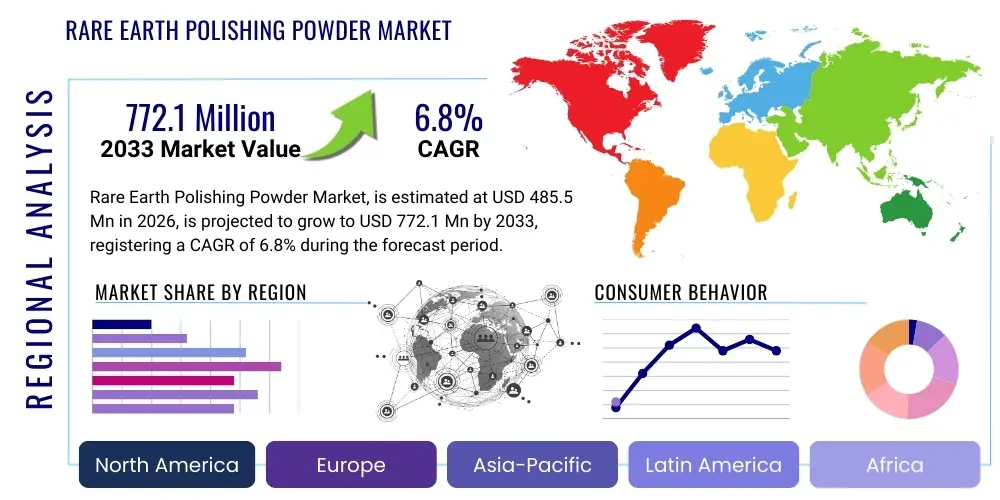

Rare Earth Polishing Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440708 | Date : Feb, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Rare Earth Polishing Powder Market Size

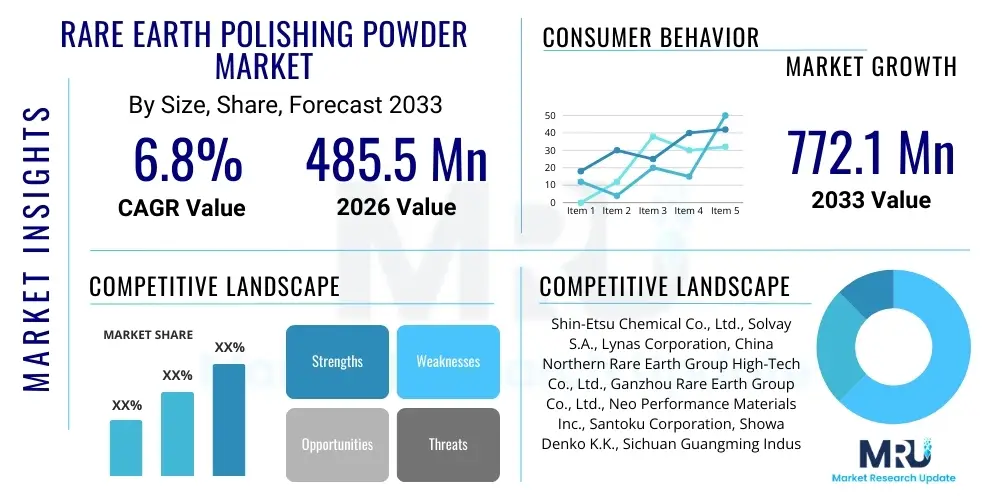

The Rare Earth Polishing Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 720 Million by the end of the forecast period in 2033. This growth is primarily driven by the escalating demand for high-precision finishes across various industries, particularly in electronics, automotive, and optics, which rely heavily on the superior polishing capabilities of rare earth compounds. The inherent properties of these powders, such as their unique atomic structure and excellent abrasive characteristics, position them as indispensable materials for achieving mirror-like surfaces and stringent dimensional tolerances critical for advanced technological applications.

Rare Earth Polishing Powder Market introduction

The Rare Earth Polishing Powder market encompasses the production and consumption of abrasive materials derived from rare earth elements, primarily cerium oxide, used for achieving high-precision surface finishes on various substrates. These powders are essential for the meticulous polishing of critical components in diverse industries, including advanced electronics, optical systems, and precision mechanics. Their unique crystalline structures and controlled particle sizes enable superior material removal rates and unparalleled surface quality, making them indispensable for applications where clarity, smoothness, and structural integrity are paramount. The market's foundational role lies in supporting the manufacturing processes that require extremely flat, scratch-free, and highly reflective surfaces, which are crucial for the performance and longevity of modern technological devices.

The primary products within this market are typically cerium oxide-based powders, although formulations may also include lanthanum, neodymium, and yttrium oxides, each offering specific performance characteristics tailored to different material requirements. These powders are categorized by their purity levels, particle size distribution, and specific additive formulations, all of which influence their efficacy in diverse polishing applications. Major applications span the polishing of glass substrates for LCDs, OLEDs, and plasma displays, semiconductor wafers in microelectronics, optical lenses for cameras and telescopes, automotive windshields and mirrors, and precision components in medical devices. The demand for these sophisticated polishing agents is intricately linked to the innovation cycles and production volumes of these high-tech sectors, driving continuous research into optimized compositions and manufacturing techniques.

The numerous benefits offered by rare earth polishing powders include their exceptional polishing efficiency, superior surface quality devoid of defects, high material removal rates, and excellent chemical stability during processing. These advantages directly contribute to enhanced product performance and reduced manufacturing costs by minimizing rework and improving yield. Key driving factors propelling market expansion include the relentless growth of the consumer electronics industry, with increasing demand for high-definition displays and powerful semiconductor devices. Furthermore, the rapid advancements in automotive technologies, especially for autonomous driving systems requiring sophisticated sensor optics and durable glass, along with the burgeoning renewable energy sector's need for high-efficiency solar panels, significantly boost the demand for these specialized polishing materials. The precision requirements across these industries continue to intensify, cementing the critical role of rare earth polishing powders.

Rare Earth Polishing Powder Market Executive Summary

The Rare Earth Polishing Powder market is currently undergoing significant transformations, driven by evolving business trends focused on supply chain resilience, sustainability, and technological innovation. Enterprises within this sector are increasingly investing in research and development to create more efficient and environmentally friendly polishing solutions, including powders with finer particle sizes and customized formulations for emerging materials. Consolidation activities and strategic partnerships are also prominent, as companies seek to secure raw material access, expand geographical reach, and leverage specialized expertise. Furthermore, the market is seeing a push towards automation in manufacturing processes for polishing powders, aiming to reduce costs and enhance consistency, reflecting a broader industry trend towards operational optimization and advanced material science. These strategic shifts are crucial for companies aiming to maintain a competitive edge and address the dynamic demands of end-use industries.

Regional trends reveal Asia-Pacific as the undisputed dominant force in the rare earth polishing powder market, primarily due to its robust electronics manufacturing base, extensive automotive production, and significant rare earth mining and processing capabilities, particularly in China. The region benefits from a well-established supply chain and a high concentration of end-use industries requiring advanced polishing solutions. North America and Europe, while smaller in production volume, exhibit strong growth in high-value, specialized applications such as aerospace, medical devices, and advanced optical systems, driven by rigorous quality standards and technological leadership. These regions are also witnessing increased efforts to diversify rare earth supply sources and develop domestic processing capabilities to reduce dependence on single-country suppliers, spurred by geopolitical considerations and the imperative for supply chain security.

Segment-wise, the market is observing pronounced trends towards higher purity grades and ultrafine particle sizes, particularly for semiconductor and advanced display applications where even microscopic imperfections can compromise device performance. Cerium oxide remains the leading product type due to its superior performance characteristics, but there is growing interest in blended rare earth oxide powders that offer optimized performance for specific substrates or polishing processes. Application trends indicate a sustained demand from the consumer electronics and automotive sectors, with emerging opportunities in the medical and aerospace industries where precision and reliability are paramount. The shift towards miniaturization in electronics and the development of next-generation display technologies further amplify the need for highly specialized and efficient rare earth polishing powders, prompting continuous innovation in material science and engineering within the industry.

AI Impact Analysis on Rare Earth Polishing Powder Market

Common user questions regarding AI's impact on the Rare Earth Polishing Powder market frequently revolve around its potential to optimize manufacturing processes, enhance quality control, and predict market demand and supply chain dynamics. Users are curious about how AI can lead to more efficient production of these specialized powders, potentially reducing costs and environmental footprint, and how it might influence the formulation and customization of polishing powders for novel applications. There is also significant interest in AI's role in improving the end-use polishing processes themselves, leading to higher yields and reduced defects, and how it could help navigate the complexities and volatilities of the rare earth supply chain. Overall, users expect AI to drive efficiency, precision, and strategic foresight across the entire value chain of the rare earth polishing powder industry.

- AI can optimize rare earth polishing powder manufacturing processes by analyzing real-time sensor data from production lines, identifying inefficiencies, and recommending adjustments to parameters like milling speed, calcination temperature, and particle classification, leading to reduced energy consumption and improved yield.

- Predictive analytics powered by AI can forecast demand for specific rare earth polishing powder types based on trends in end-use industries (e.g., consumer electronics, automotive), geopolitical factors, and economic indicators, enabling manufacturers to optimize inventory levels and production schedules, thereby minimizing waste and lead times.

- AI-driven image recognition and machine learning algorithms can significantly enhance quality control by detecting microscopic defects or inconsistencies in particle size and morphology of polishing powders during production, ensuring higher product quality and consistency before shipment to critical end-users.

- The integration of AI in R&D accelerates the discovery and optimization of new rare earth polishing powder formulations, simulating interactions between different rare earth oxides and additives to predict performance characteristics, thus reducing the extensive physical experimentation traditionally required and speeding up innovation cycles for specialized applications.

- AI can improve supply chain transparency and resilience by monitoring global rare earth raw material markets, identifying potential disruptions, and suggesting alternative sourcing strategies or inventory adjustments, which is crucial for a market highly dependent on a geopolitically sensitive commodity.

DRO & Impact Forces Of Rare Earth Polishing Powder Market

The Rare Earth Polishing Powder market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating demand for high-precision optics and electronics, fueled by advancements in consumer devices, data centers, and telecommunications infrastructure. The proliferation of high-definition displays, powerful semiconductor chips, and advanced camera lenses necessitates exceptionally smooth and defect-free surfaces, which rare earth polishing powders uniquely facilitate. Furthermore, the expanding automotive industry, particularly with the rise of electric vehicles and autonomous driving, increases the need for durable and high-clarity glass components, sophisticated sensor covers, and precision-polished metal parts. These technological imperatives consistently push the boundaries of surface finishing requirements, thereby sustaining and augmenting the demand for these specialized abrasive materials.

However, the market also faces significant restraints. The notorious volatility and geopolitical sensitivity of the rare earth supply chain present a substantial challenge; disruptions in mining, processing, or trade can lead to sharp price fluctuations and supply shortages, impacting production costs and availability. Environmental regulations surrounding rare earth mining and processing, which are often energy-intensive and can generate hazardous waste, impose additional compliance costs and restrict operational expansion. Moreover, the inherently high production costs associated with extracting, separating, and refining rare earth elements, coupled with the specialized manufacturing processes for polishing powders, contribute to elevated market prices. While less prevalent, the potential for substitution by non-rare earth alternative materials in certain less demanding applications could also pose a long-term restraint, although for high-precision needs, rare earths remain largely unrivaled.

Despite these challenges, numerous opportunities exist to propel market growth. The emergence of new display technologies, such as advanced OLED, micro-LED, and augmented reality (AR)/virtual reality (VR) devices, requires ever-finer and more precise polishing techniques for their intricate components. The increasing demand from high-growth sectors like medical devices, requiring sterile, ultra-smooth surfaces for implants and surgical instruments, and aerospace and defense, where lightweight and high-performance optical components are critical, opens new lucrative avenues. Additionally, ongoing research and development in sustainable production methods for rare earth polishing powders, including recycling and more efficient extraction techniques, present opportunities not only for environmental compliance but also for cost reduction and enhanced supply security. The continuous quest for technological superiority across industries ensures a consistent demand for advanced polishing solutions, fostering innovation and market expansion.

The market is also shaped by various impact forces. Regulatory landscapes, particularly environmental protection policies and international trade agreements, directly affect rare earth mining and processing, influencing availability and pricing. Geopolitical factors, including trade disputes, resource nationalism, and international relations among major rare earth-producing and consuming nations, can introduce significant uncertainty into the supply chain. Technological advancements in polishing equipment and methodologies, such as robotic polishing systems and advanced metrology, can drive demand for more refined and consistent polishing powders. Furthermore, macroeconomic conditions, including global industrial output and consumer spending on electronics, dictate the overall market demand for end-products requiring rare earth polishing, making the market susceptible to broader economic trends and fluctuations.

Segmentation Analysis

The Rare Earth Polishing Powder market is comprehensively segmented to provide a detailed understanding of its diverse applications, material compositions, and end-user requirements. This segmentation allows for precise market analysis, identifying key growth drivers, niche opportunities, and competitive landscapes across various product types, application areas, purity grades, particle sizes, and end-use industries. The inherent versatility of rare earth elements, particularly cerium, enables the formulation of a wide array of polishing powders each optimized for specific material substrates and desired surface finishes. Understanding these segments is crucial for stakeholders to develop targeted strategies, innovate new products, and effectively address the nuanced demands of a rapidly evolving global market. The differentiation in segments often correlates with varying performance criteria such as material removal rate, scratch resistance, and final surface roughness, all of which are critical for high-precision manufacturing processes.

- By Type

- Cerium Oxide: The most widely used due to its superior chemical-mechanical polishing (CMP) properties and cost-effectiveness.

- Lanthanum Oxide: Utilized for specific optical applications and glass compositions.

- Yttrium Oxide: Employed in specialized ceramic and high-temperature applications.

- Neodymium Oxide: Offers unique abrasive characteristics for specific polishing tasks.

- Others: Includes blends and other rare earth oxides tailored for niche applications.

- By Application

- Glass Polishing: Dominant segment, including LCD, OLED, automotive, and architectural glass.

- Ceramic Polishing: For advanced ceramics used in electronics, medical, and industrial sectors.

- Metal Polishing: Applied to precision metal components, molds, and decorative surfaces.

- Semiconductor Wafer Polishing: Critical for achieving ultra-flat surfaces in microchip manufacturing.

- Others: Includes polishing of plastics, composites, and specialized materials.

- By End-Use Industry

- Electronics & Displays: Smartphones, tablets, TVs, monitors, semiconductor devices.

- Automotive: Windshields, mirrors, headlights, interior displays, sensor optics.

- Optical Lenses: Cameras, telescopes, microscopes, eyeglasses, laser optics.

- Medical Devices: Endoscopes, surgical instruments, diagnostic equipment.

- Aerospace & Defense: Precision optical systems, satellite components, specialty windows.

- Jewelry: Gemstone and precious metal polishing.

- Others: Industrial components, laboratory equipment.

- By Purity Grade

- High Purity (99.9% and above): Essential for semiconductors, advanced optics, and critical electronic components where impurities can compromise performance.

- Standard Purity (99%-99.9%): Suitable for general glass polishing, automotive applications, and less stringent requirements.

- By Particle Size

- Ultrafine (less than 1 micron): For super-precision polishing, achieving atomic-level flatness, critical for semiconductor wafers and high-end optics.

- Fine (1-5 microns): Widely used for general high-quality glass and display panel polishing.

- Medium (5-10 microns): Suitable for faster material removal and initial polishing stages.

- Coarse (greater than 10 microns): Primarily for rough polishing and bulk material removal.

Value Chain Analysis For Rare Earth Polishing Powder Market

The value chain for the Rare Earth Polishing Powder market is a multi-stage process beginning with the complex extraction and processing of rare earth ores and culminating in the highly specialized application of the finished powders in various end-use industries. Upstream activities are critical and involve the mining of rare earth minerals, primarily from bastnasite and monazite deposits, followed by an intricate series of beneficiation steps to concentrate the rare earth elements. This concentrate then undergoes a sophisticated refining process, which includes solvent extraction and ion exchange techniques, to separate individual rare earth oxides with very high purity. The cost and environmental impact at this stage are substantial, influencing the final price and sustainability profile of the polishing powders, and highlighting the importance of efficient and environmentally responsible rare earth processing technologies.

Midstream activities focus on the transformation of purified rare earth oxides into functional polishing powders. This involves precision engineering processes such as precipitation, calcination, milling, and advanced classification to achieve specific particle size distributions, morphologies, and surface chemistries tailored for distinct polishing applications. Manufacturers invest heavily in research and development to optimize these processes, aiming to produce powders with consistent quality, high efficiency, and customized performance characteristics, such as enhanced scratch removal or reduced surface defects. The formulation of these powders often involves blending different rare earth oxides and incorporating proprietary additives to achieve superior results on various substrates, from delicate optical glass to robust semiconductor wafers, representing a crucial value-addition step in the overall chain.

Downstream activities involve the distribution, sales, and end-use application of the rare earth polishing powders. Distribution channels are varied, encompassing direct sales from manufacturers to large-scale industrial consumers, as well as indirect channels through specialized distributors who provide technical support and cater to smaller, diverse customers. Direct sales are common for major electronics manufacturers and automotive companies with high-volume requirements, fostering close collaboration on product specifications and supply security. Indirect channels leverage a network of regional and local distributors who possess specific market knowledge and can effectively reach a broader customer base, including precision optics manufacturers, medical device producers, and general industrial polishing companies. Effective distribution, coupled with robust technical service and application support, is paramount for ensuring that end-users select and correctly apply the optimal polishing powder for their specific needs, thereby maximizing efficiency and product performance. The success of the overall value chain relies on seamless coordination and technological innovation at each stage.

Rare Earth Polishing Powder Market Potential Customers

The Rare Earth Polishing Powder market serves a diverse range of industries that require high-precision surface finishing for their products, making their potential customer base broad and technologically sophisticated. Key end-users and buyers are primarily manufacturers operating in sectors where surface quality, optical clarity, and dimensional accuracy are paramount to product functionality and performance. These customers include large-scale producers of display panels for televisions, smartphones, and computers, where mirror-like finishes are essential for visual fidelity and touch-screen responsiveness. Additionally, semiconductor foundries are critical customers, utilizing these powders to achieve the ultra-flat surfaces required for the intricate fabrication of microchips, ensuring consistent device performance and reliability. The relentless drive for miniaturization and enhanced performance in these industries directly translates into sustained demand for high-quality rare earth polishing powders.

Beyond electronics, the automotive industry represents a significant customer segment, particularly for manufacturers of windshields, mirrors, and advanced sensor optics crucial for autonomous driving systems. These components demand exceptional clarity, durability, and scratch resistance, making rare earth polishing powders indispensable for their production. Optical lens manufacturers, serving applications ranging from high-end cameras and telescopes to medical instruments and eyeglasses, also constitute a vital customer base, relying on these powders to achieve precise curvatures and flawless surfaces that prevent distortion and maximize light transmission. Furthermore, the medical device industry, aerospace and defense sectors, and even precision jewelry manufacturers are increasingly important customers, as they require specialized polishing solutions for components where functionality, aesthetics, and stringent quality standards are non-negotiable. The continued innovation within these sectors ensures a steady and evolving demand for advanced rare earth polishing powders.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 720 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shin-Etsu Chemical Co., Ltd., Solvay S.A., China Northern Rare Earth Group High-Tech Co., Ltd., Inner Mongolia Baotou Steel Rare-Earth (Group) Hi-Tech Co., Ltd., Jiangsu Guosheng Rare Earth Co., Ltd., Treibacher Industrie AG, Stanford Advanced Materials, American Elements, Lynas Rare Earths Ltd., Ganzhou Rare Earth Group Co., Ltd., ProChem, Inc., Mitsubishi Chemical Corporation, Sumitomo Metal Mining Co., Ltd., Vacuum Engineering & Materials (VEM), Materion Corporation, Neo Performance Materials, Xiamen Tungsten Co., Ltd., Molycorp Chemicals & Oxides LLC, Metall Rare Earth Limited, UBE Industries, Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rare Earth Polishing Powder Market Key Technology Landscape

The technological landscape of the Rare Earth Polishing Powder market is continuously evolving, driven by the increasing demand for ultra-precision finishes and the need for more efficient and sustainable production methods. In terms of powder manufacturing, advanced techniques such as controlled precipitation, sophisticated calcination processes, and precision milling are crucial for achieving the desired crystalline structure, particle size distribution, and morphological characteristics. Manufacturers are increasingly utilizing inert atmosphere processing to prevent contamination and ensure high purity, which is critical for semiconductor and advanced optical applications. Furthermore, the development of specialized classification technologies, including air classifiers and centrifugal separators, allows for the precise sorting of particles into narrow size ranges, optimizing performance for specific polishing tasks and minimizing defects.

Beyond the production of the powders themselves, significant technological advancements are also impacting the application side. The integration of robotic polishing systems and Computer Numerical Control (CNC) polishing machines is revolutionizing the end-user industries, enabling higher levels of automation, consistency, and precision in the polishing process. These systems, often equipped with advanced force sensors and real-time metrology, can dynamically adjust polishing parameters based on feedback, leading to superior surface quality and reduced material waste. Furthermore, the development of sophisticated metrology equipment, such as atomic force microscopes (AFM) and white light interferometers, allows for ultra-high-resolution surface characterization, enabling manufacturers to verify the efficacy of polishing powders and optimize their usage for achieving atomic-level flatness.

Research and development efforts within the market are predominantly focused on creating novel formulations and enhancing existing technologies. This includes the exploration of nano-sized rare earth polishing powders for extremely demanding applications where conventional micron-sized abrasives may cause micro-scratches. Scientists are also investigating hybrid polishing powders that combine rare earth oxides with other abrasive materials or chemical agents to achieve synergistic effects, offering improved material removal rates with reduced damage. Moreover, there is a strong emphasis on developing more environmentally friendly and cost-effective production methods, including improved recycling techniques for rare earth elements from spent polishing slurries and the development of less energy-intensive synthesis routes. These technological advancements are pivotal for meeting the stringent requirements of next-generation devices and ensuring the long-term sustainability of the rare earth polishing powder industry.

Regional Highlights

- Asia Pacific (APAC): The Asia Pacific region stands as the dominant market for rare earth polishing powders, primarily driven by its robust manufacturing base in consumer electronics, automotive components, and display panels. Countries such as China, South Korea, Japan, and Taiwan are global hubs for semiconductor fabrication, LCD/OLED production, and optical lens manufacturing, leading to exceptionally high demand. China, in particular, not only holds the largest share in rare earth mining and processing but also has a significant domestic market for polished products, making it a critical player in both supply and demand. The region's sustained economic growth and rapid technological adoption in emerging economies further solidify its leadership position.

- North America: North America represents a significant market for high-performance rare earth polishing powders, particularly for specialized applications in aerospace, defense, medical devices, and advanced optics. The region emphasizes innovation and high-purity materials, with a strong focus on R&D for next-generation technologies. While not a major rare earth producer, there's growing investment in processing capabilities and supply chain diversification to reduce reliance on external sources. The demand here is driven by stringent quality standards and the development of cutting-edge products, fostering a market for premium and customized polishing solutions.

- Europe: Europe is a mature market characterized by strong demand from its automotive, precision engineering, and high-end optical industries. Countries like Germany, France, and the UK leverage rare earth polishing powders for sophisticated automotive glass, precision instruments, and specialized optical components used in research and industrial applications. Environmental regulations and a focus on sustainable manufacturing practices are shaping the market, pushing for greener production methods and circular economy initiatives within the rare earth supply chain. Innovation in advanced materials and manufacturing processes also contributes to a stable demand for high-quality powders.

- Latin America: The Latin America rare earth polishing powder market is an emerging region, largely dependent on imports to meet its industrial needs. Growth is primarily linked to the expansion of its automotive assembly plants and increasing investment in local manufacturing capabilities for consumer goods. While the overall market size is smaller compared to other regions, opportunities exist for suppliers to cater to growing industrialization and infrastructure development, particularly in countries like Brazil and Mexico, which are experiencing increased demand for polished glass and metal components.

- Middle East and Africa (MEA): The MEA region represents a developing market for rare earth polishing powders, with demand driven by infrastructure development projects, increasing automotive assembly, and nascent electronics manufacturing. Countries in the Gulf Cooperation Council (GCC) are investing in diversification away from oil, leading to the growth of various industrial sectors that require precision polishing. South Africa, with its mining capabilities, also shows potential for rare earth processing. The market here is characterized by gradual growth and increasing awareness of the benefits of high-precision polishing in industries aiming to meet international quality standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rare Earth Polishing Powder Market.- Shin-Etsu Chemical Co., Ltd.

- Solvay S.A.

- China Northern Rare Earth Group High-Tech Co., Ltd.

- Inner Mongolia Baotou Steel Rare-Earth (Group) Hi-Tech Co., Ltd.

- Jiangsu Guosheng Rare Earth Co., Ltd.

- Treibacher Industrie AG

- Stanford Advanced Materials

- American Elements

- Lynas Rare Earths Ltd.

- Ganzhou Rare Earth Group Co., Ltd.

- ProChem, Inc.

- Mitsubishi Chemical Corporation

- Sumitomo Metal Mining Co., Ltd.

- Vacuum Engineering & Materials (VEM)

- Materion Corporation

- Neo Performance Materials

- Xiamen Tungsten Co., Ltd.

- Molycorp Chemicals & Oxides LLC

- Metall Rare Earth Limited

- UBE Industries, Ltd.

Frequently Asked Questions

What are rare earth polishing powders primarily used for?

Rare earth polishing powders are predominantly used for achieving ultra-precision surface finishes on various materials, especially glass in displays (LCDs, OLEDs), semiconductor wafers, optical lenses, and automotive glass, where exceptional clarity and smoothness are critical for performance.

Which rare earth element is most commonly used in these powders?

Cerium oxide is the most common and widely utilized rare earth element in polishing powders due to its superior chemical-mechanical polishing (CMP) properties, high efficiency, and ability to achieve excellent surface quality on a broad range of substrates.

What are the key drivers of the rare earth polishing powder market?

Key market drivers include the escalating demand for high-precision electronics and optics (e.g., smartphones, advanced displays, camera lenses), the expanding automotive industry's need for high-clarity glass, and technological advancements requiring sophisticated surface finishes for next-generation devices.

What challenges does the rare earth polishing powder market face?

Major challenges include the volatility and geopolitical sensitivity of the rare earth supply chain, strict environmental regulations impacting mining and processing, the inherently high production costs of rare earth elements, and potential (though limited) substitution by alternative materials.

How does AI impact the rare earth polishing powder industry?

AI significantly impacts the industry by optimizing manufacturing processes, enhancing quality control through defect detection, enabling predictive demand forecasting, accelerating R&D for new powder formulations, and improving supply chain resilience through real-time monitoring and analysis.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager