Thermally Modified Wood Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441568 | Date : Feb, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Thermally Modified Wood Market Size

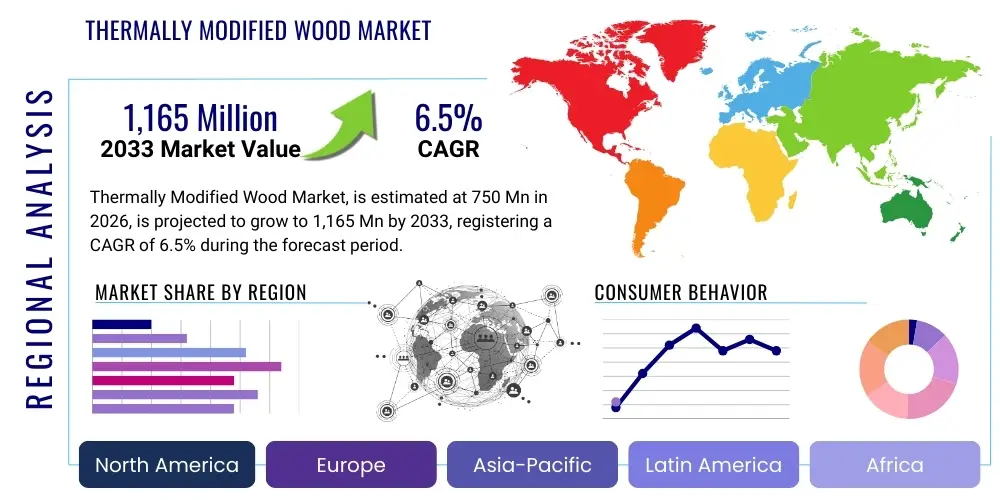

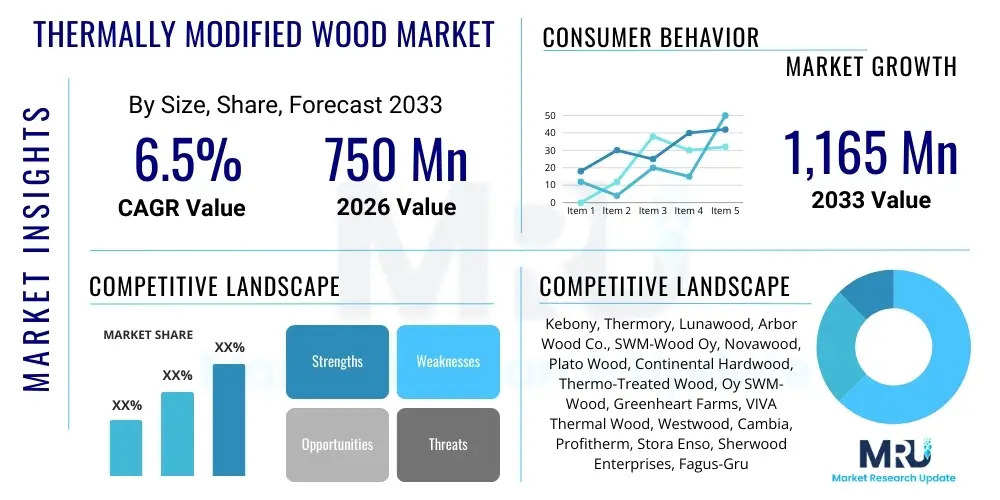

The Thermally Modified Wood Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,165 Million by the end of the forecast period in 2033.

Thermally Modified Wood Market introduction

The Thermally Modified Wood (TMW) market encompasses the production and sale of wood products treated using controlled high temperatures (typically 180°C to 230°C) in a low-oxygen environment, often utilizing steam or inert gas. This process structurally and chemically alters the wood, significantly enhancing its durability, dimensional stability, and resistance to decay, moisture, and pests without the use of chemical preservatives. The resulting material, often referred to as 'thermo-wood,' addresses critical performance limitations of conventional timber, making it suitable for demanding exterior applications such as decking, cladding, and outdoor furniture. The modification process essentially reduces the wood’s hygroscopicity and removes volatile organic compounds, leading to an aesthetically pleasing dark color and extended service life.

Major applications of thermally modified wood span across the residential and non-residential construction sectors. In residential projects, TMW is highly favored for high-performance decking, fencing, and siding due to its low maintenance requirements and superior stability compared to pressure-treated or conventional kiln-dried lumber. Non-residential applications, including commercial facades, public park installations, and marina decking, leverage the wood’s longevity and resistance to challenging weather conditions. The primary benefits driving market adoption include its eco-friendliness, as no harmful chemicals are introduced; enhanced aesthetic appeal due to its deep, rich color; and superior functional properties like reduced swelling and shrinking. This sustainability profile aligns strongly with global green building standards and consumer demand for natural, durable materials.

Key driving factors accelerating the growth of the TMW market include stringent environmental regulations limiting the use of chemically treated wood, particularly in Europe and North America, necessitating safer alternatives. Furthermore, increasing consumer awareness regarding sustainable and durable building materials, coupled with growth in high-end construction and remodeling activities, contributes significantly to market expansion. The technological advancements in thermal modification equipment, leading to improved consistency and efficiency in treatment processes, also make TMW more cost-competitive against exotic hardwoods and composites, positioning it as a preferred material solution across diverse architectural and landscaping projects globally.

Thermally Modified Wood Market Executive Summary

The Thermally Modified Wood market is poised for robust expansion, fundamentally driven by the architectural shift toward sustainable and high-performance exterior materials. Business trends indicate a strong focus on capacity expansion among key manufacturers, particularly in optimizing continuous thermal modification processes to improve scalability and reduce energy consumption. Strategic partnerships between TMW producers and major construction distributors are accelerating market penetration, moving TMW from a niche specialty product to a mainstream construction material. Furthermore, increasing investment in research and development targets the use of lesser-known or fast-growing wood species for thermal modification, broadening the raw material base and mitigating reliance on traditional, slow-growth softwoods and hardwoods. The market is witnessing competitive differentiation based on the modification technique (e.g., steam-based vs. oil-based) and the certification of sustainability, such as FSC or PEFC accreditation, which is crucial for securing large commercial contracts.

Regionally, Europe continues to dominate the market, largely due to its established environmental standards, mature green building industry, and long-standing acceptance of thermo-wood products in Nordic and Central European countries. However, North America is emerging as the fastest-growing region, fueled by increasing residential remodeling activities and a growing appreciation for the premium aesthetics and durability of thermally modified products, replacing traditional cedar and redwood alternatives. Asia Pacific, while currently smaller, is showing promising growth, especially in developed economies like Japan and South Korea, where high-quality construction materials and sustainability are becoming prioritized in luxury housing and commercial infrastructure projects. Government initiatives promoting sustainable forestry and construction practices further bolster regional growth trajectories worldwide.

Segment trends reveal that the Softwood category, primarily using species like Pine and Spruce, maintains the largest market share due to its wide availability and cost-effectiveness when modified. However, the Hardwood segment, focusing on Ash and Oak, is exhibiting the highest growth rate, driven by demand for ultra-premium decking and interior applications where superior hardness and aesthetic finish are paramount. Application-wise, the Decking and Cladding segments remain the largest revenue generators, reflecting the primary use case of TMW in exterior construction where weather resistance is critical. Meanwhile, the Furniture segment is steadily expanding, leveraging TMW’s stability for outdoor furniture that must withstand harsh environmental cycles without warping or decaying, confirming the material's versatile appeal across various high-value end-user industries.

AI Impact Analysis on Thermally Modified Wood Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Thermally Modified Wood market typically revolve around optimizing the complex thermal treatment process, predicting wood quality and yield, and enhancing supply chain efficiency. Key themes include the desire to use AI for predictive quality control—specifically, assessing the raw wood material pre-treatment and determining the precise heat schedule required for different species and desired outcomes. Users are concerned with minimizing defects (e.g., checking and cracking) and maximizing the energy efficiency of kilns. There is significant expectation that AI algorithms can manage the vast amounts of sensor data generated during the modification cycle (temperature, humidity, pressure) to achieve perfect batch consistency, reducing waste and standardizing the final product properties, which is currently a challenge dependent on operator expertise. Furthermore, AI is expected to play a role in advanced demand forecasting and inventory management, optimizing the logistics of raw timber sourcing and distribution of finished goods globally.

- AI-Powered Process Optimization: Utilizing machine learning algorithms to monitor kiln temperature and humidity profiles in real-time, ensuring optimal thermal modification based on wood density and moisture content, thus minimizing defects and ensuring batch consistency.

- Predictive Quality Control: Implementing AI vision systems and sensor fusion to grade raw timber inputs and predict the final mechanical and dimensional stability properties post-treatment, significantly improving yield management.

- Energy Efficiency Enhancement: Employing AI to dynamically adjust heating and cooling cycles in response to real-time environmental and internal wood characteristics, leading to substantial reduction in energy consumption during the lengthy thermal process.

- Supply Chain and Logistics Optimization: Using AI for sophisticated demand forecasting and inventory placement, optimizing the global supply chain for raw materials (wood species) and distribution channels for finished TMW products.

- Automated Defect Detection: Integrating deep learning models into sorting lines to automatically identify and classify surface and internal defects (checks, cracks, internal stresses) on the treated wood, leading to faster and more reliable quality assurance.

- Market Trend Analysis: Leveraging AI to analyze construction market data, regulatory changes, and consumer preferences to inform product development, identifying specific wood types and treatment levels demanded by different regional markets (AEO and GEO relevance).

DRO & Impact Forces Of Thermally Modified Wood Market

The Thermally Modified Wood market is primarily driven by the escalating global demand for sustainable, non-toxic building materials and superior performance characteristics, particularly dimensional stability and resistance to decay, which are critical for long-term exterior applications. However, the market faces significant restraints, chiefly stemming from the high initial capital investment required for specialized thermal modification machinery, which creates barriers to entry for new players, and the relatively higher price point of TMW compared to standard, chemically treated wood alternatives. Opportunities abound in expanding into high-growth construction markets in developing regions and diversifying TMW applications beyond traditional decking and cladding into structural elements and interior design. These market forces collectively shape the competitive landscape and technological investment decisions within the industry.

Driving factors center on environmental legislation, particularly the phase-out of certain chromated copper arsenate (CCA) and other toxic wood preservatives, which positions TMW as a compelling, environmentally benign substitute. The rising popularity of biophilic design and natural aesthetics in both commercial and residential architecture also fuels demand, as TMW maintains the natural look and feel of wood while offering enhanced longevity. Furthermore, increased product standardization and growing certification efforts build consumer trust and facilitate broader adoption by architects and specifiers, accelerating market growth in highly regulated construction markets across Europe and North America.

The most significant restraints include the susceptibility of TMW to surface checking (fine cracks) if not properly maintained or installed, and its inherent reduction in bending strength compared to untreated wood, limiting its use in certain high-load structural applications. The intensive energy consumption of traditional batch-style thermal modification processes also poses a cost challenge and sustainability concern, necessitating technological innovation toward more energy-efficient continuous flow systems. Despite these challenges, the overwhelming opportunity lies in technological advancements, such as hybrid modification techniques combining heat with natural oils or waxes, which aim to improve TMW’s mechanical properties and further enhance its weather resistance, securing its long-term competitive position against wood-plastic composites and metal alternatives.

DRO & Impact Forces Summary:

- Drivers: Demand for sustainable, chemical-free building materials; superior dimensional stability; stringent environmental regulations against toxic wood preservatives; growth in high-end residential and commercial construction.

- Restraints: High initial investment cost for production facilities; reduced mechanical strength compared to native wood; energy intensity of the modification process; higher price point relative to conventional lumber.

- Opportunities: Expansion into emerging economies; application diversification (e.g., marine environments, acoustic paneling); technological innovation in continuous flow modification; strategic partnerships with global construction firms.

- Impact Forces: Environmental compliance requirements, material performance expectations in extreme weather conditions, raw material sourcing costs, consumer preference for natural aesthetics.

Segmentation Analysis

The Thermally Modified Wood market is comprehensively segmented based on the type of wood utilized, the specific application area, and the modification technology employed. Understanding these segments is crucial for manufacturers to tailor their product offerings and marketing strategies effectively. The segmentation by wood type, distinguishing between readily available softwoods and premium hardwoods, dictates the target price range and specific end-user performance expectations, particularly concerning density and aesthetic quality. The application segment reflects the market's primary reliance on exterior uses, such as decking and cladding, which demand the highest levels of durability and stability inherent to the thermal modification process. Furthermore, the segmentation by modification method highlights the technological diversity in the market, where different processes achieve varying levels of performance enhancement and visual characteristics, catering to distinct consumer preferences and regulatory requirements across global construction standards.

The Softwood category, typically encompassing Pine (Scots Pine, Radiata Pine) and Spruce, commands the largest volume share due to the widespread availability and relatively low initial cost of the raw material. Softwoods, post-modification, exhibit sufficient stability and durability for standard exterior residential applications. Conversely, the Hardwood segment, focusing on species like European Ash, Oak, and Birch, though smaller in volume, accounts for a higher value share. Thermally modified hardwoods are highly sought after for luxury projects, interior flooring, and demanding outdoor applications where density, superior surface hardness, and a rich, uniform color are prioritized. The differentiation in material properties between the two wood types drives pricing and geographic distribution strategies.

From an application standpoint, Decking represents the single largest consumer segment, benefiting immensely from TMW’s water resistance and reduced need for periodic sealing and staining, offering a long-life alternative to composite or tropical wood decking. Cladding (siding) is the second major application, where dimensional stability is essential to maintain structural integrity and aesthetic appeal over wide external surfaces exposed to temperature fluctuations. The burgeoning Furniture segment focuses on creating high-quality, durable outdoor furnishings resistant to rot and insect infestation, further cementing TMW’s position as a premium, functional material across the entire spectrum of architectural and design needs, from structural exteriors to finished products.

- By Wood Type:

- Softwood (Pine, Spruce, Fir)

- Hardwood (Ash, Oak, Birch, Poplar)

- By Application:

- Decking

- Cladding/Siding

- Flooring

- Furniture (Outdoor and Indoor)

- Fencing and Landscaping

- Other Construction Materials

- By Treatment Method:

- Traditional Thermal Modification (Steam/Water-based)

- Oil/Vacuum Assisted Modification

- Heat and Pressure Treatment

- By End-User:

- Residential Construction

- Non-Residential/Commercial Construction

- DIY and Retail

Value Chain Analysis For Thermally Modified Wood Market

The value chain for the Thermally Modified Wood market begins with the Upstream segment, dominated by sustainable forestry management and timber harvesting. Sourcing high-quality, defect-free lumber of specific species (e.g., clear grade pine or ash) is crucial, as the thermal process highlights existing defects. Key players in this stage include certified forest owners and raw timber suppliers who must adhere to stringent sustainability standards (FSC, PEFC) to meet the market's ecological expectations. Efficiency in this stage is driven by optimizing log transportation and initial kiln-drying preparation, ensuring the wood is ready for the high-temperature treatment, directly influencing the quality and cost of the final product.

The Midstream segment, which encompasses the core thermal modification process, represents the highest value addition. This stage involves sophisticated manufacturing facilities equipped with specialized kilns and proprietary heating technologies. Manufacturers focus intensely on process control, energy management, and product finishing (milling, sanding, profiling). Distribution channels are primarily handled through specialized building material distributors and wholesalers (indirect channel), who manage inventory and logistical complexity between the manufacturer and the final construction site or retail outlet. Direct sales channels are often utilized for large, bespoke commercial projects or high-volume original equipment manufacturer (OEM) sales, providing manufacturers with greater control over pricing and customer feedback.

The Downstream segment involves the marketing, distribution, installation, and end-use of TMW products. Architects, designers, and construction contractors (the main buyers) play a crucial role in specifying TMW over competitors, relying on technical data regarding durability and sustainability certifications. Retail outlets and specialized lumber yards serve the residential DIY market. Successful companies differentiate themselves downstream through strong branding, technical support, installation guidance, and providing robust warranties, ensuring that the enhanced material properties translate into long-term customer satisfaction and reduced post-installation claims, thereby reinforcing the material's premium position in the competitive building products market.

Thermally Modified Wood Market Potential Customers

The primary consumers and end-users of Thermally Modified Wood products span across professional contractors, architectural firms, and individual homeowners engaged in high-quality construction and remodeling projects. These buyers prioritize material longevity, minimal maintenance, and environmental sustainability. Professional construction companies specializing in bespoke residential homes and high-end commercial projects, such as luxury resorts and corporate campuses, constitute a crucial segment, utilizing TMW extensively for exterior cladding and robust decking systems that require extended service life in exposed environments. Architectural and landscape design firms often specify TMW due to its superior aesthetic qualities—namely the deep, uniform color and the absence of toxic leaching—which aligns with modern design principles and environmental certifications like LEED or BREEAM.

Another significant segment comprises manufacturers of outdoor furniture and specialized industrial components. These manufacturers use TMW for its inherent resistance to moisture and insects, which is essential for furniture that is permanently exposed to the elements or components used in demanding industrial settings. Additionally, the DIY and residential renovation market, accessed primarily through retail lumber yards and large home improvement chains, represents a growing segment. These individual homeowners are increasingly educated about the long-term cost benefits of durable, non-toxic materials, shifting away from cheaper, shorter-life alternatives like traditional pressure-treated lumber, especially for applications like patio decking and garden structures. The key characteristic unifying all these potential customers is the willingness to invest a premium for demonstrably higher performance and environmental integrity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,165 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kebony, Thermory, Lunawood, Arbor Wood Co., SWM-Wood Oy, Novawood, Plato Wood, Continental Hardwood, Thermo-Treated Wood, Oy SWM-Wood, Greenheart Farms, VIVA Thermal Wood, Westwood, Cambia, Profitherm, Stora Enso, Sherwood Enterprises, Fagus-Gruppen, HeatWood, Greenleaf Forest Products |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Thermally Modified Wood Market Key Technology Landscape

The technology landscape of the Thermally Modified Wood market is primarily defined by the evolution of high-temperature treatment methods aimed at enhancing wood properties while minimizing environmental impact and process costs. The foundational technology involves specialized industrial kilns where wood is heated above 180°C under carefully controlled low-oxygen conditions, typically using steam or nitrogen gas to prevent combustion. The most common commercialized methods include the ThermoWood process (originating in Finland), which utilizes steam, and various oil modification techniques, such as the Plato process or newer vacuum-assisted methods. Continuous improvement in this domain focuses heavily on enhancing the uniformity of heat penetration across large batches, which is critical for achieving consistent material performance. Modern facilities are increasingly adopting highly sophisticated sensor arrays and data logging systems to precisely monitor internal wood temperatures and moisture content throughout the treatment cycle, moving toward automated, self-regulating systems that optimize resource use and reduce human error, thereby ensuring higher product quality and reliability.

A significant technological shift involves moving from traditional batch processing, which requires significant time and energy to heat and cool large static chambers, toward continuous-flow thermal modification systems. These continuous processes, still in earlier stages of adoption but gaining traction, promise substantial gains in energy efficiency and output throughput, making TMW production more economically viable for high-volume markets. Furthermore, hybrid modification technologies represent another key area of innovation. These methods often combine thermal treatment with impregnation of natural substances, such as bio-oils or waxes, either before or after heating. This synergistic approach aims to mitigate the natural strength reduction often associated with high-temperature processing, particularly increasing the wood’s resistance to surface checking and further improving its hydrophobic properties, making the material suitable for even harsher environments like marine or desert climates.

Another crucial technological aspect is the development of advanced quality assessment tools. Spectroscopy and ultrasonic testing are being integrated into production lines to perform non-destructive testing on finished boards, ensuring that the modified structure meets predefined standards for durability and dimensional stability before distribution. Additionally, advancements in sustainable raw material preparation, including sophisticated pre-drying and conditioning techniques, are necessary to maximize the utilization of diverse wood species, particularly fast-growing, non-traditional softwood or temperate hardwood sources. The competitive edge in this market is increasingly determined not just by the final product quality, but by the efficiency and environmental footprint of the modification technology employed, driving significant investment toward carbon capture and heat recovery systems within production facilities globally.

Regional Highlights

The global Thermally Modified Wood market exhibits distinct regional dynamics, influenced by local construction practices, environmental regulations, and consumer awareness of sustainable materials. Europe remains the indisputable leader in both consumption and production, driven primarily by the pioneering efforts in Nordic countries (Finland and Sweden) and stringent EU regulations favoring natural, non-toxic building materials. The region possesses a mature supply chain and widespread consumer acceptance, with TMW often replacing conventional exotic hardwoods in decking, facades, and noise barriers. European growth is characterized by high-value applications and continuous innovation in treatment processes, ensuring the highest standards of quality and sustainability, reinforcing its position as the global benchmark for thermo-wood products.

North America, encompassing the United States and Canada, represents the fastest-growing market segment. This rapid expansion is primarily fueled by a booming residential remodeling sector, where homeowners are seeking premium, durable alternatives to chemically treated lumber and cedar. The perception of TMW as a high-performance, eco-friendly material justifies its premium price point. Market penetration is increasing through aggressive distribution strategies and successful efforts by major manufacturers to secure building code approvals and increase product visibility among architects and home builders, signaling a decisive shift in material preference toward sustainable durability in exterior construction.

The Asia Pacific (APAC) region is an emerging market with significant long-term potential. Growth is concentrated in developed economies like Japan, Australia, and South Korea, characterized by high standards for resilient construction materials due to climatic challenges (humidity, cyclones). While currently smaller than the Western markets, the increasing focus on green infrastructure projects and the rising wealth leading to higher adoption of premium, durable housing materials are driving demand. Latin America and the Middle East & Africa (MEA) currently hold smaller market shares, but increasing urbanization and growing construction activities, particularly in large infrastructure and hospitality projects, present latent opportunities for TMW as architects seek innovative, low-maintenance materials suited to extreme climate variations prevalent across these regions.

- Europe: Dominant market share due to stringent environmental policies, early adoption, strong green building momentum, and mature production technologies primarily originating in Scandinavia. High demand for cladding and decking applications.

- North America: Fastest-growing region, driven by residential remodeling, preference for high-quality exterior materials, and substitution of traditional pressure-treated wood. Focus on Ash and Pine modification for decking and siding.

- Asia Pacific (APAC): Emerging high-growth market, propelled by urbanization, increasing adoption of sustainable building standards in countries like Japan and South Korea, and demand for durable materials resistant to high humidity.

- Latin America: Moderate growth potential tied to luxury residential construction and eco-tourism infrastructure, demanding durable, sustainably certified wood products.

- Middle East and Africa (MEA): Growth driven by commercial projects and large hospitality developments where dimensional stability under extreme temperature fluctuations is critical; limited local production currently means high reliance on imports.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Thermally Modified Wood Market.- Kebony

- Thermory

- Lunawood

- Arbor Wood Co.

- SWM-Wood Oy

- Novawood

- Plato Wood

- Continental Hardwood

- Thermo-Treated Wood

- Oy SWM-Wood

- Greenheart Farms

- VIVA Thermal Wood

- Westwood

- Cambia

- Profitherm

- Stora Enso

- Sherwood Enterprises

- Fagus-Gruppen

- HeatWood

- Greenleaf Forest Products

Frequently Asked Questions

Analyze common user questions about the Thermally Modified Wood market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of using thermally modified wood (TMW)?

The primary benefits of TMW include dramatically enhanced dimensional stability, superior resistance to rot, fungal decay, and insects, and the material is completely non-toxic and environmentally friendly, requiring minimal maintenance compared to conventional timber. The thermal process reduces the wood's ability to absorb moisture (hygroscopicity).

How does thermal modification affect the strength and mechanical properties of wood?

Thermal modification generally reduces the wood's mechanical strength, particularly its bending and impact resistance, due to changes in the cellular structure. Therefore, TMW is typically not recommended for high-load structural applications, but its surface hardness is often slightly improved, making it suitable for decking and cladding.

Is thermally modified wood suitable for exterior applications like decking and cladding?

Yes, TMW is exceptionally suitable for exterior applications such as decking, cladding, and siding. The process imparts long-lasting durability, similar to tropical hardwoods, without the environmental concerns, making it highly resistant to harsh weather cycles and essential for exterior longevity.

What is the typical lifespan of thermally modified wood compared to standard treated wood?

Thermally modified wood typically offers a lifespan of 20 to 30 years or more, often exceeding the durability of standard pressure-treated lumber in terms of decay resistance and dimensional integrity. Its longevity significantly reduces the lifecycle cost of construction projects.

Which wood species are most commonly used for thermal modification?

The most commonly modified species are softwoods, such as Pine (Scots and Radiata) and Spruce, due to their availability and cost-effectiveness. Among hardwoods, European Ash and Oak are highly preferred for premium TMW products, offering superior hardness and aesthetic appeal after treatment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Thermally Modified Wood Boards Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Thermally Modified Wood Market Statistics 2025 Analysis By Application (Residential, Commercial), By Type (Thermo-S, Thermo-D, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Thermally Modified Wood Boards Market Statistics 2025 Analysis By Application (Commercial, Residential), By Type (Thermo-S, Thermo-D), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager