wood, plastic, rubber). Major applications span across the entire precast concrete industry, including the production of structural components like beams, columns, and wall panels; architectural elements requiring pristine surface quality; and infrastructure products such as pipes, manholes, and railway sleepers. The growing global focus on rapid urbanization and infrastructure renewal directly propels the demand for efficient demolding solutions that maximize mold reuse and operational efficiency.

The principal benefits derived from the use of high-quality release agents include prolonged mold life, reduced cleaning and maintenance costs, minimization of bug holes and surface imperfections (reducing rework), and ultimately, faster turnaround times for precast production cycles. Driving factors for market expansion are centered around the increasing adoption of precast techniques in emerging economies due to their speed and quality control advantages, coupled with stringent environmental regulations pushing manufacturers toward sustainable, biodegradable agent formulations. Furthermore, innovations in chemical engineering are leading to highly concentrated and efficient products that cater to high-performance concrete specifications.

Precast Concrete Release Agents Market Executive Summary

The global Precast Concrete Release Agents Market is characterized by steady expansion, underpinned by robust growth in residential, commercial, and infrastructure construction sectors globally, particularly in the Asia Pacific region. Key business trends indicate a definitive shift towards environmentally sustainable products, driven by stricter regulatory frameworks concerning volatile organic compounds (VOCs) and occupational safety. Manufacturers are increasingly investing in bio-based and water-soluble formulations, which offer reduced environmental impact without compromising demolding performance. Furthermore, strategic partnerships and mergers among key players are common, aimed at consolidating market share and expanding specialized product portfolios tailored for high-demand applications like self-compacting concrete (SCC) and ultra-high-performance concrete (UHPC).

Regionally, the Asia Pacific (APAC) market maintains the highest growth trajectory, fueled by large-scale infrastructure projects in China, India, and Southeast Asian nations, where precast technology is rapidly displacing conventional cast-in-place methods. North America and Europe, while being mature markets, are witnessing demand stabilization coupled with a significant premium placed on performance and environmental compliance, driving the uptake of highly specialized and premium-priced release agents. The Middle East and Africa (MEA) region presents burgeoning opportunities linked to ambitious urban development and housing projects, demanding reliable supply chains for quality precast chemicals.

In terms of segment trends, the Water-Based agents segment is forecasted to exhibit the fastest CAGR, primarily due to global environmental mandates and improved performance capabilities matching traditional oil-based counterparts. Structurally, the application segment of Pipes & Manholes and large-scale Structural Precast components remains the dominant revenue generator, reflecting sustained investments in municipal water, sanitation, and transportation infrastructure. Technology innovation focuses heavily on optimizing agent coverage and efficiency, utilizing advanced emulsification techniques and specialized additive packages to handle complex mold geometries and aggressive concrete mix constituents effectively.

AI Impact Analysis on Precast Concrete Release Agents Market

User queries regarding AI's impact on the Precast Concrete Release Agents Market primarily focus on optimizing application efficiency, predicting maintenance cycles for molds, and improving quality control in precast facilities. Users are keen to understand if AI can minimize waste, specifically the over-application or under-application of release agents, which directly affects both cost and product quality. Key concerns revolve around the integration cost of sensor technology and AI platforms within existing, often rugged, precast environments, and the ability of AI to consistently manage varying environmental factors like temperature and humidity that influence agent performance and curing. Expectations include AI-driven process automation that moves beyond simple quality inspection to proactive process adjustment.

AI technology is beginning to influence the manufacturing and application stages of release agents, although its direct impact on the chemical formulation itself remains limited. In production facilities, AI algorithms analyze application data gathered through automated spraying systems, adjusting flow rates and nozzle positions in real-time based on mold shape and size to ensure optimal film thickness and consistent coverage, thus minimizing material consumption. This predictive application modeling drastically reduces waste and ensures uniform demolding quality across massive production runs, which is critical for large infrastructure components.

Furthermore, AI-powered predictive maintenance models are leveraging data from mold wear and frequency of use, coupled with the chemical interaction characteristics of the release agent, to forecast when mold cleaning or replacement is required. This systemization transforms mold management from reactive to predictive, extending the lifespan of costly formwork and reducing unexpected downtime. Although the penetration rate of AI in the entire precast supply chain is currently moderate, its application in smart manufacturing, specifically for process optimization involving chemicals, is positioned as a significant future differentiator for market leaders focused on operational excellence.

- Optimization of Release Agent Application: AI-driven sensors and vision systems optimize spraying patterns and film thickness, ensuring minimal waste and superior surface finish.

- Predictive Mold Maintenance: Algorithms analyze usage data and surface conditions to schedule cleaning and agent reapplication precisely, extending mold lifespan and reducing operational interruption.

- Supply Chain and Inventory Management: AI predicts demand fluctuations for specific agent types based on regional construction forecasts and project pipelines, improving logistics efficiency.

- Quality Assurance Automation: Automated inspection of demolded pieces identifies defects (e.g., pitting or sticking) and correlates them back to specific application parameters for continuous process improvement.

DRO & Impact Forces Of Precast Concrete Release Agents Market

The market dynamics for precast concrete release agents are defined by the robust growth in global infrastructure and construction sectors (Drivers), balanced against stringent environmental compliance costs and formulation challenges (Restraints). Opportunities lie primarily in the development of high-performance, sustainable, and specialized agents for advanced concrete types, while the key impact forces relate to regulatory shifts demanding greener chemistry and technological advancements in automated precasting techniques. This interplay necessitates continuous innovation in product development to maintain efficacy while meeting ecological standards.

The primary drivers include the global trend toward off-site construction, which inherently relies on precast methods for speed, cost efficiency, and quality control. Rapid urbanization, especially in emerging economies, necessitates massive investments in high-density housing and supporting infrastructure, thus sustaining high demand for precast elements. Simultaneously, increasing awareness among precast manufacturers regarding the direct correlation between release agent quality and labor costs (due to reduced cleaning and rework) further accelerates the adoption of premium products. However, the market faces significant restraints, chiefly concerning the volatility in raw material prices, particularly for base oils and specific additives, which affects manufacturing costs and pricing stability. Additionally, the fragmented nature of the end-user market, comprising many small and medium-sized precast manufacturers, makes standardization and large-scale marketing challenging.

Opportunities are abundant in developing advanced biodegradable and non-staining agents optimized for architectural precast elements where surface aesthetics are paramount. Furthermore, specialized release agents for new-generation materials like Ultra-High Performance Concrete (UHPC) and Self-Compacting Concrete (SCC) represent niche, high-value segments ripe for technological penetration. The key impact forces shaping the market include strict regulatory pressure from entities like the EPA and REACH regarding VOC content and biodegradability, which forces R&D focus toward eco-friendly alternatives. The shift towards highly automated precasting plants requires agents compatible with sophisticated spraying robots and rapid curing cycles, acting as a technological force demanding superior performance consistency.

Segmentation Analysis

The Precast Concrete Release Agents Market is comprehensively segmented based on its chemical composition (Type), the specific industrial application or product being manufactured (Application), and the environmental impact profile (Formulation). This multidimensional segmentation allows for targeted product development and marketing strategies, addressing the specific performance requirements dictated by differing mold materials, concrete formulations, and curing methodologies used by global precast manufacturers. Understanding these segments is crucial as market dynamics vary significantly between the high-volume use of oil-based agents in structural applications versus the premium, performance-driven demand for water-based agents in architectural projects.

- By Type:

- Oil-Based Release Agents

- Water-Based Release Agents

- Solvent-Based Release Agents

- By Application:

- Pipes & Manholes

- Architectural Precast

- Structural Precast (Beams, Columns, Panels)

- Others (Railway Sleepers, Barriers, Paving Slabs)

- By Formulation:

- Biodegradable Agents

- Non-Biodegradable Agents

Value Chain Analysis For Precast Concrete Release Agents Market

The value chain for precast concrete release agents begins with the upstream sourcing and refining of raw materials, predominantly base oils (mineral, vegetable) and specialty chemical additives (surfactants, corrosion inhibitors, emulsifiers). Raw material quality and availability significantly influence production costs and the final performance characteristics of the agent. Manufacturers often engage in vertical integration or secure long-term contracts for high-purity components to ensure stable supply and quality control. The efficiency of the manufacturing process, involving formulation, blending, and quality testing, is key to delivering consistent products tailored for various precasting environments.

The middle segment involves the formulation and manufacturing of the release agents, where chemical expertise transforms basic ingredients into high-performance products. Innovation in this stage focuses on enhancing demolding capabilities, improving environmental safety, and ensuring compatibility with high-tech concrete mixes and automated application systems. Key manufacturing activities include optimizing the concentration and stability of emulsions, especially for water-based agents, and rigorous testing to ensure compliance with industry standards regarding residual staining and VOC limits.

The downstream flow is characterized by sophisticated distribution channels, linking manufacturers to the end-users—the precast concrete producers. Distribution often utilizes a combination of direct sales for major, international precast corporations (offering customized technical support) and indirect distribution through specialized chemical distributors and construction supply houses for smaller, regional customers. Technical support and local inventory availability are critical factors in the downstream logistics, ensuring rapid response to technical queries and just-in-time delivery required by fast-paced precasting operations.

Precast Concrete Release Agents Market Potential Customers

The primary consumers and end-users of precast concrete release agents are the various types of precast concrete manufacturers, ranging from large multinational firms specializing in modular construction to localized entities focused on utility and municipal products. These customers are categorized by their production volume, specialization, and technological maturity, driving varied demands for product type, pricing, and support. Customers specializing in architectural elements prioritize non-staining, high-definition agents, while those in structural or infrastructure sectors focus more on volume efficiency, cost-effectiveness, and compatibility with heavy-duty steel formwork.

Major end-user segments include infrastructure contractors and government agencies involved in large public works projects, which indirectly drive the demand through their specifications for precast components like bridges, tunnels, and railway infrastructure. Furthermore, commercial and residential developers who adopt modular and pre-engineered construction methods constitute a significant customer base. The decision to purchase is generally centralized within the procurement or technical services departments of precast plants, often involving testing and approval by site engineers to ensure the agent performs effectively under specific production conditions (e.g., curing temperature, mold material).

Emerging potential customers are those adopting specialized concrete technologies, such as fiber-reinforced concrete or 3D-printed concrete components, which require uniquely tailored release solutions to manage the complexity of demolding these innovative materials. These customers require highly technical, specialized solvent or water-based agents engineered for minimal residue and maximum surface preservation. The shift towards automated and enclosed production environments also increases the value proposition of low-VOC and user-friendly formulations, appealing to customers prioritizing worker health and safety alongside productivity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million USD |

| Market Forecast in 2033 | $810 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Sika AG, Fosroc International Ltd., GCP Applied Technologies, Mapei S.p.A, Cemex S.A.B. de C.V., The Sherwin-Williams Company, Doka GmbH, Euclid Chemical, Kurita Water Industries Ltd., Henkel AG & Co. KGaA, CHRYSO SAS, Evonik Industries AG, MBCC Group (Master Builders Solutions), US Spec, Franklin International, W. R. Meadows, Inc., Sonneborn Building Products, Laticrete International, Inc., Ardex GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Precast Concrete Release Agents Market Key Technology Landscape

The technological evolution within the Precast Concrete Release Agents Market is primarily centered on sustainable chemistry, focusing on reducing environmental impact while simultaneously enhancing demolding efficiency under highly demanding production conditions. A significant technological advancement is the shift towards advanced emulsion technology, particularly for water-based systems. These modern emulsions utilize sophisticated surfactant packages and micro-encapsulation techniques to ensure uniform dispersion and stability of active ingredients, allowing for extremely thin, yet highly effective, barrier layers. This results in agents that offer performance comparable to traditional oil-based systems but with reduced VOC emissions and improved user safety, directly addressing regulatory pressures.

Another crucial technological area involves the development of chemically reactive release agents. Unlike barrier-type agents that rely purely on physical separation, reactive agents contain fatty acid derivatives that react chemically with the alkaline components of fresh concrete. This reaction forms a thin, soap-like film at the interface, facilitating superior and residue-free release, which is essential for high-quality architectural concrete. Research is currently focused on optimizing the speed and consistency of this chemical reaction, ensuring its effectiveness across a wider range of curing temperatures and mix designs, including those with high cement replacement materials like fly ash or slag.

Furthermore, technology is focused not just on the chemical composition but also on the application methodologies. The increased adoption of automated spray and dosing equipment in precast plants necessitates release agents with precise viscosity and spray characteristics. Manufacturers are engineering agents specifically compatible with robotic application systems, ensuring non-clogging performance and consistent atomization. This technological synergy between the chemical product and the application machinery is vital for achieving the high throughput and uniform quality demanded by modern, high-volume precasting operations, especially those producing repetitive components like railway sleepers or infrastructure segments.

Regional Highlights

- Asia Pacific (APAC): Dominant Growth Hub

- APAC is projected to remain the fastest-growing and largest market for precast concrete release agents throughout the forecast period. The explosive growth is attributed to massive governmental investments in infrastructure development, including high-speed rail networks, urban mass transit systems, and vast housing projects, particularly in India, China, and ASEAN countries. The increasing acceptance of precast technology as a faster, more reliable alternative to traditional construction methods is fueling demand. Furthermore, the establishment of sophisticated, factory-based precast operations in countries like South Korea and Singapore drives demand for advanced, high-performance agents compatible with automated production lines.

- North America: Focus on Sustainability and Specialty Applications

- The North American market is characterized by high technological maturity and strict environmental regulations, particularly regarding VOC emissions (driven by states like California). This region leads the global demand for bio-based and highly specialized water-based agents. Demand is consistent, driven by the replacement of aging infrastructure and complex commercial projects requiring high-quality architectural precast components. Manufacturers here compete heavily on technical support, product specialization (e.g., agents for winter use or for specific rubber molds), and adherence to sustainable chemistry standards.

- Europe: Regulatory Compliance and Innovation

- Europe represents a highly mature market where innovation is strongly dictated by the REACH regulation and mandatory environmental certifications. European precast manufacturers prioritize low-odor, low-VOC, and biodegradable formulations. The market is stable, supported by refurbishment projects and steady investment in sustainable building technologies. Western European nations, such as Germany and the UK, are key adopters of premium, specialized release agents designed for energy-efficient building envelopes and bespoke architectural precasting.

- Latin America (LATAM): Urbanization and Industrialization Drive

- LATAM exhibits moderate but accelerating growth, largely dependent on macro-economic stability and urbanization rates. Countries like Brazil and Mexico are witnessing increased adoption of precast systems for efficient housing solutions and large public works projects. The market is highly price-sensitive, leading to a prevalent use of conventional oil-based agents, though regulatory movements are slowly starting to push the adoption of more cost-effective water-based alternatives.

- Middle East and Africa (MEA): Project-Based Demand Surge

- The MEA market experiences demand fluctuations directly tied to mega-project commencement in the Gulf Cooperation Council (GCC) countries. High-profile construction projects (e.g., smart cities, commercial towers) generate immense, concentrated demand for high-volume structural precast elements. Due to the extreme heat conditions prevalent in the region, release agents must be specifically formulated to resist rapid evaporation and ensure performance under high curing temperatures, adding a layer of technical complexity to regional supply.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Precast Concrete Release Agents Market.- BASF SE

- Sika AG

- Fosroc International Ltd.

- GCP Applied Technologies

- Mapei S.p.A

- Cemex S.A.B. de C.V.

- The Sherwin-Williams Company

- Doka GmbH

- Euclid Chemical

- Kurita Water Industries Ltd.

- Henkel AG & Co. KGaA

- CHRYSO SAS

- Evonik Industries AG

- MBCC Group (Master Builders Solutions)

- US Spec

- Franklin International

- W. R. Meadows, Inc.

- Sonneborn Building Products

- Laticrete International, Inc.

- Ardex GmbH

Frequently Asked Questions

Analyze common user questions about the Precast Concrete Release Agents market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between oil-based and water-based concrete release agents?

Oil-based agents, typically mineral or vegetable oil derivatives, form a physical barrier and are cost-effective for general structural precast. Water-based agents utilize advanced emulsions and often contain less volatile organic compounds (VOCs), making them environmentally preferable and suitable for applications requiring superior surface finish (architectural concrete).

Which factors determine the best type of release agent for a specific precast project?

The selection depends on the mold material (steel, wood, plastic), the complexity of the mold geometry, the type of concrete mix (SCC, UHPC), the curing method (steam curing), and regulatory compliance requirements regarding VOC content and biodegradability.

How is the market adapting to increasing environmental regulations regarding VOCs?

The market is rapidly shifting toward high-performance, bio-based formulations derived from vegetable oils and advanced water-based emulsions. Manufacturers are investing heavily in R&D to ensure these environmentally friendly products maintain or surpass the demolding performance of traditional solvent and mineral oil-based alternatives.

What role does automation play in the consumption patterns of release agents?

Increased automation (robotic spraying) in modern precast plants favors highly consistent, low-viscosity agents compatible with precision dosing equipment. This ensures optimal film thickness, reduces waste, and demands agents formulated for reliable, non-clogging performance under continuous operation.

Which regional market is exhibiting the highest growth rate for release agents?

The Asia Pacific (APAC) region currently exhibits the highest growth rate, driven by massive infrastructure expansion and urbanization projects in countries like China, India, and Indonesia, leading to a substantial increase in precast production volume.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager