Rolled Annealed Copper Foil Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 443619 | Date : Feb, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Rolled Annealed Copper Foil Market Size

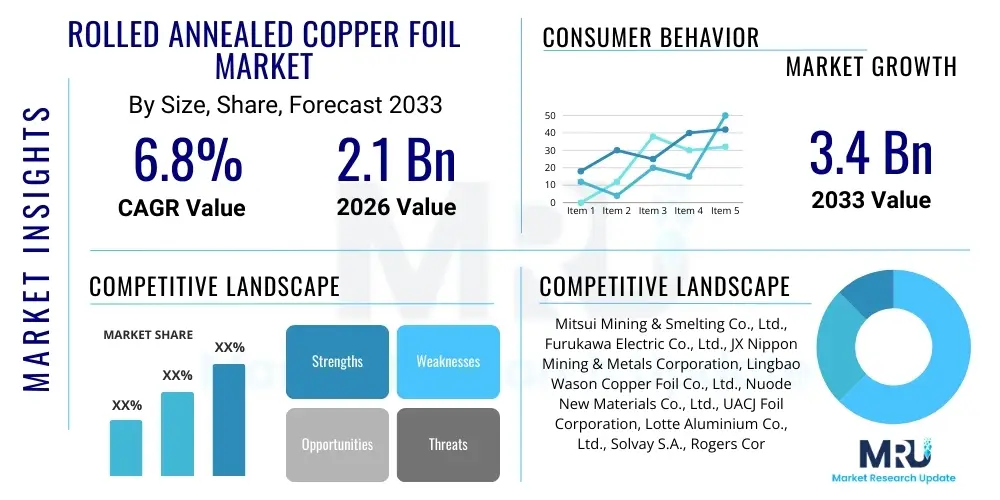

The Rolled Annealed Copper Foil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 8.7 Billion by the end of the forecast period in 2033.

Rolled Annealed Copper Foil Market introduction

The Rolled Annealed Copper Foil market encompasses the production and distribution of high-purity copper sheets manufactured through mechanical rolling and subsequent thermal annealing processes. This specialized manufacturing technique yields copper foil characterized by exceptional ductility, high tensile strength, superior fatigue resistance, and smooth surface properties, making it distinct from traditional electrodeposited (ED) copper foil. The rolling process allows for precise control over grain structure and thickness uniformity, enabling the production of ultra-thin foils crucial for advanced technological applications. The intrinsic quality and performance characteristics of Rolled Annealed Copper Foil position it as an indispensable material in high-demand sectors requiring reliability and miniaturization.

Product description highlights the material's structural integrity, which is vital for applications requiring flexibility and repeated bending, such as Flexible Printed Circuits (FPCs). Unlike the columnar grain structure of ED foil, RA foil exhibits an equiaxed, flattened grain structure that significantly enhances its mechanical robustness. Major applications span high-performance lithium-ion batteries (particularly for electric vehicles and energy storage systems), where it serves as the anode current collector due to its excellent conductivity and corrosion resistance. Furthermore, it is extensively used in advanced communication infrastructure components, high-frequency signal transmission modules, and sophisticated consumer electronics where space constraints demand extremely thin yet reliable conductive layers.

The primary benefits driving market expansion include its superior flexural endurance, crucial for dynamic flexing applications, and its low resistivity, ensuring efficient electrical performance. Driving factors are primarily centered around the exponential growth in electric vehicle (EV) production globally, increasing investments in 5G and 6G telecommunications infrastructure, and the persistent trend toward miniaturization and higher functionality in portable electronic devices. The transition from internal combustion engine vehicles to electrified platforms mandates high-capacity, durable battery systems, solidifying the demand trajectory for high-quality Rolled Annealed Copper Foil.

Rolled Annealed Copper Foil Market Executive Summary

The Rolled Annealed Copper Foil market is poised for robust expansion, driven primarily by transformative technological shifts in the automotive and consumer electronics sectors. Business trends indicate a strong focus on capacity expansion and technological innovation among key manufacturers, aimed at producing thinner, wider, and more defect-free foils to meet the stringent quality requirements of next-generation batteries and high-frequency PCBs. Strategic alliances and joint ventures, particularly in Asia Pacific, are prevalent as companies seek to secure raw material supply chains and optimize production efficiency. Furthermore, sustainability is emerging as a critical competitive differentiator, with companies investing in energy-efficient rolling and annealing processes to comply with stricter environmental regulations and cater to environmentally conscious end-users.

Regional trends unequivocally place Asia Pacific (APAC) as the dominant and fastest-growing region, largely attributable to the massive manufacturing bases for Li-ion batteries in China, South Korea, and Japan, alongside being the global hub for electronic device production. North America and Europe are also witnessing accelerated growth, primarily fueled by supportive government policies promoting EV adoption and localized gigafactory construction, aimed at reducing reliance on Asian supply chains. The Middle East and Africa (MEA) and Latin America currently hold smaller market shares but are expected to experience moderate growth driven by increasing industrialization and early-stage investments in renewable energy storage solutions.

Segmentation trends highlight the increasing dominance of the Lithium-Ion Battery segment due to the global transition towards electric mobility and grid-scale energy storage. Within the product thickness segment, ultra-thin foils (below 6 µm) are gaining significant traction, commanded by the requirements for high-energy density batteries and advanced flexible electronics that demand minimal weight and volume. The market is witnessing a shift toward specialized foil grades designed explicitly for specific applications, such as high-temperature resistant foils for aerospace electronics or low-profile foils optimized for complex multilayer PCBs, necessitating constant research and development efforts across the competitive landscape.

AI Impact Analysis on Rolled Annealed Copper Foil Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Rolled Annealed Copper Foil Market generally revolve around how AI can enhance manufacturing precision, optimize material properties, and improve supply chain resilience. Key themes center on leveraging machine learning for defect detection during the rolling process, predicting equipment failure to minimize downtime in high-cost production lines, and optimizing complex annealing parameters to ensure uniform mechanical properties across ultra-thin foils. Users are concerned with how AI integration can lower production costs, accelerate research and development cycles for novel copper alloys, and manage the increasingly complex logistics required to support global EV battery supply chains. Expectations are high that AI will move the industry towards 'smart manufacturing,' significantly reducing material waste and energy consumption, thereby addressing both economic efficiency and sustainability mandates.

AI's direct influence is segmented into process optimization, quality control, and predictive maintenance. In process optimization, AI algorithms analyze vast datasets derived from rolling mills and annealing furnaces, dynamically adjusting pressure, speed, and temperature settings in real-time to maintain tolerances often measured in nanometers. This precision is paramount for producing the thinnest foils required for cutting-edge Li-ion batteries without compromising structural integrity. By automating decision-making within the manufacturing environment, AI ensures consistency, reduces human error, and allows manufacturers to push the boundaries of achievable foil specifications, crucial for maintaining competitiveness in a capital-intensive sector.

Furthermore, AI-driven predictive modeling is transforming market forecasting and demand planning. By integrating external variables such as EV sales forecasts, regional regulatory changes, and raw material price volatility, AI tools provide highly accurate demand projections for specific foil types (e.g., 4.5 µm vs. 6 µm). This allows major suppliers to optimize inventory management, schedule production runs efficiently, and negotiate favorable long-term contracts for electrolytic copper cathode feedstock, mitigating risks associated with supply chain disruptions and volatile commodity markets. The utilization of AI ensures that the Rolled Annealed Copper Foil industry remains highly responsive to the rapid, global shifts in end-use markets, particularly the volatile but growing EV sector.

- AI-Enhanced Quality Control: Utilizing computer vision and machine learning for real-time, automated surface defect detection on rolling lines, dramatically improving yield rates.

- Predictive Maintenance: AI algorithms analyzing sensor data from heavy machinery (rolling mills, tension levelers) to predict equipment failure, minimizing costly unplanned downtime.

- Process Parameter Optimization: ML models fine-tuning annealing temperatures and speeds to achieve optimal grain structure and mechanical properties (ductility, tensile strength) for ultra-thin foils.

- Supply Chain Resilience: AI analyzing geopolitical risks and logistical bottlenecks to optimize sourcing and distribution strategies for high-purity copper feedstock.

- Accelerated Material R&D: Utilizing generative AI to simulate and test novel copper alloys or surface treatments, speeding up the development of higher performance foils for extreme battery conditions.

DRO & Impact Forces Of Rolled Annealed Copper Foil Market

The dynamics of the Rolled Annealed Copper Foil market are shaped by a complex interplay of Drivers, Restraints, and Opportunities, collectively determining the long-term trajectory and competitive environment. The primary drivers are rooted in global electrification trends, specifically the surging production requirements of high-energy-density Li-ion batteries for electric vehicles and large-scale energy storage systems (ESS). The superior mechanical stability and surface smoothness of RA foil make it the material of choice in these demanding applications. Concurrently, the proliferation of sophisticated, miniaturized consumer electronics and the rollout of 5G/6G infrastructure necessitate high-performance materials capable of handling high frequencies and high-density interconnection, further boosting demand for ultra-thin RA foil. These foundational drivers ensure sustained, high-volume demand well into the next decade.

However, the market faces significant restraints, notably the capital-intensive nature of RA foil manufacturing. The initial investment required for precision rolling mills, specialized annealing equipment, and cleanroom facilities is exceptionally high, creating substantial barriers to entry for new players. Furthermore, the inherent volatility and upward pressure on the price of raw copper, combined with the energy-intensive nature of the manufacturing process, pose persistent margin risks for producers. Additionally, maintaining zero defects in ultra-thin foil production requires advanced technological expertise and stringent quality control, which few companies globally can achieve consistently, limiting the overall accessible supply of premium-grade material.

Opportunities for growth are concentrated in technological advancements and diversification. The development of next-generation batteries (e.g., solid-state batteries, sodium-ion batteries) presents an opportunity for suppliers to innovate specialized RA foils tailored to new chemical compositions and operating environments. Expanding capacity in regions outside APAC, particularly in North America and Europe, to support localized gigafactories represents a significant strategic opportunity, mitigating geopolitical supply risks. Furthermore, increasing application in niche high-reliability markets, such as aerospace, defense electronics, and medical implants, where premium pricing justifies the quality of RA foil, provides avenues for market segmentation and value enhancement. Successfully navigating the high capital costs while capitalizing on the surging global electrification demand defines the market’s impact forces.

Segmentation Analysis

The Rolled Annealed Copper Foil market is comprehensively segmented based on its structural characteristics (Thickness), its functional utility (Application), and the ultimate purchasing industries (End-Use Industry). Analyzing these segments provides strategic insights into market hotspots, technological requirements, and competitive landscapes. The thickness segmentation is particularly critical as it directly correlates with the foil's performance in end applications; ultra-thin foils are primarily reserved for high-energy density batteries and flexible circuits, while thicker foils serve less demanding applications like general shielding and power transformers. Understanding these distinctions allows manufacturers to prioritize capacity investments toward the highest-growth, highest-margin segments.

The application segmentation reveals the dominant consumption patterns, with Lithium-Ion Batteries clearly leading, followed by Flexible Printed Circuits (FPCs). FPCs utilize RA foil for its exceptional flexibility, which is crucial in compact electronic devices like smartphones and wearables. The diversity in end-use industries, spanning from high-volume automotive manufacturing to specialized telecommunications equipment, underscores the material's versatility. Market strategies must be tailored to address the unique qualification processes and supply chain demands of each industry, recognizing that the automotive sector requires long-term supply agreements and stringent traceability, while the consumer electronics sector demands rapid innovation cycles and aggressive cost management.

Strategic positioning within the market requires a granular understanding of regional demand variations linked to these segments. For instance, while APAC dominates FPC production, the burgeoning EV battery market in Europe is driving intense demand for battery-grade foils manufactured closer to the point of consumption. Consequently, players specializing in high-tolerance, thin-gauge copper foil are experiencing greater market valuation and stability. The ongoing innovation in rolling technology, aimed at achieving 3 µm or even thinner foils consistently, will continue to redefine the market segment boundaries and create new competitive advantages for technology leaders.

- By Thickness:

- Below 6 µm (Ultra-Thin)

- 6 µm to 12 µm (Thin)

- Above 12 µm (Standard/Thick)

- By Application:

- Lithium-Ion Batteries (EVs, ESS, Consumer Electronics)

- Flexible Printed Circuits (FPCs)

- Shielding Materials (EMI/RFI)

- Transformers and Coils

- Other Electronic Components

- By End-Use Industry:

- Automotive (Electric Vehicles)

- Consumer Electronics (Smartphones, Tablets, Wearables)

- Telecommunications (5G/6G Infrastructure)

- Industrial and Power Distribution

- Aerospace and Defense

- By Manufacturing Process:

- Single-Side Rolling

- Double-Side Rolling

Value Chain Analysis For Rolled Annealed Copper Foil Market

The value chain for the Rolled Annealed Copper Foil market initiates with the upstream analysis, focusing heavily on the sourcing and processing of electrolytic copper cathodes, the primary raw material. Upstream suppliers are typically large global mining and smelting companies. Price volatility of copper significantly impacts the entire chain, making long-term hedging and secure supply agreements critical for foil manufacturers. Manufacturers must invest heavily in specialized rolling equipment and annealing furnaces, representing a highly capital-intensive stage where technological differentiation, particularly the ability to produce ultra-thin, high-consistency foil, determines market leadership. This stage demands exceptional energy management and process control to maintain quality standards.

The distribution channel involves both direct and indirect sales models, depending on the end-user and application scale. For large-volume, high-value applications like EV battery manufacturing, direct sales models are predominantly used, facilitating rigorous quality audits, customization, and integrated supply chain management. This ensures traceability and compliance with strict automotive standards. Indirect channels, often utilizing specialized electronic component distributors or metal wholesalers, are employed for smaller orders or standardized products used in general electronic assembly or shielding applications. These distributors provide localized inventory, technical support, and logistical solutions, especially in fragmented regional markets.

Downstream analysis focuses on the integration of RA copper foil into finished products. The immediate downstream users are battery cell manufacturers (gigafactories), Flexible Printed Circuit Board (FPCB) fabricators, and specialized electronic component makers. These entities integrate the copper foil as a critical functional material. The final end-users, encompassing the automotive sector, major consumer electronics brands (OEMs), and telecommunications providers, exert significant influence over material specifications, driving the demand for continuous improvement in tensile strength, surface roughness, and purity. The stringent requirements of the downstream battery market, in particular, dictate innovation across the entire upstream value chain, emphasizing defect-free production and adherence to increasingly thin specifications.

Rolled Annealed Copper Foil Market Potential Customers

The primary potential customers and end-users of Rolled Annealed Copper Foil are strategically concentrated in high-growth, high-technology sectors globally. These buyers fall mainly into three high-volume categories: Automotive Battery Manufacturers (Cell Makers), Tier 1 suppliers to the consumer electronics industry (FPCB manufacturers), and major telecommunications infrastructure providers. Automotive battery manufacturers, such as CATL, LG Energy Solution, Samsung SDI, and Panasonic, represent the most critical segment, requiring massive, long-term supply volumes of high-consistency, thin RA foil (4.5 µm to 6 µm) for lithium-ion cell production used in Electric Vehicles (EVs) and stationary energy storage. Their procurement decisions are based on technological capability, scale, and geographical proximity to their global gigafactories.

Another major buying segment comprises the global leaders in Flexible Printed Circuit fabrication, catering to major OEMs like Apple, Samsung, and Huawei. These FPCB houses require RA foil for its superior flexural properties, which are essential for compact, hinged, and foldable electronic devices. Procurement in this segment is driven by the need for extremely smooth surfaces and consistent mechanical properties to handle complex etching and bonding processes. Additionally, specialized industrial customers, including defense contractors and high-reliability aerospace component manufacturers, procure RA foil for shielding and specialized conductor applications where failure tolerance is near zero, demanding the highest possible quality and certified traceability.

The emergence of localized battery production hubs in North America and Europe means that new market entrants and established companies establishing regional manufacturing facilities (e.g., Tesla Giga factories, European battery consortia) are rapidly becoming high-value potential customers. These buyers are often seeking diversified, localized suppliers to de-risk their supply chains currently dominated by Asian manufacturers. For suppliers, successfully demonstrating the ability to meet regional environmental, social, and governance (ESG) standards, alongside technical specifications, is crucial for securing these lucrative, long-term contracts with the world's most innovative and resource-intensive technology producers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 8.7 Billion |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mitsui Kinzoku, JX Nippon Mining & Metals, UACJ, Furukawa Electric, Nippon Denkai, LS Mtron, ILJIN Materials, Circuit Foil, Shandong Jinbao Electronics, Tongling Nonferrous Metals, Kingboard Copper Foil, KMDM, Civen Metal, Wieland Group, Sumitomo Metal Mining, Chang Chun Group, Lotte Aluminium, SK Nexilis, Advanced Copper Foil, Fukuda Metal Foil |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Rolled Annealed Copper Foil Market Key Technology Landscape

The technological landscape of the Rolled Annealed Copper Foil market is highly specialized, centered primarily on achieving extremely high precision and uniformity across large production widths, especially for ultra-thin gauges. The core technologies involve specialized rolling mill configurations, such as high-precision cluster mills or Z-mills, which are designed to apply enormous, controlled pressure to reduce copper thickness incrementally while maintaining tight tolerance control. Continuous investment in advanced gauging systems (often utilizing X-ray or isotope sources) and automated feedback loops is essential to minimize variations and ensure that the final product meets the stringent quality requirements of battery and FPC manufacturers. Furthermore, surface treatment technologies, including specialized cleaning and anti-tarnish layers, are crucial for optimizing adhesion and electrical performance in subsequent manufacturing steps.

A critical area of innovation is the development of next-generation annealing processes. Annealing, the heat treatment stage that restores ductility and defines the final grain structure, must be meticulously controlled. Advanced continuous annealing furnaces utilize inert or controlled atmospheres and precise temperature profiles to achieve the desired equiaxed grain structure without surface oxidation or defect formation. Manufacturers are increasingly integrating process simulation and predictive modeling tools to optimize annealing recipes for different foil thicknesses and required mechanical properties (e.g., high elongation versus high tensile strength). This technological mastery directly correlates with the ability to supply premium-grade foils for high-end applications like high-power EV batteries.

Beyond the core rolling and annealing, significant technological differentiation occurs in the development of wider foils. As gigafactories seek increased throughput, there is a growing demand for copper foil delivered in wider formats (e.g., 1 meter or more) to maximize efficiency in cell manufacturing processes. Achieving ultra-thin gauge uniformity across such large widths presents formidable engineering challenges related to tension control, flatness, and slitting precision. Successful players are utilizing advanced robotics and AI-driven systems to manage these large-scale production runs, ensuring minimal material defects and maximizing yield. Moreover, research into high-strength, low-cost copper alloys suitable for rolling and specialized surface roughening techniques to enhance adhesion to cathode active materials continues to drive technological investment in this capital-intensive sector.

Regional Highlights

Regional dynamics play a paramount role in shaping the Rolled Annealed Copper Foil market, largely dictated by global manufacturing hubs for electronics and the accelerating proliferation of electric vehicle battery production.

- Asia Pacific (APAC): APAC dominates the global market both in terms of production capacity and consumption. This is driven by China, South Korea, and Japan, which are global leaders in Li-ion battery manufacturing (CATL, LGES, Panasonic, Samsung SDI) and the manufacturing of flexible printed circuits. China, in particular, represents the largest single market, fueled by massive government support for the EV ecosystem and comprehensive supply chain infrastructure. The region benefits from established expertise in precision material processing and robust downstream electronics assembly industries.

- North America: The North American market is experiencing explosive growth, propelled by significant government incentives (such as the Inflation Reduction Act in the US) aimed at localizing the EV battery supply chain. This region is seeing massive capital investment in new gigafactories by both domestic and foreign companies, creating immense demand for domestically or regionally sourced RA copper foil. The focus here is on high-performance, battery-grade materials to support large-format EV cells.

- Europe: Europe is rapidly positioning itself as a major manufacturing hub for EVs and sustainable energy storage systems. Driven by ambitious carbon neutrality targets and the phasing out of internal combustion engine sales, significant investment is being directed toward European battery consortia and multinational company expansions. Countries like Germany, Hungary, and Poland are emerging as centers for battery manufacturing, leading to a strong, localized demand for high-quality RA foil and increasing pressure on suppliers to establish European production bases.

- Latin America and Middle East & Africa (MEA): These regions currently hold smaller market shares. Growth in Latin America is primarily tied to increasing localized electronics assembly and potential mineral processing infrastructure development. MEA's market expansion is closely linked to emerging renewable energy projects, particularly solar farms requiring large-scale battery energy storage systems (BESS), where RA copper foil is integral to the battery infrastructure.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Rolled Annealed Copper Foil Market.- Mitsui Kinzoku

- JX Nippon Mining & Metals

- UACJ Corporation

- Furukawa Electric Co., Ltd.

- Nippon Denkai, Ltd.

- LS Mtron Co., Ltd.

- ILJIN Materials Co., Ltd.

- Circuit Foil Luxembourg S.à r.l.

- Shandong Jinbao Electronics Co., Ltd.

- Tongling Nonferrous Metals Group Co., Ltd.

- Kingboard Copper Foil Holdings Ltd.

- KMDM Copper Foil (Kunshan) Co., Ltd.

- Civen Metal Material (Wuxi) Co., Ltd.

- Wieland Group (Wieland Werke AG)

- Sumitomo Metal Mining Co., Ltd.

- Chang Chun Group

- Lotte Aluminium Co., Ltd.

- SK Nexilis Co., Ltd. (Subsidiary of SKC)

- Advanced Copper Foil Co., Ltd.

- Fukuda Metal Foil & Powder Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Rolled Annealed Copper Foil market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Rolled Annealed (RA) and Electrodeposited (ED) Copper Foil?

RA copper foil is mechanically processed, resulting in a dense, equiaxed grain structure that provides superior ductility, flexural strength, and fatigue resistance, making it ideal for flexible electronics and high-performance EV batteries. ED foil is electrochemically processed, featuring a columnar grain structure, generally suitable for standard PCBs.

Which end-use industry is driving the largest growth for the RA Copper Foil Market?

The automotive sector, specifically the production of high-energy-density Lithium-Ion batteries for Electric Vehicles (EVs), is the primary driver. The demand for ultra-thin (below 6 µm) and high-purity RA foil is escalating dramatically to enhance battery energy density and lifespan.

What are the main technological challenges in manufacturing ultra-thin RA copper foil?

The key challenges involve maintaining strict dimensional tolerances (uniformity) across wide production formats, achieving zero surface defects, and managing the high capital and operating costs associated with precision rolling and controlled atmospheric annealing processes necessary for thin-gauge production.

How is the current geopolitical landscape affecting the supply chain for RA Copper Foil?

Geopolitical tensions are increasing the focus on supply chain resilience, leading to significant capital investments in regional manufacturing capacity outside of the dominant Asia Pacific region, particularly in North America and Europe, to mitigate risk and secure localized supplies for new battery gigafactories.

What role does sustainability play in the Rolled Annealed Copper Foil industry?

Sustainability is becoming crucial, driving manufacturers to adopt energy-efficient production methods, minimize material waste through AI-enhanced process control, and source copper from suppliers with certified ethical and environmentally compliant mining practices, responding to pressure from automotive and high-tech OEMs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Rolled Annealed Copper Foil Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Rolled Annealed Copper Foil Market Size Report By Type (12 m, 18 m, 35 m, Others), By Application (Double-sided FPC, Single-sided FPC, Lithium Batteries, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager