Vinylene Carbonate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 441099 | Date : Feb, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Vinylene Carbonate Market Size

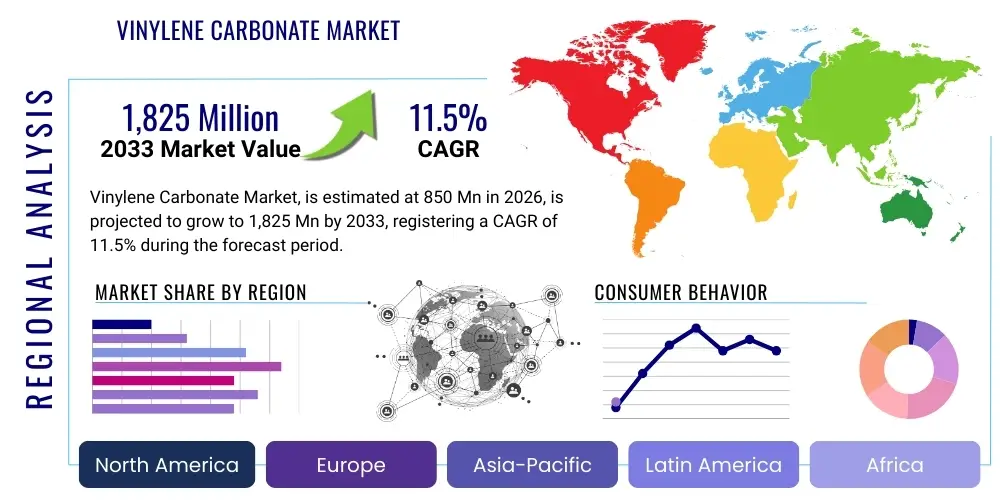

The Vinylene Carbonate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,825 Million by the end of the forecast period in 2033.

Vinylene Carbonate Market introduction

Vinylene Carbonate (VC) is a crucial, high-purity chemical compound primarily utilized as an additive in the electrolyte systems of advanced lithium-ion batteries (LIBs). As the global shift toward electrification accelerates, driven by widespread adoption of electric vehicles (EVs) and large-scale renewable energy storage solutions, the demand for stable, high-performance batteries has intensified, directly boosting the Vinylene Carbonate market. VC functions critically by forming a stable Solid Electrolyte Interphase (SEI) layer on the graphite anode surface during the initial charging cycles. This robust and thin protective layer significantly suppresses further decomposition of the organic electrolyte solvents, thereby reducing irreversible capacity loss, extending the battery life, and enhancing overall safety and cycle performance, particularly at elevated temperatures.

The primary driving factor for market growth is the exponential demand within the automotive and consumer electronics sectors. VC is indispensable in modern high-energy-density batteries used in long-range EVs and high-performance electronic devices, ensuring reliability under strenuous operating conditions. Beyond battery applications, Vinylene Carbonate serves as a specialized monomer for the synthesis of polymers, including poly(vinylene carbonate) (PVC), which find applications in specialized coatings and high-performance plastics. However, the requirement for ultra-high purity (battery grade, typically >99.99%) in electrolyte applications mandates complex manufacturing and purification processes, influencing its market price and supply chain complexity.

The key benefit of integrating VC into electrolyte formulations is the substantial improvement in battery longevity and safety profile, attributes that are non-negotiable for manufacturers aiming for competitive advantages in the energy storage market. Its low usage concentration (typically 0.5% to 2.0% by weight in the electrolyte) belies its significant impact on electrochemical stability. Ongoing research into next-generation battery technologies, such as solid-state batteries, while potentially disrupting the traditional electrolyte market in the long term, still relies on existing advancements in electrode protection chemistries derived from current VC knowledge, securing its relevance throughout the forecast period.

- Product Description: Colorless, low-melting solid or liquid, utilized primarily as a functional additive in non-aqueous electrolytes.

- Major Applications: Lithium-ion battery electrolyte stabilization, precursor for specialty polymer synthesis, chemical intermediate.

- Key Benefits: Enhances battery cycle life, improves high-temperature performance, prevents capacity fading by forming a stable SEI layer.

- Driving Factors: Rapid expansion of the global Electric Vehicle (EV) market, increasing deployment of grid-scale energy storage systems (ESS), and continuous technological advancement in LIB chemistry.

Vinylene Carbonate Market Executive Summary

The Vinylene Carbonate market is characterized by robust growth primarily driven by the unstoppable expansion of the electric mobility sector and concurrent advancements in stationary energy storage solutions. Business trends indicate a strong move toward localization and diversification of the VC supply chain, particularly in North America and Europe, as geopolitical risks and dependence on concentrated manufacturing hubs (largely in APAC) pose operational challenges to battery manufacturers. Key players are investing heavily in new purification technologies to achieve stringent battery-grade specifications, recognizing that quality control is a critical differentiator in this specialized chemical market. Consolidation among smaller producers and strategic alliances between VC manufacturers and large electrolyte solution providers are emerging to secure long-term supply agreements and optimize logistics, reflecting a strategic response to highly volatile raw material prices and escalating demand.

Regionally, the Asia Pacific (APAC) region, spearheaded by China, South Korea, and Japan, currently dominates the market both in terms of production capacity and consumption, owing to the massive presence of major LIB cell manufacturers and associated Giga-factories. However, Europe and North America are projected to exhibit the fastest growth rates during the forecast period. This accelerated growth is directly attributable to significant policy support, such as the European Green Deal and U.S. Inflation Reduction Act (IRA), which incentivize domestic battery production and establish localized EV supply chains, thus creating localized demand for essential additives like VC. Regulatory standards concerning battery safety and sustainability are also tighter in these regions, further promoting the use of high-performance stabilization additives.

Segmentation trends highlight the overwhelming dominance of the Lithium-ion Battery Electrolyte application segment, which consumes the vast majority of globally produced Vinylene Carbonate, often requiring Purity Level greater than 99.99%. Within the end-user spectrum, the Automotive sector (EVs and hybrid vehicles) represents the largest and fastest-growing segment, demanding large volumes of high-quality VC to ensure warranty-compliant battery performance and lifespan. The Industrial Grade VC segment, used in polymer synthesis, remains stable but grows at a significantly slower pace. The market structure dictates that manufacturers must focus exclusively on enhancing purity, scalability, and establishing reliable distribution channels to capitalize on the sustained, high-volume requirements emanating from Tier 1 battery manufacturers globally.

AI Impact Analysis on Vinylene Carbonate Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Vinylene Carbonate market center on how computational methods can accelerate the discovery of better electrolyte formulations, optimize VC synthesis processes, and improve quality control in high-volume battery manufacturing. Users are particularly interested in AI's role in simulating the complex SEI formation kinetics to determine optimal VC concentration and interaction with other additives, thereby minimizing costly physical experimentation. Key themes emerging from these questions involve the potential for AI to drastically reduce R&D cycles for new battery chemistries, predict material failure mechanisms in real-time, and enhance predictive maintenance in Giga-factory settings where VC must be handled and integrated precisely.

AI and Machine Learning (ML) are increasingly being deployed in computational materials science to screen potential electrolyte components and additives rapidly. For Vinylene Carbonate specifically, AI algorithms can process vast datasets related to cell performance, temperature fluctuations, current densities, and charging profiles to identify the optimal operational range and required purity levels of VC that maximize battery performance characteristics, far beyond the capability of traditional empirical testing. This predictive capability translates directly into faster innovation cycles for battery manufacturers, influencing demand specifications for Vinylene Carbonate suppliers by demanding precise consistency and tighter tolerance limits on impurities.

Furthermore, the integration of AI-driven process control systems within VC manufacturing facilities can revolutionize production efficiency and purity maintenance. AI models analyze sensor data from complex distillation and purification units, predicting potential deviations in purity before they occur and adjusting parameters automatically. This capability is critical because even trace impurities in battery-grade VC can severely compromise battery performance. Consequently, AI enables manufacturers to maintain the required ultra-high purity (e.g., 99.995%) more consistently and cost-effectively, safeguarding the supply chain stability for high-end battery producers.

- AI optimizes synthesis routes, lowering production costs and improving yield efficiency for high-purity VC.

- Machine Learning algorithms predict optimal Vinylene Carbonate concentration in electrolyte mixtures to maximize SEI layer effectiveness.

- Computational materials science accelerates the discovery of synergistic co-additives to work alongside VC, broadening market applications.

- AI-driven automated quality control systems enhance batch consistency, ensuring VC meets stringent battery-grade purity standards (AEO focus on Purity and Consistency).

- Predictive maintenance schedules for battery packs, informed by VC performance data, extend product life and reduce warranty claims.

- Simulation models based on AI help predict thermal runaway risks, optimizing VC use for enhanced battery safety.

DRO & Impact Forces Of Vinylene Carbonate Market

The Vinylene Carbonate market is profoundly shaped by the simultaneous pressures of escalating global demand for high-performance batteries, complex regulatory landscapes governing chemical production and battery safety, and the inherent technical challenge of producing ultra-high purity materials. The dominant driver remains the relentless expansion of the electric vehicle market, necessitating large-scale, reliable battery production, which in turn fuels the consistent need for VC as a foundational electrolyte stabilizing agent. However, this growth is restrained by the highly specialized nature of VC synthesis and purification, coupled with volatile pricing of precursor chemicals, which creates bottlenecks in scaling production capacity rapidly. Opportunities arise primarily from next-generation battery architectures, such as high-voltage cathodes and silicon anodes, which critically require advanced SEI formation chemistry, often reliant on optimized VC derivatives or combinations, thus expanding the product development scope.

Drivers for the Vinylene Carbonate market are deeply embedded in the strategic energy transition. Government mandates and subsidies promoting EV adoption across major economies (China, EU, US) guarantee sustained, high-volume consumption. Moreover, continuous innovation in battery technology, pushing for higher energy density (requiring higher voltage operation) and faster charging speeds, actually increases the importance of highly effective stabilizers like VC to prevent electrolyte degradation under stressed conditions. The shift towards large-format prismatic and pouch cells for EV applications, which require consistent long-term performance, further solidifies VC’s indispensable role. These market forces create a virtuous cycle of investment in VC production capacity and process refinement to meet burgeoning demand from global Giga-factories.

Conversely, significant restraints hinder unimpeded growth and supply chain resilience. Manufacturing battery-grade VC necessitates multi-stage, sophisticated distillation and chromatographic separation processes to eliminate impurities that can destabilize the battery cell. This high technical barrier limits the number of qualified suppliers. Additionally, dependency on key precursor materials, whose supply chains are concentrated, exposes VC manufacturers to supply shocks and price volatility. A major potential impact force is the emergence of radically different battery technologies, such as full solid-state electrolytes, which might theoretically bypass the need for traditional liquid electrolyte additives. However, current solid-state advancements still face significant commercialization hurdles, meaning Vinylene Carbonate's dominance in the liquid LIB segment is secured for the medium term. The current impact forces are weighted heavily towards sustained demand acceleration, prioritizing supply chain diversification and quality assurance among suppliers.

- Drivers:

- Global proliferation of Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs).

- Increasing investment in large-scale grid energy storage systems (ESS).

- Mandates for enhanced battery lifespan and safety standards, particularly in the automotive industry.

- Technological necessity of stabilizing high-voltage cathode materials (e.g., NMC 811, NCA).

- Restraints:

- High manufacturing complexity required to achieve battery-grade purity (>99.99%).

- Volatility and potential scarcity of key raw material precursors.

- Stringent environmental regulations governing chemical manufacturing processes.

- Risk associated with alternative or next-generation electrolyte additives and stabilization mechanisms.

- Opportunities:

- Development of optimized Vinylene Carbonate derivatives for specific high-performance applications (e.g., silicon anode compatibility).

- Expansion of localized VC production capacity in North America and Europe to serve newly built Giga-factories.

- Integration into specialized applications like aerospace batteries and high-durability medical device batteries.

- Leveraging AI and automation to enhance purity and reduce production costs significantly.

- Impact Forces:

- High Impact, High Probability: EV adoption rates and corresponding battery cell production targets.

- Medium Impact, Medium Probability: Success rate of emerging competing SEI forming additives or non-carbonate solvents.

- Low Impact, High Probability: Fluctuation in the price and availability of ethylene carbonate (EC) and other chemical precursors.

- High Impact, Low Probability: Breakthrough in commercially viable, room-temperature solid-state batteries rendering liquid additives obsolete.

Segmentation Analysis

The Vinylene Carbonate market segmentation provides a granular view of the consumption landscape, primarily delineating demand based on the required purity level and the ultimate application of the chemical. The purity-based segmentation is critical, as battery performance is directly linked to the stringent specifications of the Vinylene Carbonate used; Battery Grade VC constitutes the premium, high-growth segment due to its essential function in high-value automotive and energy storage applications. Application-wise, the market is overwhelmingly dominated by its use in Lithium-ion Battery Electrolytes, which dictates market dynamics, supply chain requirements, and pricing strategies for manufacturers. Secondary applications, though growing steadily, exert minimal influence on the overall market volume.

- By Application:

- Lithium-ion Battery Electrolyte

- Polymer Synthesis

- Others (Pharmaceutical Intermediates, Agrochemicals)

- By Purity Level:

- Battery Grade (>99.99%)

- Industrial Grade (99.0% - 99.9%)

- By End-User:

- Automotive (Electric Vehicles, HEVs)

- Energy Storage Systems (Grid Storage, Renewables Integration)

- Consumer Electronics (Smartphones, Laptops, Wearables)

- Medical Devices and Aerospace

Value Chain Analysis For Vinylene Carbonate Market

The value chain for Vinylene Carbonate is highly integrated and complex, characterized by stringent purity requirements that significantly influence the cost structure and competitive landscape. The upstream analysis begins with the sourcing and manufacturing of key chemical precursors, primarily Ethylene Carbonate (EC) and related halogenated compounds. The conversion of these raw materials into crude Vinylene Carbonate requires specialized chemical synthesis capabilities. Due to the toxicity and volatility associated with some intermediate stages, regulatory compliance and robust safety protocols are fundamental at this initial stage. The critical phase in the value chain, however, is the meticulous purification process—involving multi-stage distillation, solvent extraction, and sometimes proprietary chromatographic techniques—which transforms industrial-grade VC into ultra-high-purity battery-grade material, demanding specialized capital expenditure and expertise.

Midstream activities involve the primary producers and purifiers, who operate in a technically demanding environment. The successful execution of quality control, ensuring VC meets specifications such as trace metal content and moisture levels, determines market viability. Once purified, VC is then typically sold to specialized electrolyte solution manufacturers (e.g., solvent, salt, and additive mixers) who formulate the final non-aqueous electrolyte blend. This step represents a crucial intermediary stage where VC is incorporated into its final commercial form. Direct distribution channels are often favored for high-volume, long-term contracts between VC producers and major electrolyte makers, allowing for better supply chain visibility and quality assurance.

Downstream analysis focuses on the end-users, predominantly Lithium-ion cell manufacturers (such as LG Energy Solution, CATL, Panasonic). These companies integrate the VC-containing electrolyte into their battery assembly lines for applications across the automotive, grid storage, and consumer electronics sectors. Indirect distribution, involving chemical distributors and trading houses, handles smaller volumes, particularly for R&D purposes or for industrial-grade VC used in polymerization. The tight relationship between upstream purity control and downstream battery performance means the value chain is highly sensitive to quality failures, necessitating strong collaborative partnerships and mutual transparency across all tiers, from precursor supply to final cell testing.

Vinylene Carbonate Market Potential Customers

Potential customers for Vinylene Carbonate are predominantly global manufacturers operating within the advanced energy storage ecosystem, characterized by demanding technical specifications and high-volume procurement needs. The primary buyer category consists of specialized Electrolyte Solution Providers who procure VC as a foundational additive before blending it with solvents (like ethylene carbonate and diethyl carbonate) and lithium salts (LiPF6). These providers act as crucial intermediaries, formulating bespoke electrolyte mixtures tailored to the specific anode and cathode chemistry employed by various battery cell manufacturers. Their purchasing power and required purity levels set the standard for the entire VC market.

The secondary, yet largest volume-consuming, customers are the Tier 1 and Tier 2 Lithium-ion Battery Cell Manufacturers. These Giga-factory operators, serving the automotive and grid markets, directly specify the required concentration and purity of VC in the electrolytes they purchase or produce in-house. Their purchasing decisions are driven by factors such as battery performance warranties (cycle life, capacity retention), safety compliance, and supply chain security. As the automotive industry mandates longer range and faster charging, these manufacturers become increasingly reliant on high-quality VC to ensure competitive differentiation and meet strict regulatory requirements.

Beyond the core battery sector, potential customers also include specialty chemical producers and polymer research organizations. These entities utilize industrial-grade Vinylene Carbonate as a monomer or cross-linking agent for synthesizing specialized polymers, often targeted for medical applications, high-performance coatings, or specific electronic components. Although these volumes are minor compared to the battery sector, they represent valuable niche markets demanding high consistency for non-electrolyte-related chemical processes. Ultimately, the End-User/Buyers of VC are tied directly to the global investment trends in electrification and renewable energy infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,825 Million |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daiichi Kogyo Seiyaku (DKS), Merck KGaA, TCI Chemicals, Alfa Aesar (Thermo Fisher), Lishida Chemical, Shandong Jincheng, Zibo Xinfu, BASF SE, Mitsubishi Chemical, Sumitomo Chemical, Solvay, Central Glass Co., Ltd., Wuxi New Energy, Jiangxi Longwang, Zhejiang Kaiyuan, Dojindo Laboratories, Hubei Changyuan, Suzhou Huayi, Fushuo Chemical, Novolyte Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Vinylene Carbonate Market Key Technology Landscape

The technological landscape surrounding the Vinylene Carbonate market is centered less on radical invention of the compound itself and more on the refinement of synthesis and purification methods to meet the extraordinarily high demands of the battery industry. The predominant industrial method for VC synthesis involves the dehydrohalogenation of halohydrin esters, often requiring precise control over temperature and pressure to ensure high conversion rates and minimal side-product formation. However, the crucial differentiator in this market is the purification technology. Traditional batch distillation is still widely used, but leading manufacturers are moving towards proprietary multi-stage fractional distillation and highly selective membrane separation technologies to remove trace contaminants, such as halides, water, and acidic residues, to achieve purity levels consistently above 99.99%.

Advanced chemical engineering techniques are being implemented to enhance process safety and efficiency. Continuous flow reactors are gradually replacing traditional batch processes, offering better control over reaction kinetics, resulting in higher product consistency and reduced processing time. Furthermore, catalytic methods, often involving specialized metal-organic catalysts, are being explored to lower the energy consumption during synthesis and improve yield, making the production process more environmentally sustainable and cost-effective. These technological improvements are essential to support the projected scaling requirements of the battery industry, which demands stable, high-volume supply chains for critical additives.

A significant area of ongoing R&D focuses on functionalizing Vinylene Carbonate—developing VC derivatives or structural analogs that offer improved performance, especially for next-generation electrodes like silicon anodes. Silicon anodes exhibit massive volumetric expansion, making the SEI layer derived from standard VC prone to cracking. New derivatives are designed to form more flexible and mechanically robust SEI layers, enhancing battery performance under extreme cycling conditions. Technology deployment is also increasingly focused on integrating advanced analytical tools, such as Gas Chromatography-Mass Spectrometry (GC-MS) coupled with high-resolution sensors, directly into the production line to facilitate real-time purity monitoring, a vital step for maintaining the tight specifications required by automotive battery manufacturers.

Regional Highlights

- Asia Pacific (APAC): APAC is the unquestioned global powerhouse for Vinylene Carbonate production and consumption, driven by the concentration of the world's largest lithium-ion battery manufacturers (China, South Korea, Japan). China, in particular, dominates both the supply of raw materials and the manufacturing capacity of battery-grade VC, benefiting from established chemical infrastructure and governmental support for the EV ecosystem. The region's high demand is intrinsically linked to the massive output of Giga-factories serving both domestic and international EV markets. Sustained investment in high-density batteries in this region ensures that APAC will maintain its market leadership throughout the forecast period, although competitive pressures from North America and Europe are growing.

- North America: The Vinylene Carbonate market in North America is entering a phase of rapid expansion, transitioning from reliance on imports to developing localized supply chains. Driven heavily by the US Inflation Reduction Act (IRA), which mandates domestic content thresholds for EV tax credits, significant investments are being channeled into establishing VC purification and electrolyte formulation facilities within the US and neighboring countries. This region's demand growth rate is projected to be among the highest, catering primarily to the burgeoning EV manufacturing capacity established by Tesla, Ford, GM, and various joint ventures with Asian battery makers. The focus is strictly on high-quality, traceable battery-grade VC.

- Europe: Europe represents another high-growth region, propelled by the EU's "Fit for 55" package and the overarching European Green Deal, which foster a localized, sustainable battery value chain. Countries like Germany, Poland, and Hungary are witnessing the establishment of large Giga-factories, creating substantial regional demand for VC. European buyers prioritize sustainability certifications and compliance with REACH regulations, pushing VC suppliers to adopt greener synthesis methods and ensure transparent sourcing. The regional growth strategy is focused on reducing dependence on Asian imports and building resilient local capacity to support the automotive sector's ambitious electrification targets.

- Latin America, Middle East, and Africa (MEA): These regions currently hold smaller market shares, but their importance is growing, particularly due to increasing mining and processing of key battery raw materials (like lithium in Latin America) and emerging local EV assembly operations. Demand for Vinylene Carbonate in MEA is primarily focused on small-scale specialized energy storage projects and niche consumer electronics manufacturing. While production capacity is minimal, these regions serve as strategic future markets as global electrification trends eventually penetrate deeper into emerging economies, leading to localized battery pack assembly and repair.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Vinylene Carbonate Market.- Daiichi Kogyo Seiyaku (DKS)

- Merck KGaA

- TCI Chemicals

- Alfa Aesar (Thermo Fisher)

- Lishida Chemical

- Shandong Jincheng

- Zibo Xinfu

- BASF SE

- Mitsubishi Chemical

- Sumitomo Chemical

- Solvay

- Central Glass Co., Ltd.

- Wuxi New Energy

- Jiangxi Longwang

- Zhejiang Kaiyuan

- Dojindo Laboratories

- Hubei Changyuan

- Suzhou Huayi

- Fushuo Chemical

- Novolyte Technologies

Frequently Asked Questions

Analyze common user questions about the Vinylene Carbonate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Vinylene Carbonate in lithium-ion batteries?

Vinylene Carbonate (VC) serves as a critical electrolyte additive that decomposes during the initial charging cycle to form a stable Solid Electrolyte Interphase (SEI) film on the anode surface. This SEI layer prevents continuous reaction between the electrolyte and the electrode, significantly enhancing battery cycle life, stability, and high-temperature performance.

Which geographical region dominates the production and consumption of Vinylene Carbonate?

The Asia Pacific (APAC) region, specifically led by China, dominates both the manufacturing capacity and consumption of Vinylene Carbonate, due to the high concentration of major global lithium-ion battery cell producers (Giga-factories) located within the region.

What are the purity requirements for battery-grade Vinylene Carbonate?

Battery-grade Vinylene Carbonate must meet extremely stringent purity standards, typically requiring a purity level of 99.99% or higher. Low impurity levels, particularly of water and halides, are essential to prevent irreversible side reactions that degrade battery performance and safety.

How is the growth of the Electric Vehicle (EV) market impacting VC demand?

The rapid global expansion of the EV market is the single most important driver for VC demand. EVs require large, long-lasting, and highly stable batteries, necessitating high volumes of battery-grade VC to ensure the required 8 to 10-year warranty periods and operational reliability.

What are the main alternatives or competing technologies to Vinylene Carbonate?

While VC remains the dominant SEI-forming additive, research is focused on derivatives and alternative additives such as Fluoroethylene Carbonate (FEC) and Propylene Carbonate (PC)-based systems. These alternatives are often explored to improve performance in specific environments, such as very low temperatures or in conjunction with new electrode materials like silicon anodes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Electronic Grade Vinylene Carbonate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Electrolyte Additives for Lithium Ion Battery Market Statistics 2025 Analysis By Application (Power Electrolyte, Consumer Electrolyte, Energy Storage Electrolyte), By Type (Vinylene Carbonate (VC), Fluorinated Ethylene Carbonate (FEC), 1,3-Propane Sultone (1,3-PS), Vinyl Ethylene Carbonate (VEC)), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Vinylene Carbonate Market Statistics 2025 Analysis By Application (Lithium Ion Battery, Chemical Intermediate), By Type (Purity 99.99%, Purity 99.99%), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager